Pre-coating material efficiency increasing and consumption reducing method and pre-coating material efficiency increasing and consumption reducing apparatus in MTO quenching water pre-coating pressure filtration separation system

A separation system and quench water technology, which are applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of high maintenance costs, failure to meet industrial requirements, and high construction costs, reduce industrial water consumption, and increase utilization times. , the effect of reducing the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

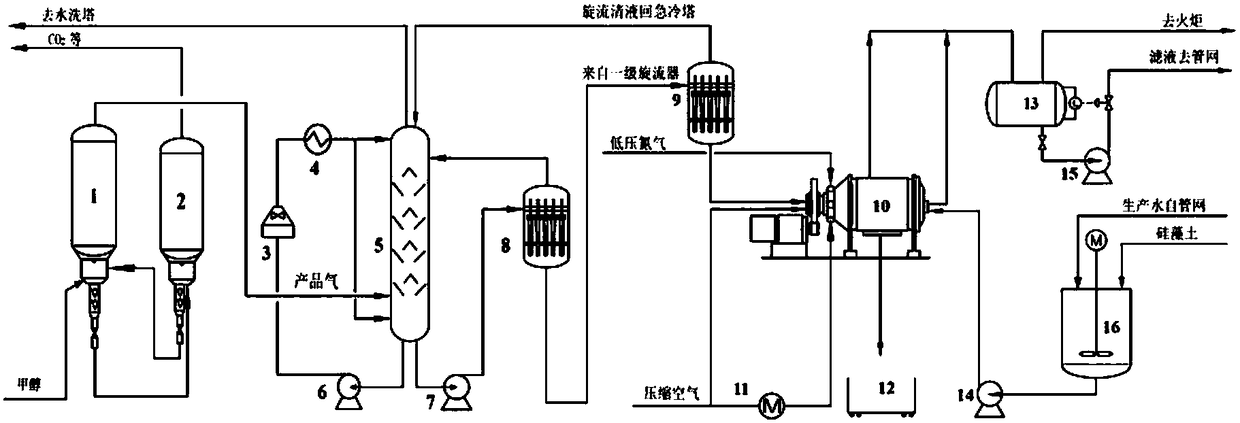

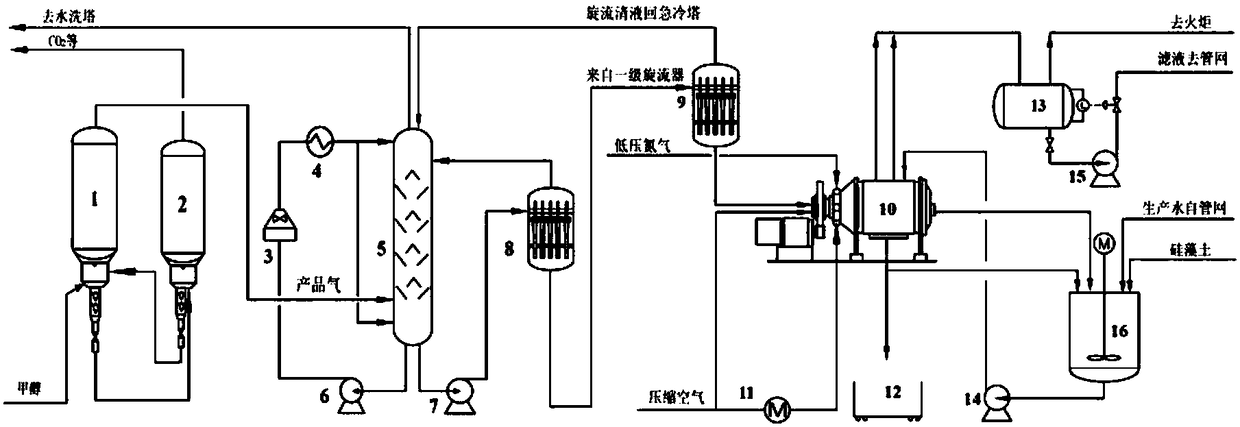

[0057] Process flow:

[0058] Such as figure 2 shown. In the initial stage of filtration, 39 μm diatomite was selected as the filter aid and added to the filter aid mixing tank. When the mass concentration of the precoat suspension was controlled at 1%, it was pressurized to 0.3 MPa by the filter aid pump and injected into the filter press. In the pre-coating unit chamber, a layer of pre-coating with a thickness of 7mm is formed on the filter cloth of the filter press before filtration, the amount of pre-coating agent is 13kg / h, and the pore size of the selected filter cloth is 400 mesh. The solid content of the catalyst suspension concentrated by the secondary cyclone is 30000mg / L, and the particle size of the catalyst is 3μm. After entering the filter press, the flow rate of the concentrated suspension is kept at 4m 3 / h, filter on the pre-coating; in the early stage of filtration, the filter cake is first returned to the filter aid mixing tank, mixed with the filter aid ...

Embodiment 2

[0062] Process flow:

[0063] Such as figure 2 shown. In the initial stage of filtration, 50 μm diatomite was selected as the filter aid and added to the filter aid mixing tank. When the mass concentration of the precoat suspension was controlled at 1%, it was pressurized to 0.3 MPa by the filter aid pump and injected into the filter press. Pre-coating unit chamber, before filtering, a layer of pre-coating layer is formed on the filter cloth of the filter press with a thickness of 5mm, the amount of pre-coating agent is 11kg / h, and the pore size of the selected filter cloth is 400 mesh; after being concentrated by the secondary cyclone The solid content of the catalyst suspension is 30125mg / L, and the particle size of the catalyst is 3μm. After entering the filter press, the flow rate of the concentrated suspension is kept at 4m 3 / h, filter on the pre-coating; in the early stage of filtration, the filter cake is first returned to the filter aid mixing tank, mixed with the ...

Embodiment 3

[0067] Process flow:

[0068] Such as figure 2shown. In the initial stage of filtration, 39 μm diatomite was selected as the filter aid and added to the filter aid stirring tank. When the mass concentration of the precoat suspension was controlled to be 3%, the filter aid pump was pressurized to 0.3 MPa and injected into the precoating tank of the filter press. Coating unit chamber, before filtering, a layer of pre-coating layer is formed on the filter cloth of the filter press with a thickness of 3mm, the amount of pre-coating agent is 7kg / h, and the pore size of the selected filter cloth is 400 mesh; after being concentrated by the secondary cyclone The solid content of the catalyst suspension is 29132 mg / L, and the particle size of the catalyst is 3 μm. After entering the filter press, the flow rate of the concentrated suspension is kept at 4 m 3 / h, filter on the pre-coating; in the early stage of filtration, the filter cake is first returned to the filter aid stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com