Steel member laser rust removal device

A technology for laser derusting and steel components, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as the inability to guarantee stable coating quality, and achieve the effect of avoiding redundant processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with embodiment.

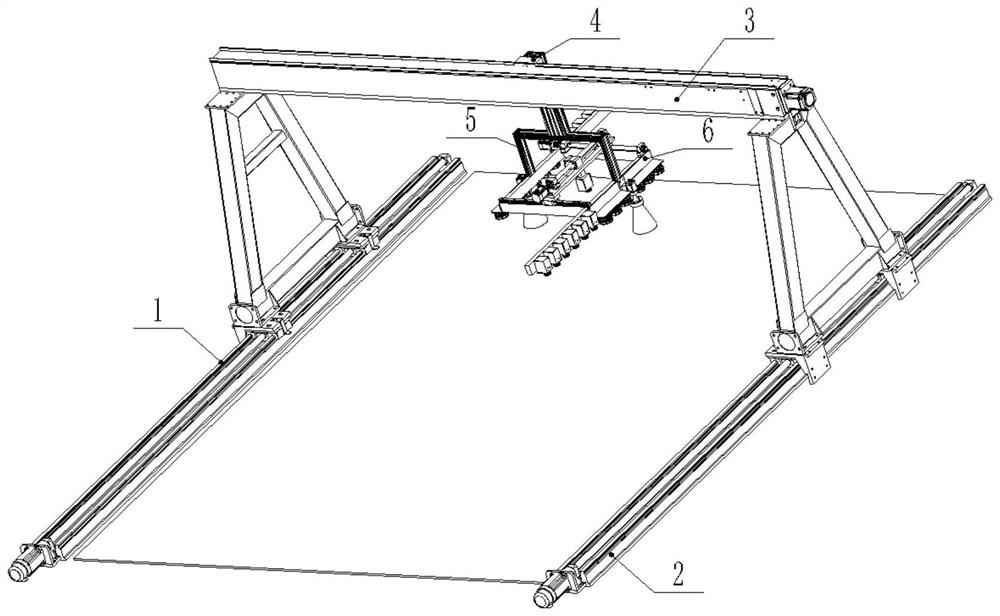

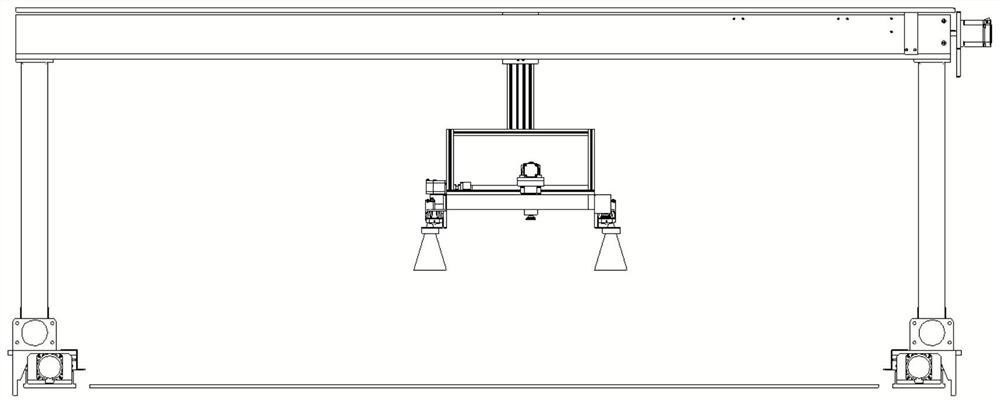

[0054] Such as figure 1 As shown, a laser derusting device for steel components according to the present application is characterized in that it includes a propulsion mechanism composed of mutually parallel left rails 1 and right rails 2, and a gantry 3 that is transmission-connected to the propulsion mechanism, The propulsion mechanism can drive the gantry to move and park at a specified speed on the left track 1 and the right track 2;

[0055] It also includes a boom 4 that can be driven to move at a specified speed along the beam of the gantry 3 at a constant speed. A suspension is fixedly connected to the bottom of the boom 4, and a working head is installed on the suspension;

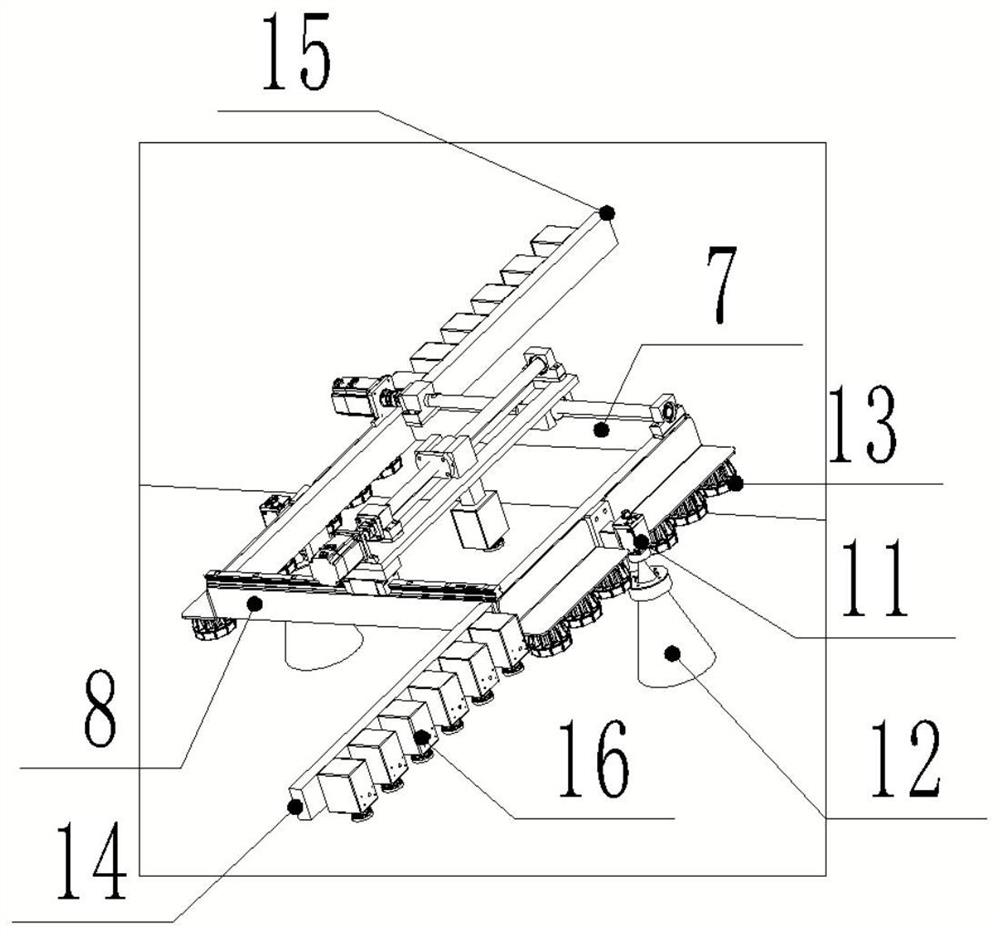

[0056] Described working head comprises square frame 6, and described square frame 6 is made of four identical length frame bars, is rear frame bar 8, front frame bar 7, left frame bar 9 and right frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com