Medium-high-voltage electronic aluminum foil for high-capacity and high-strength capacitor and preparation method thereof

An electronic aluminum foil, high-strength technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of shortening production cycle, uneven casting structure, etc., to eliminate the influence of uneven casting, avoid coarse grains, and prevent surface damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

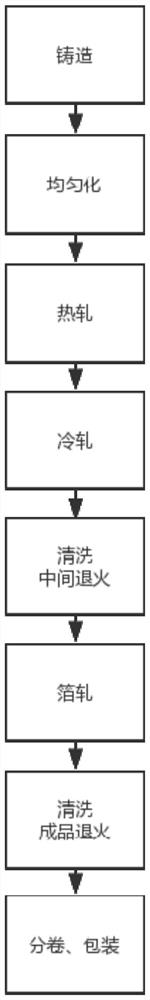

[0062] A method for preparing medium and high voltage electronic aluminum foil for high-capacity and high-strength capacitors, comprising the following steps:

[0063] 1) Casting: After smelting, heat preservation, refining and standing still, the raw materials of high-purity molten aluminum casting are used to produce flat ingots by semi-continuous casting. The casting temperature is 695°C, and the formed flat ingots are obtained by rapid cooling;

[0064] 2) Homogenization: Homogenize the shaped slab obtained in the previous step through an annealing furnace, the homogenization temperature is 570°C, the homogenization time is 19h, and air-cool to room temperature after homogenization;

[0065] 3) Hot rolling: the slab after the homogenization treatment in the previous step is hot-rolled by an integrated roughing and finishing rolling unit, the hot rolling start temperature is 520°C, and the final rolling temperature is 280°C to obtain a hot rolled thickness of 6mm. Coil;

...

Embodiment 2

[0077] A method for preparing medium and high voltage electronic aluminum foil for high-capacity and high-strength capacitors, comprising the following steps:

[0078] 1) Casting: After smelting, heat preservation, refining and standing still, the raw materials of high-purity molten aluminum casting are used to produce flat ingots by semi-continuous casting. The casting temperature is 680°C, and the formed flat ingots are obtained by rapid cooling;

[0079] 2) Homogenization: Homogenize the shaped slab obtained in the previous step through an annealing furnace, the homogenization temperature is 560°C, the homogenization time is 15h, and air-cool to room temperature after homogenization;

[0080] 3) Hot rolling: the slab after the homogenization treatment in the previous step is hot-rolled by an integrated roughing and finishing rolling unit, the hot rolling start temperature is 500°C, and the final rolling temperature is 350°C to obtain a hot rolled thickness of 9mm. Coil;

...

Embodiment 3

[0092] A method for preparing medium and high voltage electronic aluminum foil for high-capacity and high-strength capacitors, comprising the following steps:

[0093] 1) Casting: After smelting, heat preservation, refining and standing still, the raw materials of high-purity molten aluminum casting are used to produce flat ingots by semi-continuous casting. The casting temperature is 710°C, and the formed flat ingots are obtained by rapid cooling;

[0094] 2) Homogenization: Homogenize the shaped slab obtained in the above step through an annealing furnace, the homogenization temperature is 550°C, the homogenization time is 25h, and air-cool to room temperature after homogenization;

[0095] 3) Hot rolling: the slab after the homogenization treatment in the previous step is hot-rolled by the integrated roughing and finishing rolling unit, the starting temperature of the hot rolling is 550°C, and the finishing temperature is 250°C to obtain a hot-rolled hot-rolled sheet with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com