In-pipe electrolysis brush head device

A technology of internal electrolysis and tube body, which is applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of equipment mass transfer and heat transfer efficiency and other performance degradation, equipment can not meet the design and use requirements, and there are safety hazards, etc., to achieve convenience Effect of quality control, reduction of current loss and unevenness, simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

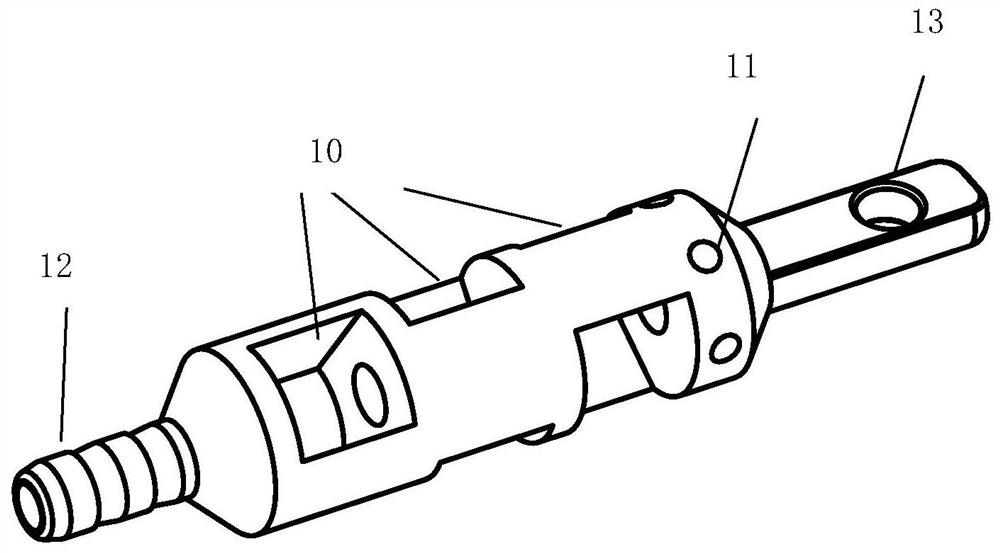

[0020] The in-tube electrolytic brush head device provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

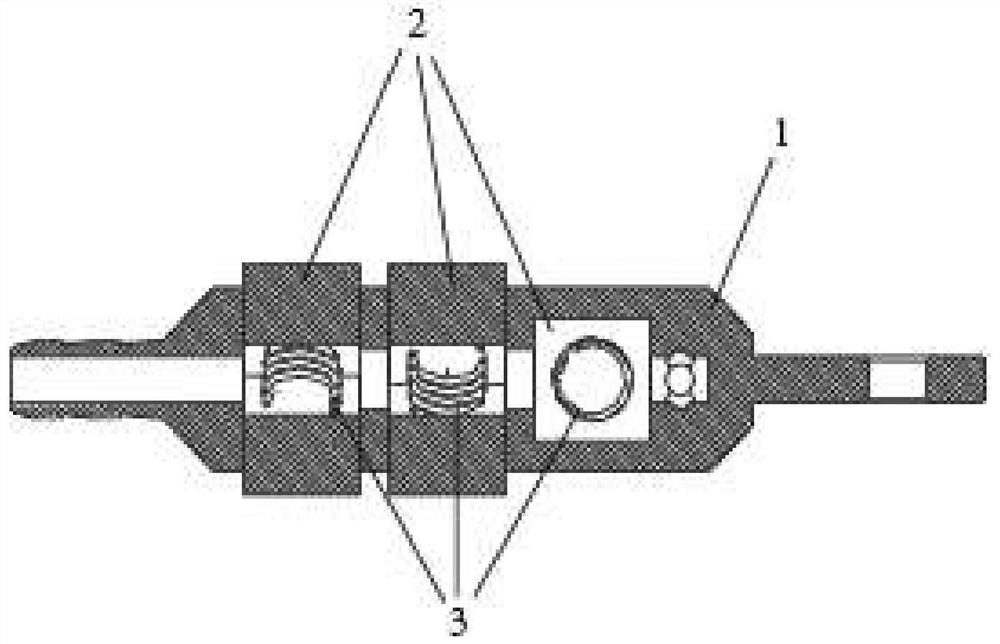

[0021] figure 1 and figure 2 It is shown that an in-tube electrolytic brush head device includes a device body 1, a graphite sliding block 2, and a spring 3. The device body 1 is a hollow tube body. The surface of the device body 1 has a sliding block mounting hole 10, and the spring 3 The graphite sliding block 2 is connected, and the graphite sliding block 2 is embedded in the installation hole 10 of the sliding block of the device main body 1 .

[0022] Three sliding block mounting holes 10 are provided on the surface of the tube body of the device main body 1 , graphite sliding blocks 2 are respectively provided at both ends of each sliding block mounting hole 10 , and a spring 3 is provided between the two graphite sliding blocks 2 .

[0023] The three sliding block mounting holes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com