Nonblocking web plate of high speed needle machine

A technology for supporting screen and acupuncture machine, which is applied in the direction of acupuncture machine, textile and papermaking, non-woven fabrics, etc. The effect of needle deformation, simple structure and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

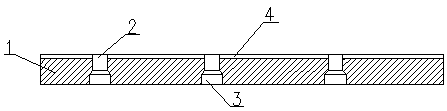

[0014] A non-clogging support plate for a high-speed acupuncture machine, comprising a support plate body 1, a plurality of circular pinholes 2 are provided on the horizontal surface of the support plate body 1, and counterbores 3 are provided at the lower ends of the circular pinholes 2, The diameter of the counterbore 3 is larger than the diameter of the circular pinhole 2 .

[0015] A layer of hard chrome layer 4 is provided on the upper end surface of the supporting plate body 1 of the present invention.

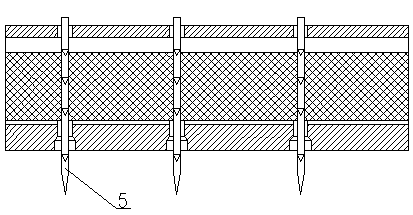

[0016] When the needle 5 moves downwards, the fiber breaking chip is attached to the inner wall of the round needle hole 2 of the support plate at the beginning, and as the needle 5 continues to go down, the breaking chip is also moving downward, and when the breaking chip meets the counterbore 4, Since the diameter of the counterbore 4 is larger than that of the round needle hole 3, the broken chips will fall easily, so that the support plate is not blocked, the resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com