Laser rust removal steel component surface roughness control method

A surface roughness and control method technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as unfavorable coating operations, burns, uneven surface quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with embodiment.

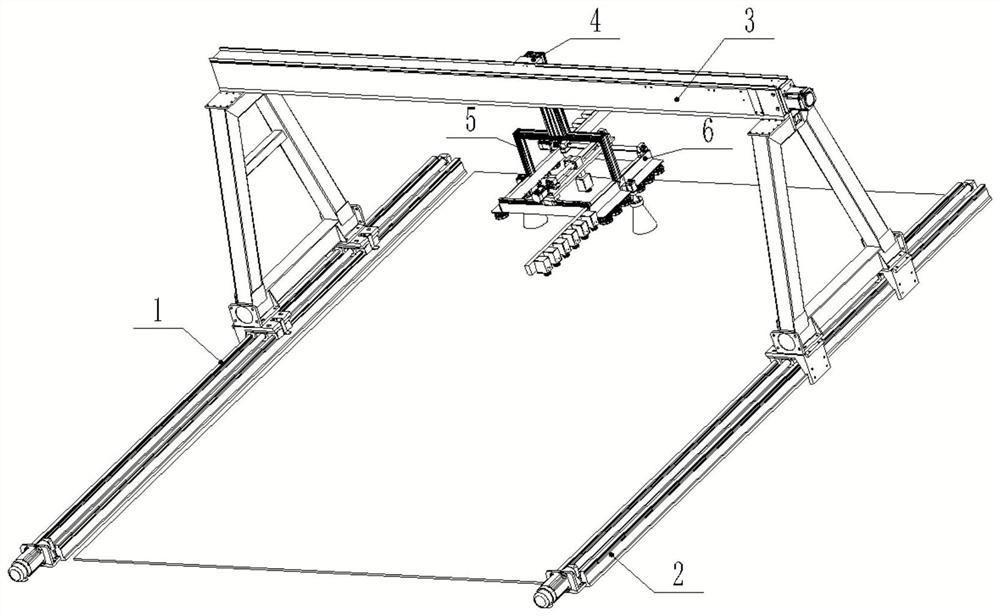

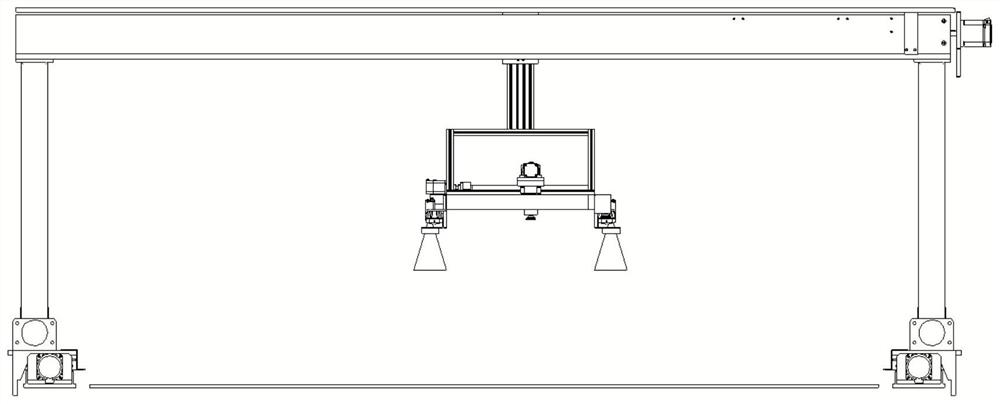

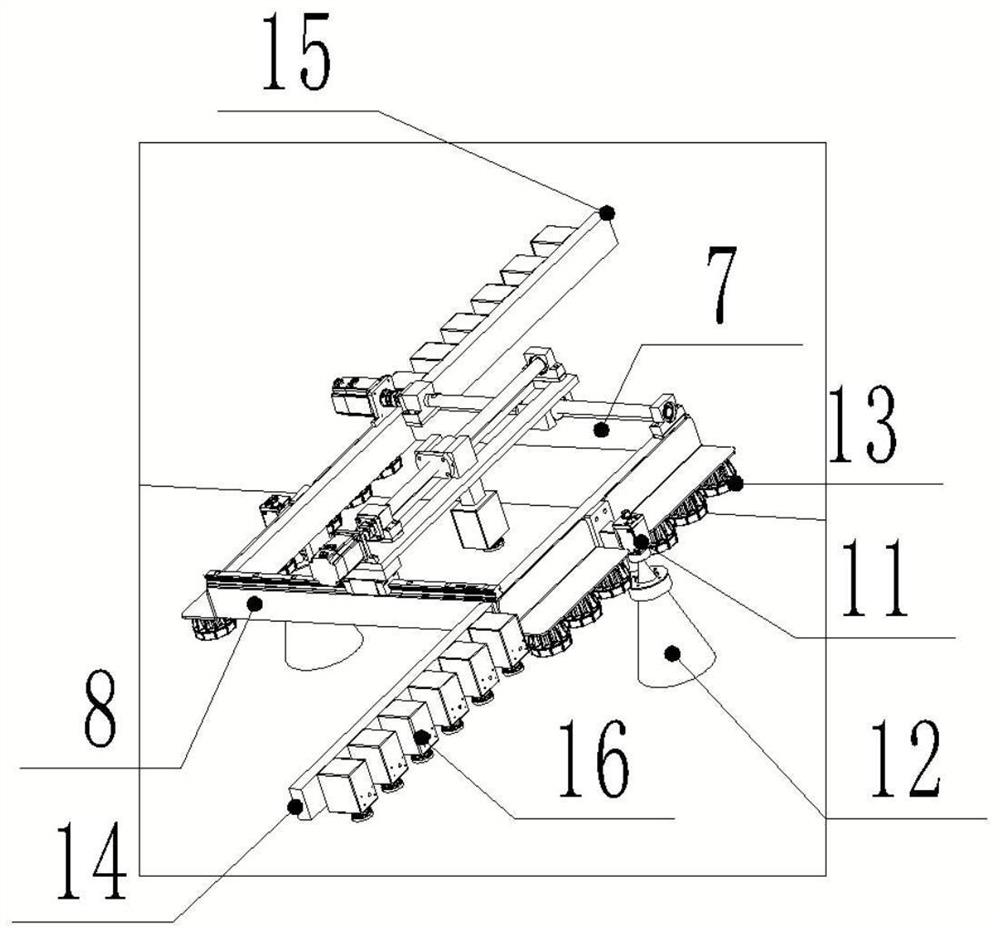

[0062] Such as Figure 1-8 As shown, according to a method for controlling the surface roughness of laser derusting steel components of the present application, the derusting device used includes a propulsion mechanism composed of a left rail 1 and a right rail 2, and a gantry frame connected to the propulsion mechanism by transmission. 3. The boom 4 that can be driven to move along the crossbeam of the gantry frame 3, a suspension is fixedly connected to the bottom of the boom 4, and a working head is installed on the suspension; the working head includes a square frame 6, and the square frame 6 is composed of Four frame bars with the same length are composed of rear frame bar 8, front frame bar 7, left frame bar 9 and right frame bar 10, cameras are respectively installed at the midpoints of left frame bar 9 and right frame bar 10 , the left frame bar 9 and the right frame bar 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com