Cutting liquid as well as preparation method and application thereof

A cutting fluid and kerosene technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as difficulty in meeting processing requirements, uneven surface quality, diamond tool wear, etc., and achieve good processing conditions, low cost, and precision. high effect

Active Publication Date: 2013-10-09

CANGZHOU HUARUN CHEM

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the problems of uneven processing surface quality, serious wear of diamond tools in the later stage of processing, and difficulty in meeting actual processing requirements after turning large-diameter Fresnel lens molds with ordinary cutting fluids, the present invention provides a method that can reduce the amount of diamond Tool wear, special cutting fluid to improve the processing quality and precision of large-diameter Fresnel lens molds

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

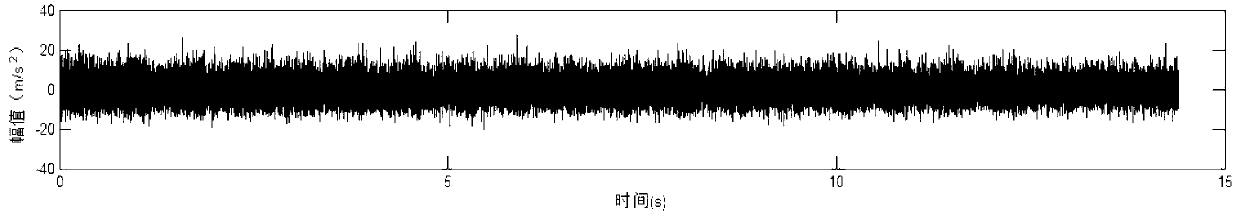

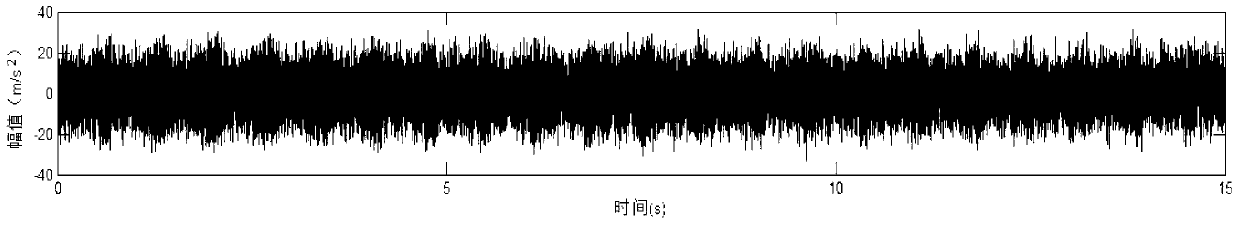

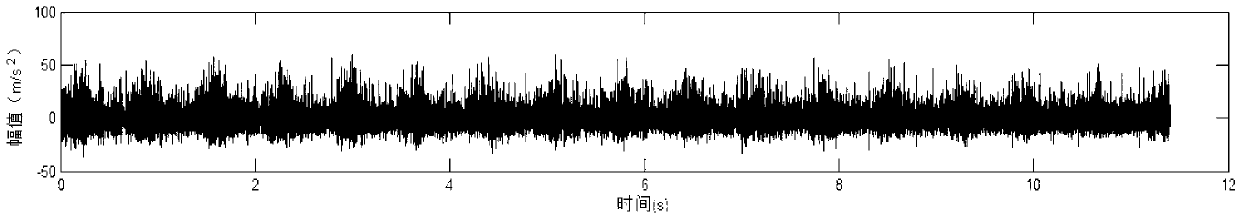

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the effect of the special cutting fluid is verified through the large-diameter Fresnel lens mold turning experiment below, and the comparative experiment with the traditional cutting fluid is carried out to highlight the superiority of the present invention.

[0030] 1. Implementation conditions

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cutting liquid as well as a preparation method and application thereof, belonging to the technical field of cutting liquids. The cutting liquid is prepared from the following raw material components in percentage by mass: 58-62% of coal oil, 9-11% of lard oil, 5-6% of span-80, 3-4% of petroleum sulfonate, 3-4% of fatty alcohol polyoxyethylene ether, 4-6% of nitrogen-contained borate ester, 0.8-1.2% of triethanolamine, 0.8-1.2% of phenol, 0.2-0.4% of benzotriazole, 0.1-0.3% of soybean oil and 9-11% of distilled water. When a large-diameter Fresnel lens die is processed by using the cutting liquid, a workpiece is uniform in surface quality and high in precision, the amplitude of a vibration signal is small during processing, and the sound emitting energy is low. The special cutting liquid plays roles of lubricating, cooling, resisting to abrasion, preventing rust, sterilizing, cleaning and workpiece surface film forming when used for processing the large-diameter Fresnel lens die, and is low in cost and free of pollution.

Description

technical field [0001] The invention belongs to the technical field of cutting fluid, and is mainly used for ultra-precision turning of large-diameter Fresnel lens molds, and is also suitable for turning of other similar materials and working conditions. Background technique [0002] Fresnel lens molds have optical focusing and optical imaging performance not inferior to traditional lenses. Because of their light weight, thin thickness, large diameter, and compact structure, they are widely used in solar water heaters, solar power stations, display imaging, and space solar cells. Photovoltaic systems and other fields have important commercial and military application value. However, the processing of large-diameter Fresnel lens molds is difficult, and tool change operations cannot be performed during the entire workpiece processing process. The material of the Fresnel lens mold is H62 brass, and the tool is a diamond tool. The larger the diameter of the Fresnel lens mold, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M163/00C10M167/00C10M173/00

Inventor 关佳亮朱莉莉曹成国王志伟

Owner CANGZHOU HUARUN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com