Ceramic printer and process method thereof

A technology of printers and ceramics, which is applied in the field of ceramic printers and its technology, can solve the problems of automatic filling of ceramic slurry, insufficient surface quality of molded parts, uneven filling, etc., to achieve easy promotion and use, uniform and continuous ceramic slurry, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

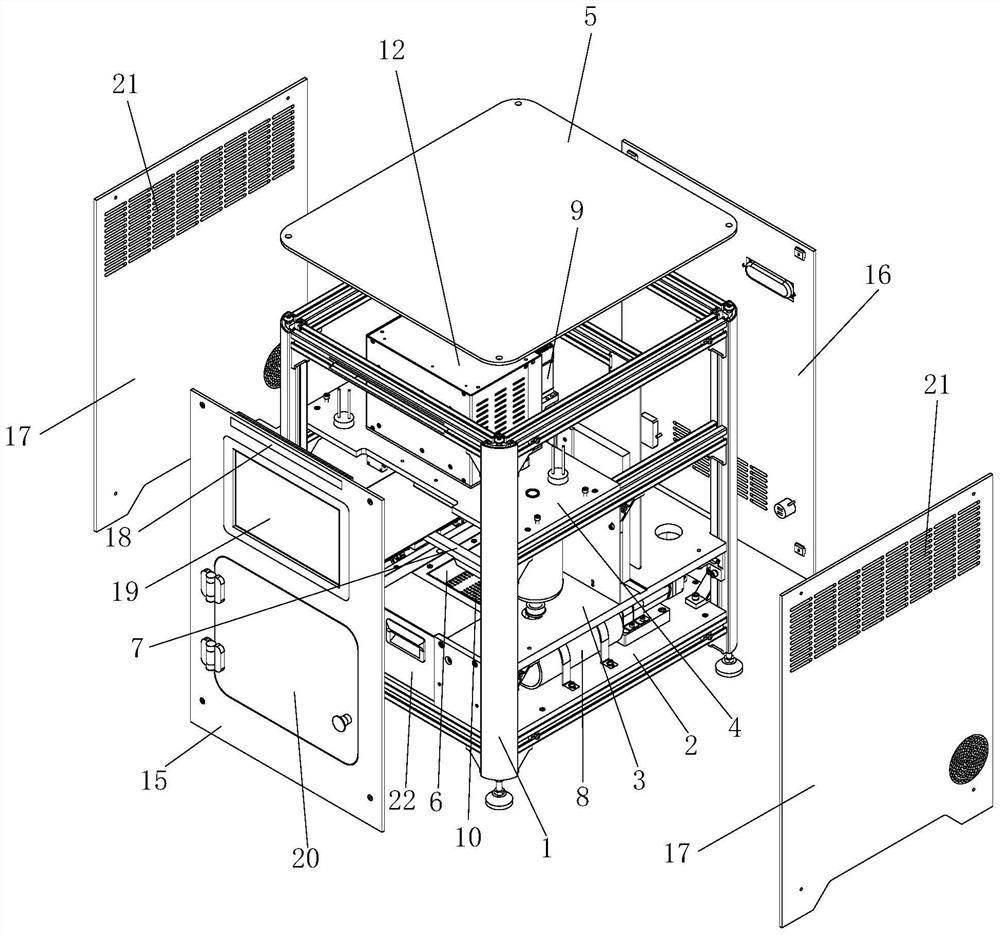

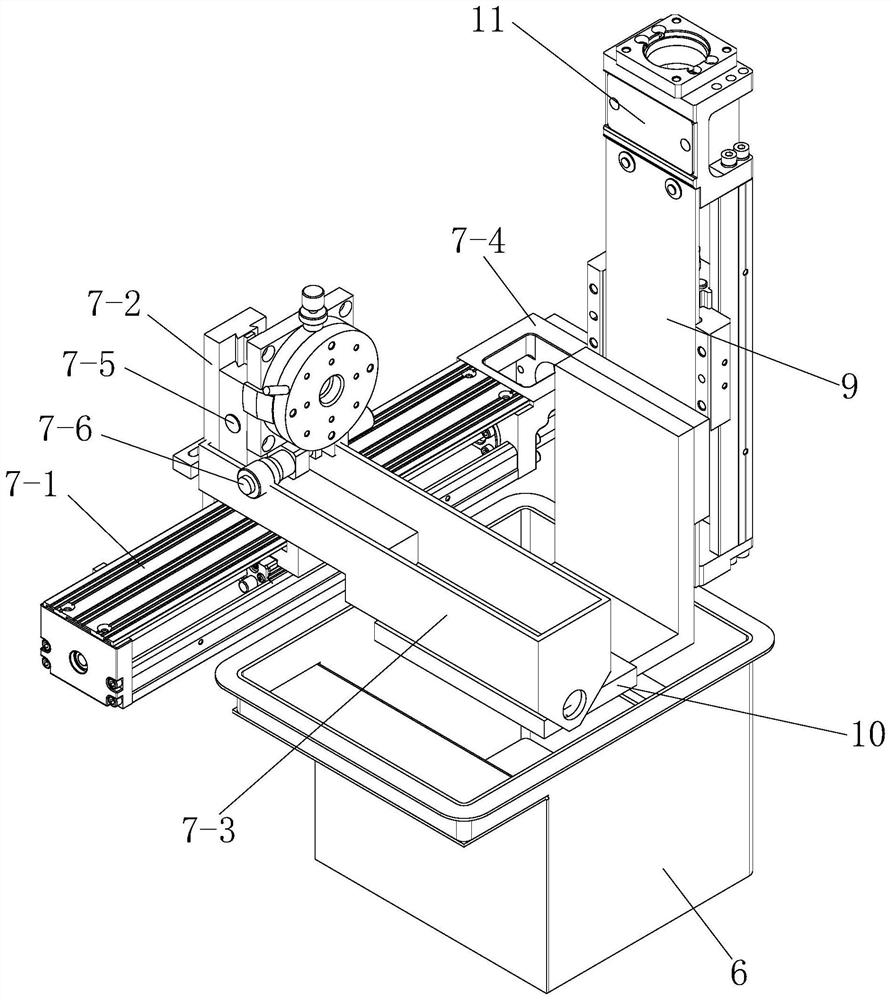

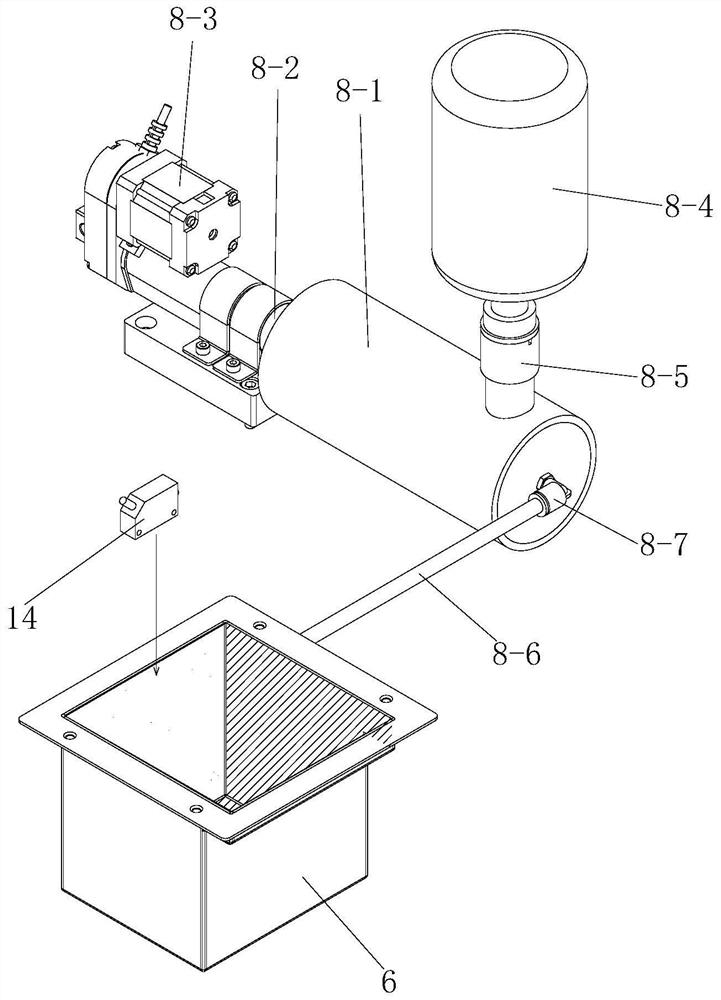

[0047] like figure 1 As shown, the ceramic printer of the present invention includes a frame 1, and the frame 1 is provided with a bottom plate 2, a first mounting substrate 3, a second mounting substrate 4 and a top plate 5 in order from bottom to top. The first mounting substrate 3 is installed with a slurry tank 6 and a scraper device 7 for scraping the paving material, the bottom plate 2 is installed with a replenishing device 8 capable of continuously replenishing the ceramic slurry for the slurry tank 6, inside the frame 1 A lift plate 9 is vertically arranged, the lower part of the lift plate 9 is provided with a printing platform 10 that can extend into the slurry tank 6, and a lift motor 11 is arranged on the top of the lift plate 9. A laser light source 12 mounted on the second mounting substrate 4 is provided above.

[0048] During specific implementation, the solidification and molding of the ceramic part to be printed is realized on the printing platform 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com