A four-station mobile trolley-type v-method molding production line

A mobile trolley and four-station technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as consuming large time costs, affecting production continuity, and increasing equipment costs, so as to reduce equipment and time costs, The effect of reducing energy consumption and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

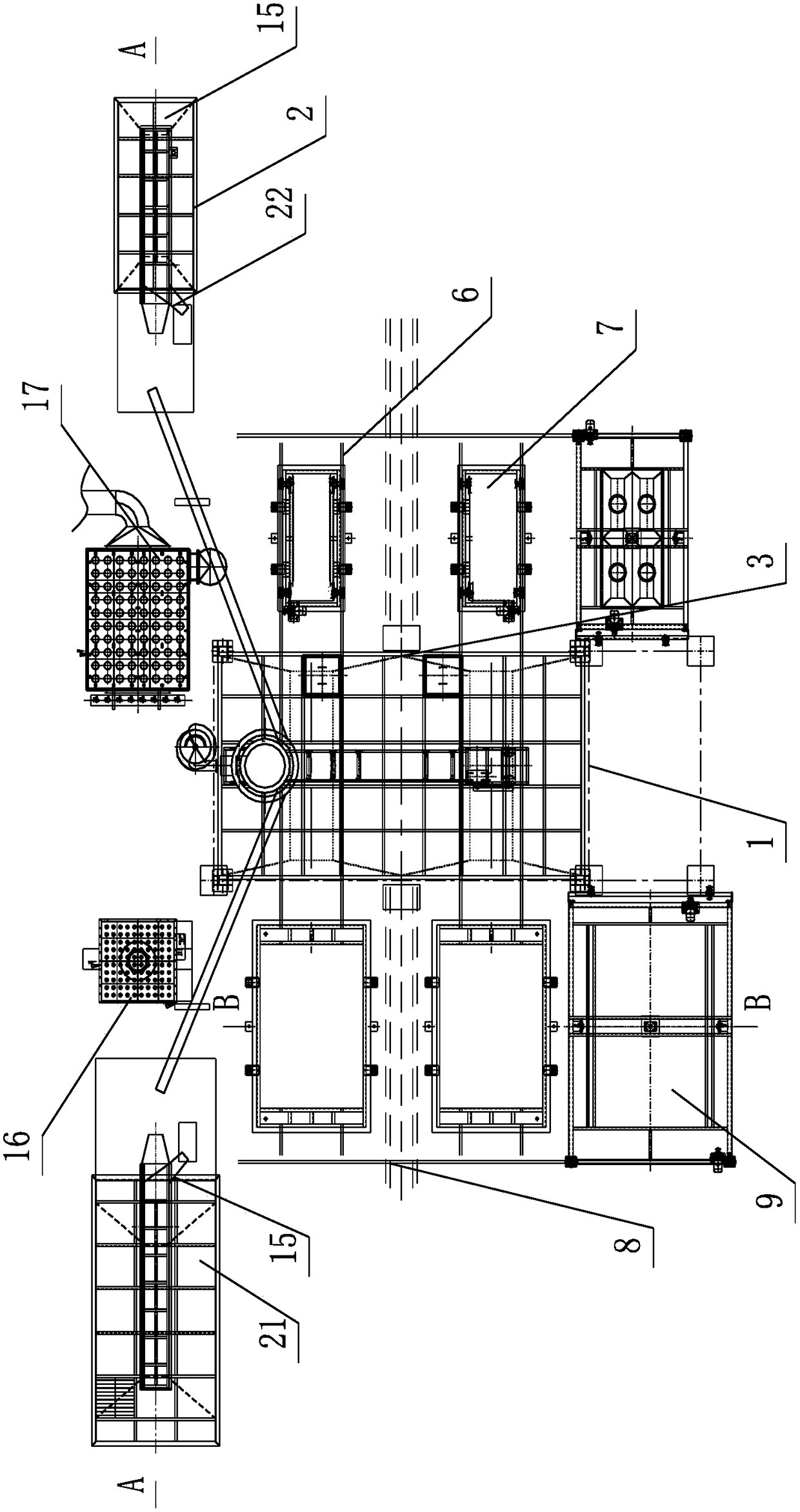

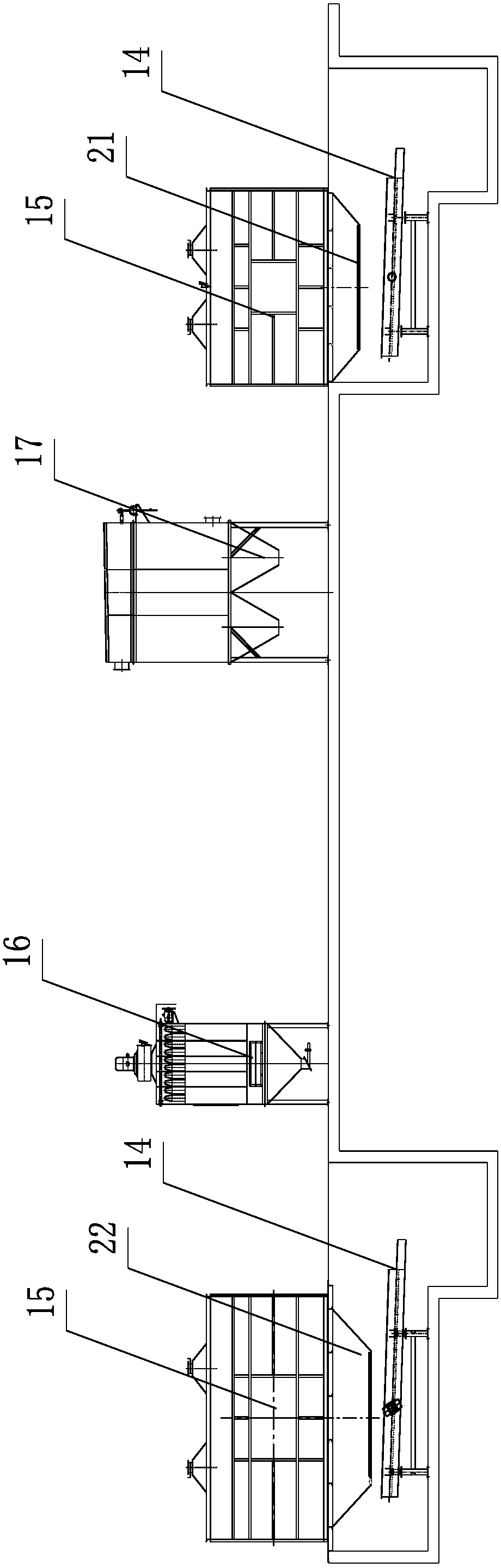

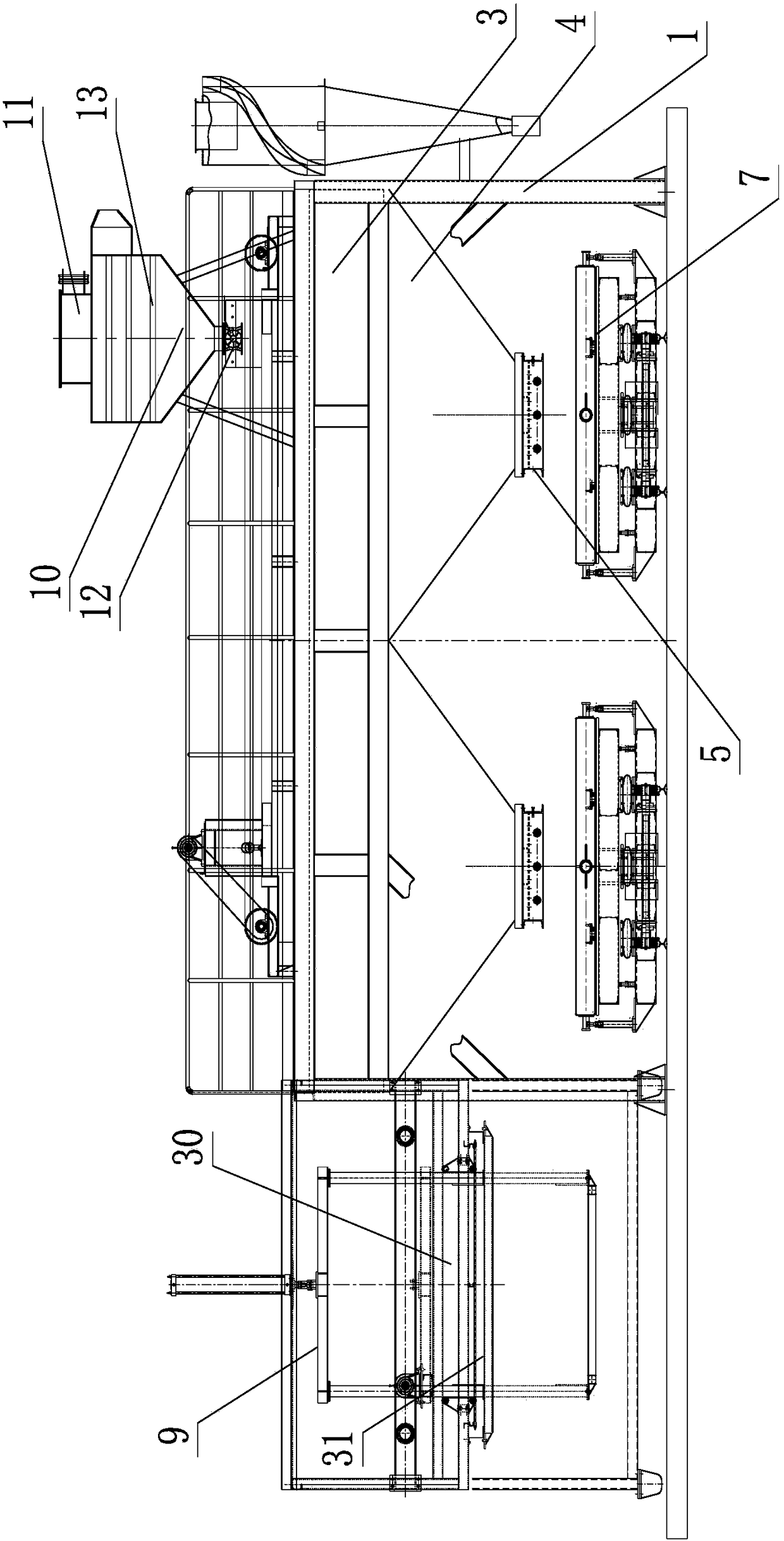

[0022] refer to figure 1 and figure 2 , the present invention includes a frame 1, a shakeout bucket 2 for recycling molding sand, and a sand storehouse 3 arranged on the frame 1 for containing the molding sand, and the shakeout bucket 2 is connected to the The sand storehouse 3 is connected, the sand storehouse 3 is provided with a cyclone sand suction mechanism, the cyclone sand suction mechanism can make the inner cavity of the sand storehouse 3 form a negative pressure so that the molding sand in the shakeout bucket 2 is sucked into the sand storehouse 3, The sand storehouse 3 is provided with two sand outlet buckets 4, and the sand outlet buckets 4 are provided with rain shower sanders 5, and two slide rails 6 are arranged below the sand storeroom 3, and each slide rail 6 are equipped with two molding cars 7, and the two molding cars 7 are respectively located at both sides of the rain sanding device 5 and can slide along the slide rail 6 to enter below the rain sanding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com