Patents

Literature

32results about How to "Uniform surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

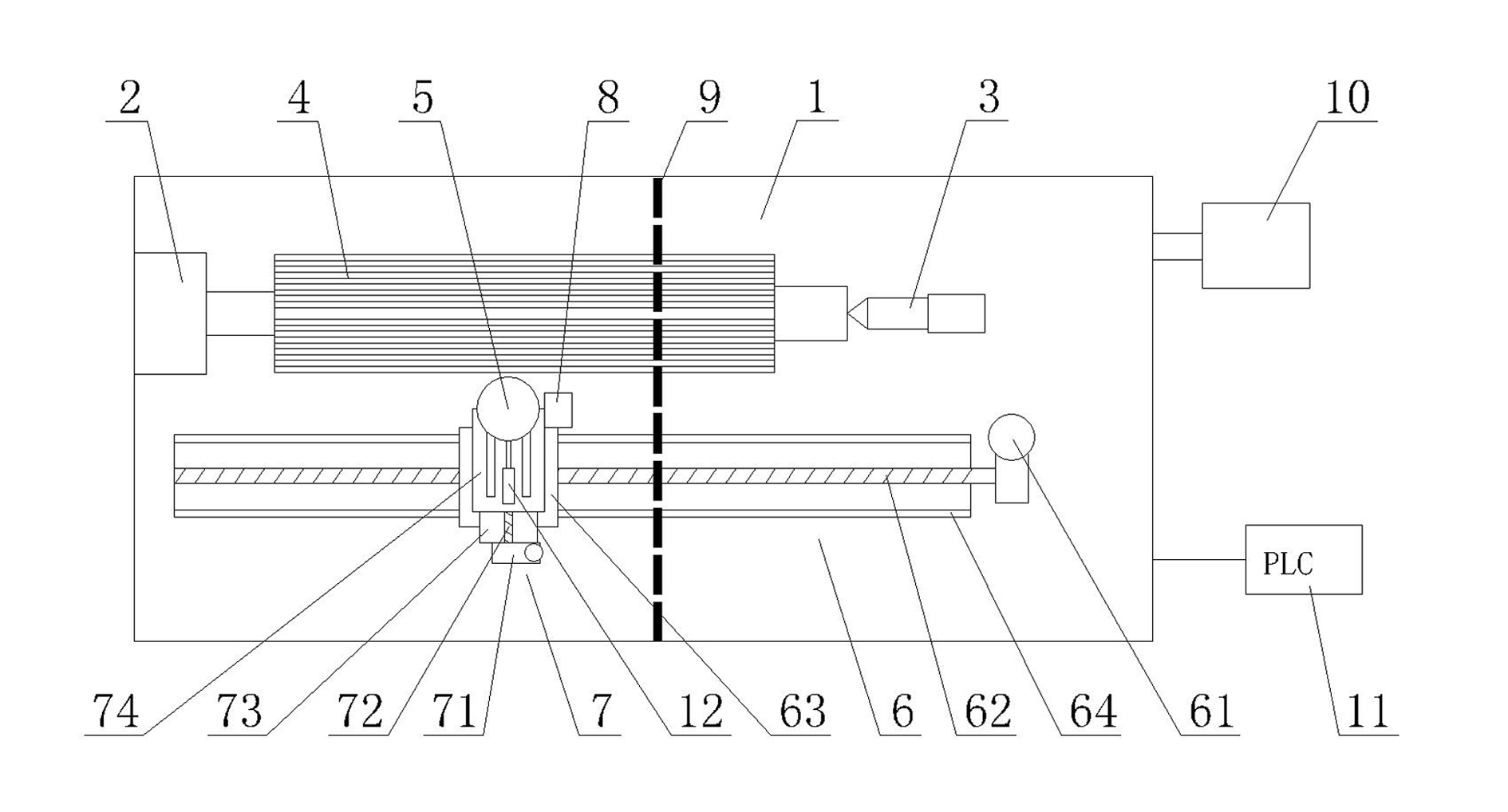

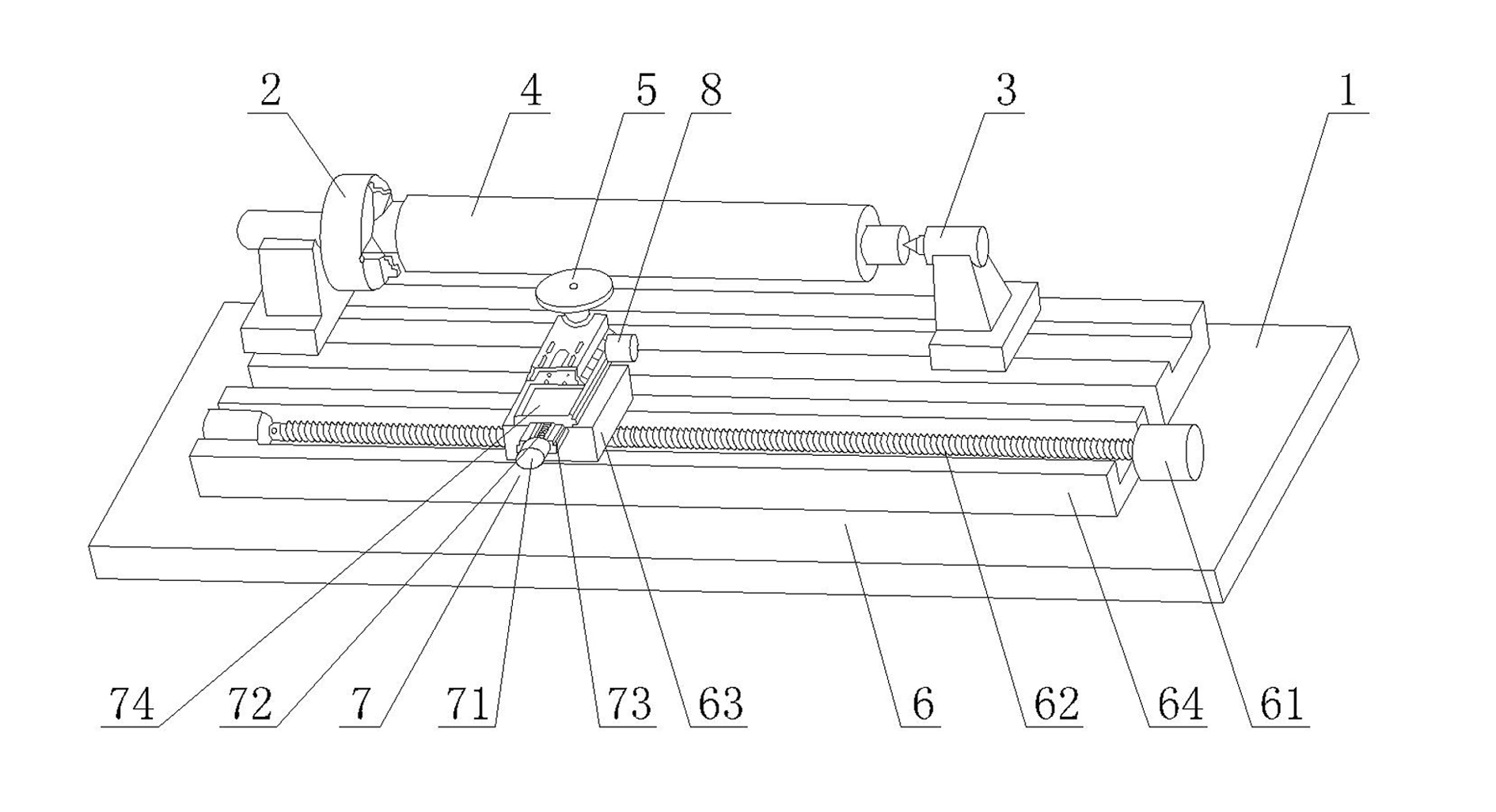

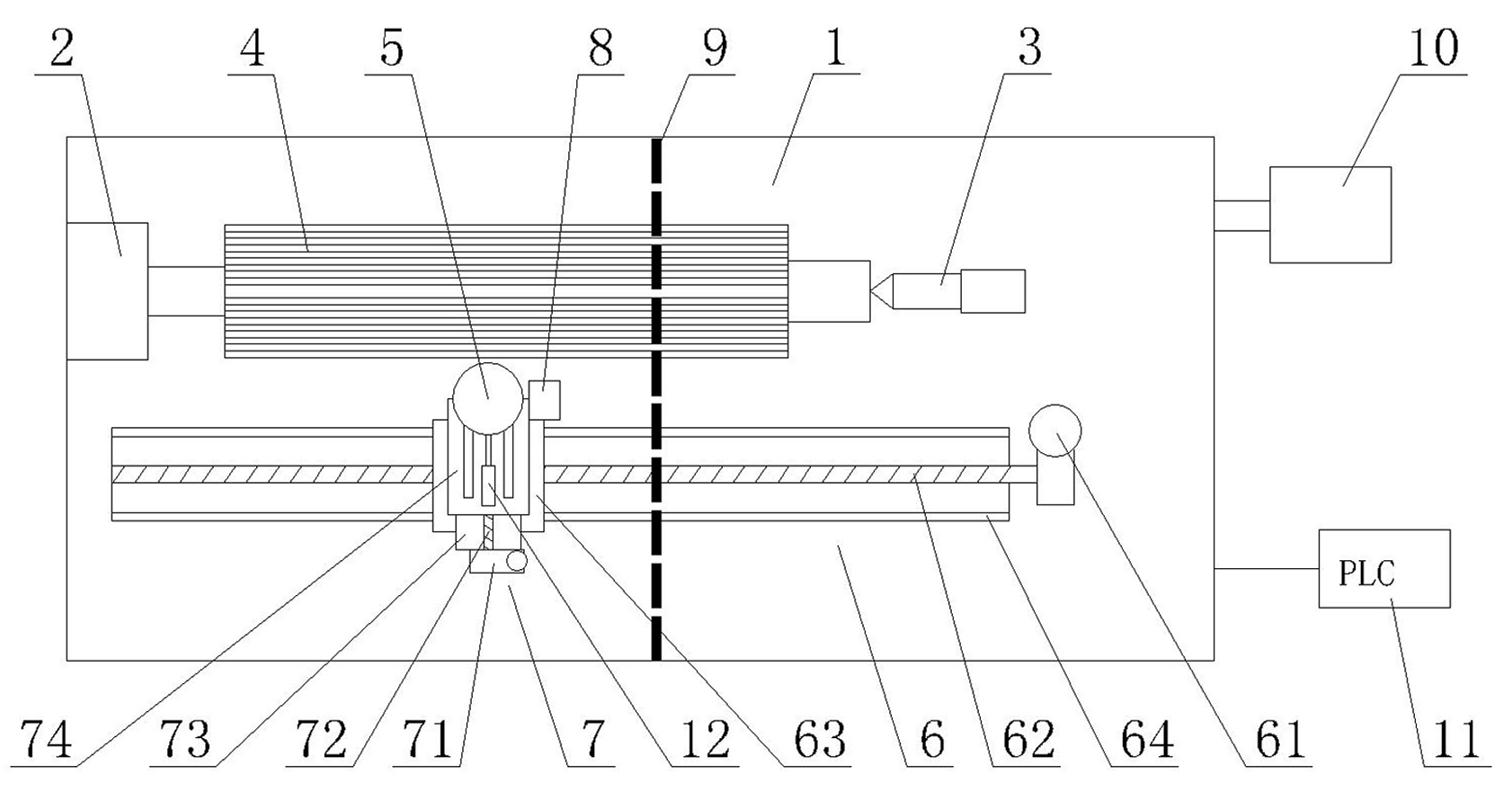

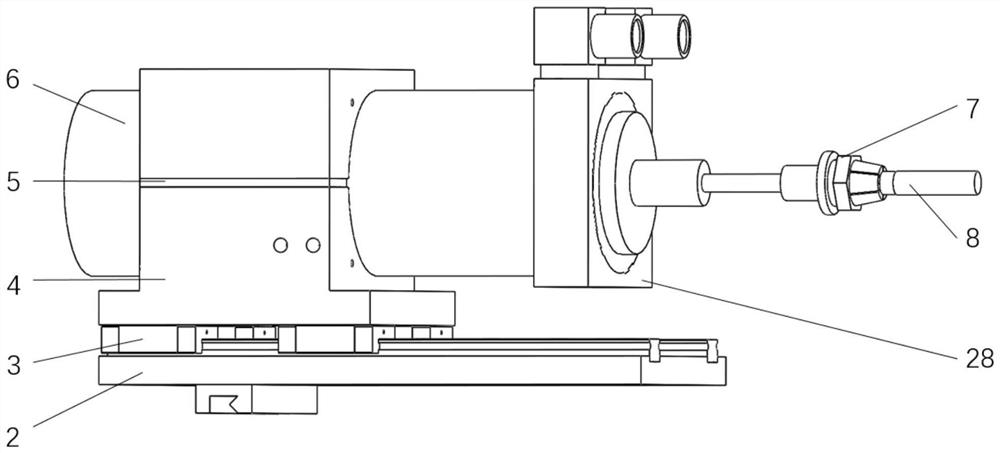

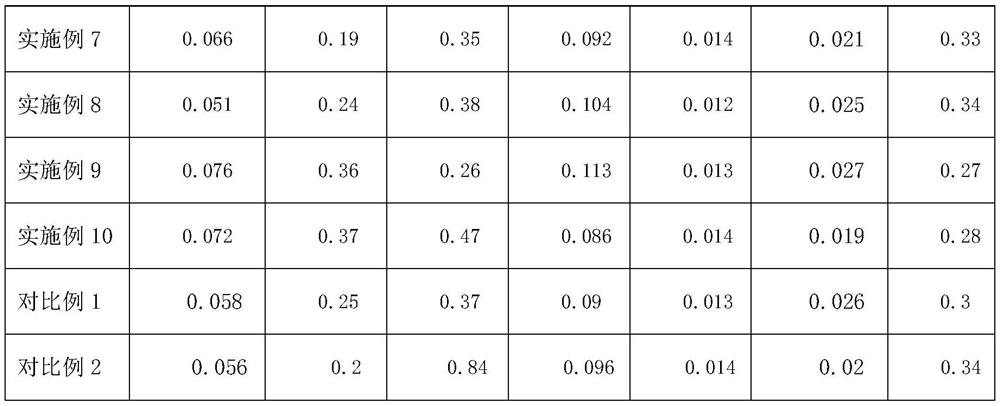

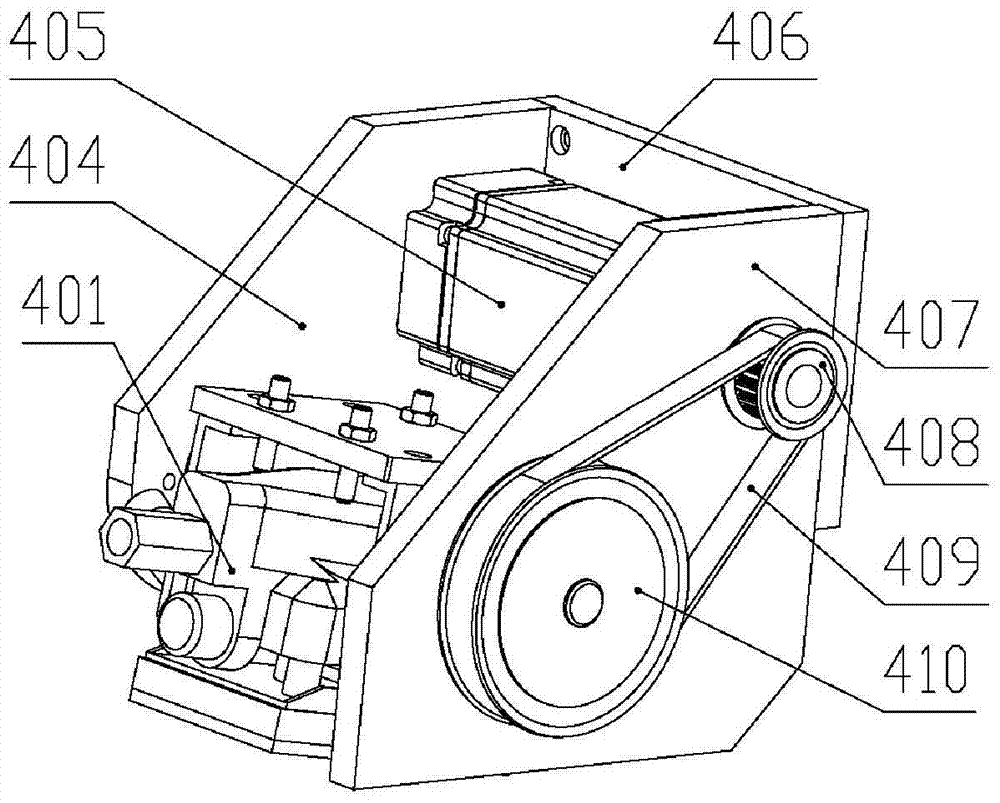

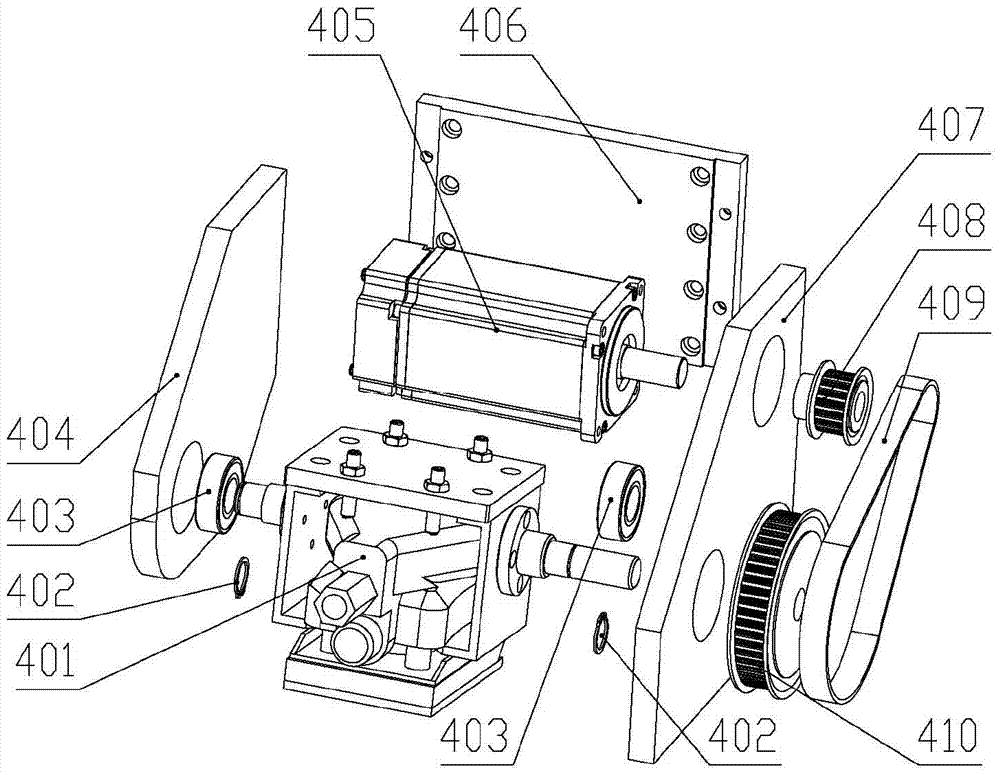

Full-automatic polishing tool for environmental ultrahard coating corrugator roll

InactiveCN101972973AHigh degree of automationProduction environmental protectionPolishing machinesFluteSurface roughness

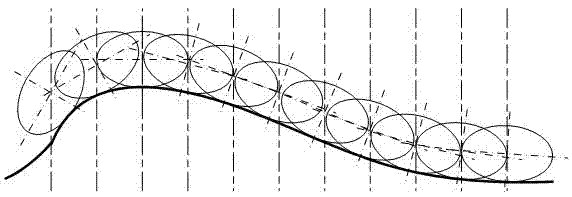

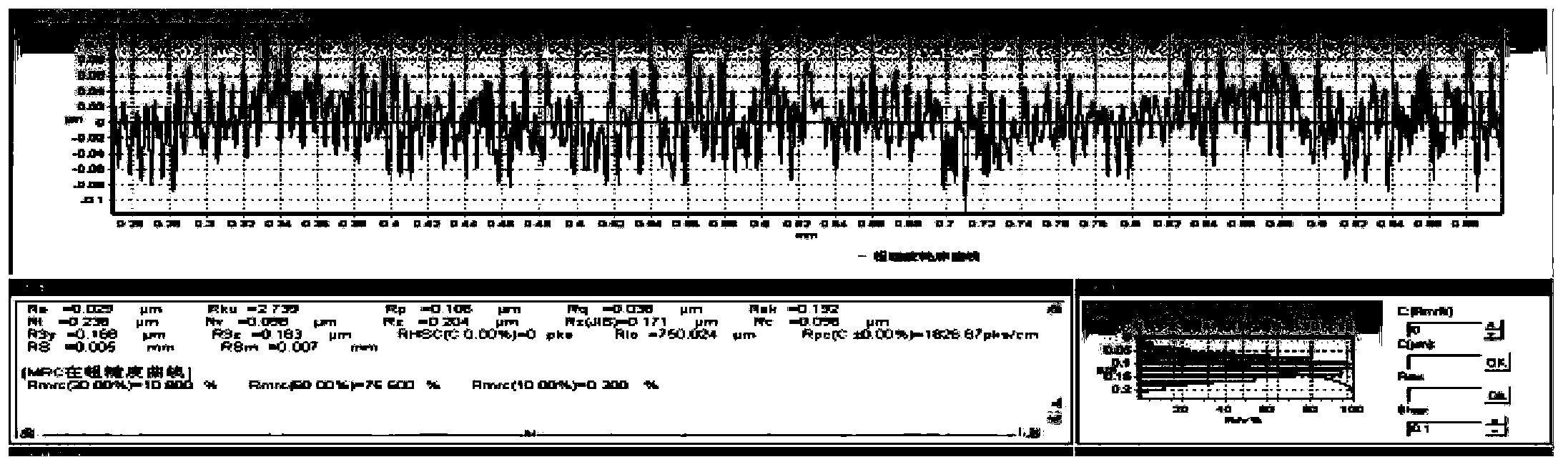

The invention relates to a full-automatic polishing tool for an environmental environmental ultrahard coating corrugator roll, comprising a manipulate platform, an air draft dust collector and a control device, wherein the manipulate platform is provided with an index chuck for clamping and regulating angles of a corrugator roll to be processed, a tail seat tip, a flexible polishing wheel for polishing the corrugator roll to be processed, a horizontal drive device for driving the flexible polishing wheel to horizontally move, a vertical drive device for driving the flexible polishing wheel to vertically move and a power-driven device for driving the flexible polishing wheel to rotate. The core of the invention is as follows: the special flexible polishing wheel and a high-speed rotating motor automatic drive device are adopted so that the flexible polishing wheel can be pressed on the flute teeth of the corrugator roll under the high speed rotation for coping and shaping while grinding effect on the coating does not generated, and the surface roughness of the coating corrugator roll can be processed from Ra3.0-4.0 microns in a spraying state to Ra 0.8-1.6 microns, thereby reaching the use environments.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

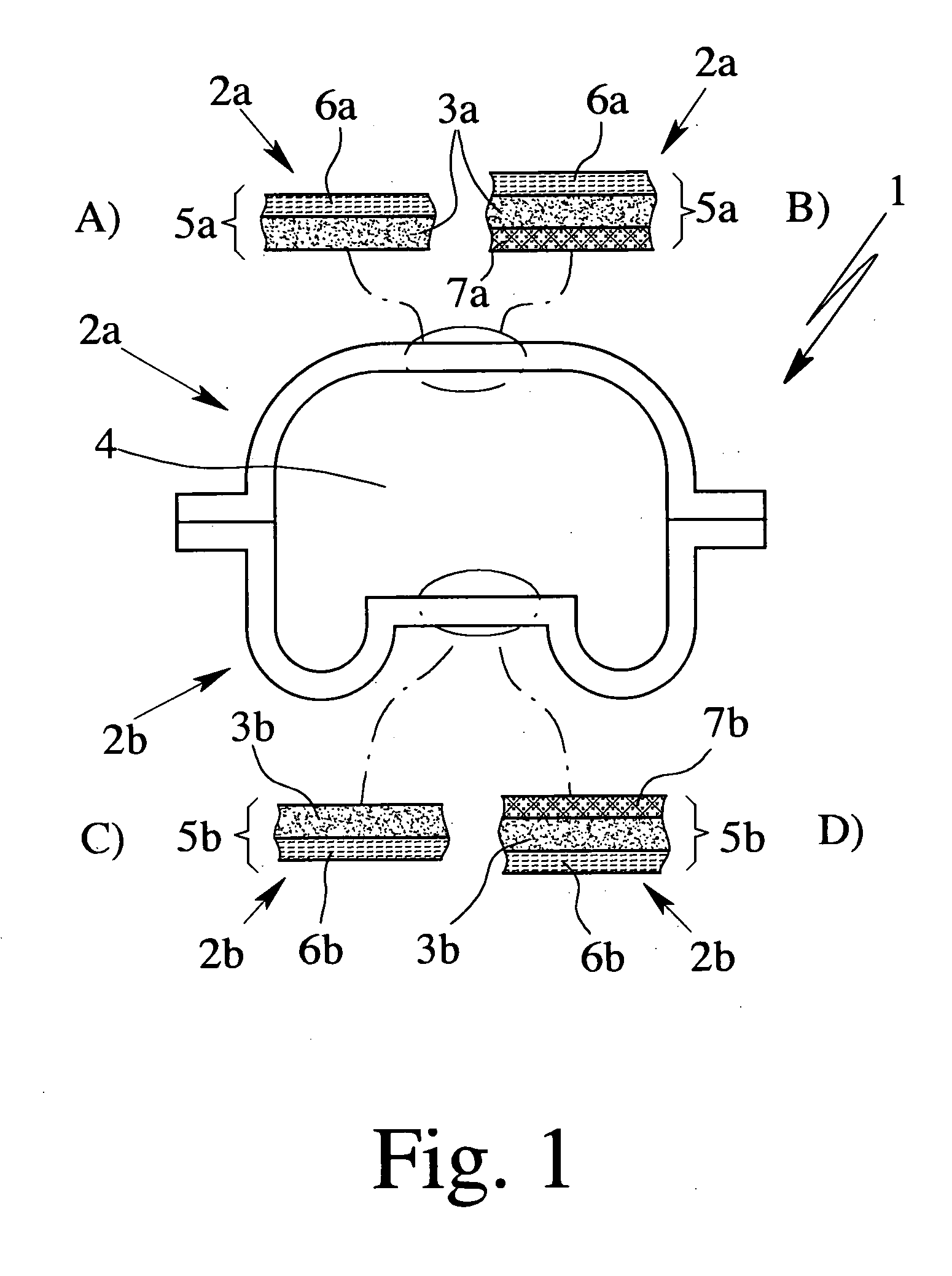

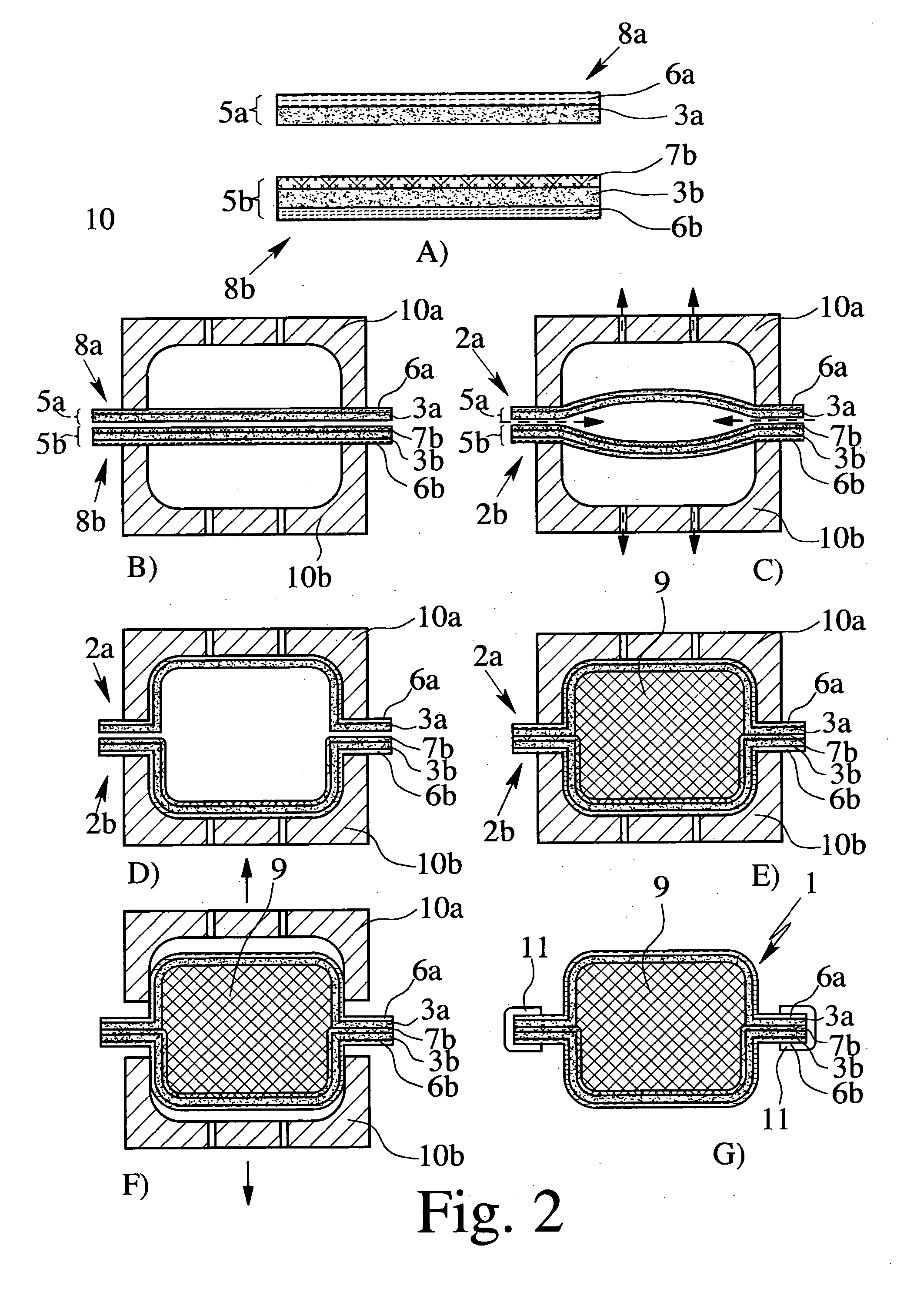

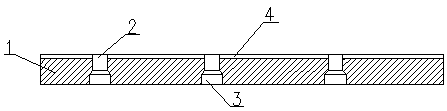

Structural unit in the form of a cavity-formed part, and use thereof

InactiveUS20060258244A1Uniform structureUniform surface qualitySynthetic resin layered productsStoolsStructural unitEngineering

The present invention relates to a structural unit (1) made of at least two formed parts (2a, 2b) which fashion or form at least one cavity (4), at least the first formed part (2a) having a multilayered structure (5a) having a flat, in particular textile, material (6a) associated to a support layer (3a), and the flat material (6a) being laminated to the support layer (3a) on the side of the support layer (3a) facing away from the cavity (4), and also to furnishing articles which have the structural unit (1), and to a process for production of the structural unit (1).

Owner:SKS SITZKOMPONENTEN

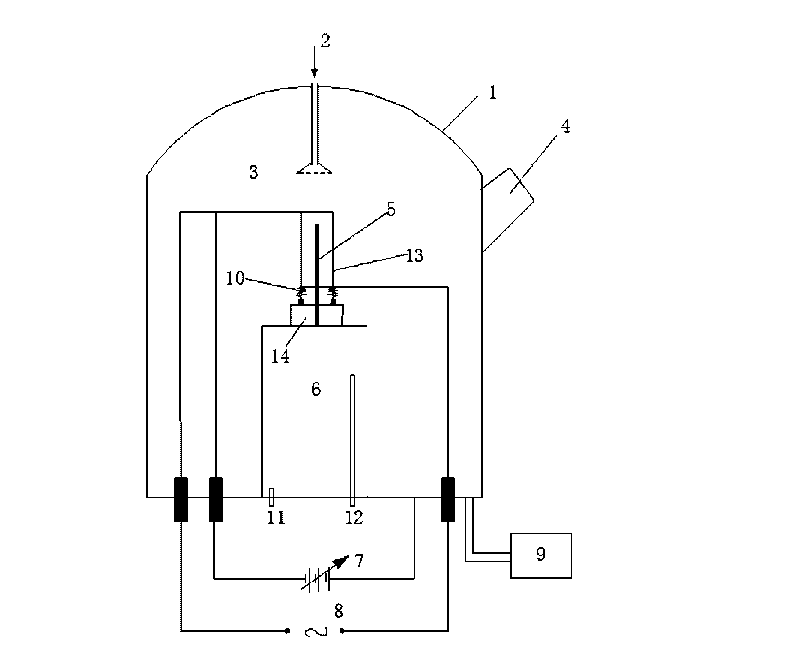

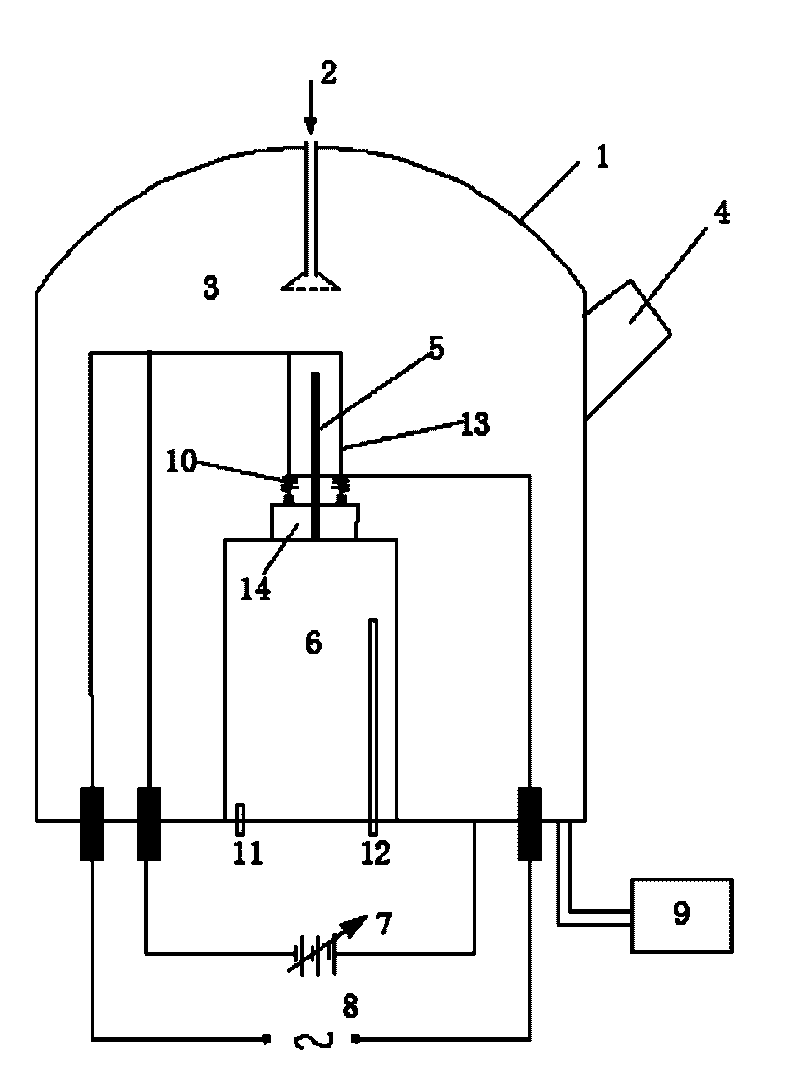

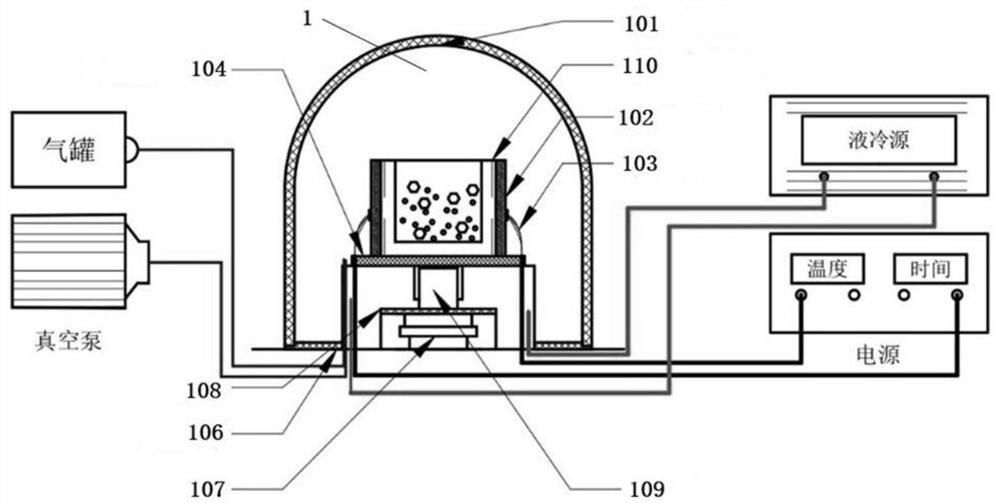

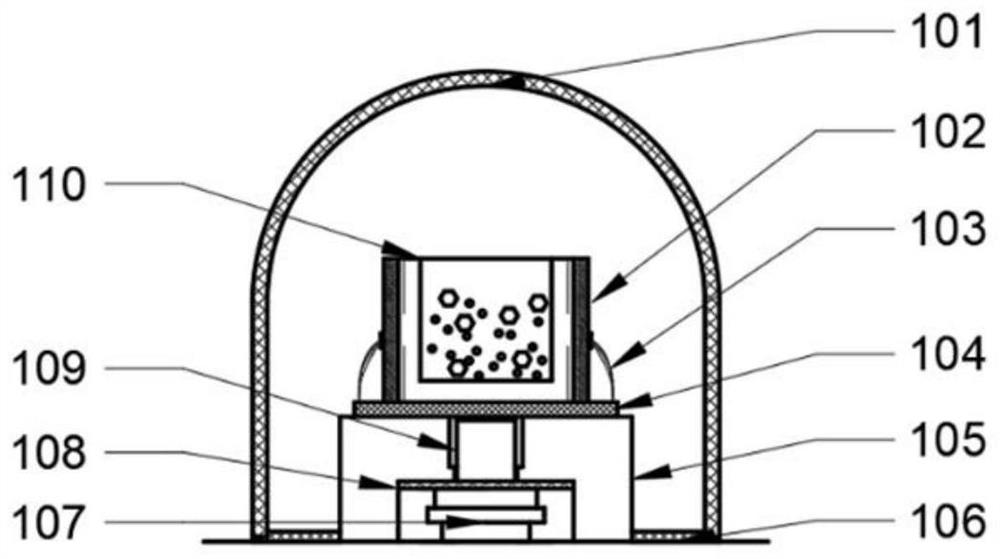

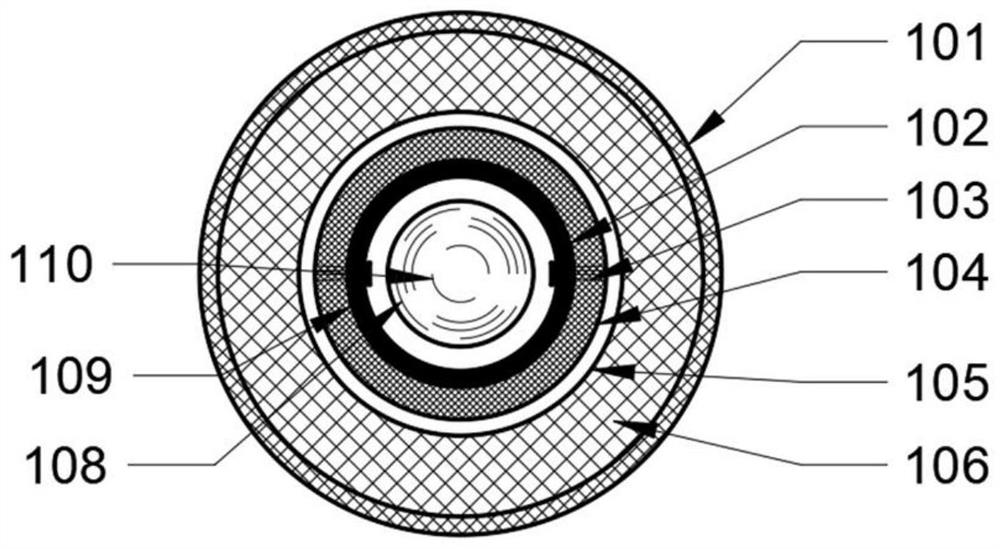

Device for preparing boron-doped diamond composite coating on surface of cutter

ActiveCN101736323AImprove adhesion strengthUniform surface qualityChemical vapor deposition coatingManufacturing technologyComposite film

The invention discloses a device for preparing a boron-doped diamond composite coating on the surface of a cutter, belonging to the technical field of cutters. The device comprises a reaction hood, an alloy drilling bit, a supporting table, a cooling device, a direct current voltage bias power supply, a heat wire power source, air pressure control device, a high-temperature resistant spring, a heat wire and a drilling bit bracket, wherein the alloy drilling bit and the high-temperature resistant spring are respectively and vertically arranged on the drilling bit bracket; two ends of the heat wire are respectively connected with the high-temperature resistant spring; the drilling bit bracket is fixed on the supporting table and the cooling device; the reaction device is fixed on the supporting table and the cooling device and the outer part of the drilling bit bracket is connected with the air pressure control device; the direct current voltage bias power source is respectively connected with the heat wire and the shell of the reaction hood; and the heat wire power source is respectively connected with the heat wire and the high-temperature resistant spring. The invention can ensure excellent adhesive strength between a diamond composite film and a matrix and can effectively improve the surface quality and the uniformity of the diamond film, thereby improving the service life and the cutting performance of the cutter with the diamond film coating.

Owner:SHANGHAI JIAO TONG UNIV

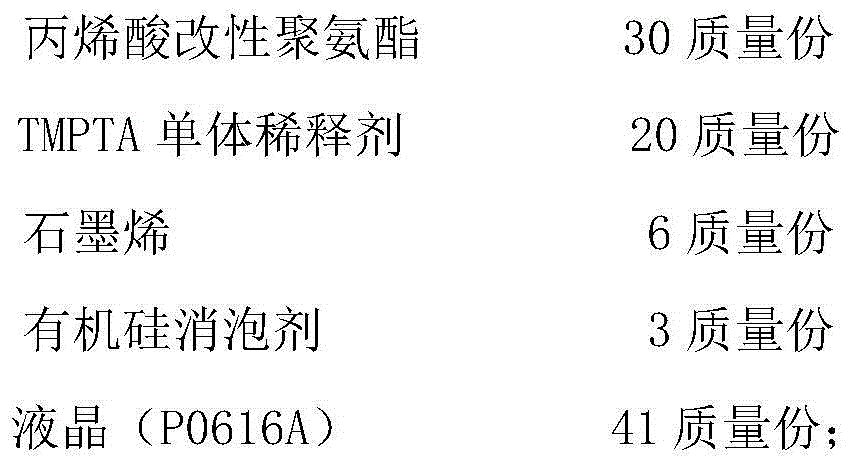

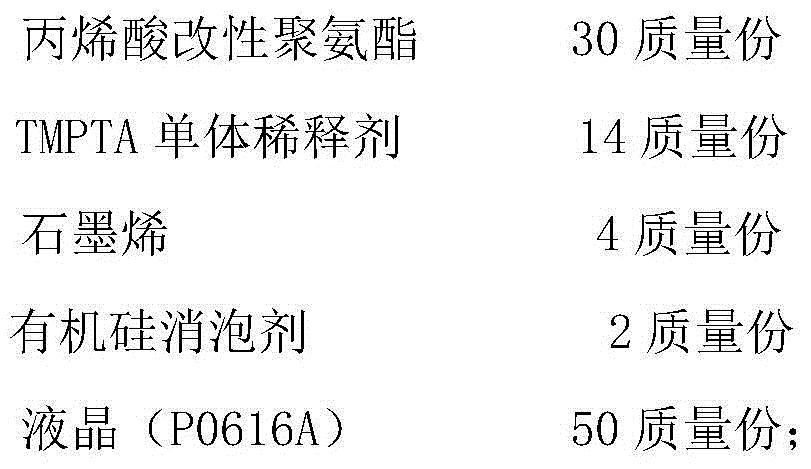

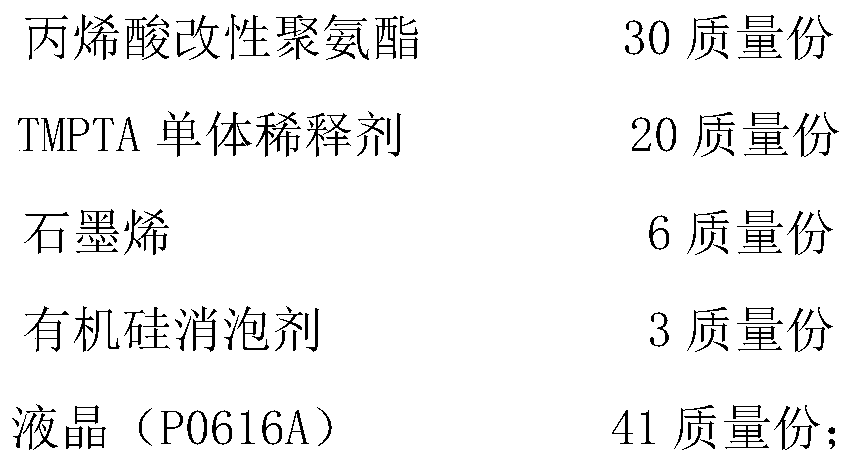

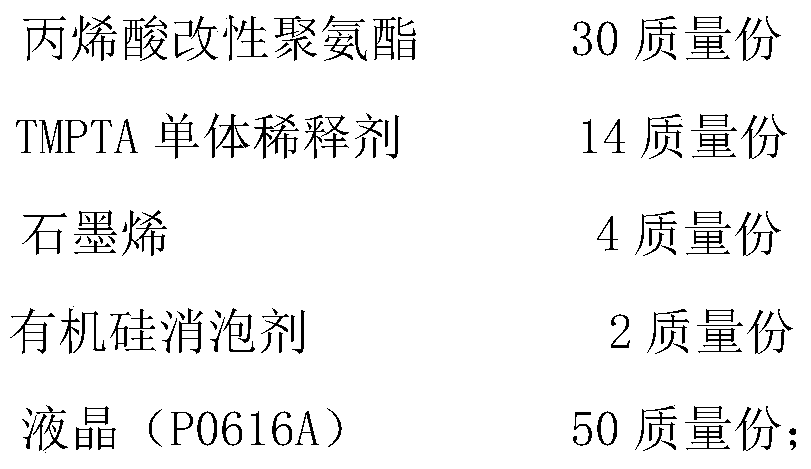

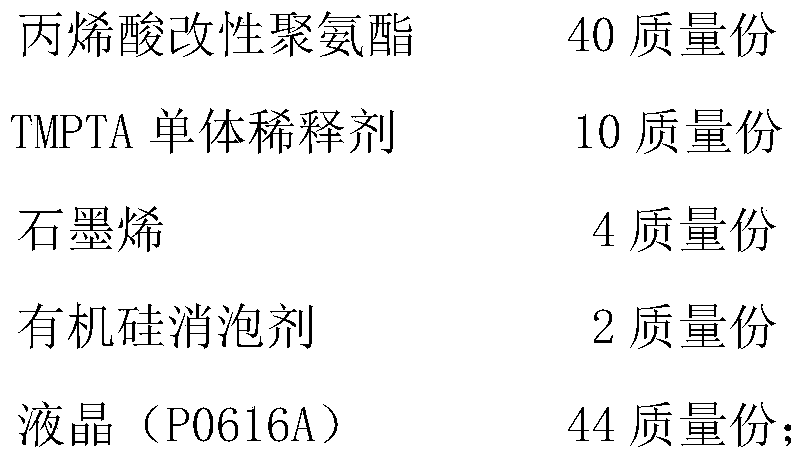

Nano conducting particle doped PDLC (polymer dispersed liquid crystal) membrane and preparation method thereof

The invention provides a nano conducting particle doped PDLC (polymer dispersed liquid crystal) membrane. The nano conducting particle doped PDLC is prepared by stirring polyurethane modified by acrylic acid, a TMPTA (trimethylolpropane triacrylate) monomer thinner, grapheme nano conductive particles, an antifoaming agents and liquid crystal for 60-120 minutes under the constant temperature ranging from 100r / min to 300r / min and subjecting the same to radiation curing with an electron beam 150-300keV in energy for 0.1-0.3 seconds. The grapheme nano conduction particles are combined with a traditional PDLC membrane, driving voltage of the PDLC membrane is lowered from dielectric constant and liquid crystal orientation, main materials for preparing the PDLC membrane are not needed to be changed, original optical-electrical characteristics of the PDLC are guaranteed, the driving voltage of the PDLC membrane is low, good thermal stability and mechanical stability are achieved, and simpleness in preparation process is realized.

Owner:BEIJING SAN WU JIU INVESTMENT

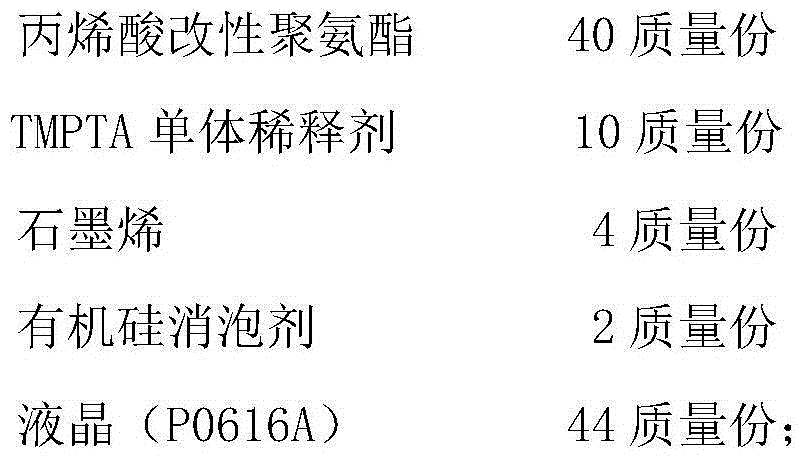

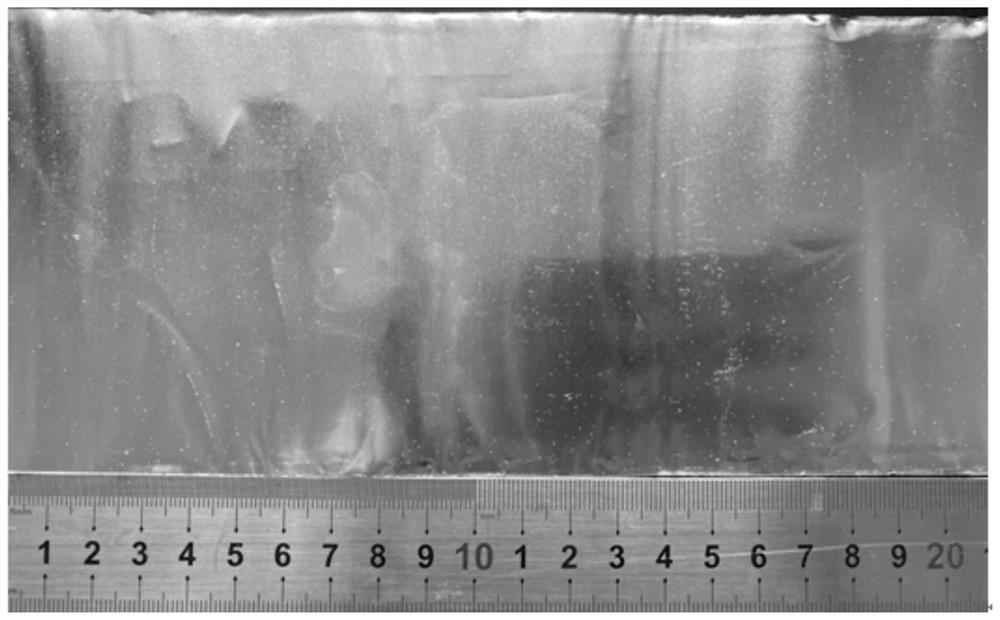

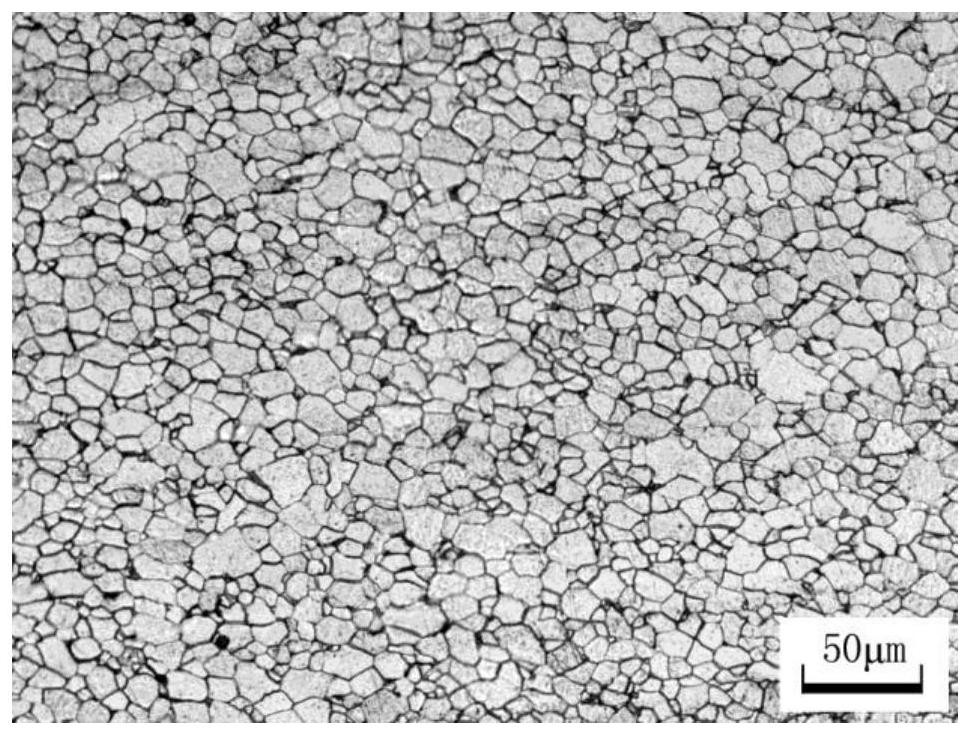

Medium-high-voltage electronic aluminum foil for high-capacity and high-strength capacitor and preparation method thereof

ActiveCN113234907AIncrease capacityIncrease the proportionElectrolytic capacitorsFurnace typesAluminum foilCapacitor

The invention discloses a medium-high-voltage electronic aluminum foil for a high-capacity and high-strength capacitor and a preparation method thereof. Through the production modes of casting and a continuous air cushion furnace, the specific volume is increased, and the production period is shortened; and the continuous air cushion furnace is used for multiple times for homogenization and annealing, and the problem that a casting structure is not uniform is solved, so that the performance and the cubic texture are improved, and the medium-high-voltage high-purity aluminum foil for the high-capacity and high-strength capacitor is obtained.

Owner:广西广投正润新材料科技有限公司

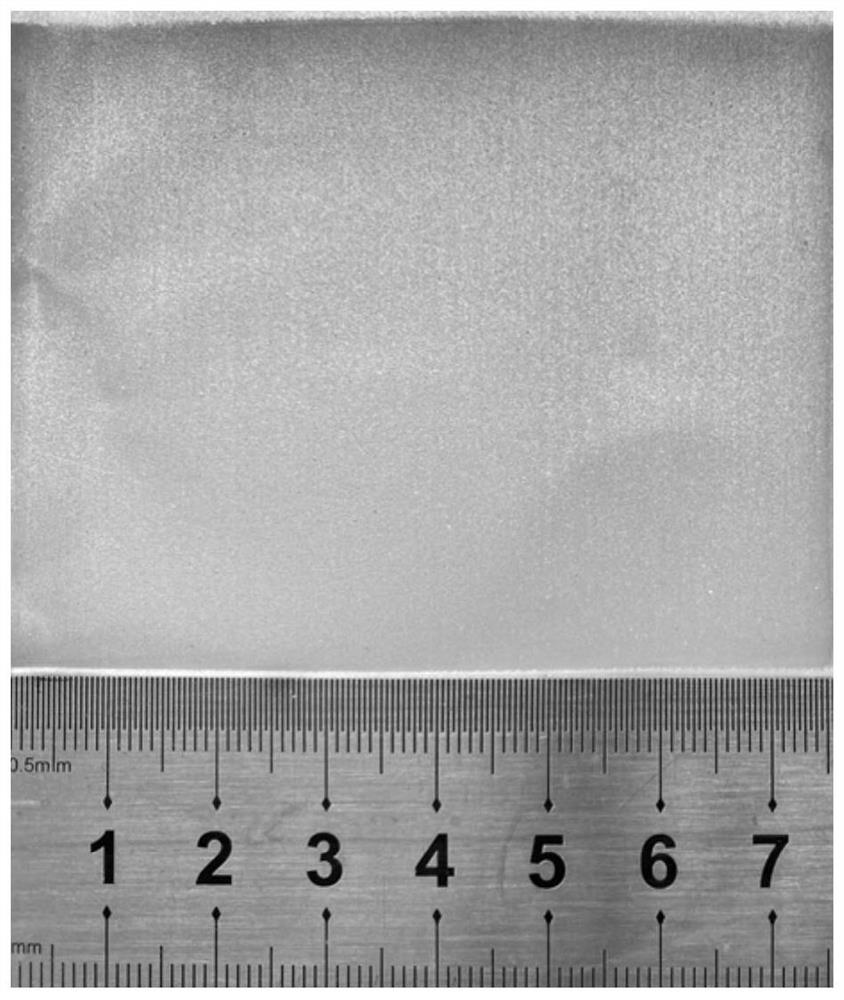

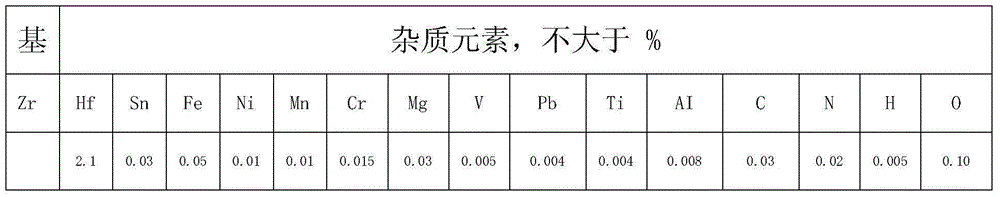

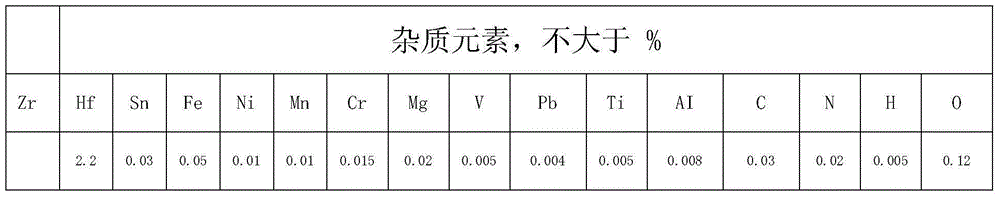

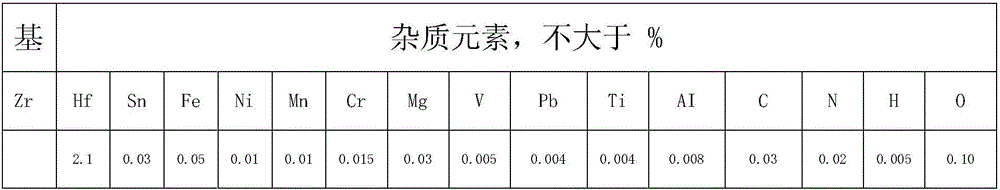

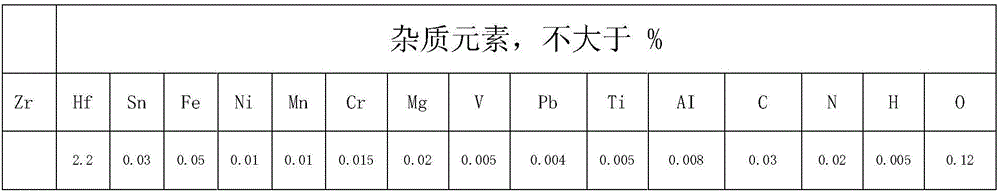

Production method of zirconium and zirconium alloy strip coil

ActiveCN105032974ASolve the problem that cannot be rolled into coils by hot rollingSolution not easy to removeProduction lineNuclear power

The invention provides a production method of a zirconium and zirconium alloy strip coil. The production method comprises the steps that a zirconium or zirconium alloy strip blank is heated in a heating furnace before production and is rolled on a steekle mill or a tandem rolling unit to the thickness that the blank can be transferred to a cold mill to be rolled, and the blank is directly coiled; surface treatment is carried out on a hot-rolling zirconium coil obtained through rolling on a continuous annealing-shot blasting-acid pickling production line, and a zirconium strip obtained after surface treatment is a smooth and clean zirconium strip which is in the metal natural color and free of oxide skin or harmful air suction layers; then a cold mill unit is adopted for carrying out cold rolling on the zirconium strip to obtain a thin strip, and cold rolling is carried out after annealing is carried out in an on-line annealing or vacuum annealing manner in the process of cold rolling; and finally various finished zirconium or zirconium alloy thin strip products of target thickness are obtained in a rolled manner. According to the production method, the cost is low, the product quality is good, and the rate of the finished products is improved by more than 15%; the requirements of nuclear power, chemical engineering and other aspects for thin zirconium materials and zirconium strips for thin-wall zirconium pipe welding can be completely met; and energy saving and consumption reduction are achieved, and high practical value is achieved.

Owner:BAOJI TUPENG METAL MATERIALS CO LTD

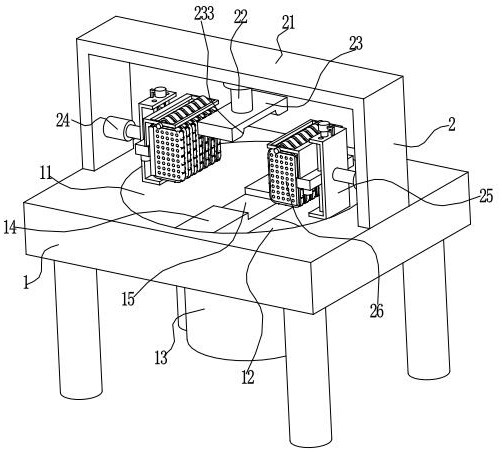

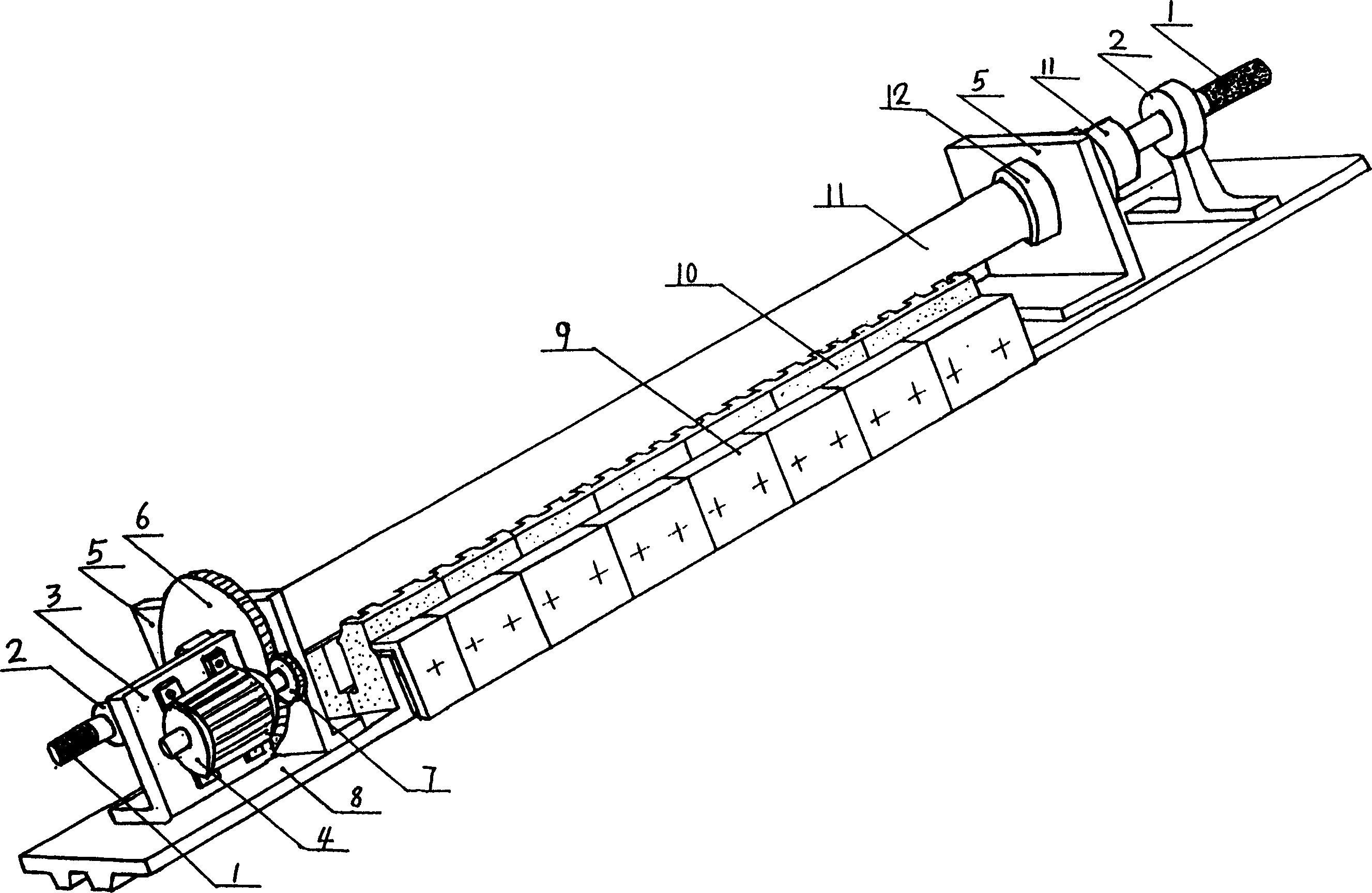

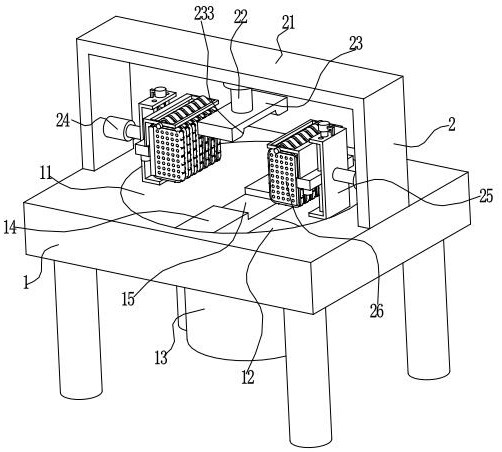

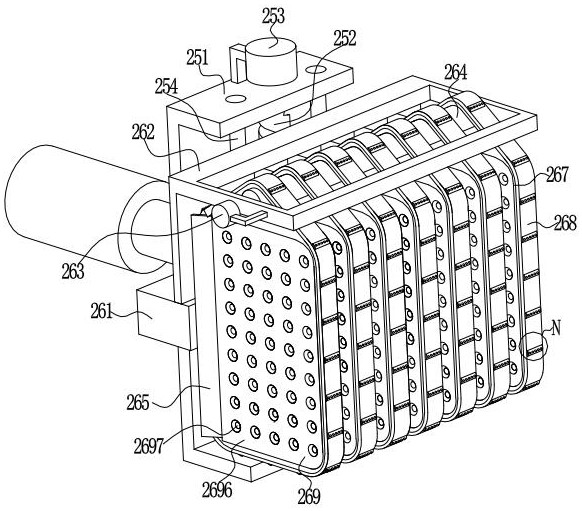

Rectifier heat dissipation shell manufacturing and forming machining equipment

ActiveCN114310580AImprove processing efficiencyUniform surface qualityEdge grinding machinesBelt grinding machinesElectric machineryEngineering

The invention relates to the technical field of rectifier heat dissipation shell machining, in particular to rectifier heat dissipation shell manufacturing and forming machining equipment which comprises a machining table and a positioning device, the positioning device is fixedly installed on the upper end face of the machining table, and the positioning device comprises an inverted-U-shaped plate, a positioning air cylinder, an extrusion plate, an electric telescopic rod, a moving frame, a grinding frame and a cleaning frame. The grinding frame comprises a moving plate, an L-shaped frame, a first motor, a first chain wheel, a support, a second chain wheel, a toothed chain belt, a grinding belt and a grinding plate, the machining table is matched with the positioning device to position a heat dissipation shell, the heat dissipation shell is ground through the positioning device, chippings on the surface of a part can be removed in time in the grinding process, and in the whole process, the machining efficiency is improved. Workers do not need to carry out machining operation, the machining efficiency of the equipment for machining the heat dissipation shell is improved, and meanwhile it is guaranteed that the surface quality of the heat dissipation shell is uniform.

Owner:江苏凯西电气设备科技有限公司

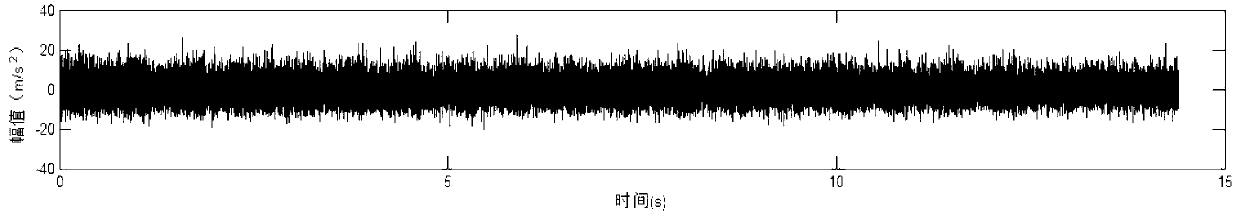

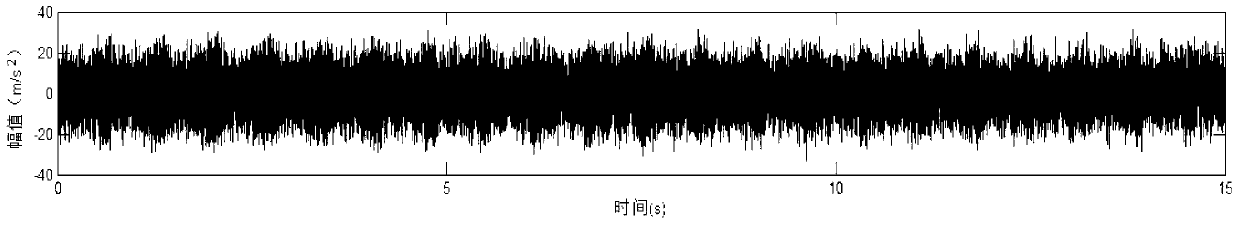

Cutting liquid as well as preparation method and application thereof

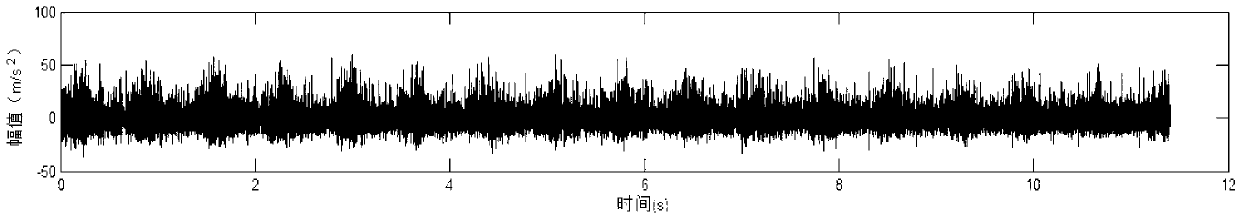

The invention discloses a cutting liquid as well as a preparation method and application thereof, belonging to the technical field of cutting liquids. The cutting liquid is prepared from the following raw material components in percentage by mass: 58-62% of coal oil, 9-11% of lard oil, 5-6% of span-80, 3-4% of petroleum sulfonate, 3-4% of fatty alcohol polyoxyethylene ether, 4-6% of nitrogen-contained borate ester, 0.8-1.2% of triethanolamine, 0.8-1.2% of phenol, 0.2-0.4% of benzotriazole, 0.1-0.3% of soybean oil and 9-11% of distilled water. When a large-diameter Fresnel lens die is processed by using the cutting liquid, a workpiece is uniform in surface quality and high in precision, the amplitude of a vibration signal is small during processing, and the sound emitting energy is low. The special cutting liquid plays roles of lubricating, cooling, resisting to abrasion, preventing rust, sterilizing, cleaning and workpiece surface film forming when used for processing the large-diameter Fresnel lens die, and is low in cost and free of pollution.

Owner:CANGZHOU HUARUN CHEM

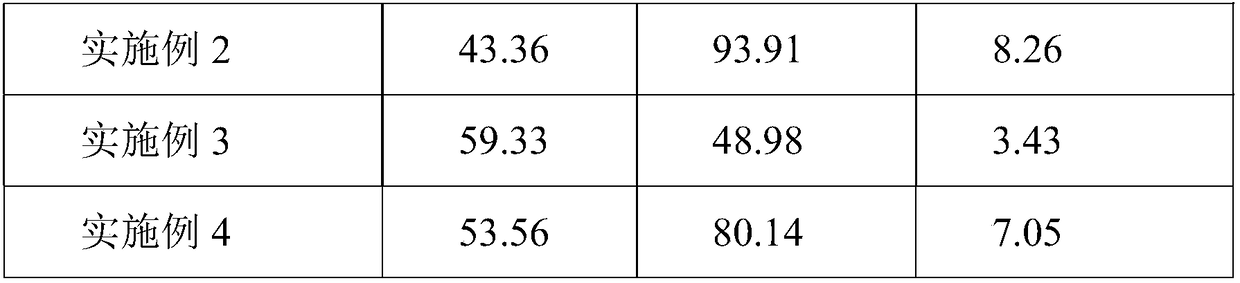

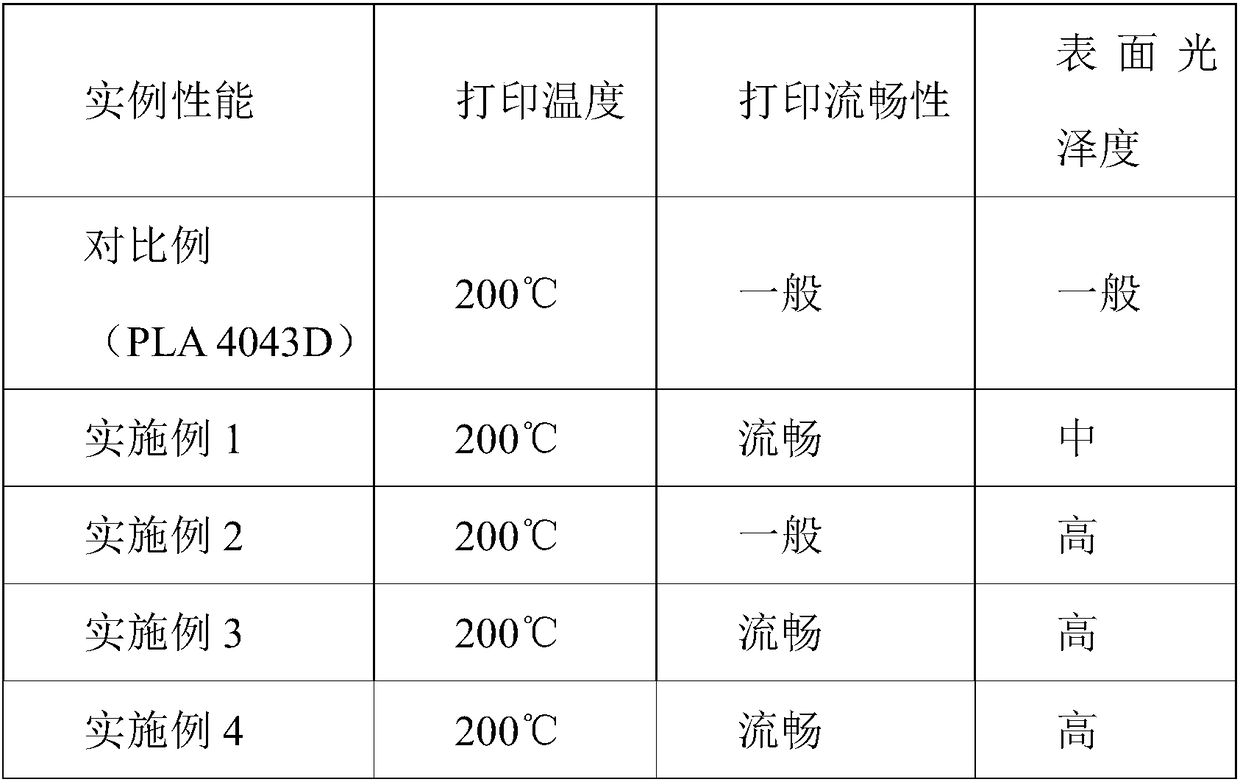

Toughened polylactic acid material for additive manufacturing

InactiveCN108192305AImprove toughnessUniform tensile strengthAdditive manufacturing apparatusUltravioletPhenol

The invention relates to a toughened polylactic acid material for additive manufacturing. The toughened polylactic acid material comprises the following components in percentage by weight: 75-90% of polylactic acid, 8-22% of a polyurethane elastomer, 0.1-0.3% of styrene / acrylic acid polymer, 0.2-0.4% of a hindered phenol antioxidant, 0.2-0.4% of a sulfur-containing auxiliary antioxidant, 0.1-0.3%of a benzophenone ultraviolet absorber, 1-2% of a lubricant and 0.2-0.3% of diffusion oil. The toughened polylactic acid material provided by the invention has the beneficial effects that the toughness of the obtained polylactic acid material is greatly improved and the elongation at break is greatly improved by adjusting the contents of the polyurethane elastomer and the styrene / acrylic acid polymer and adjusting other components, and the product has high glossiness and shows silk luster, so that the surface quality of the product is not influenced by printing layer lines in a printing process of a wire rod.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Nonblocking web plate of high speed needle machine

The invention relates to a nonblocking web plate of a high speed needle machine. The nonblocking web plate comprises a web plate body. A plurality of round needle holes are formed in the horizontal plane of the web plate body; the lower end of each round needle hole is provided with a sinking hole; and the aperture of each sinking hole is larger than the aperture of each round needle hole. The nonblocking web plate of the high speed needle machine is simply structure; meshes of the web plate cannot be blocked by fiber broken chips, so resistance to the needle is reduced and needle deformation can be avoided; and even fabric surface quality can be achieved.

Owner:YIZHENG HUAKAI NON WOVEN EQUIP

Pan head self-drilling screw and machining method thereof

PendingCN112695331AGuaranteed surface qualitySufficient surface qualityScrewsFurnace typesOXALIC ACID DIHYDRATEWire rod

The invention relates to the technical field of screw machining, and particularly discloses a pan head self-drilling screw and a machining method thereof. The machining method of the pan head self-drilling screw comprises the following steps that 1), a steel wire rod is subjected to wire drawing and annealing treatment, and then the steel wire rod is sequentially subjected to acid pickling and phosphating; the acid pickling comprises acid pickling by mixed acid A, water washing, drying and acid pickling by mixed acid B which are carried out in sequence, the mixed acid A is obtained by mixing hydrochloric acid and sulfuric acid, and the mixed acid B is obtained by mixing oxalic acid, lactic acid and water; phosphating is carried out by soaking in a phosphating solution, and the phosphating solution is obtained by mixing zinc dihydrogen phosphate and water according to the mass ratio of 5-8 to 100; 2), finish drawing, heading, tail clamping and thread rolling are carried out on the wire rod subjected to acid pickling and phosphating treatment to obtain a semi-finished product workpiece; and 3), preservative treatment is carried out on the obtained semi-finished product workpiece to obtain the pan head self-drilling screw. According to the machining method of the pan head self-drilling screw, the surface of the steel wire rod keeps good surface quality, and then the performance of the screw is improved.

Owner:SHANGHAI HONGTING FASTENER MFG CO LTD

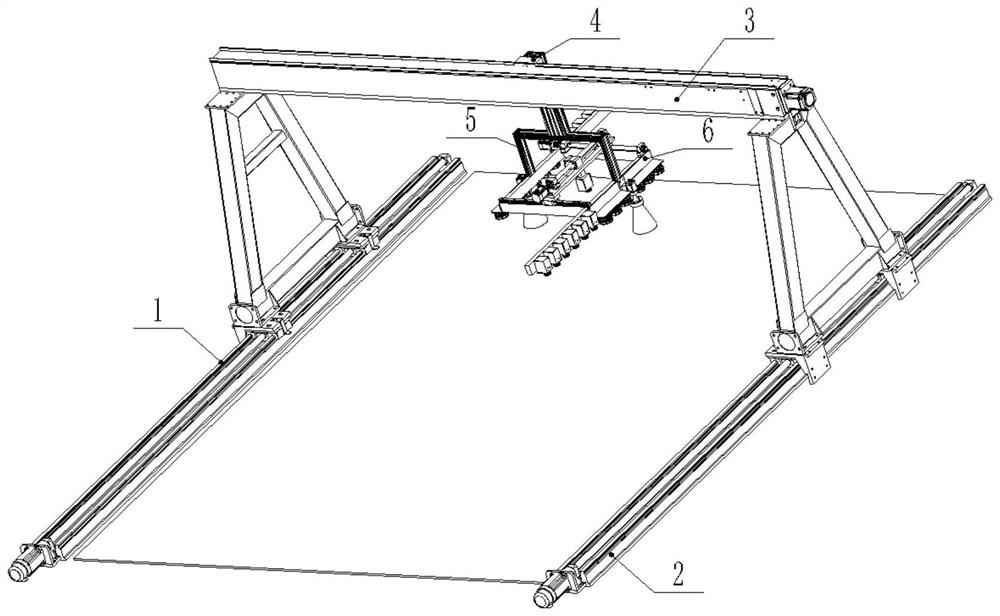

Steel member laser rust removal device

ActiveCN112620950AUniform surface qualityReduce processingLaser beam welding apparatusIlluminanceClassical mechanics

The invention relates to a steel member laser rust removal device. The steel member laser rust removal device is characterized by comprising a propelling mechanism composed of a left rail and a right rail which are parallel to each other, and a portal frame connected to the propelling mechanism in a transmission mode; the propelling mechanism can drive the portal frame to move and stop on the left rail and the right rail at a specified speed; the steel member laser rust removal device further comprises a suspension arm which can be driven to do uniform motion along a cross beam of the portal frame at a specified speed, a suspension is fixedly connected below the suspension arm, and a working head is mounted on the suspension; and the working head comprises a square frame, the square frame is composed of four frame strips with the same length, the four frame strips are a rear frame strip, a front frame strip, a left frame strip and a right frame strip respectively, cameras are installed at the midpoints of the left frame strip and the right frame strip respectively, and illuminating lamp sets are installed below the left frame strip and the right frame strip correspondingly, so that the illuminance in the shooting range of the corresponding cameras is uniform.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

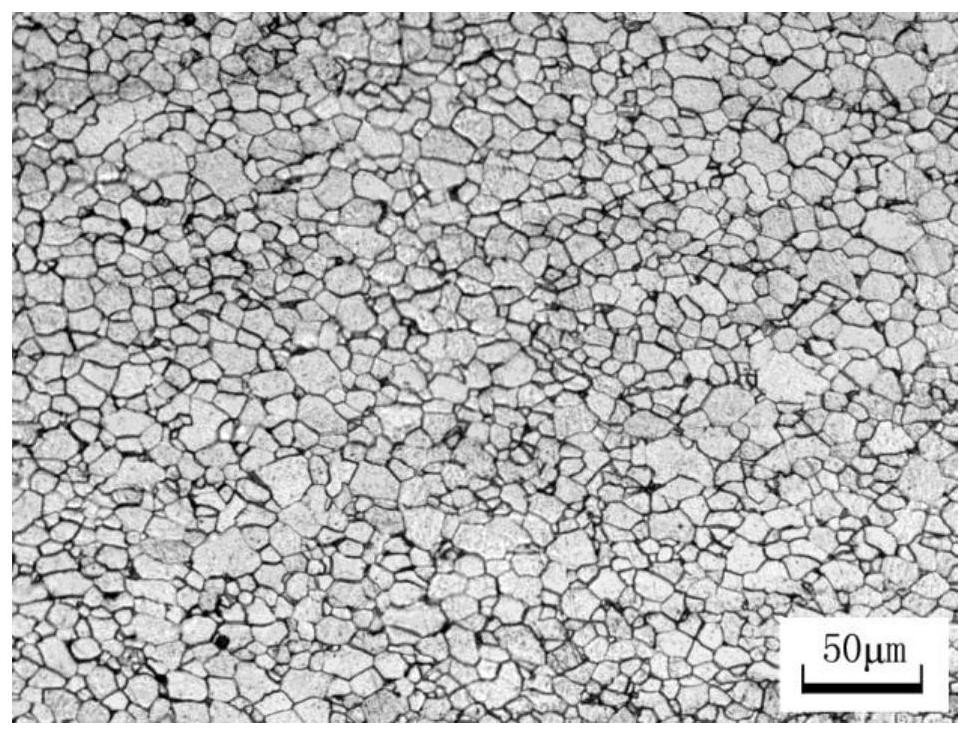

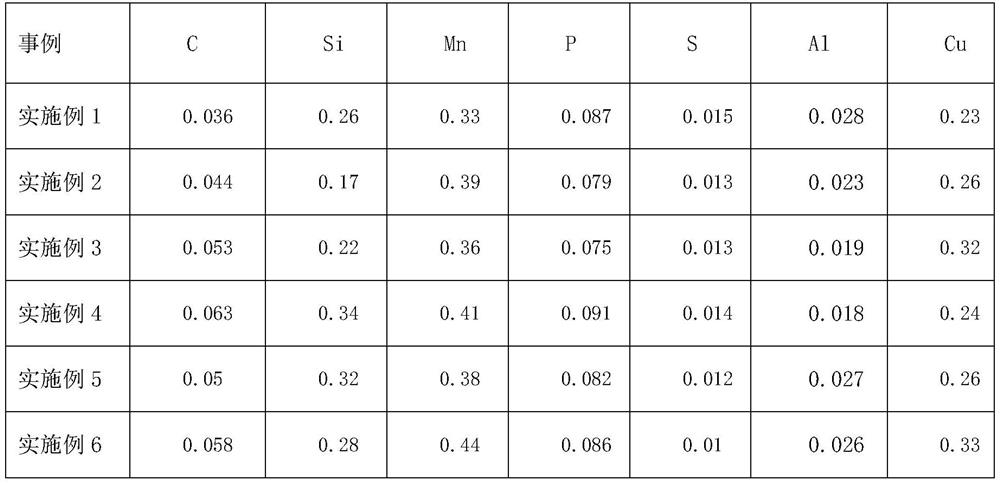

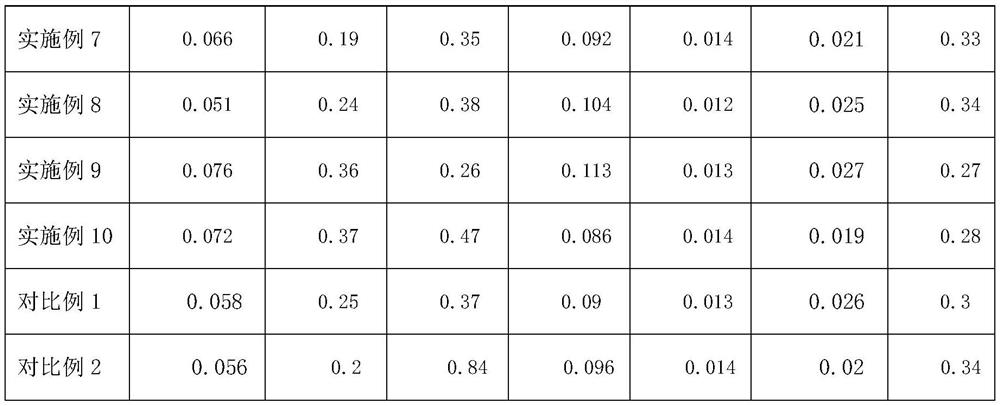

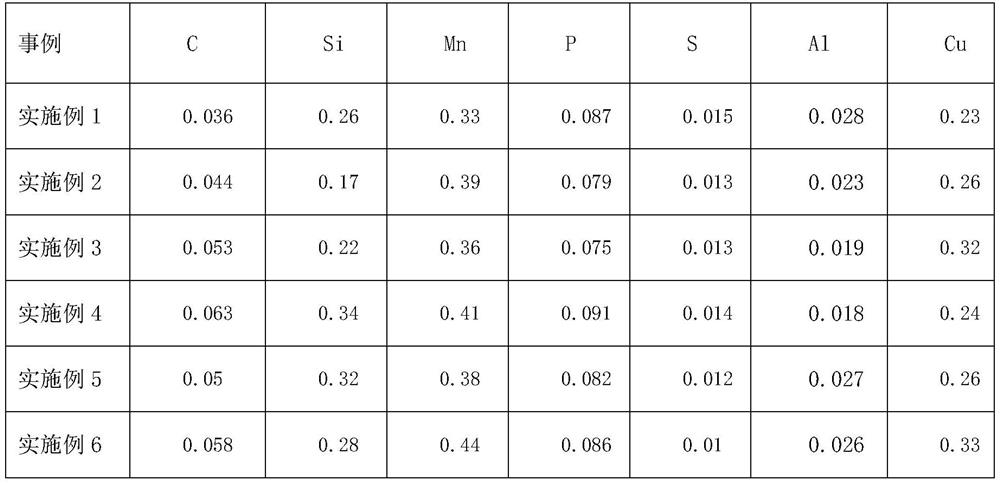

310MPa-grade cold-rolled low-cost weathering steel for automobile and preparation method of 310MPa-grade cold-rolled low-cost weathering steel

The invention relates to the field of steel smelting, and relates to production and manufacturing of cold-rolled weathering steel for automobiles, in particular to 310MPa-grade cold-rolled low-cost weathering steel for an automobile and a preparation method of the 310MPa-grade cold-rolled low-cost weathering steel. The weathering steel comprises the following chemical components in percentage by weight: 0 to 0.09 percent of C, 0.10 to 0.40 percent of Si, 0.20 to 0.50 percent of Mn, 0.05 to 0.12 percent of P, 0 to 0.015 percent of S, 0.010 to 0.030 percent of Al, 0.2 to 0.4 percent of Cu and the balance of Fe and inevitable impurities. According to the 310MPa-grade cold-rolled low-cost weathering steel for the automobile and the preparation method of the 310MPa-grade cold-rolled low-cost weathering steel, measures of controlling hot rolling in-furnace time, dephosphorization high-pressure water pressure, rough rolling temperature and the like are emphatically adopted, and the occurrence probability and degree of Cu brittleness and iron oxide scale are reduced. The steel has the advantages of being low in cost, excellent in surface quality, good in machining forming performance and atmospheric corrosion resistance and the like, and can be applied to industries such as automobiles and household appliances which have requirements for corrosion resistance.

Owner:武汉钢铁有限公司

Laser rust removal steel component surface roughness control method

ActiveCN112620949AUniform surface qualityReach the surface roughness rangeLaser beam welding apparatusEngineeringShooting range

The invention provides a laser rust removal steel component surface roughness control method. An adopted rust removal device comprises a propelling mechanism composed of a left rail and a right rail, a portal frame connected to the propelling mechanism in a transmission mode and a suspension arm capable of being driven to move along a cross beam of the portal frame, a suspension is fixedly connected to the lower portion of the suspension arm, a working head is installed on the suspension, the working head comprises a square frame, the square frame is composed of four frame strips with the same length, the four frame strips are the rear frame strip, the front frame strip, the left frame strip and the right frame strip respectively, cameras are installed at the midpoints of the left frame strip and the right frame strip respectively, an illuminating lamp set is installed below the left frame strip and the right frame strip, and the illuminance in the shooting ranges of the corresponding cameras is uniform.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

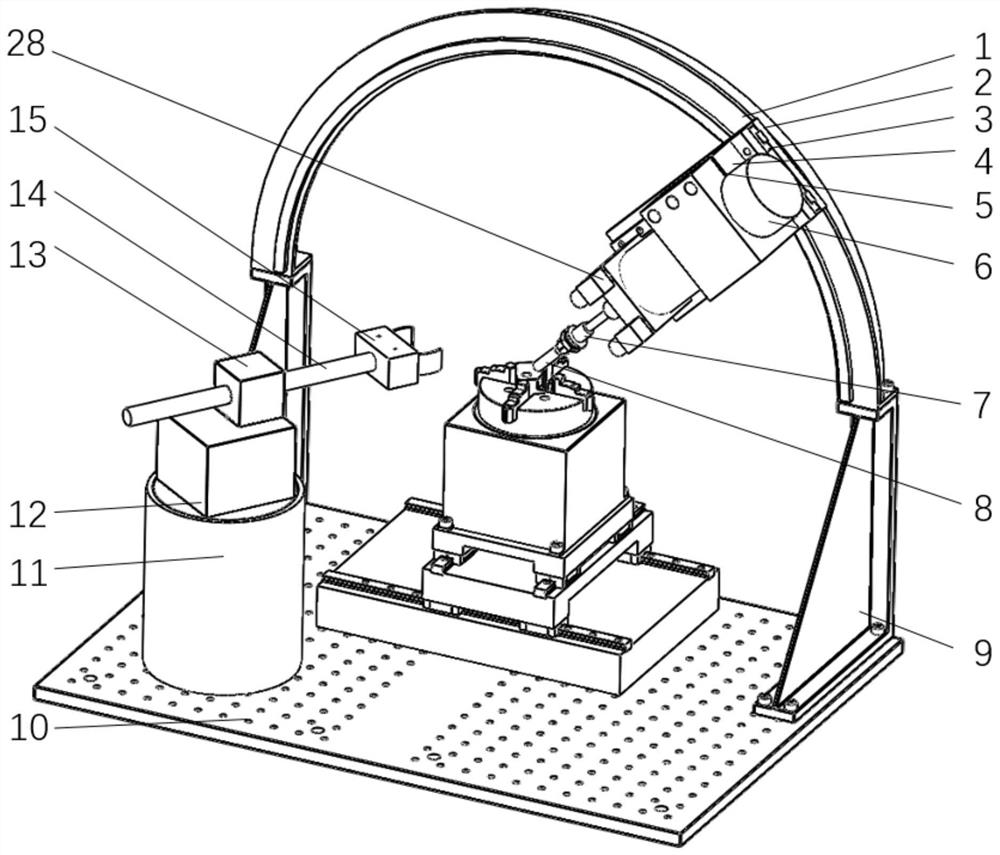

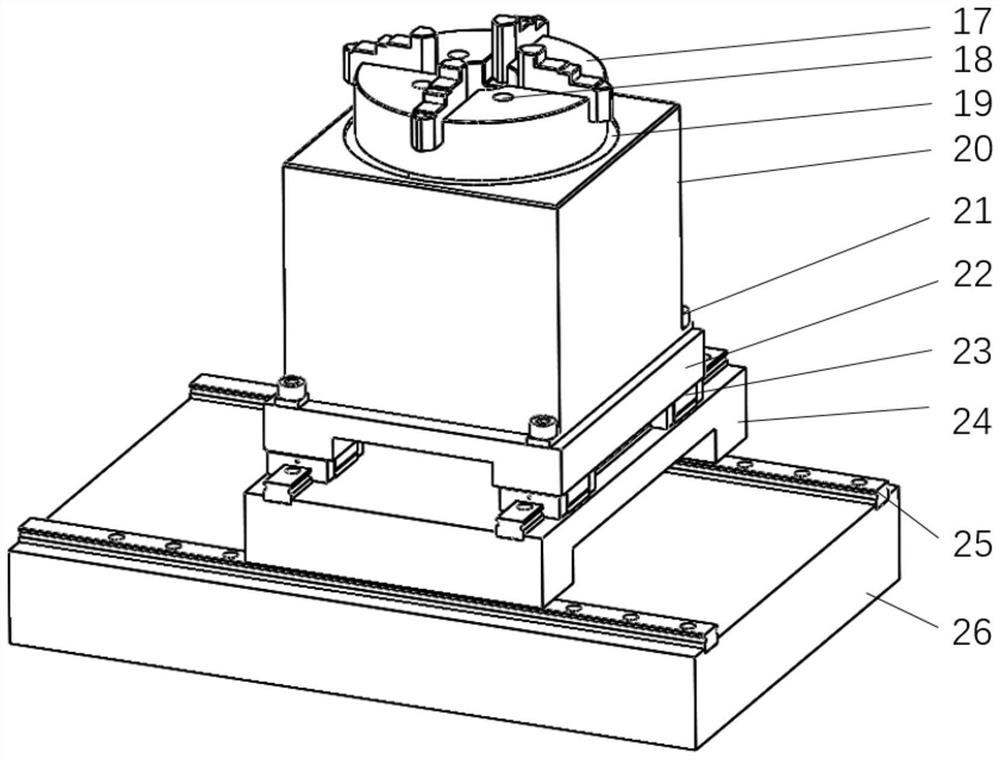

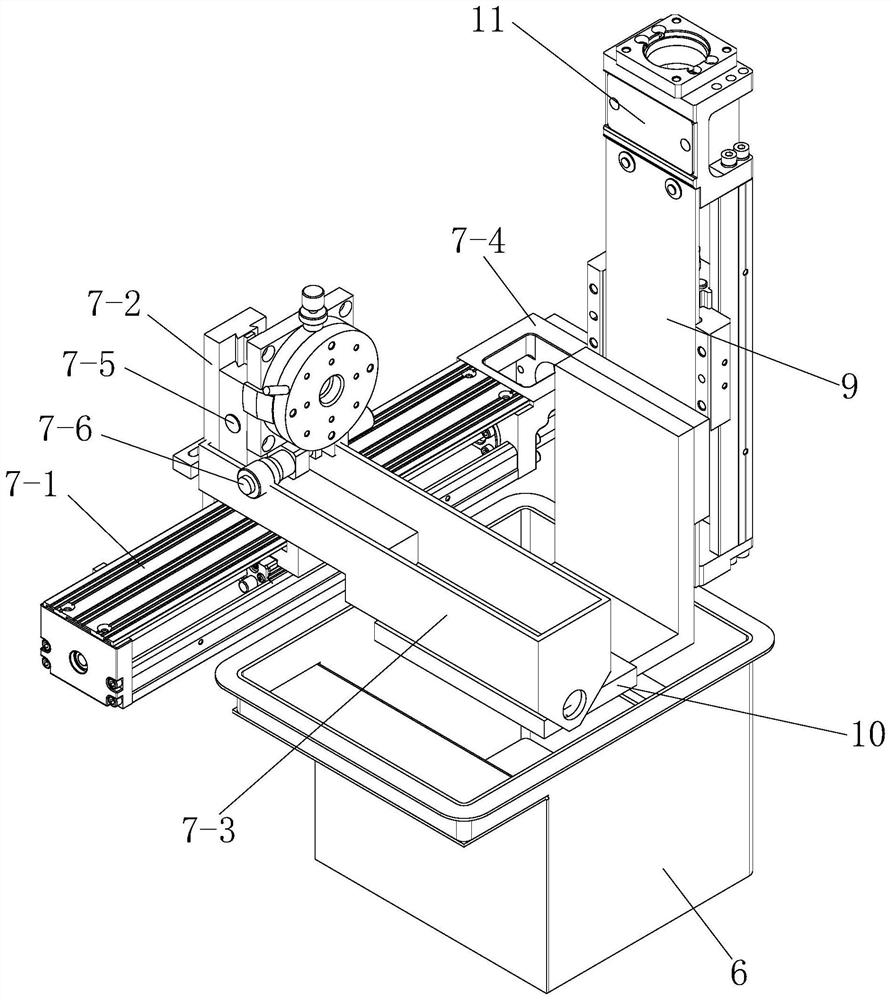

Intelligent polishing device and method for sapphire of special-shaped structure

PendingCN114473813ASolve the accuracy problemSolve efficiency problemsGrinding carriagesPolishing machinesPolishingEngineering

According to the automatic polishing device and method for the sapphire of the special-shaped structure, by means of the extrusion effect of a grinding head, grinding paste generates the micro-cutting effect on micro protrusions on all the surfaces of the sapphire of the special-shaped structure, and materials are removed. The device comprises a polishing system, a precise displacement system, a clamping system and a clamping system. The polishing system can accurately adjust the position and the angle of a grinding head, and the polishing requirement of a complex structure is met; the precise displacement system can drive the clamping system and the workpiece to move in the horizontal plane, displacement can be adjusted according to polishing force data collected by the polishing system, the polishing force is constant, and the machining quality is uniform. The clamping system is responsible for positioning and clamping a workpiece, and different clamps are selected according to the structural characteristics of the sapphire with the special-shaped structure; the clamping system can achieve work such as disassembly, assembly and turn-over of the workpiece. The sapphire polishing device is uniform in machining quality, wide in application range, high in automation degree, small in environmental pollution and capable of achieving high-quality polishing of various complex structures of the sapphire of the special-shaped structure.

Owner:DALIAN UNIV OF TECH +1

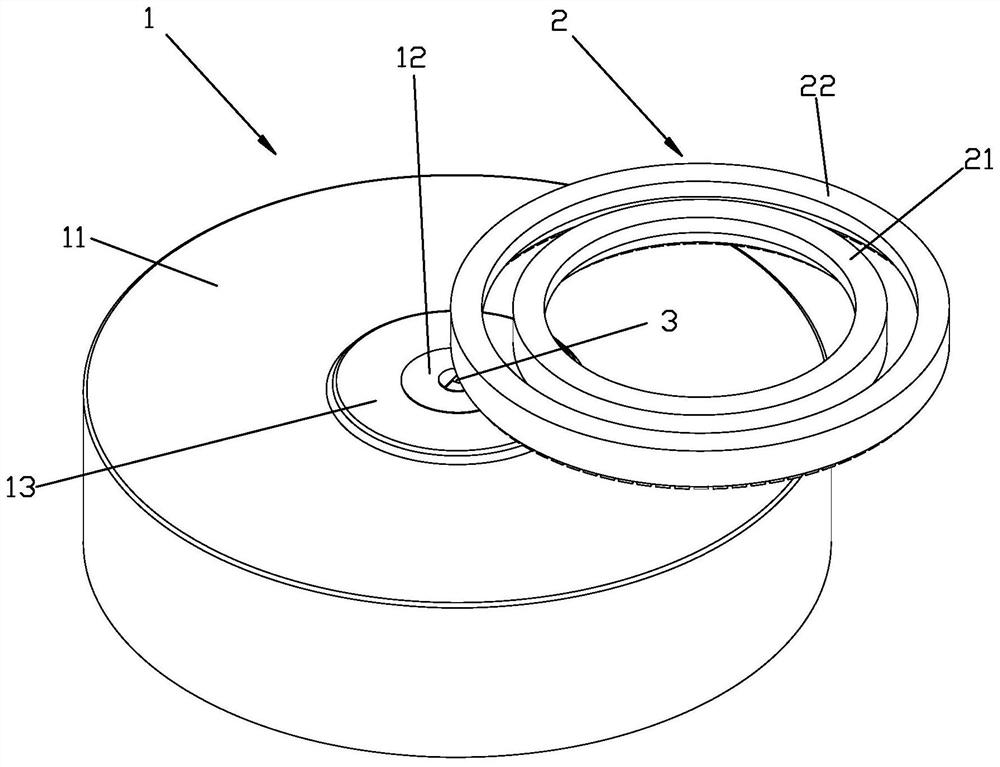

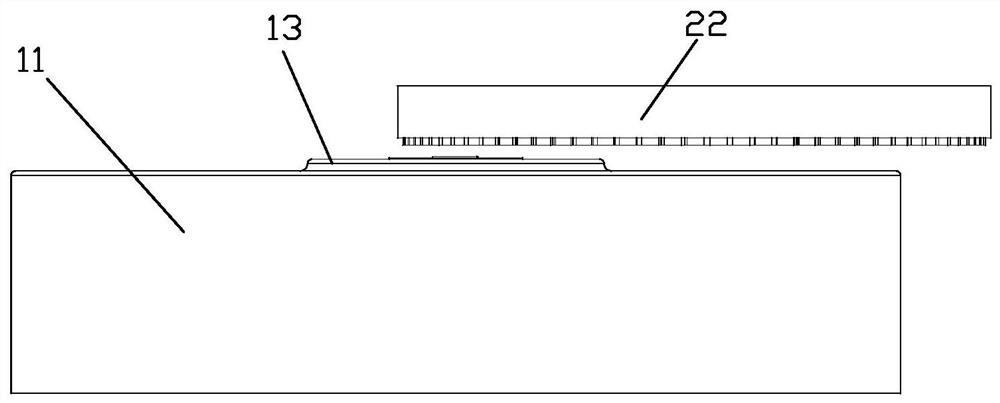

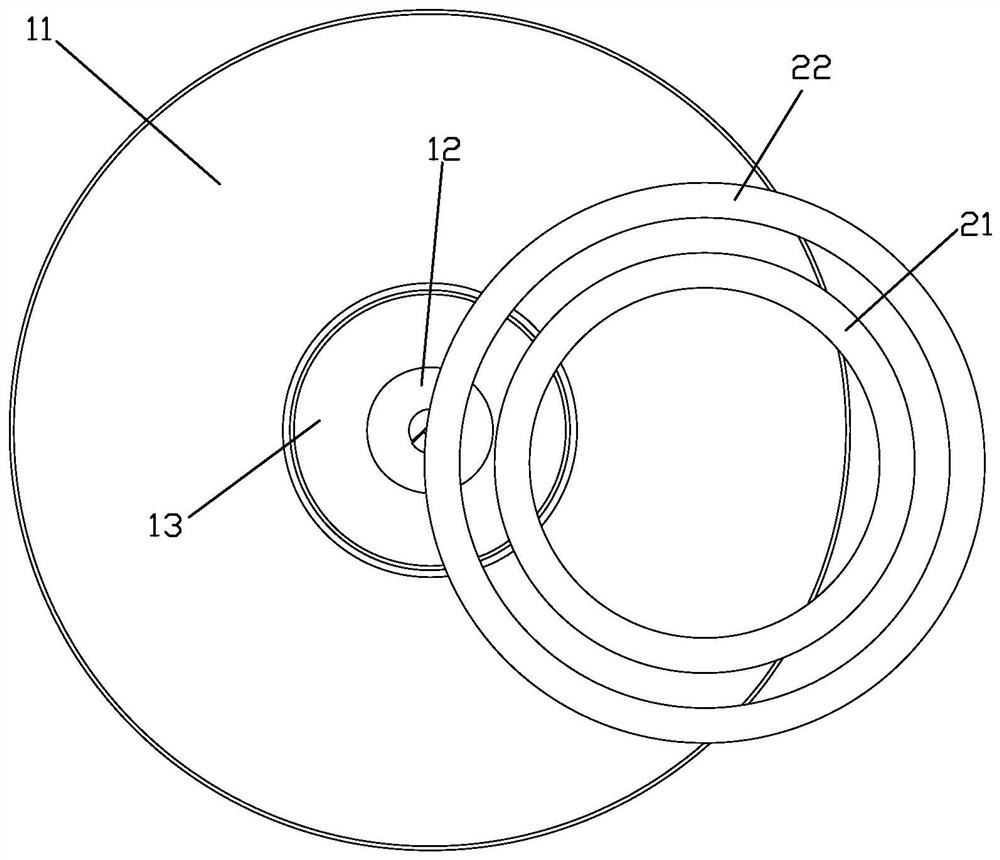

Diamond grinding and polishing integrated machining equipment and machining method thereof

PendingCN112676999ALess scratch damageUniform surface qualityGrinding carriagesGrinding drivesPolishingStructural engineering

The invention discloses diamond grinding and polishing integrated machining equipment and a machining method thereof. The machining equipment comprises a rack, a base device and a grinding and polishing device. The base device comprises a sliding seat capable of feeding along a Y axis and a base capable of being connected to the sliding seat in a rotating mode around a Z axis, and a clamp capable of clamping diamond is arranged on the base. The grinding and polishing device comprises a main shaft arranged along the Z axis, an inner ring grinding wheel and an outer ring polishing wheel sleeve the main shaft, the outer ring polishing wheel surrounds the inner ring grinding wheel, the main shaft rotates to drive the inner ring grinding wheel and the outer ring polishing wheel to rotate together, and the vertical position relation of the inner ring grinding wheel and the outer ring polishing wheel along the Z axis can be adjusted. The diamond on the clamp is ground and polished through rotation of the inner ring grinding wheel and the outer ring polishing wheel, feeding of the sliding seat and rotation of the base. The diamond grinding and polishing integrated machining equipment and the machining method thereof have the following advantages that diamond grinding and polishing are integrated into one procedure for machining, scratches and damage to the surface of the diamond are small, and the surface quality is uniform.

Owner:HUAQIAO UNIVERSITY

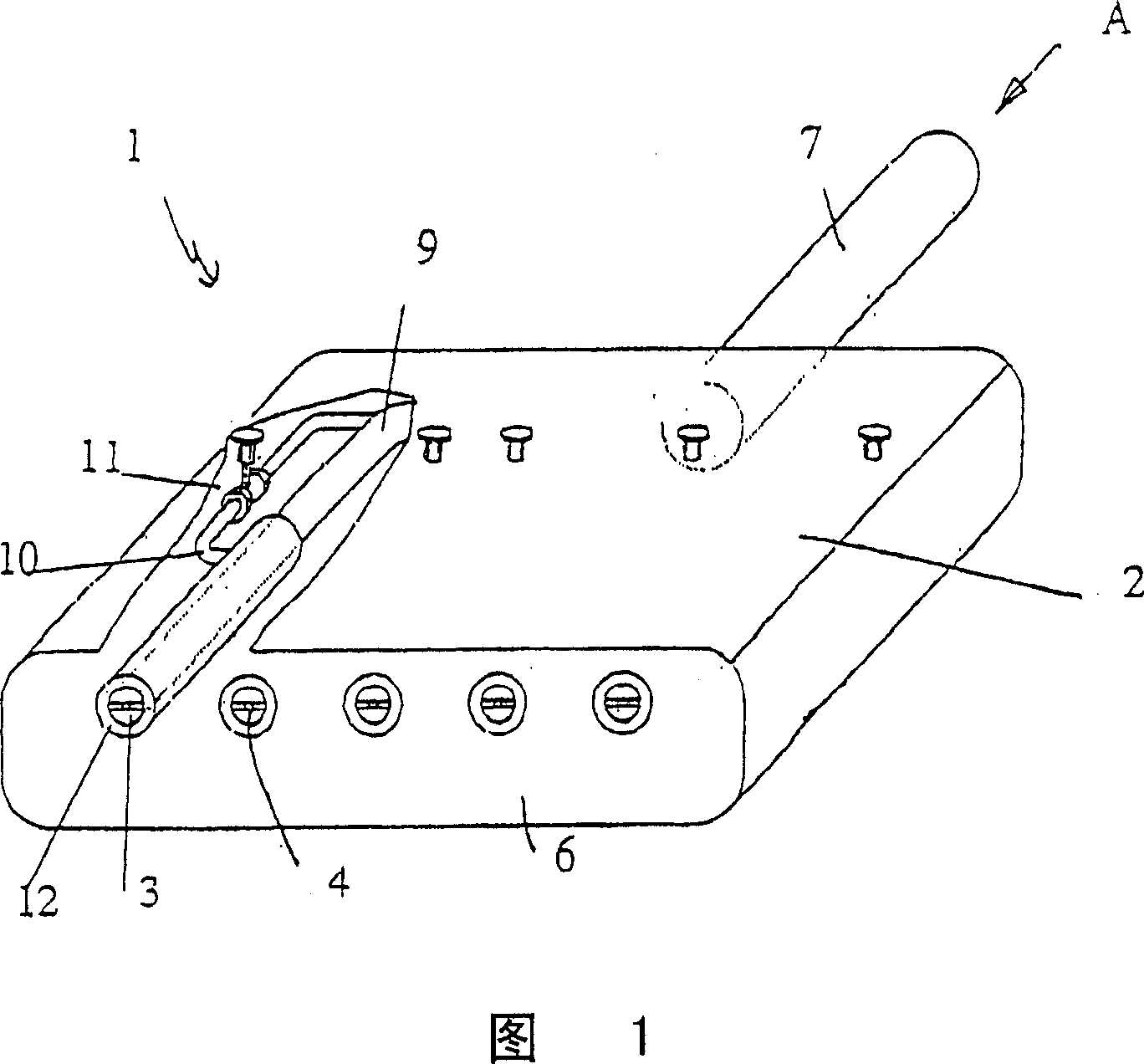

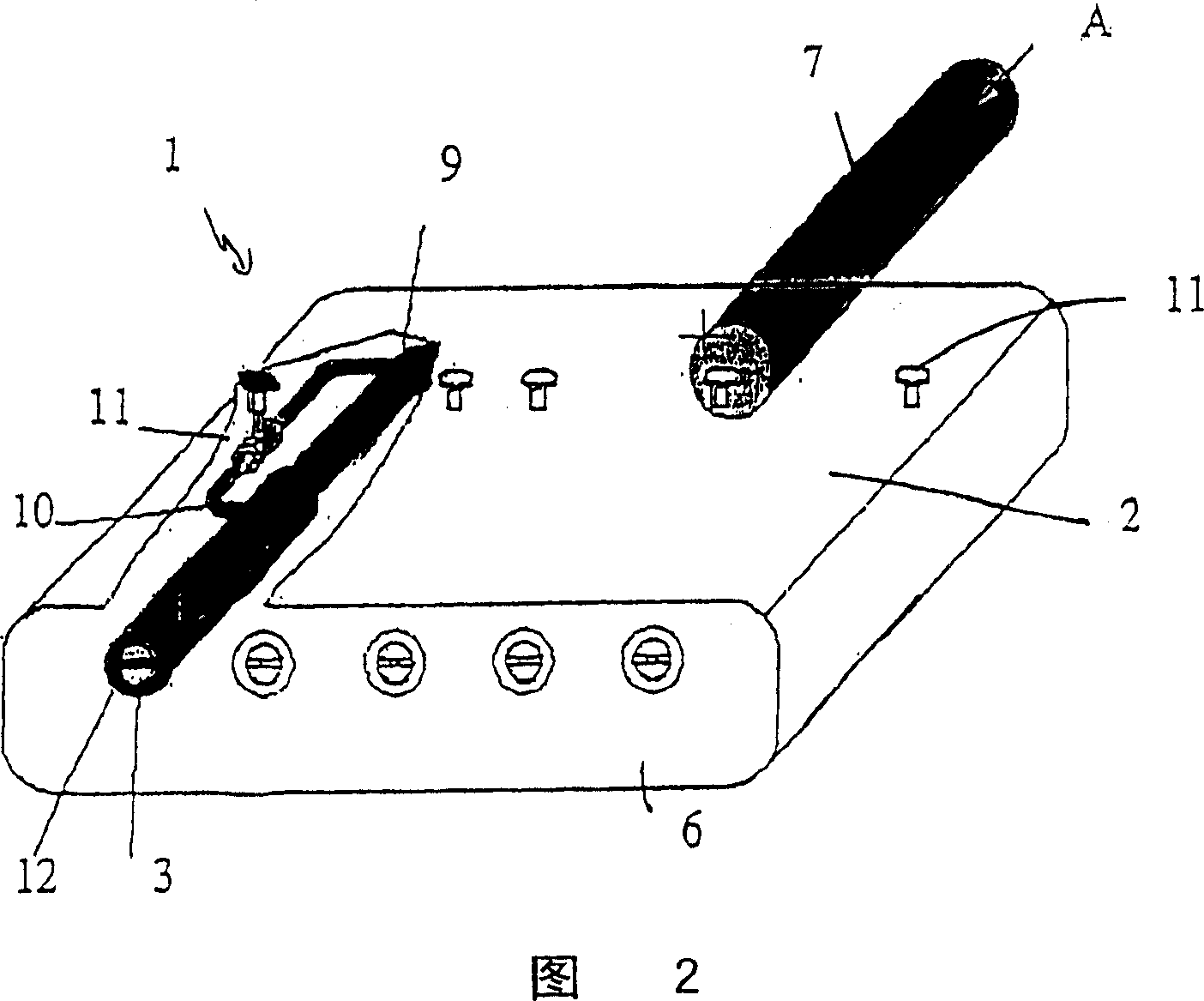

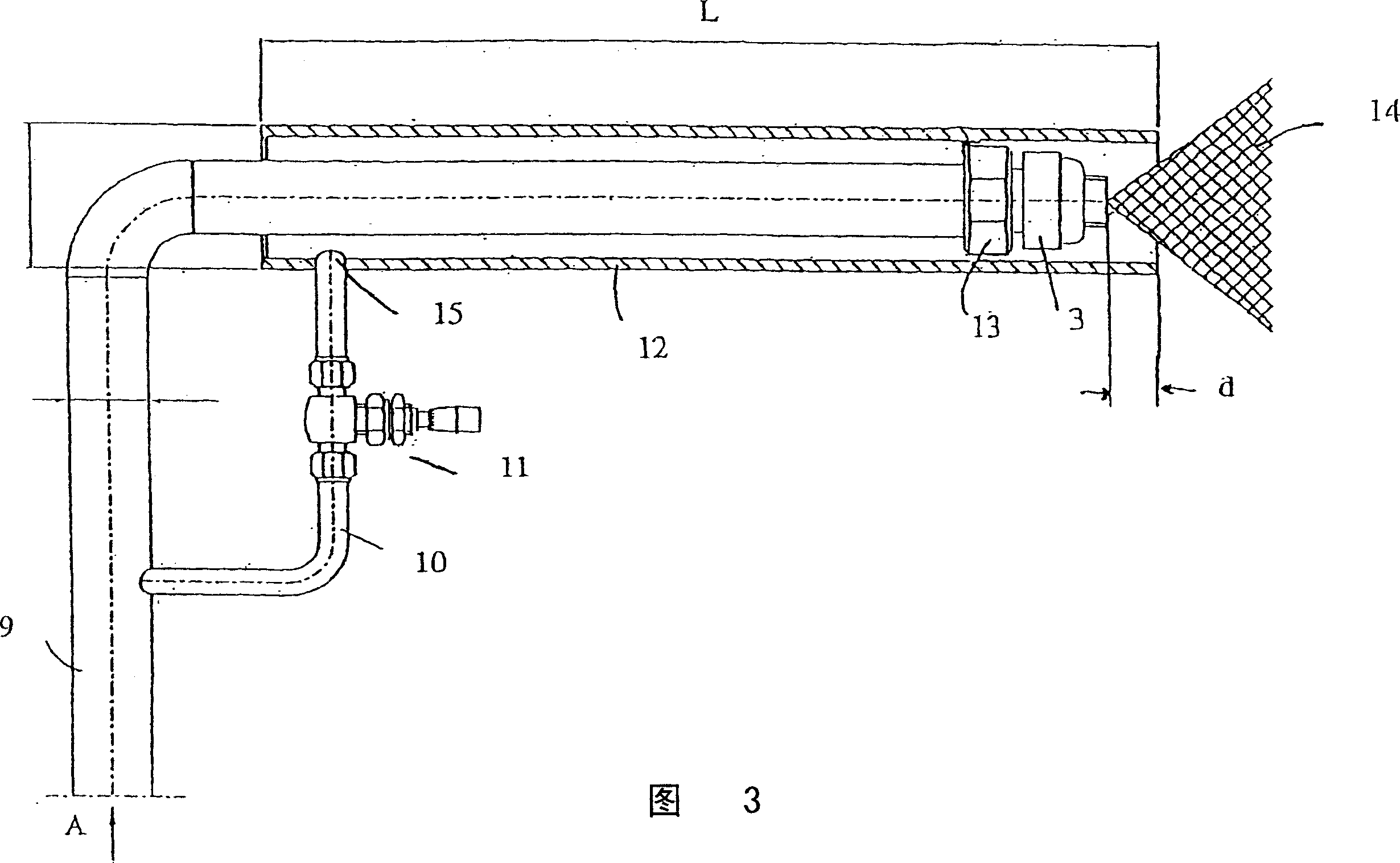

A process and roll stand for cold rolling of a metal strip

InactiveCN1927487AImprove surface qualityUniform surface qualityRollsWork cooling devicesMetal stripsStrip mill

A process is set forth for cold rolling of a metal strip, comprising: making the metal strip (18) pass through a roll gap (17) between two counter-rotating rolls (16); blowing cold and / or liquefied gas into the area of roll gap (17) by at least one nozzle (4) of a nozzle device (1); mounting a case (2) including a front top (6) partly surrounding at least one nozzle (4), wherein the front top (6) covers the nozzle device at least round the nozzle (4) of the nozzle device to prevent being effected by surrounding atmosphere so that water or ice generated round the nozzle (4) can be prevented; the front top (6) is provided with at least one opening (3), each of which aligns with the nozzle (4); heating at least one of the case (2) and the front top (6) to prevent water or ice aggradation. The invention further provides a corresponding cold roller for a metal strip.

Owner:AIR PROD & CHEM INC

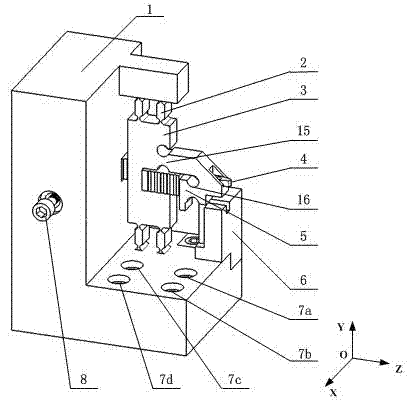

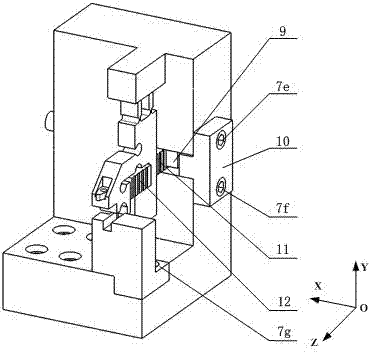

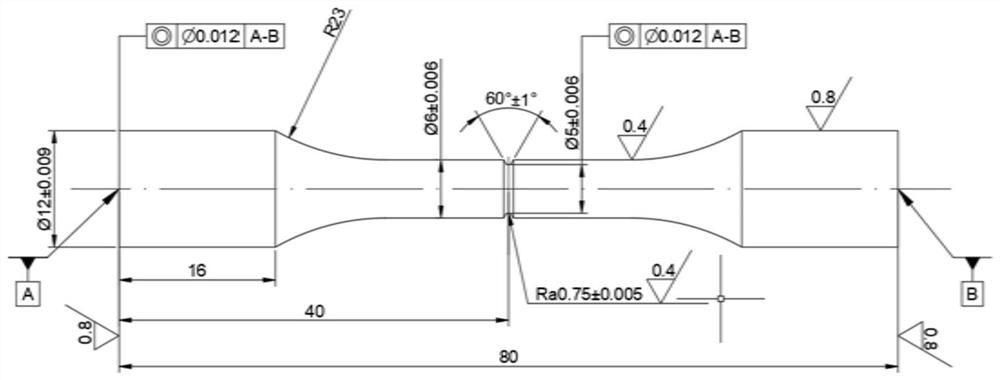

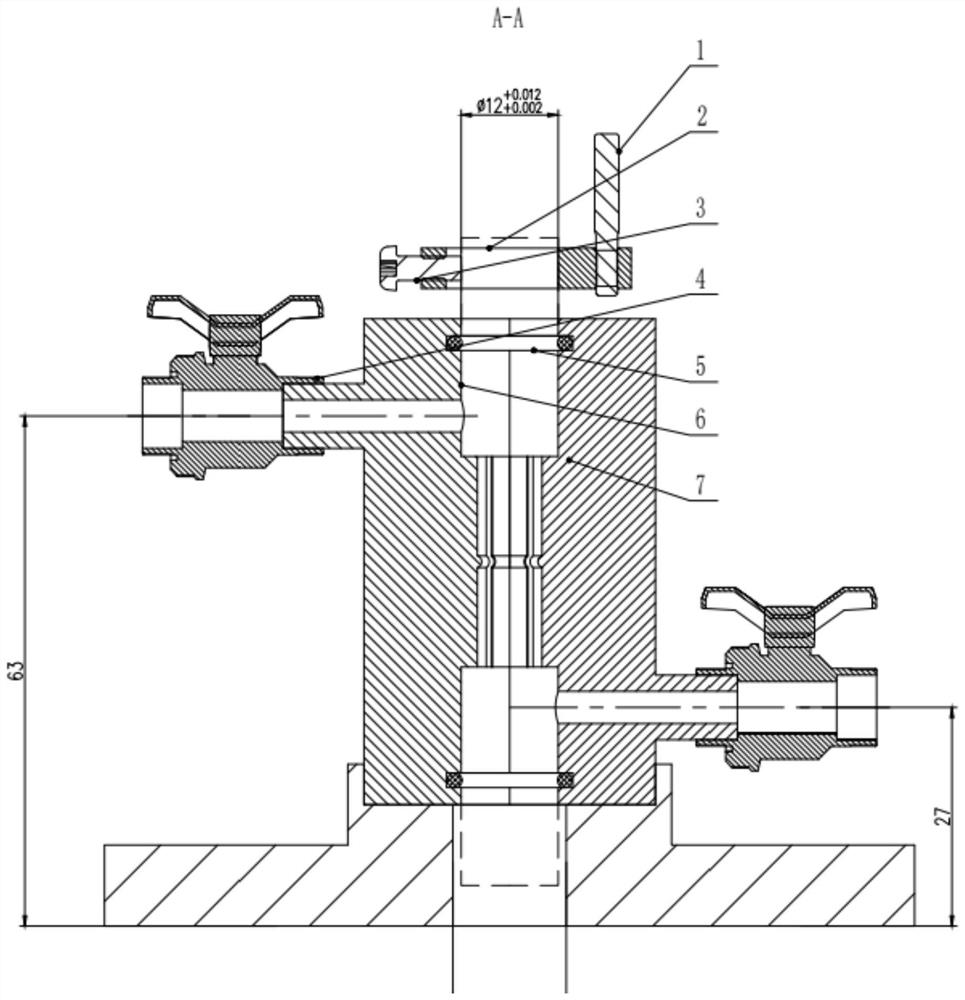

Live axle tunneling/turning method and device

InactiveCN102179530BLarge asymmetryReduce wearAutomatic control devicesFeeding apparatusReciprocating motionEngineering

Owner:JILIN UNIV

A kind of low-cost weathering steel for 310mpa grade cold-rolled automobile and its preparation method

The invention relates to the field of iron and steel smelting, and relates to the production and manufacture of cold-rolled weather-resistant steel for automobiles, in particular to a low-cost weather-resistant steel for 310MPa grade cold-rolled automobiles and a preparation method thereof. The chemical composition and weight percentage of the weathering steel are: C: 0-0.09, Si: 0.10-0.40, Mn: 0.20-0.50, P: 0.05-0.12, S: 0-0.015, Al: 0.010-0.030, Cu: 0.2 ~0.4, the balance is Fe and unavoidable impurities. The present invention mainly adopts measures such as controlling the time of hot rolling in the furnace, the pressure of high pressure water for dephosphorization, and the temperature of rough rolling, so as to reduce the occurrence probability and degree of Cu embrittlement and iron oxide scale. The steel has the characteristics of low cost, excellent surface quality, processing and forming, and excellent atmospheric corrosion resistance. It can be used in industries that require corrosion resistance, such as automobiles and home appliances.

Owner:武汉钢铁有限公司

Electric heating dual-pipe type contact type singeing frame

InactiveCN1260419CRaise the gradeTo achieve the purpose of contact singeing processingSingeingDouble tubeEngineering

Owner:赵文兰 +2

Ceramic printer and process method thereof

InactiveCN114872165ASpread evenlyRealize automatic continuous replenishmentAdditive manufacturing apparatusAuxillary shaping apparatusCeramic moldingComputer printing

The ceramic printer comprises a rack, a bottom plate, a first mounting base plate, a second mounting base plate and a top plate are sequentially arranged on the rack from bottom to top, and a slurry tank and a scraper device used for scraping tiled materials are mounted on the first mounting base plate; a material supplementing device capable of continuously supplementing ceramic slurry for the slurry tank is installed on the bottom plate, a lifting plate is vertically arranged in the rack, a printing platform capable of stretching into the slurry tank is arranged on the lower portion of the lifting plate, a lifting motor is arranged on the top of the lifting plate, and a laser source installed on the second installation base plate is arranged over the printing platform. The ceramic printer is simple in structure, the sinking type printing platform is adopted in the technological method, the ceramic slurry is fully immersed in the slurry tank for dipping, and then the scraper device and the material supplementing device are matched, so that the surface quality of a ceramic formed part is uniform, forming is easy, the using effect is good, and application and popularization are convenient.

Owner:西安优梨数字科技有限公司

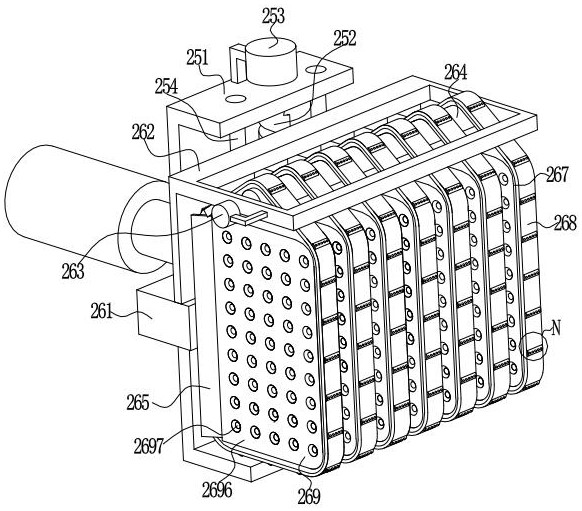

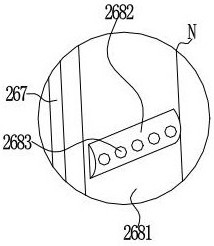

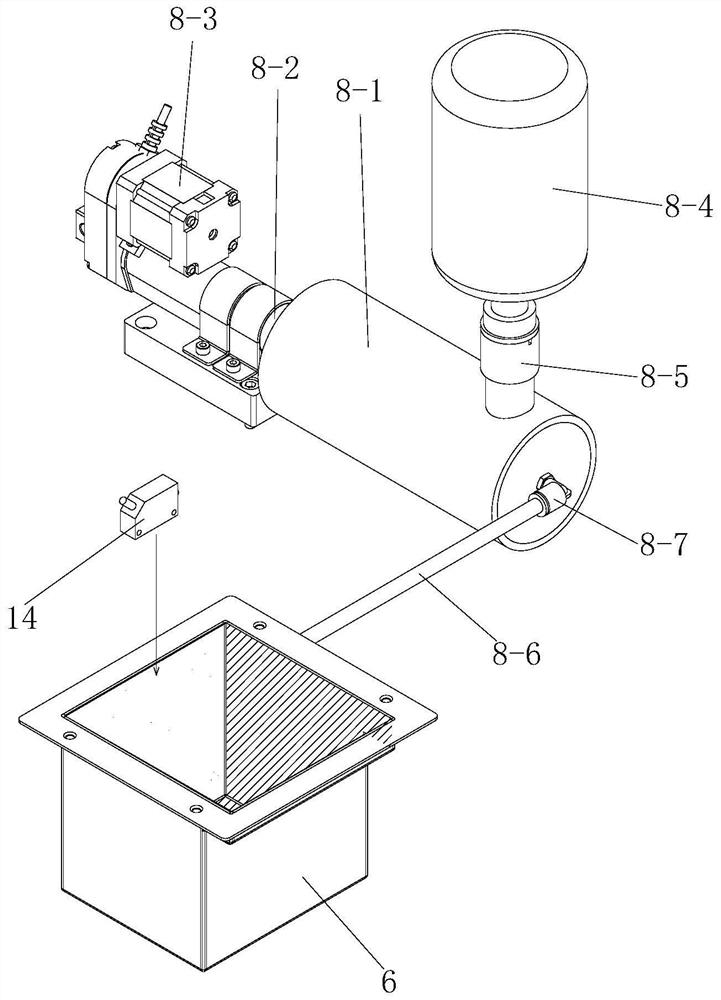

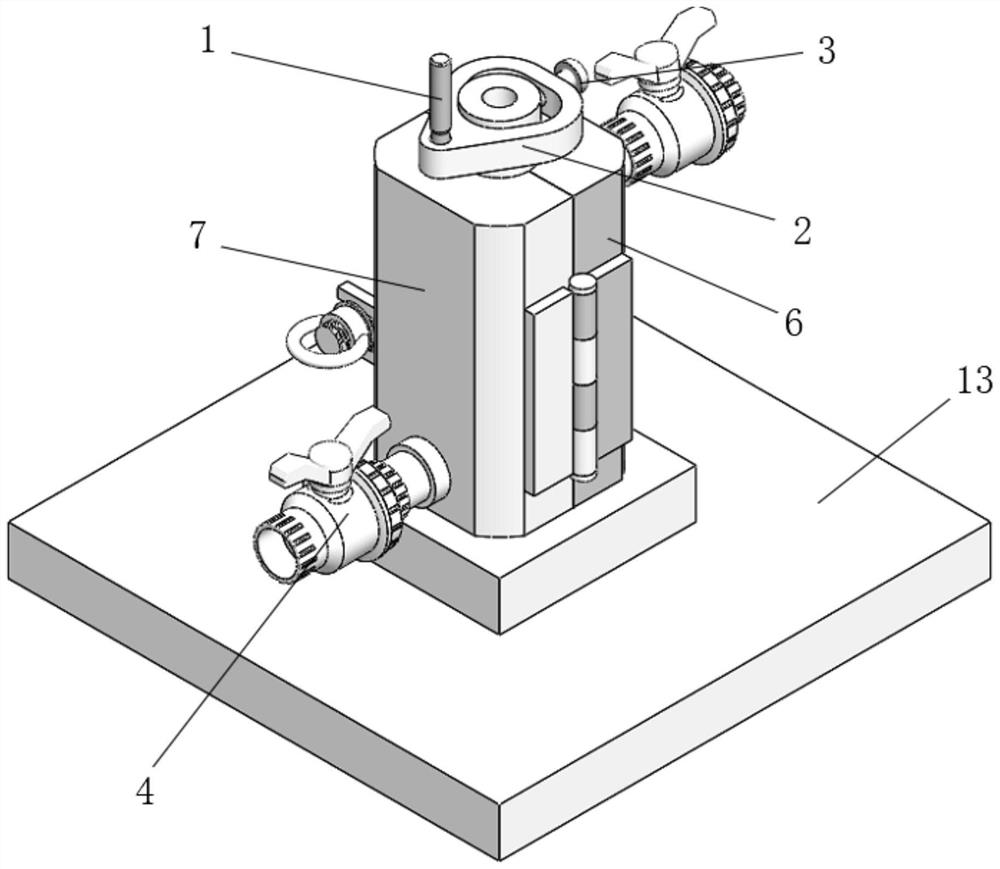

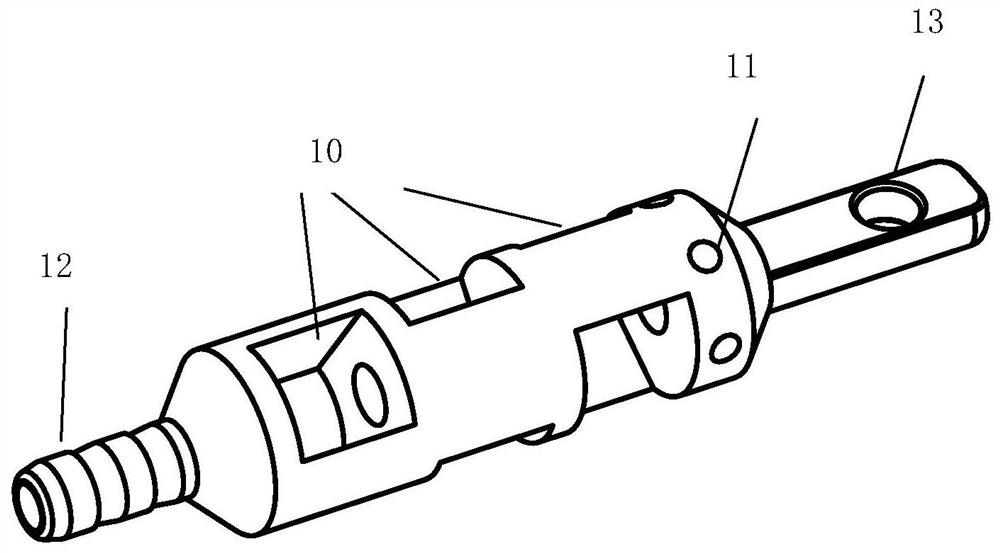

Rotary bending fatigue specimen V-shaped notch abrasive flow grinding device and process

PendingCN114346889AExtended service lifeUniform surface qualityEdge grinding machinesPolishing machinesMachine partsStructural engineering

The invention discloses a rotating bending fatigue sample V-shaped notch abrasive flow grinding device and process, the rotating bending fatigue sample V-shaped notch abrasive flow grinding device comprises a cylindrical clamp, the cylindrical clamp comprises a first clamp body and a second clamp body which are connected through a hinge shaft, and a locking device used for tightly attaching the first clamp body and the second clamp body is installed on the cylindrical clamp. A cavity matched with a part to be machined in shape is formed in the cylindrical clamp, a first channel communicated with the cavity is formed in the bottom of one side of the first clamp body in the direction perpendicular to the axis of the first clamp body, and a second channel communicated with the cavity is formed in the top of one side of the second clamp body in the direction perpendicular to the axis of the second clamp body. The abrasive material flows through the to-be-machined part in the axial direction, machining textures in the axial direction can be left on the surface of the to-be-machined part, the machining texture direction on the surface of the to-be-machined part is perpendicular to the fatigue stress sensitive direction of the part, and the service life of the part can be greatly prolonged.

Owner:ZHENGZHOU UNIV

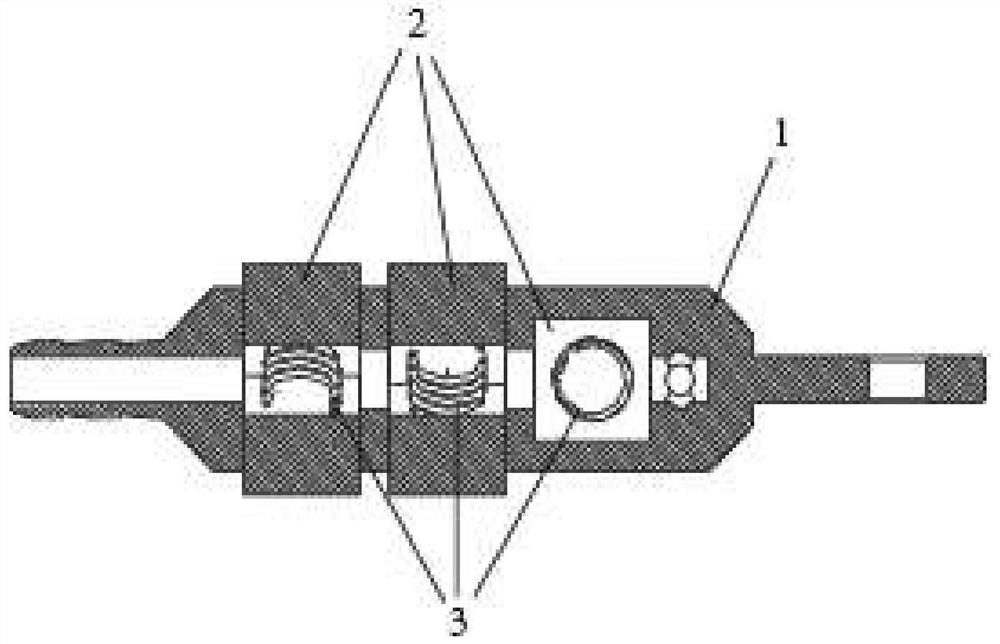

In-pipe electrolysis brush head device

The invention provides an in-tube electrolytic brush head device which comprises a device main body (1), a graphite sliding block (2) and a spring (3), and is characterized in that the device main body (1) is a hollow tube body, a sliding block mounting hole (10) is formed in the surface of the tube body of the device main body (1), the spring (3) is connected with the graphite sliding block (2), and the graphite sliding block (2) is embedded in the sliding block mounting hole (10) of the device main body (1). The specially designed anode is used for electrolyzing the inner wall of the long tube section by section; the anode structure is changed, and current loss and non-uniformity caused by the length of the to-be-treated pipe fitting are reduced; and a stepping mode is adopted, so that the power-on time can be effectively controlled, and the surface quality uniformity of the product is ensured. The method is small in product size limitation, simple in construction, small in investment and convenient for quality control.

Owner:SHENZHEN CANDORTECH INC CO

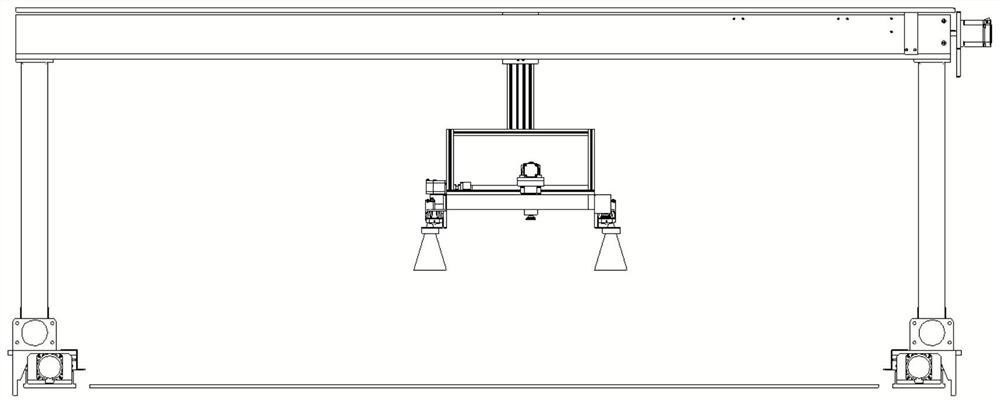

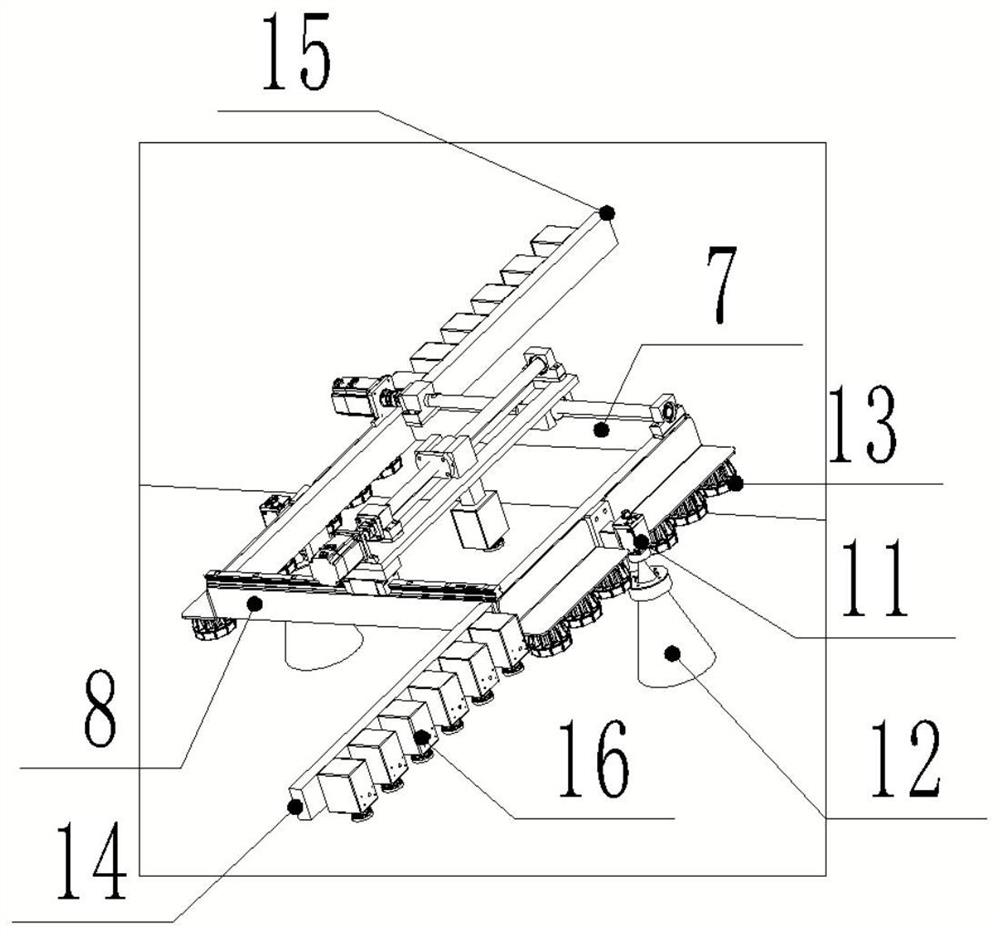

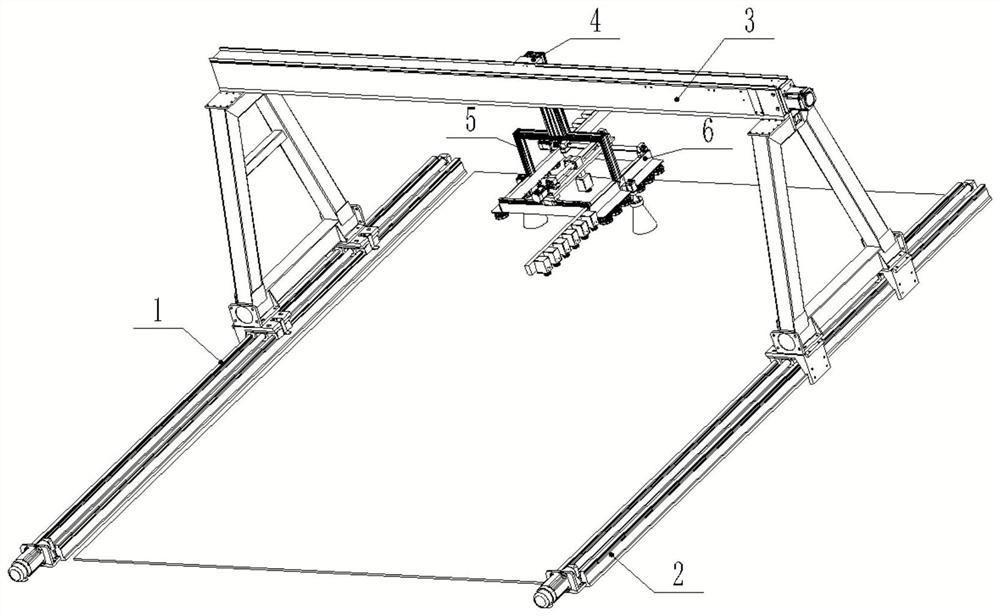

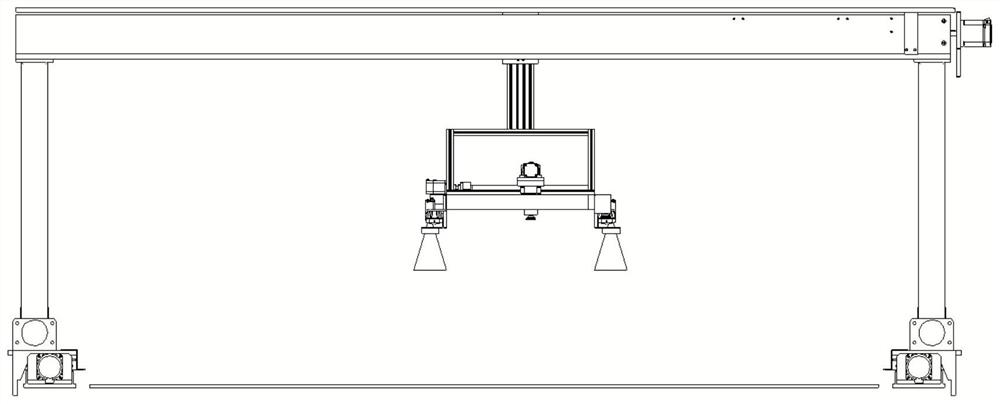

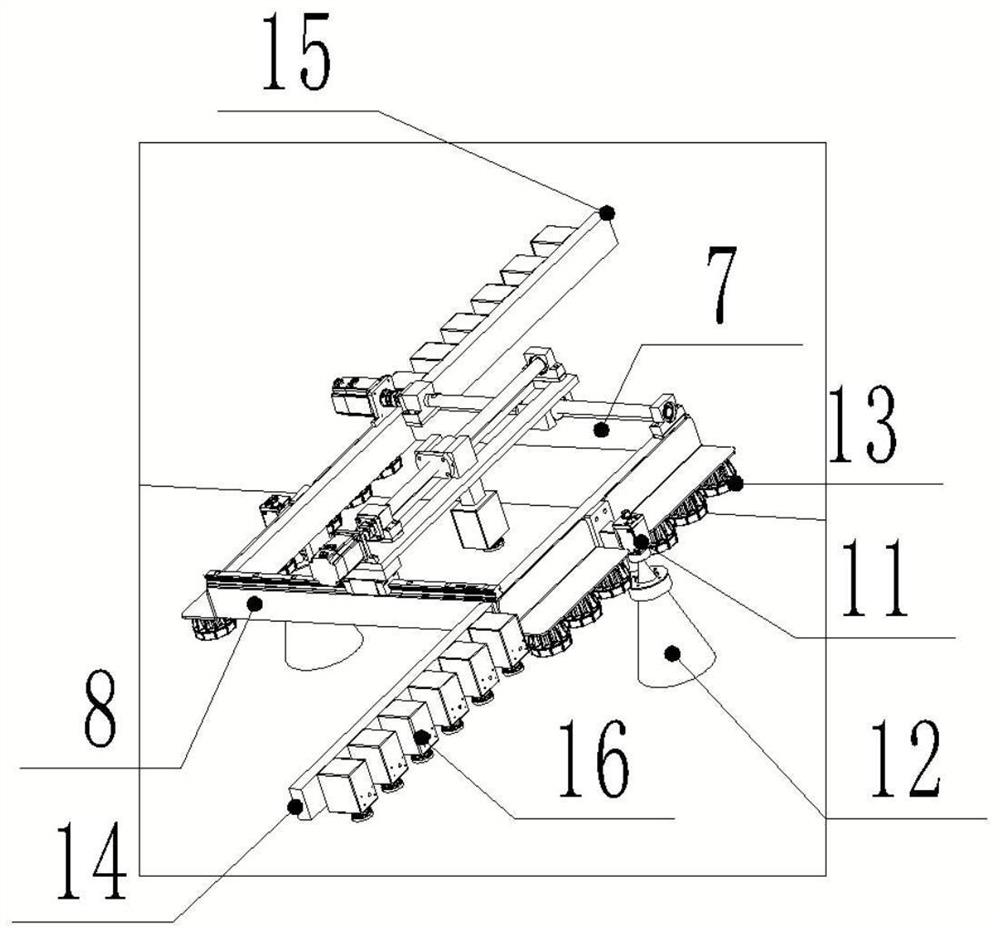

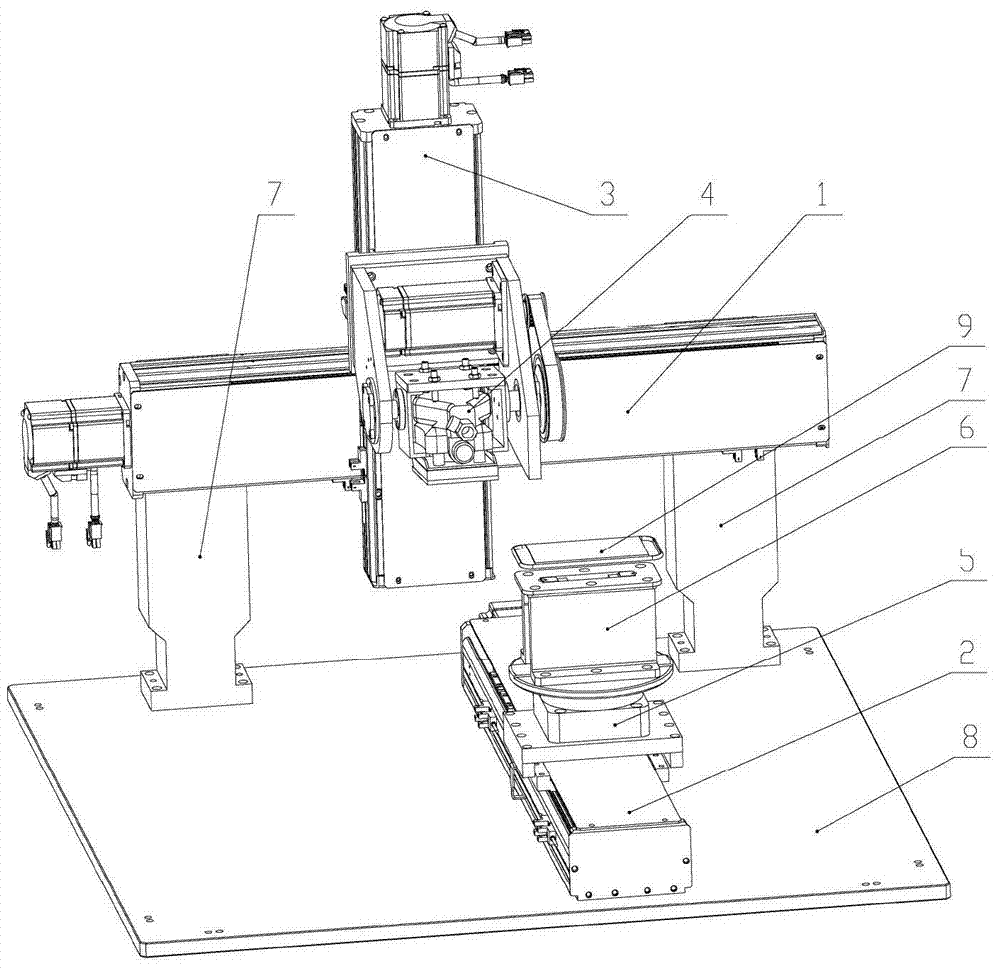

Five-axis automation device for CNC grinding and polishing of mobile phone shells

InactiveCN105290919BReduce manufacturing costUniform surface qualityEdge grinding machinesGrinding drivesRotary stageCnc grinding

The invention discloses a five-axis automated device for mobile phone shell numerical control grinding and polishing. The five-axis automated device comprises a base, gantry stand columns, an X-axis module, a Y-axis module, a Z-axis module, a C-axis rotating table and a grinding and polishing tool system. The gantry stand columns and the Y-axis module are arranged on the base. The X-axis module is arranged on the gantry stand columns. The Z-axis module is arranged on a guide rail slide block of the X-axis module. The grinding and polishing tool system is fixedly connected with a guide rail slide block of the Z-axis module. The C-axis rotating table is fixed to a guide rail slide block of the Y-axis module. A mobile phone shell pneumatic clamping device is fixed to the C-axis rotating table. The five-axis automated device is compact in structure and easy to carry, clamping of mobile phone shell pneumatic clamps is reliable, the surface quality of ground and polished mobile phone shells is uniform, one mobile phone shell can be ground and polished within 1 min, the production efficiency is greatly improved, and the production cost of mobile phones is reduced.

Owner:SUZHOU BOYINUO INTELLIGENT EQUIP

Production method of zirconium and zirconium alloy coil

ActiveCN105032974BSolve the problem that cannot be rolled into coils by hot rollingSave industrial waterProduction lineNuclear power

The invention provides a production method of a zirconium and zirconium alloy strip coil. The production method comprises the steps that a zirconium or zirconium alloy strip blank is heated in a heating furnace before production and is rolled on a steekle mill or a tandem rolling unit to the thickness that the blank can be transferred to a cold mill to be rolled, and the blank is directly coiled; surface treatment is carried out on a hot-rolling zirconium coil obtained through rolling on a continuous annealing-shot blasting-acid pickling production line, and a zirconium strip obtained after surface treatment is a smooth and clean zirconium strip which is in the metal natural color and free of oxide skin or harmful air suction layers; then a cold mill unit is adopted for carrying out cold rolling on the zirconium strip to obtain a thin strip, and cold rolling is carried out after annealing is carried out in an on-line annealing or vacuum annealing manner in the process of cold rolling; and finally various finished zirconium or zirconium alloy thin strip products of target thickness are obtained in a rolled manner. According to the production method, the cost is low, the product quality is good, and the rate of the finished products is improved by more than 15%; the requirements of nuclear power, chemical engineering and other aspects for thin zirconium materials and zirconium strips for thin-wall zirconium pipe welding can be completely met; and energy saving and consumption reduction are achieved, and high practical value is achieved.

Owner:BAOJI TUPENG METAL MATERIALS CO LTD

An Ultrasonic Vibration Assisted Vacuum Micro Evaporation Plating Equipment

ActiveCN111575654BEasy to controlReduce lossVacuum evaporation coatingSputtering coatingEvaporation (deposition)Busbar

Owner:南京长江工业技术研究院有限公司

A kind of pdlc thin film doped with nano conductive particles and preparation method thereof

InactiveCN104698668BReduce the driving voltageLow dielectric constantNon-linear opticsMechanical stabilityThermal stability

The invention provides a nano conducting particle doped PDLC (polymer dispersed liquid crystal) membrane. The nano conducting particle doped PDLC is prepared by stirring polyurethane modified by acrylic acid, a TMPTA (trimethylolpropane triacrylate) monomer thinner, grapheme nano conductive particles, an antifoaming agents and liquid crystal for 60-120 minutes under the constant temperature ranging from 100r / min to 300r / min and subjecting the same to radiation curing with an electron beam 150-300keV in energy for 0.1-0.3 seconds. The grapheme nano conduction particles are combined with a traditional PDLC membrane, driving voltage of the PDLC membrane is lowered from dielectric constant and liquid crystal orientation, main materials for preparing the PDLC membrane are not needed to be changed, original optical-electrical characteristics of the PDLC are guaranteed, the driving voltage of the PDLC membrane is low, good thermal stability and mechanical stability are achieved, and simpleness in preparation process is realized.

Owner:BEIJING SAN WU JIU INVESTMENT

Production method for stainless steel seamless steel tube

The invention discloses a production method for a stainless steel seamless steel tube. The production method comprises the following steps: immersing the stainless steel seamless steel tube into an acidic solution to perform chemical reaction; flushing inner and outer surfaces of the stainless steel seamless tube through pressure water, and performing point-like polishing on surface defects of theacidified stainless steel seamless steel tube; fixing the stainless steel seamless tube onto an oil coater so as to be fixed, and using a rotary brush to coat oil for inner and outer surfaces, and lubricate. The production method has the beneficial effects that: production efficiency is improved, and stable product quality also can be guaranteed according to the production method for the stainless steel seamless steel tube and application of the production method; special cleaning fluid can be used for enabling the steel tube to obtain uniform surface quality, so that the service life of thesteel tube is prolonged; and moreover, several different cold-processing methods are disclosed according to different needs, so that different consumer needs can be met, sales range is increased, andeconomic benefits are improved.

Owner:四川艾格瑞特航空技术股份有限公司

A rectifier heat dissipation shell production molding processing equipment

ActiveCN114310580BImprove processing efficiencyUniform surface qualityEdge grinding machinesBelt grinding machinesElectric machineryProcess engineering

The invention relates to the technical field of rectifier cooling shell processing, in particular to a rectifier cooling shell manufacturing and processing equipment, including a processing table and a positioning device, the upper end of the processing table is fixedly installed with a positioning device, and the positioning device includes an inverted U-shaped plate, positioning cylinder, extruding plate, electric telescopic rod, moving frame, grinding frame and cleaning frame, the grinding frame includes moving plate, L-shaped frame, motor one, sprocket one, bracket, sprocket two, toothed chain belt , the grinding belt and the grinding plate, the present invention coordinates the processing table with the positioning device to position the heat dissipation shell, grinds the heat dissipation shell through the positioning device, and can clean the debris on the surface of the parts in time during the grinding process. During the process, workers are not required to perform processing operations, which improves the processing efficiency of the equipment for processing the heat dissipation shell, and at the same time ensures that the surface quality of the heat dissipation shell is uniform.

Owner:江苏凯西电气设备科技有限公司

Special polishing fluid for plastic soft metallic materials and method for preparing polishing fluid

InactiveCN103333617BUniform surface qualityEasy surface qualitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesVegetable oilKerosene

The invention relates to special polishing fluid for plastic soft metallic materials and a method for preparing the polishing fluid and belongs to the technical field of the polishing fluid. The polishing fluid is prepared from a ground material, a solvent and additives which are in a certain volume ratio, namely 2% of brightener, 3% of diamond micro powder, 15% of additives and 80% of kerosene. The method comprises the steps of: adding the diamond micro powder into melted lard or vaseline, and stirring uniformly; then, adding the kerosene, and cooling down to room temperature for standby; and adding stearic acid particles (C17H35COOH), vegetable oil and spindle oil into a clean vessel, stirring uniformly, adding the brightener, and uniformly mixing and stirring the solution, thereby obtaining the polishing fluid. The surface of a niobium alloy workpiece processed by the polishing fluid is uniform in mass, is free from polishing lines and can reach a mirror polishing effect. Meanwhile, the polishing fluid can play a role in cooling, lubrication, adsorption and washing during processing and can also be applied to the mirror polishing processing of similar plastic soft metallic materials, the operation is simple, the efficiency is high, the cost is low, and no pollution is caused.

Owner:东莞市硕丰研磨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com