Water cooling mechanism with buffering and self-circulating device

A buffer device and water cooling technology, applied in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of corporate resource waste, single mode of cooling device, etc., to reduce industrial water consumption and equipment life cycle and longevity, the effect of reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

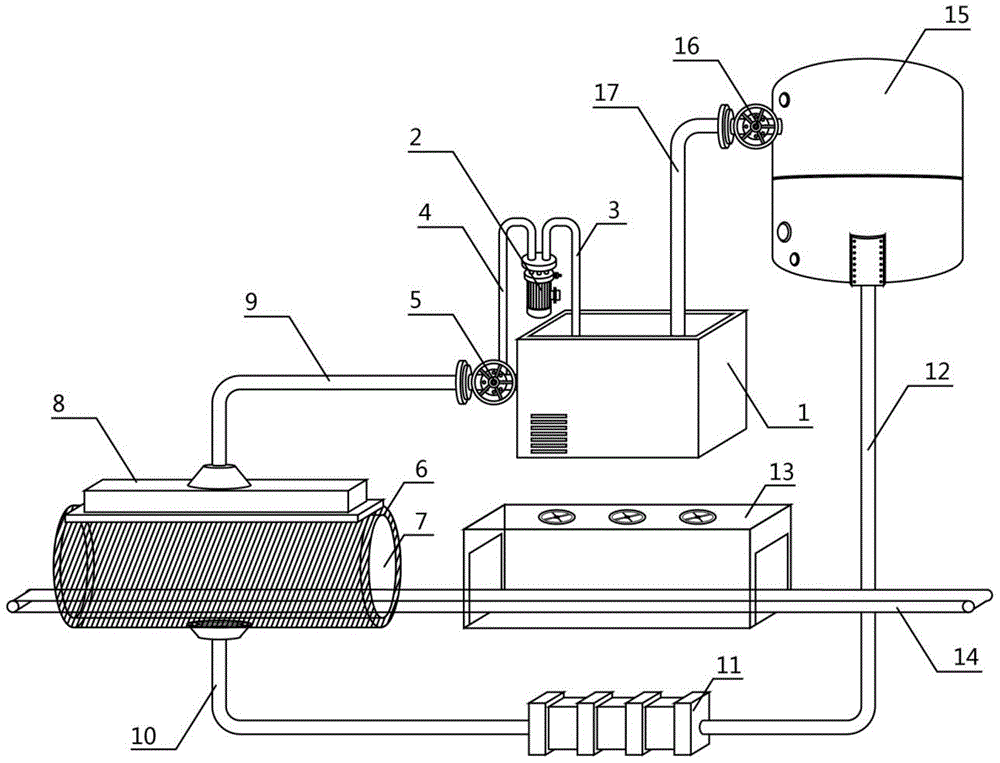

[0020] Such as figure 1 Shown is a water cooling mechanism with a buffer self-circulation device, which is characterized in that: a water tank 1, a water pump 2, a main valve 5, a water-cooled water storage bin 6, a filter device 11, a natural cooling bin 13, a conveyor belt 14 and a cooling water storage tank 15, the water pump 2 is located on the top of the water tank 1, and the water pump 2 is also provided with a suction pipe 3 and a water delivery pipe 4, the water suction pipe 3 is located on one side of the water pump 2, and one end of the water suction pipe 3 passes through the water pump 2 is a fixed connection, the other end of the pumping pipe 3 is fixedly connected through the water tank 1, the main valve 5 is located at one side of the water tank 1, the main valve 5 is fixedly connected with the water tank 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com