Dewatering technology of biological gasoline and diesel oil

A diesel and biological technology, applied in the petroleum industry, hydrocarbon oil dehydration, hydrocarbon distillation, etc., can solve the problems of energy waste and low fuel calorific value, and achieve the effect of being suitable for popularization and application, increasing fuel calorific value, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The bio-oil produced mainly from straw contains 1.47% benzene and does not contain medium-carbon alcohols. During the evaporation process, they will contain 0.33% water in the azeotrope. Gasoline and diesel are only allowed to contain 0.2% water. Therefore, there is a problem of benzene dehydration; its steps include:

[0023] Send the above-mentioned water-containing bio-oil to an atmospheric distillation device for layered distillation, and recover the distillate liquid containing benzene and water between 80°C and 120°C;

[0024] The above-mentioned distillate liquid containing benzene and water is cooled to normal temperature and sent to a stratifier with a bottleneck to separate benzene and water.

Embodiment 2

[0026] The bio-oil mainly produced from cotton stalks contains 1.39% benzene and no medium-carbon alcohols. During the evaporation process, they will contain 0.31% water in the azeotrope. Gasoline and diesel are only allowed to contain 0.2% water. Therefore, there is also a problem of benzene dehydration; its steps include:

[0027] Send the above-mentioned water-containing bio-oil to an atmospheric distillation device for layered distillation, and recover the distillate liquid containing benzene and water between 80°C and 120°C;

[0028] The above-mentioned distillate liquid containing benzene and water is cooled to normal temperature and sent to a stratifier with a bottleneck to separate benzene and water.

Embodiment 3

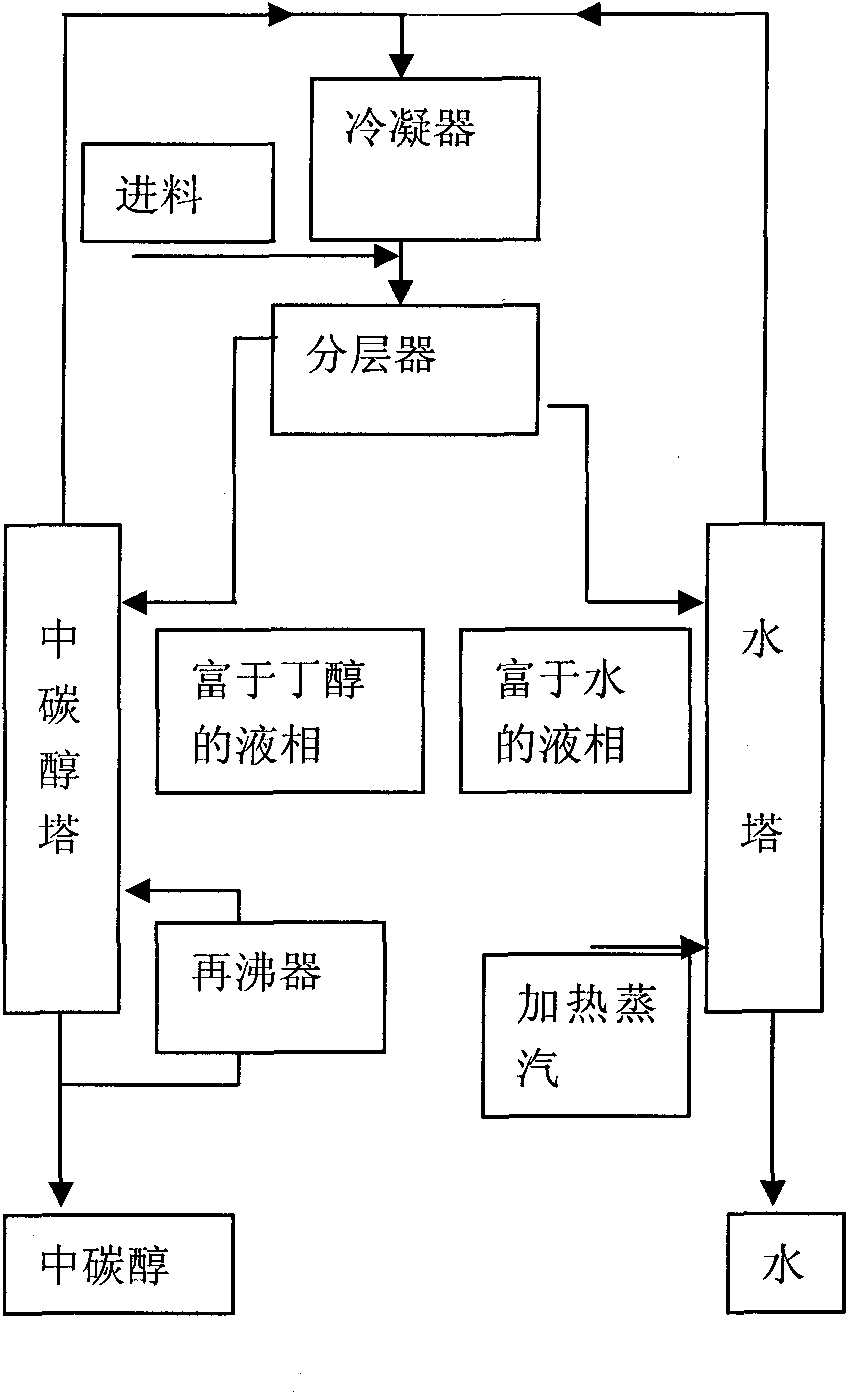

[0030] There are a series of medium-carbon alcohols in the biochemical raw materials of biomass waste, and their water content is relatively high, with 15% water. Its steps include:

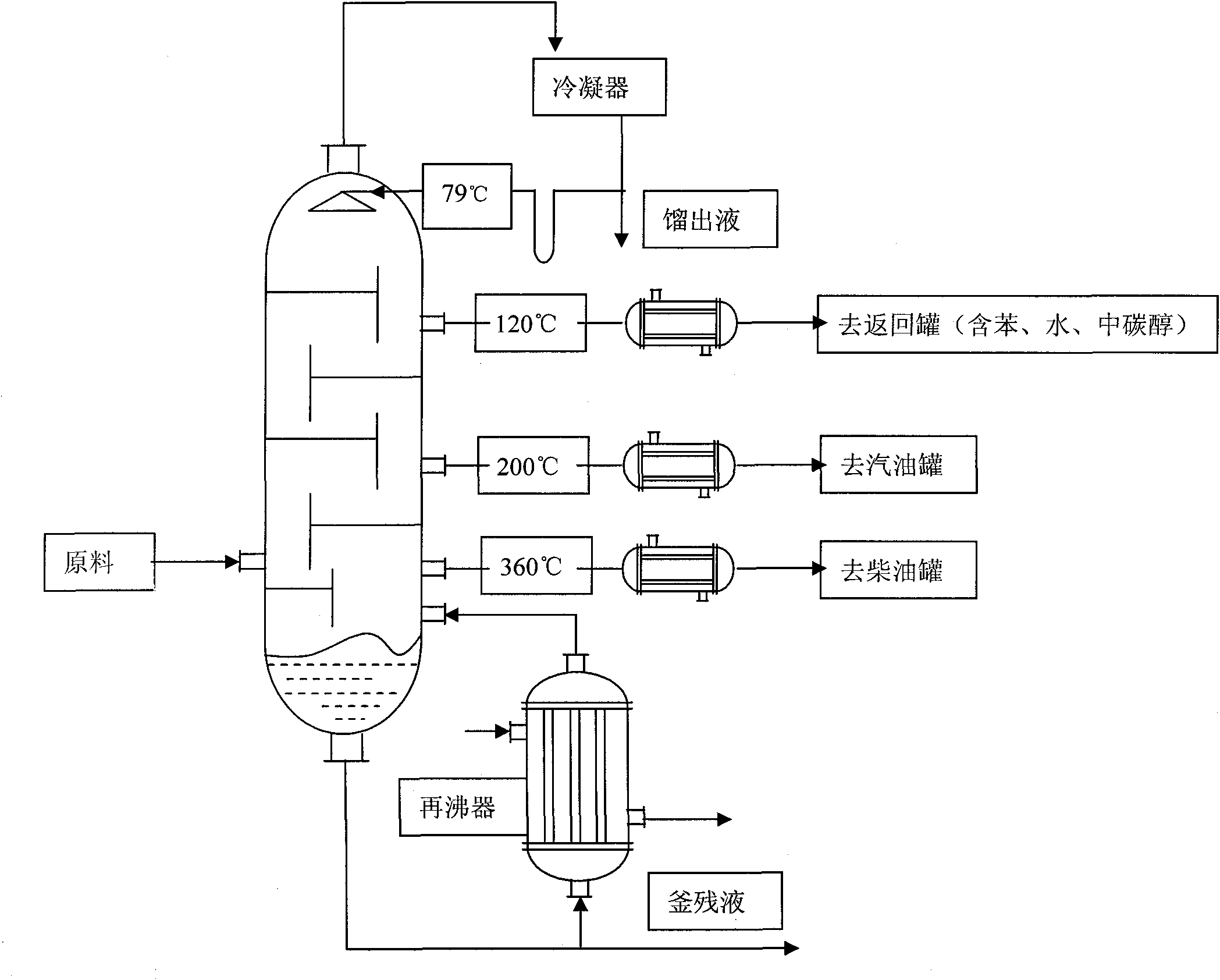

[0031] Stratified distillation: send the water-containing bio-oil to the atmospheric distillation device for stratified distillation, and the fraction at 79°C is used as the distillate; the fraction at 200°C is condensed through the condenser and enters the gasoline tank; the fraction at 360°C is condensed through the condenser Then enter the diesel tank; recover the distillate liquid containing benzene, water and medium carbon alcohol between 80°C and 120°C;

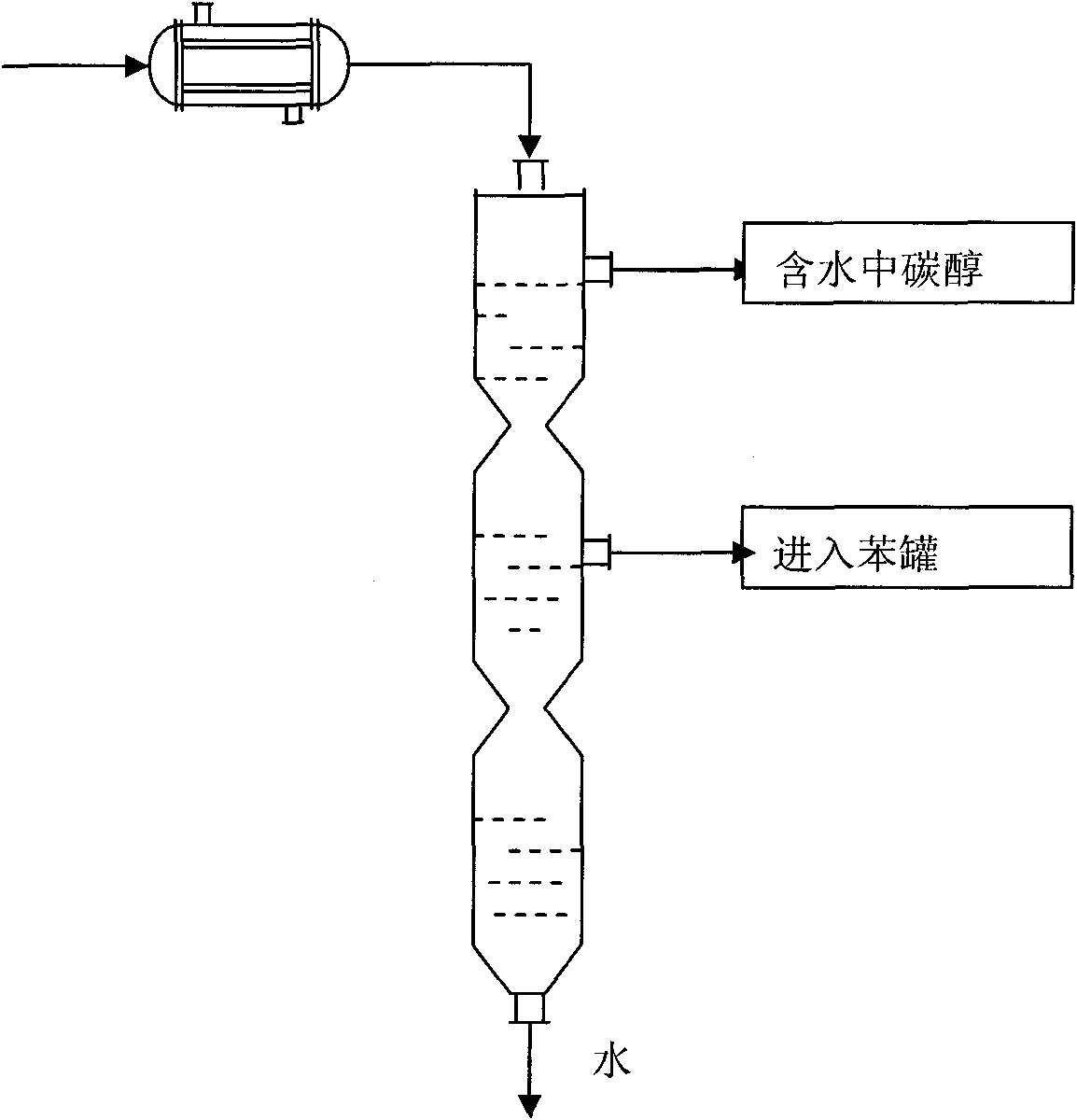

[0032] Separation of benzene: Cool the above-mentioned distillate liquid containing benzene, water, and medium-carbon alcohol to normal temperature, and send it to a stratifier with a bottleneck to separate benzene. Since the specific gravity of water is 1, the specific gravity of benzene is 0.879. Benzene is insoluble in Water, the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com