Co-production processing method and equipment for carbon black and oil

A carbon black and equipment technology, which is applied in the direction of tar processing by distillation, dehydration of hydrocarbon oil, fibrous filler, etc., can solve the problems of increasing equipment investment and power consumption, increasing the flow of exhaust gas, and reducing the chemical calorific value of exhaust gas. Achieve the effect of reducing equipment investment and operating power consumption, and reducing equipment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

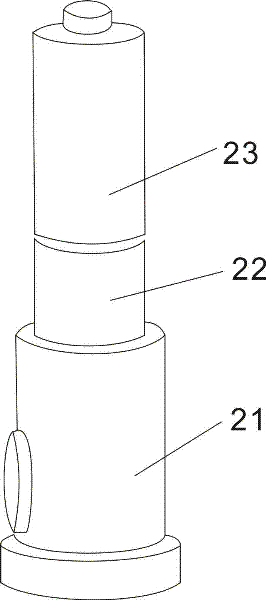

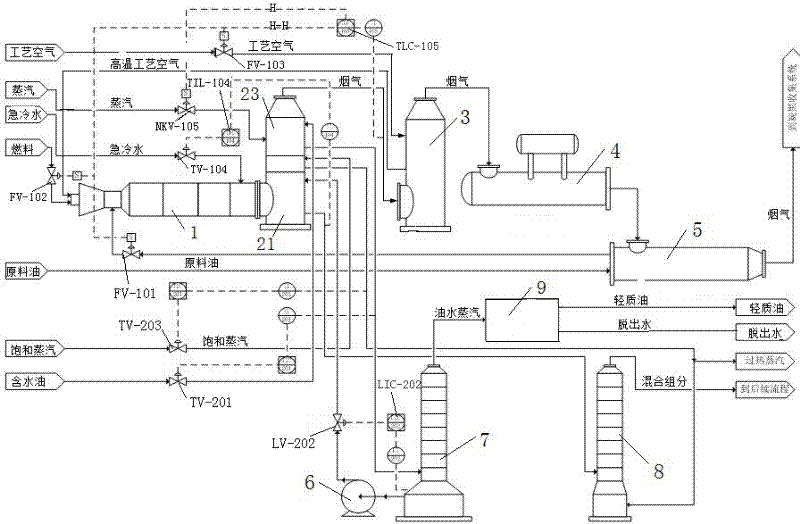

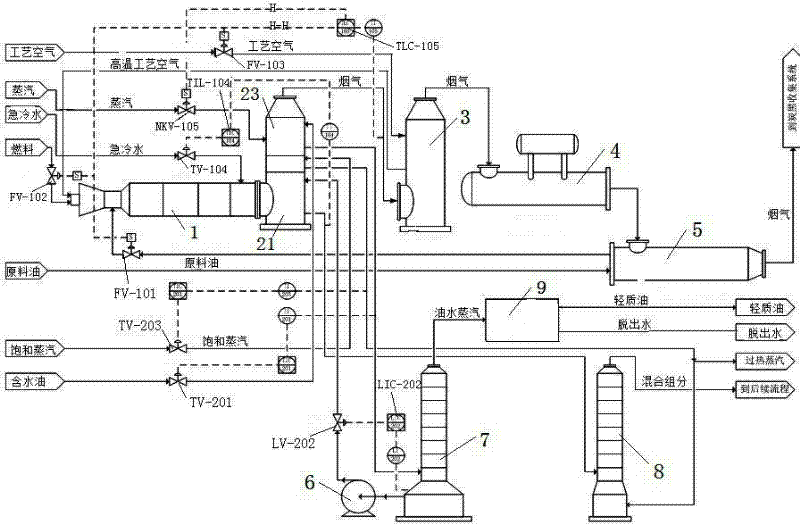

[0034] Such as figure 1 with figure 2 As shown, a carbon black and oil processing co-production equipment includes a carbon black reaction furnace 1, an air preheater 3, a waste heat boiler 4 and a raw oil preheater 5 connected in sequence; Device 7, and two-stage evaporator 8, an online tube furnace is set between the carbon black reaction furnace 1 and the air preheater 3, the online tube furnace is a shell and tube heat exchanger, and the cylinder body adopts ordinary carbon steel, It is lined with refractory materials, and the tube is made of high-temperature resistant steel, which also has certain corrosion resistance. The online tube furnace is divided into radiant section 21, superheating section 22 and convection section 23 from bottom to top, and each section is equipped with inlet and Outlet, wherein the inlet of the radiation section is connected to the anhydrous oil pump 6, the outlet of the radiation section is connected to the inlet of the second-stage evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com