Production method of zirconium and zirconium alloy strip coil

A production method and zirconium alloy technology, applied in the field of metallurgy, can solve problems such as difficult rolling, huge differences in weld structure and performance, and strip surface damage, so as to achieve rolling and related cost reduction and uniform surface quality , The effect of shortening the production period of cold rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: First, heat a zirconium strip slab of 180х1050х7100mm in a walking gas heating furnace for 4 hours, heat it to 850°C, keep it warm for 2 hours, and roll it out of the furnace with a 1800 four-roller reversible double-stand double-steel hot rolling mill. The billet is made, rolled to a thickness of 40mm after 8 passes, rolled into a coil in the furnace, and rolled to a thickness of 4mm after 5 passes;

[0029] Then, the zirconium belt with a thickness of 4mm, a width of 1050mm and a weight of about 8.73 tons is pulled through the 1450mm annealing-shot peening-pickling unit for annealing and surface treatment. min, the shot peening speed reaches 90m / s. The ratio of pickling solution is: H 2 O-62%: HF3%: HNO 3 -35, the processing line speed of the unit is 20m / min.

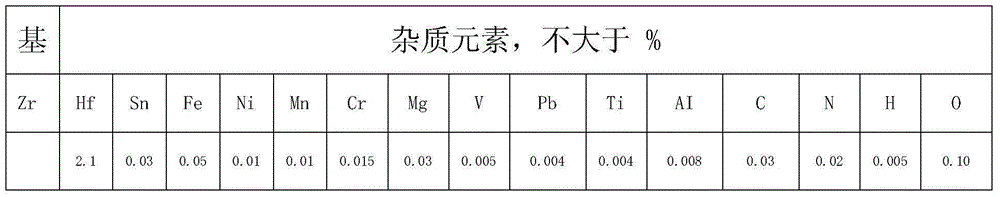

[0030] The chemical composition of zirconium tape is as follows:

[0031]

Embodiment 2

[0032] Example 2: First, heat a 205х1150х7040mm zirconium alloy strip slab in a walking gas heating furnace for 4 hours, heat it to 850°C, keep it warm for 2 hours, and use a 1800 four-roller reversible double-stand double-steel coil hot rolling mill The billet is rolled and rolled to a thickness of 40mm after 9 passes, rolled into a furnace coil and rolled to a thickness of 3.2mm after 7 passes.

[0033] Then, a zirconium alloy strip with a thickness of 3.2mm, a width of 1150mm, and a weight of about 10.79 tons is pulled through a 1450mm annealing-shot peening-pickling unit by a welding leader for annealing and surface treatment. 1300Kg / min, shot peening speed up to 55m / s, pickling solution ratio: H 2 O-67%: HF3%: HNO 3 -30, the processing line speed of the unit is 45m / min.

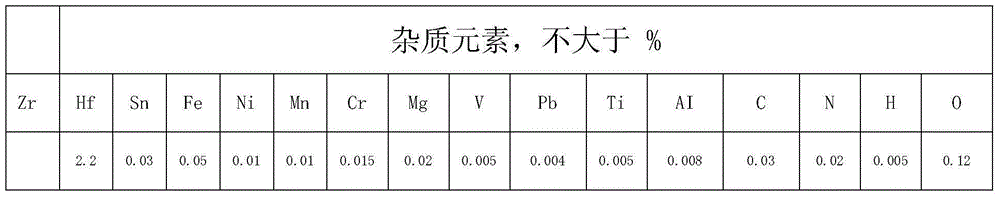

[0034] The chemical composition of zirconium alloy coils is as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com