Incoming film arc rail with good swinging flexibility

An arc-shaped track and film feeding technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of film deviation and affect the effect of film pulling, and achieve the effect of reducing friction coefficient and smooth transition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

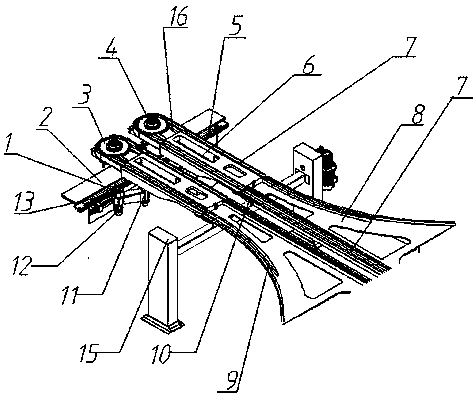

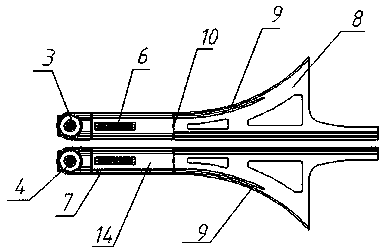

[0018] like figure 1 and figure 2 The shown a flexible film-entry arc track includes two symmetrical semicircular track plates 16, two straight track plates 14 and two symmetrical arc track plates 8; the arc Track plate 8 is fixed on frame 15, and the inner side of arc-shaped track plate 8 is provided with straight guide groove 7, and the outside is provided with arc-shaped guide groove 9. The arc of the arc-shaped guide groove 9 gradually increases from the arc near the straight track plate 14 to the other side. Straight guide groove 7 and arc guide groove 9 the inside are all provided with transmission chain.

[0019] The inside and the outside of described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com