Spherical inorganic particles with surface bumps and method for preparing same

A technology of inorganic particles and small particles, which is applied in the direction of chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve problems such as particle agglomeration, shape or property changes, and achieve improved grinding speed and grinding Excellent efficiency and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

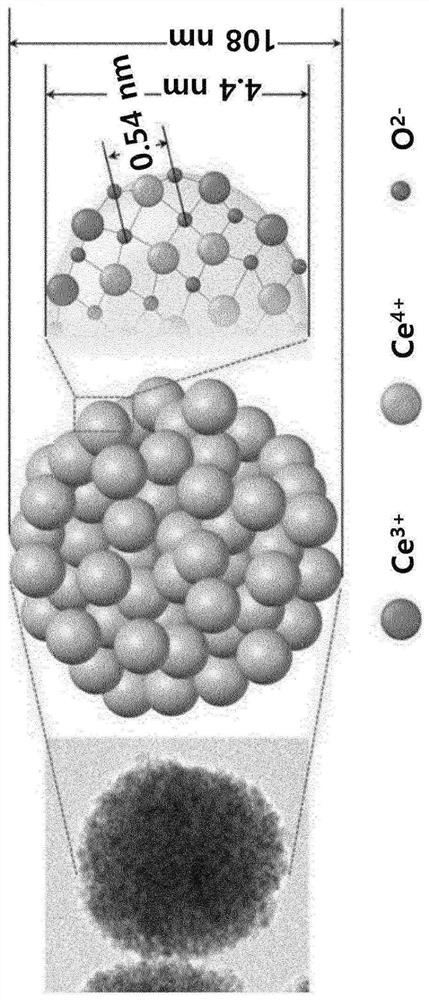

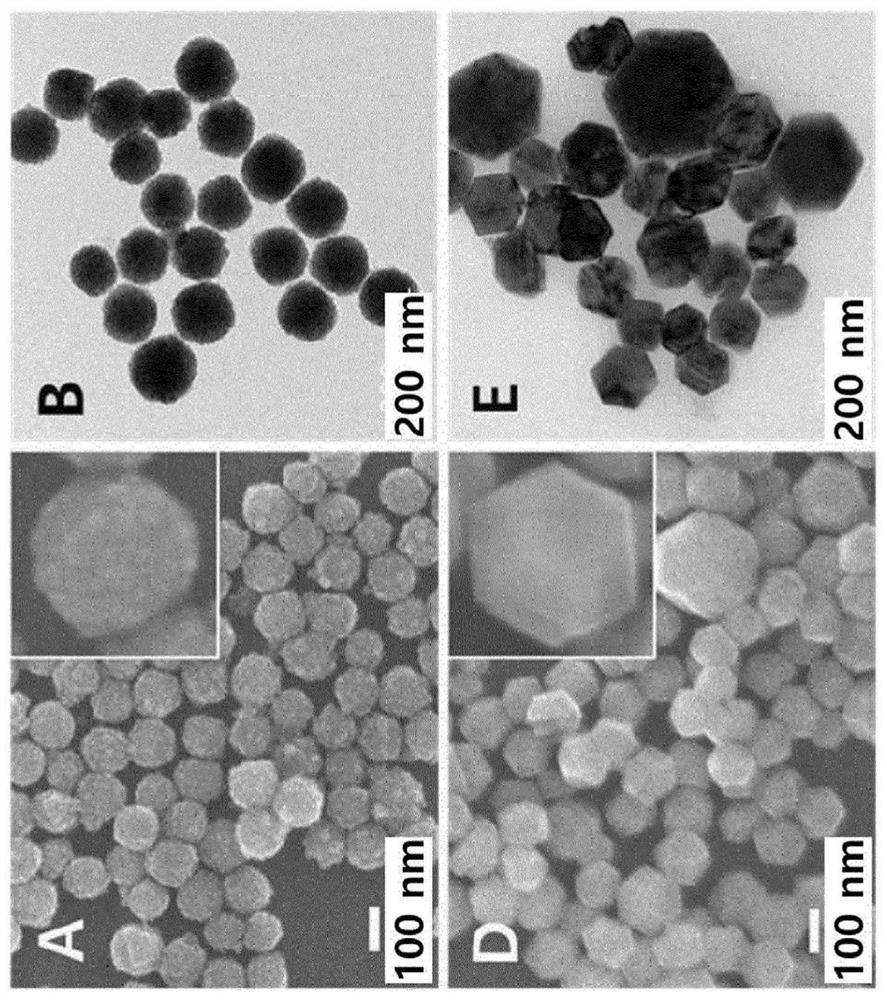

[0118] In 160 ml of solvent mixed with ethylene glycol (99%) and water at a volume ratio of 100:100, add 2 g of poly(N-isopropylacrylamide) (Poly(N-isopropylacrylamide)) (Aldrich) company, Mw: 30,000) as a self-assembled surfactant and stirred using a magnetic stirrer. After confirming complete dissolution, add 2 g of Aldrich Corporation (Aldrich Corporation) cerium nitrate hexahydrate (Cerium nitrate hexahydrate) (Ce(NO 3 ) 3 ·6H 2 O) as a cerium precursor and dissolved to prepare a cerium precursor solution.

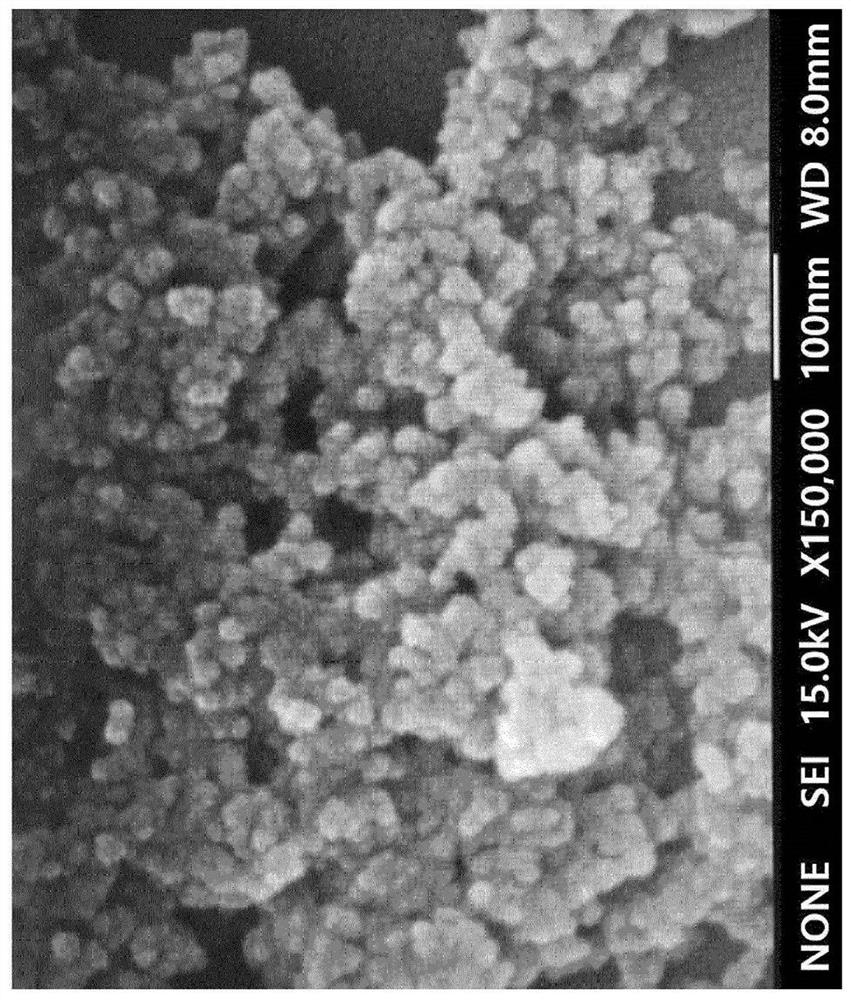

[0119] The cerium precursor solution was added to a liquid-phase reactor maintained at a temperature, and a synthesis reaction was performed at a temperature ranging from 90° C. to 140° C. for about 165 minutes. After the reaction was completed, the cerium oxide particle solution obtained was centrifuged at 4000rpm for 1 hour and 30 minutes using a centrifugal separator, and the precipitate was separated, and then repeated 3 times with water (H 2 O) A process of wa...

Embodiment 2

[0121] In 180ml of water, 2.4g of poly(N-isopropylacrylamide) (Poly(N-isopropylacrylamide)) (Austria) with molecular weight different from that of the user in Example 1 was added to an aqueous solution of 2.4g of cerium chloride (Cerium chloride). (Aldrich Company, Mw: 85,000), and stirred at 70° C. to 90° C. for 6 hours to carry out the reaction. Thereafter, separation and washing were carried out in the same manner as in Example 1 above to obtain ceria particles having spherical bumps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com