Special polishing fluid for plastic soft metallic materials and method for preparing polishing fluid

A soft metal, polishing liquid technology, applied in polishing compositions containing abrasives, semiconductor/solid-state device manufacturing, electrical components, etc. Polished texture, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

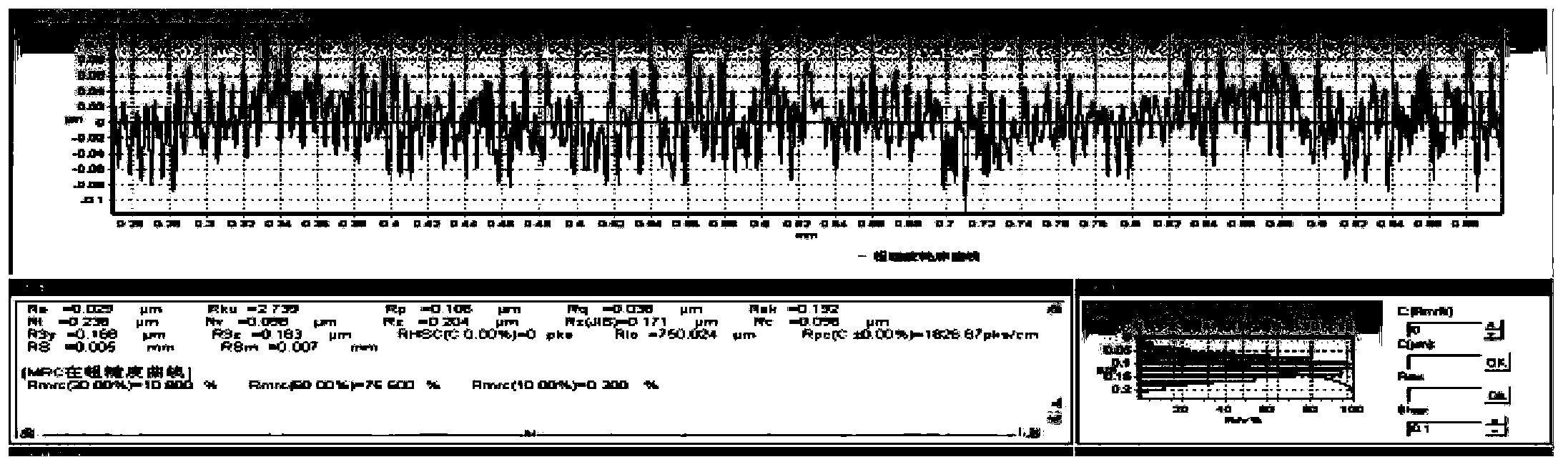

[0022] ⑴Implementation conditions

[0023] Experimental equipment: BDE-1B frequency conversion and speed regulation optical two-axis grinding and polishing machine, Beijing Times Surface Roughness Measuring Instrument TR300, image acquisition microscope + Panasonic WV-CP460;

[0024] Polishing conditions: ambient temperature 10°C, special polishing liquid, niobium and niobium alloy workpieces, special silk polishing pads;

[0025] The polishing parameters are: the speed of the polishing disc is 60-150r / min, and the polishing pressure is 0.2-0.6N / cm 2 , the grinding and polishing eccentricity is 30-40mm, the frequency is 13-16Hz, and the polishing time is 20-30min.

[0026] ⑵ Preparation of special polishing liquid

[0027] According to the volume ratio: the polishing liquid is prepared by abrasives, solvents and additives in a certain volume ratio: 2% brightener, 3% abrasives, 15% additives, and 80% kerosene. The additives are prepared by volume percentage. 30% lard, 30% st...

Embodiment 2

[0034] ⑴Implementation conditions

[0035] Experimental equipment: BDE-1B frequency conversion and speed regulation optical two-axis grinding and polishing machine, Beijing Times Surface Roughness Measuring Instrument TR300, image acquisition microscope + Panasonic WV-CP460;

[0036] Polishing conditions: ambient temperature 20°C, special polishing liquid, niobium and niobium alloy workpieces, special silk polishing pads;

[0037] The polishing parameters are: the speed of the polishing disc is 60-150r / min, and the polishing pressure is 0.2-0.6N / cm 2 , the grinding and polishing eccentricity is 30-40mm, the frequency is 13-16Hz, and the polishing time is 20-30min.

[0038] ⑵ Preparation of special polishing liquid

[0039] The polishing liquid is prepared by abrasives, solvents and additives in a certain volume ratio: 2% brightener, 3% abrasives, 15% additives, and 80% kerosene. The additives are made of 25% lard, 20% stearic acid granules (C 17 h 35 COOH), 30% vegetable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com