Intelligent polishing device and method for sapphire of special-shaped structure

A polishing device, sapphire technology, applied in the direction of grinding/polishing equipment, surface polishing machine tools, manufacturing tools, etc., can solve the problems of poor polishing accuracy, low polishing efficiency, and inability to realize automatic polishing, etc., to achieve poor polishing accuracy, The effect of uniform surface quality and high positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

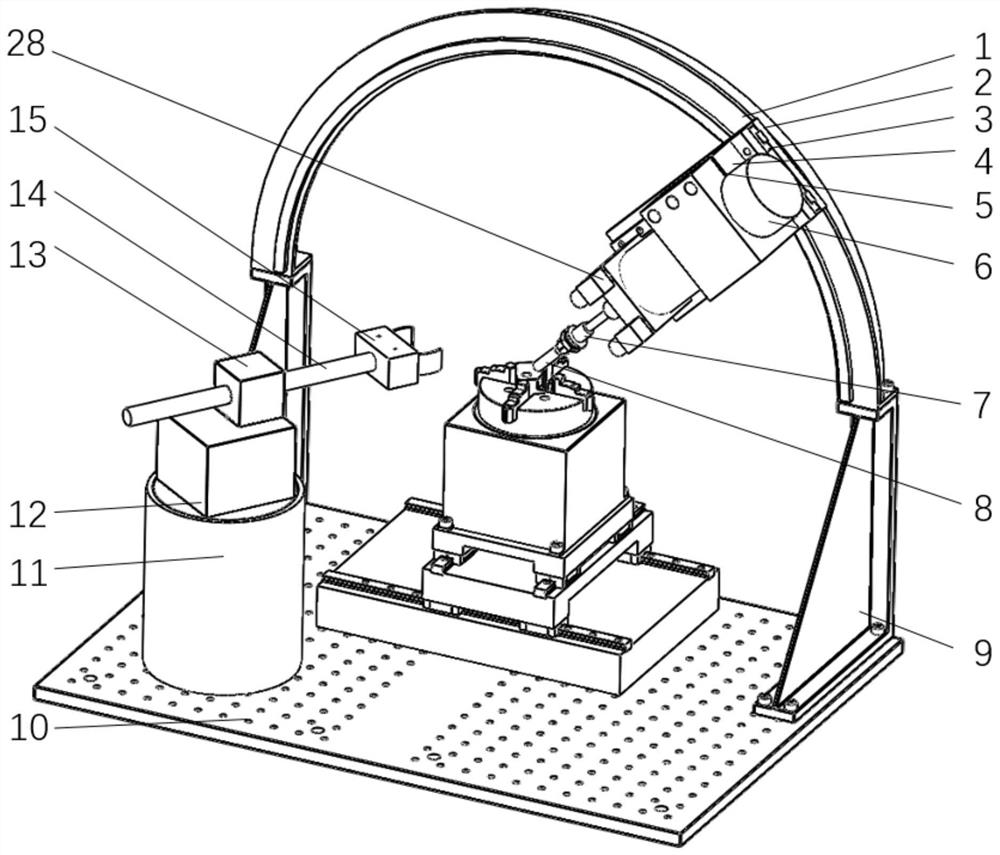

[0039] For the special-shaped sapphire intelligent polishing device and method based on the circular track polishing system, when polishing the upper surface plane and chamfer structure of the special-shaped sapphire, the processing steps are as follows:

[0040] Include the following steps:

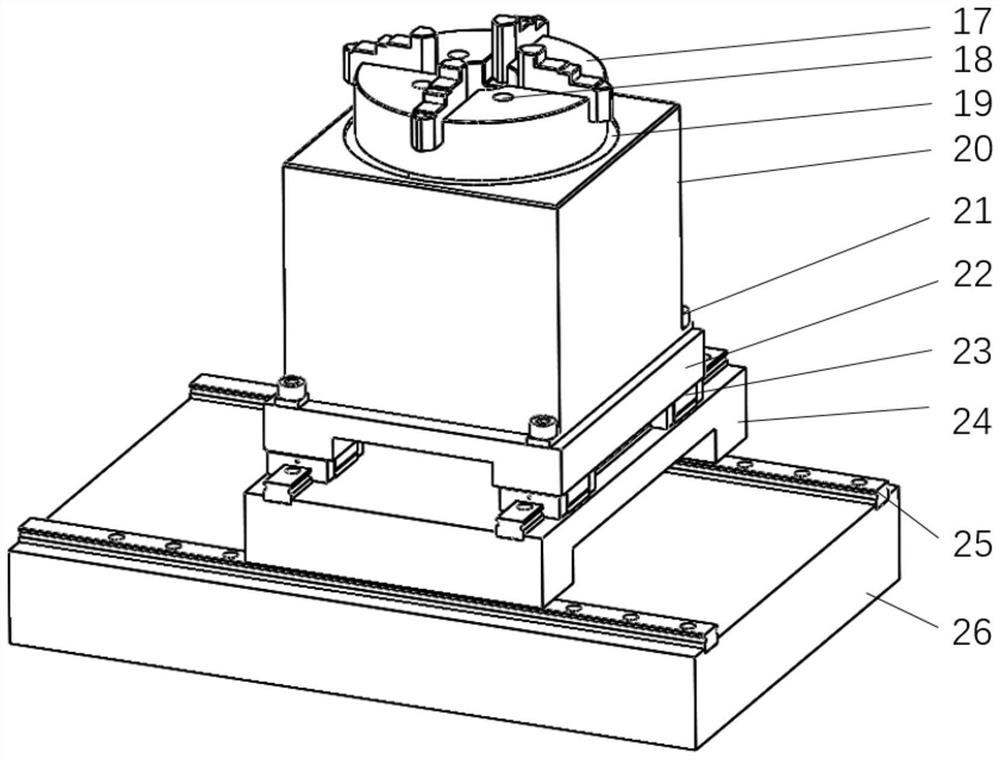

[0041] 1) Start the device, run the corresponding program, the manipulator 15 clamps the workpiece 16, and installs it on the vise 27. Described vise 27 is installed on the working surface 19 by bolt 18;

[0042] 2) The binocular vision module 28 cooperates with the circular track 1 to identify the workpiece from multiple angles, identify different structures on the workpiece, and upload the identification information to the control terminal, and plan the best polishing sequence and polishing trajectory according to the different structures of the workpiece ;

[0043] 3) coating the grinding paste on the surface of workpiece 16;

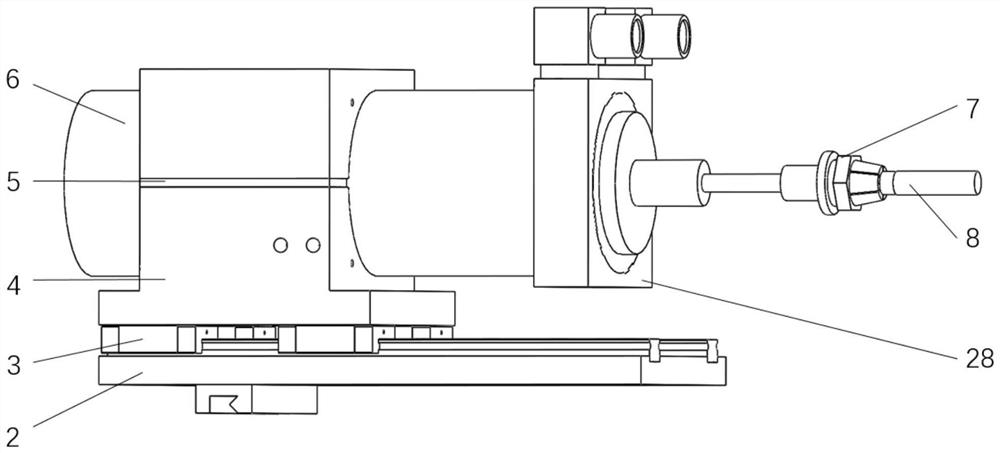

[0044] 4) The main shaft 6 starts to rotate, and the v...

Embodiment 2

[0048] For the special-shaped sapphire intelligent polishing device and method based on the circular track polishing system, when polishing the central hole and step structure of the special-shaped sapphire, the processing steps are as follows:

[0049] Include the following steps:

[0050] 1) Start the device, run the corresponding program, the manipulator 15 clamps the workpiece 16, and installs it on the four-jaw chuck 17.

[0051] Described four-jaw chuck 17 is installed on the working surface 19 by bolt 18;

[0052] 2) The binocular vision module 28 cooperates with the circular track 1 to identify the workpiece from multiple angles, identify different structures on the workpiece, and upload the identification information to the control terminal, and plan the best polishing sequence and polishing trajectory according to the different structures of the workpiece ;

[0053] 3) coating the grinding paste on the surface of workpiece 16;

[0054] 4) The main shaft 6 starts t...

Embodiment 3

[0058] For the special-shaped sapphire intelligent polishing device and method based on the circular track polishing system, when polishing the special-shaped sapphire arc structure, the processing steps are as follows:

[0059] Include the following steps:

[0060] 1) Start the device, run the corresponding program, the manipulator 15 clamps the workpiece 16, and installs the workpiece 16 on the vise 27 with its upper surface facing down. Described vise 27 is installed on the working surface 19 by bolt 18;

[0061] 2) The binocular vision module 28 cooperates with the circular track 1 to identify the workpiece from multiple angles, identify different structures on the workpiece, and upload the identification information to the control terminal, and plan the best polishing sequence and polishing trajectory according to the different structures of the workpiece ;

[0062] 3) coating the grinding paste on the surface of workpiece 16;

[0063] 4) The main shaft 6 starts to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com