A chainless transmission mechanism

A transmission mechanism, chainless technology, applied in the direction of transmission, gear transmission, mechanical equipment, etc., can solve the problems of huge machines, increased production costs, and bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

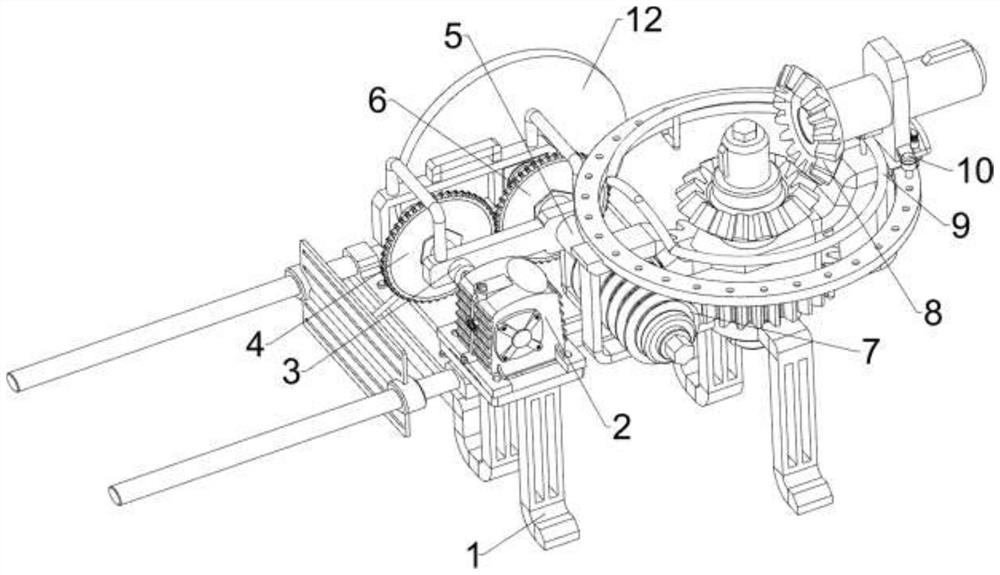

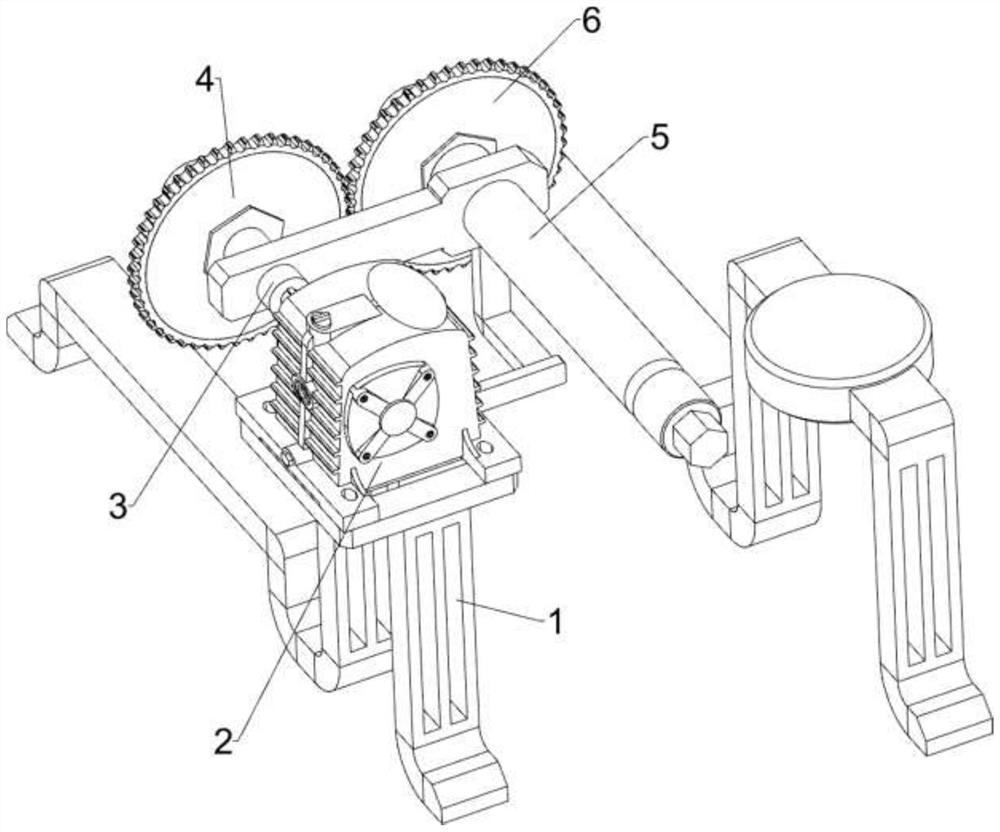

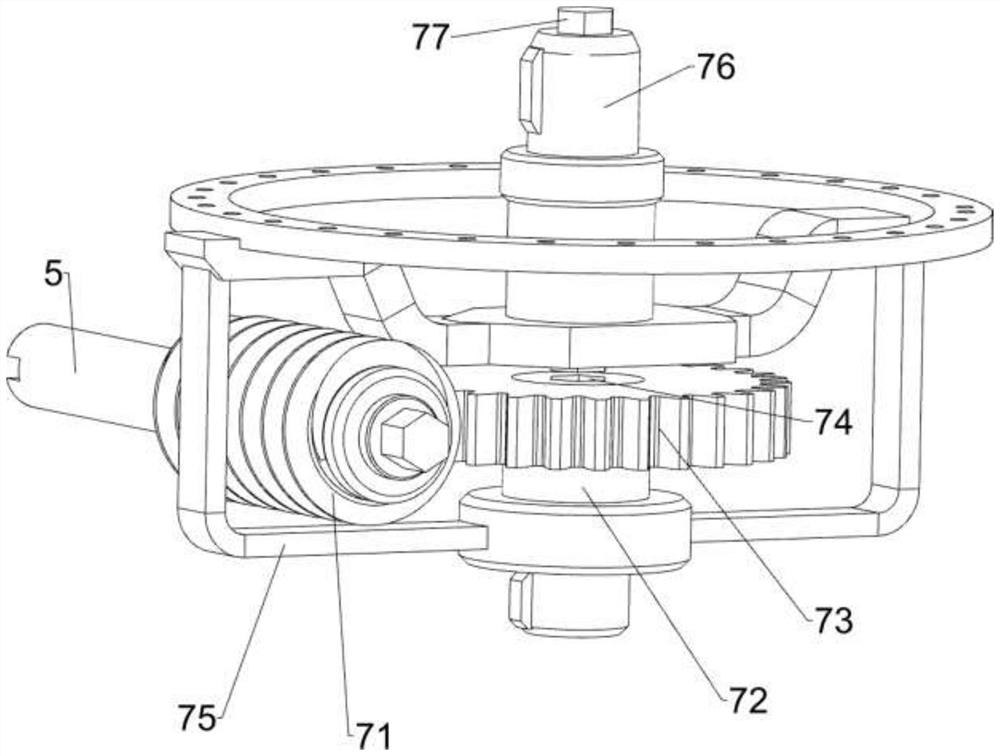

[0026] A chainless transmission mechanism, such as Figure 1-4 As shown, it includes a support 1, a motor 2, a first rotating shaft 3, a first gear 4, a second rotating shaft 5, a second gear 6, a deceleration assembly 7 and a transmission direction changing assembly 8, and there are two support 1, the left The upper side of the side support 1 is provided with a motor 2, the output shaft of the motor 2 is connected with a first rotating shaft 3, the first rotating shaft 3 is connected with the left side support 1 in a rotating manner, and the rear side of the first rotating shaft 3 is connected with The first gear 4, the right side of the left support 1 is rotationally connected with the second rotating shaft 5, the rear side of the second rotating shaft 5 is connected with the second gear 6, the second gear 6 meshes with the first gear 4, and the right side A deceleration assembly 7 is provided between the bracket 1 and the second rotating shaft 5 , and a transmission directi...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 As shown, a separation assembly 9 is also included, the separation assembly 9 includes a special-shaped ring 91 and a push rod 93, the fixed ring 81 is connected with a special-shaped ring 91, the upper side of the left part of the special-shaped ring 91 has a limiting groove 92, and a sliding plate 83 The left side of the top is connected with a push rod 93, and the push rod 93 cooperates with the limit groove 92.

[0034]When there is no need to use the transmission direction changing assembly 8, the arc slider 82 can be controlled to move, so that the sliding plate 83 and the push rod 93 can move, and when the push rod 93 moves to the left side of the special-shaped ring 91, the special-shaped ring 91 will Make the push rod 93 move upwards, so that the sliding plate 83 moves upwards, and then the bevel gears 85 on both sides are no longer engaged. The bit groove 92 fixes the push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com