Method for comprehensive treatment and utilization of industrial water

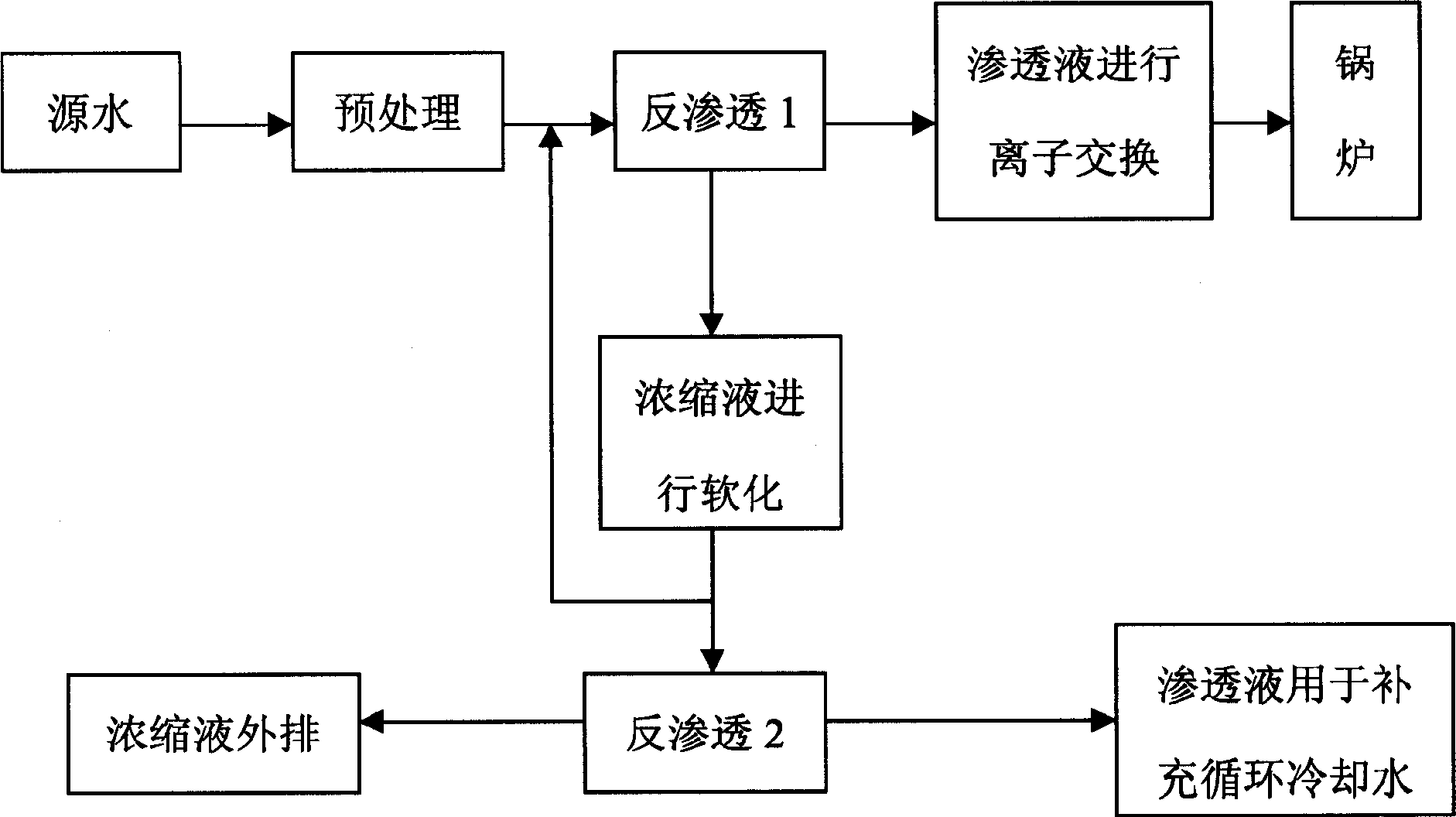

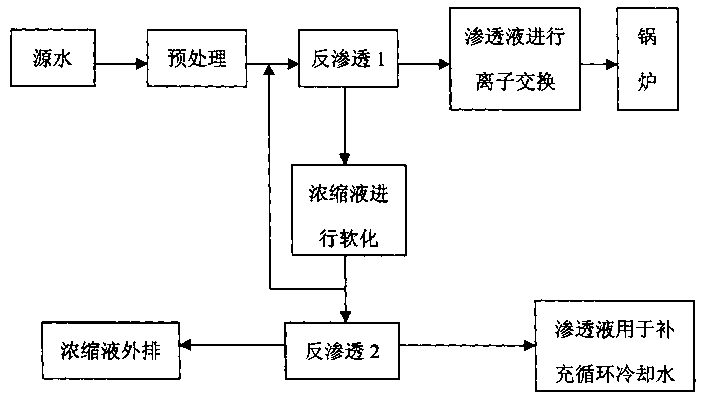

A comprehensive treatment and industrial water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the waste of water resources, increase operating costs, and increase exchange resin exchange Load and other issues, to achieve the effect of reducing sewage discharge, saving exchange capacity load, and improving water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: A domestic petrochemical refinery uses fresh surface water as the source water for steam boiler feed water preparation and supplementary water for the circulating cooling water system. The average source water quality is: calcium hard 55.5mgL -1 , Alkalinity 85mgL -1 , Turbidity 105mgL -1 , conductance 875us / cm, pH7.05, total dissolved solids 435mgL -1 , the amount of water used to supplement the steam boiler feed water and circulating water system due to evaporation and air cooling tower loss is 295m respectively 3 h -1 and 210m 3 h -1 . At present, pretreatment, reverse osmosis membrane method and ion exchange combined process are used to prepare steam boiler feed water. Since the source water contains high concentrations of calcium and magnesium ions, the reverse osmosis unit can only be operated at a low water recovery rate of 60%. , so that the source water required for the process reaches 490m 3 h -1 , the reverse osmosis concentrate can only be...

Embodiment 2

[0015] Embodiment 2: the source water in embodiment 1 is replaced surface water by groundwater, and the average groundwater source water quality is: calcium hard 200mgL -1 , Alkalinity 250mgL -1 , Turbidity 0.2mgL -1 , conductance 930us / cm, pH7.7, total dissolved solids 465mgL -1 , using the method provided by the present invention, in the preparation process of steam boiler feed water, the concentrated solution treated by the reverse osmosis unit is subjected to sulfonated coal softening treatment, and then partly circulated back to the reverse osmosis influent water for circulation treatment, and enters after pretreatment The source water treated by the reverse osmosis unit is 367m 3 h -1 , the average permeation water production is 295m 3 h -1 , reverse osmosis process concentrate circulation treatment capacity 144m 3 h -1 , which circulates back to reverse osmosis feed water 72m 3 h -1 , the system discharges 72m 3 h -1 , according to the calculation of the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com