Diamond grinding and polishing integrated machining equipment and machining method thereof

A kind of processing equipment and diamond technology, applied in metal processing equipment, grinding/polishing equipment, grinding workpiece support, etc., can solve the problem of poor flatness and parallelism of the diamond surface, increase the cost and time-consuming of diamond single crystal surface processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

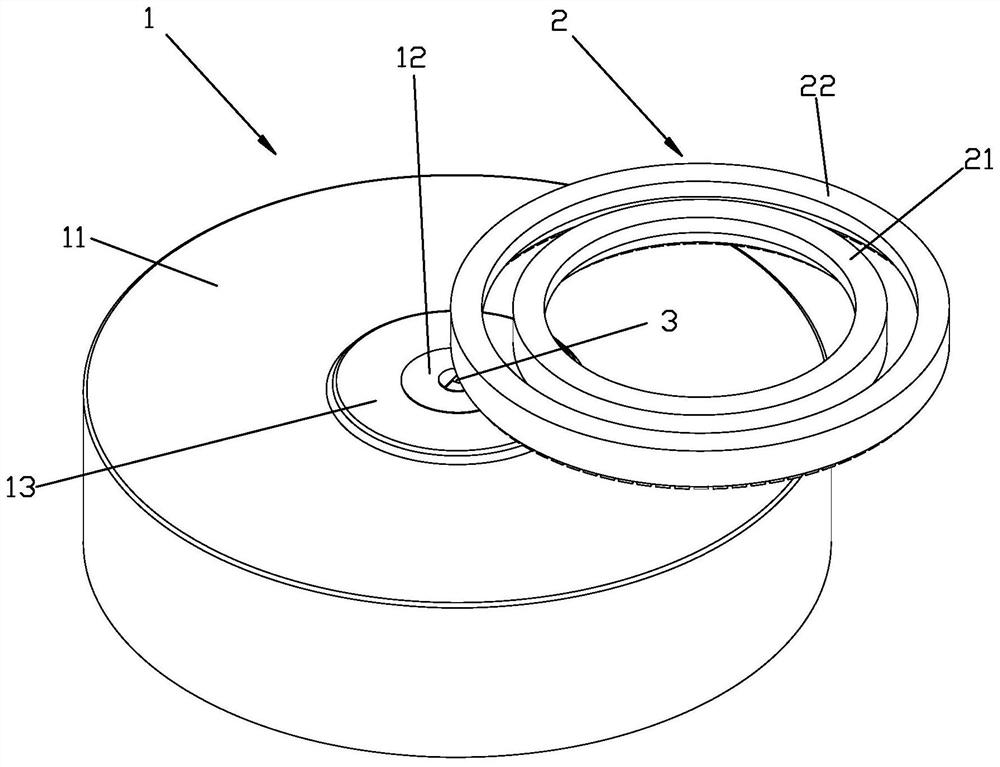

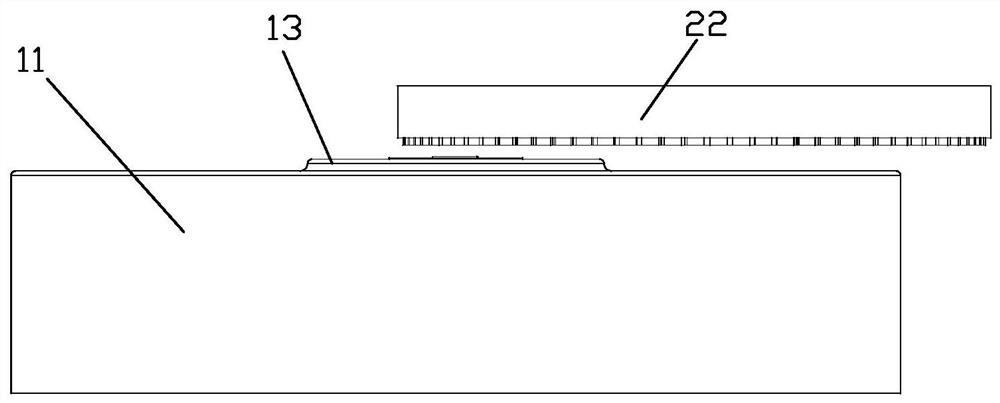

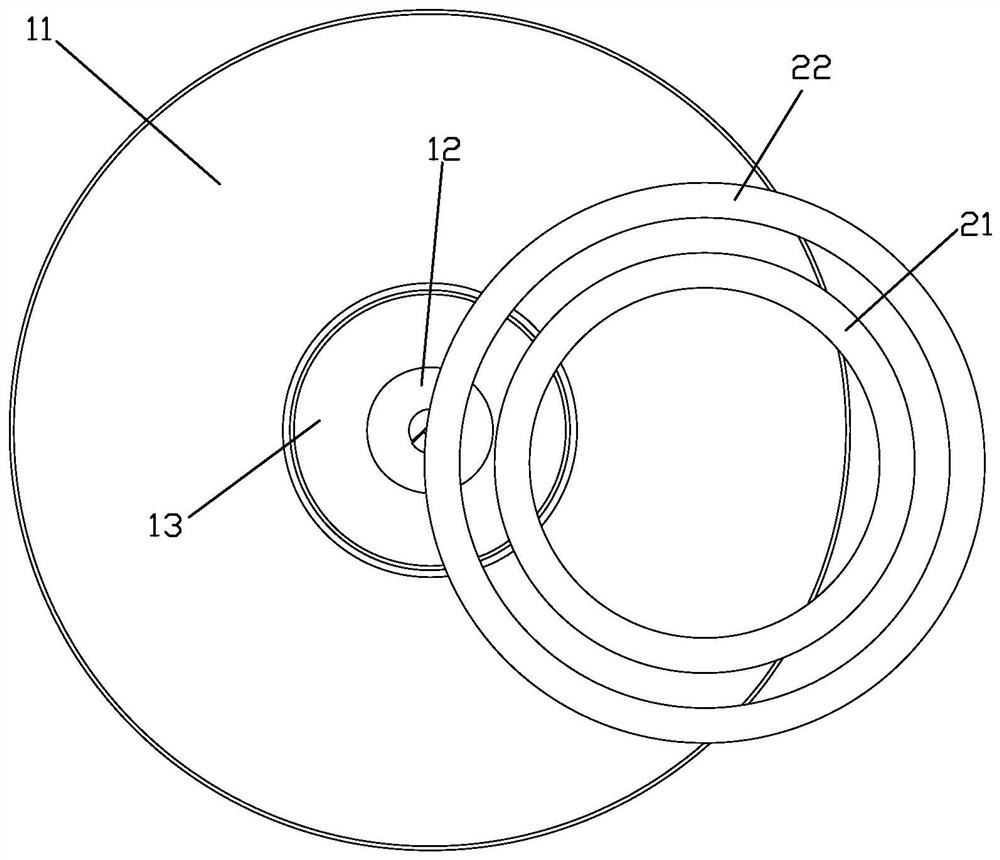

[0034] Please check Figure 1 to Figure 3 , diamond grinding and polishing integrated processing equipment, including a frame, a base device 1 and a grinding and polishing device 2; The base 11 on the sliding seat is equipped with a clamp 12 capable of clamping the single crystal diamond 3; the grinding and polishing device 2 includes a main shaft arranged along the Z axis, and the inner ring grinding wheel is set on the main shaft 21 and outer ring grinding wheel 22, the outer diameter of the inner ring grinding wheel 21 is smaller than the inner diameter of the outer ring grinding wheel 22, the outer ring grinding wheel 22 surrounds the inner ring grinding wheel 21, and the outer ring grinding wheel 22 is fixed on the main shaft , the inner ring grinding wheel 21 can slide up and down relative to the main shaft along the Z axis and the inner ring grinding wheel 21 and the main shaft are synchronously rotated and connected, and the inner ring grinding wheel 21 and the outer r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com