Pan head self-drilling screw and machining method thereof

A technology for drilling tail screws and processing methods, which is applied to screws, manufacturing tools, threaded fasteners, etc., can solve problems such as affecting processing, and achieve the effects of improving cleanliness, uniform surface quality of workpieces, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

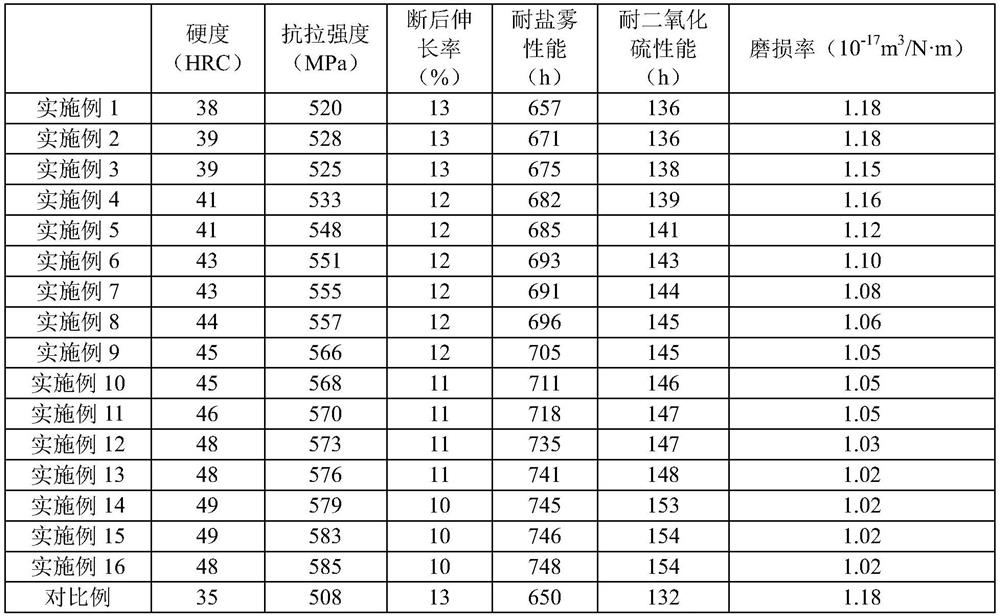

Examples

Embodiment 1

[0050] The processing method of the pan head drill tail screw of the present embodiment comprises the following steps:

[0051] 1) Pickling the steel wire for the first time, washing with water, drying, and then coating a layer of lubricant on the surface of the steel wire, the lubricant is aluminum stearate; the first pickling is soaked in hydrochloric acid with a mass fraction of 10% 8min;

[0052] 2) cold drawing the steel wire after step 1), pulling the wire to a suitable wire diameter, and then performing annealing treatment;

[0053] 3) The steel wire rod after the annealing treatment is carried out pickling for the second time, the pickling solution used in the second pickling is mixed acid A, mixed acid A is prepared by mixing hydrochloric acid and sulfuric acid with a volume ratio of 3:1, and the hydrochloric acid Mass fraction is 15%, and the mass fraction of sulfuric acid is 40%;

[0054] The second pickling is soaked in mixed acid A for 2 minutes, after the secon...

Embodiment 2

[0063] The difference between the processing method of the pan head drilling screw of the present embodiment and the embodiment 1 is that in step 2), the mixed acid B is mixed evenly with oxalic acid, lactic acid, glycolic acid and water with a mass ratio of 20:12:6:100 be made of.

Embodiment 3

[0065] The difference between the processing method of the pan head drilling screw of the present embodiment and the embodiment 2 is that in step 2), the mixed acid B is composed of oxalic acid, lactic acid, glycolic acid, polymerized acid with a mass ratio of 22:15:7:2.5:100 Prepared by mixing aluminum sulfate and water evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com