Rotary type atomizing sprayer

An atomization spraying and rotary technology, applied in the direction of spray evaporation, hydrocarbon oil dehydration, etc., can solve the problems of difficult oil-water separation, accelerated wear and corrosion of equipment, and achieve the reduction of bonding rate, the improvement of atomization efficiency, and the increase of fog The effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

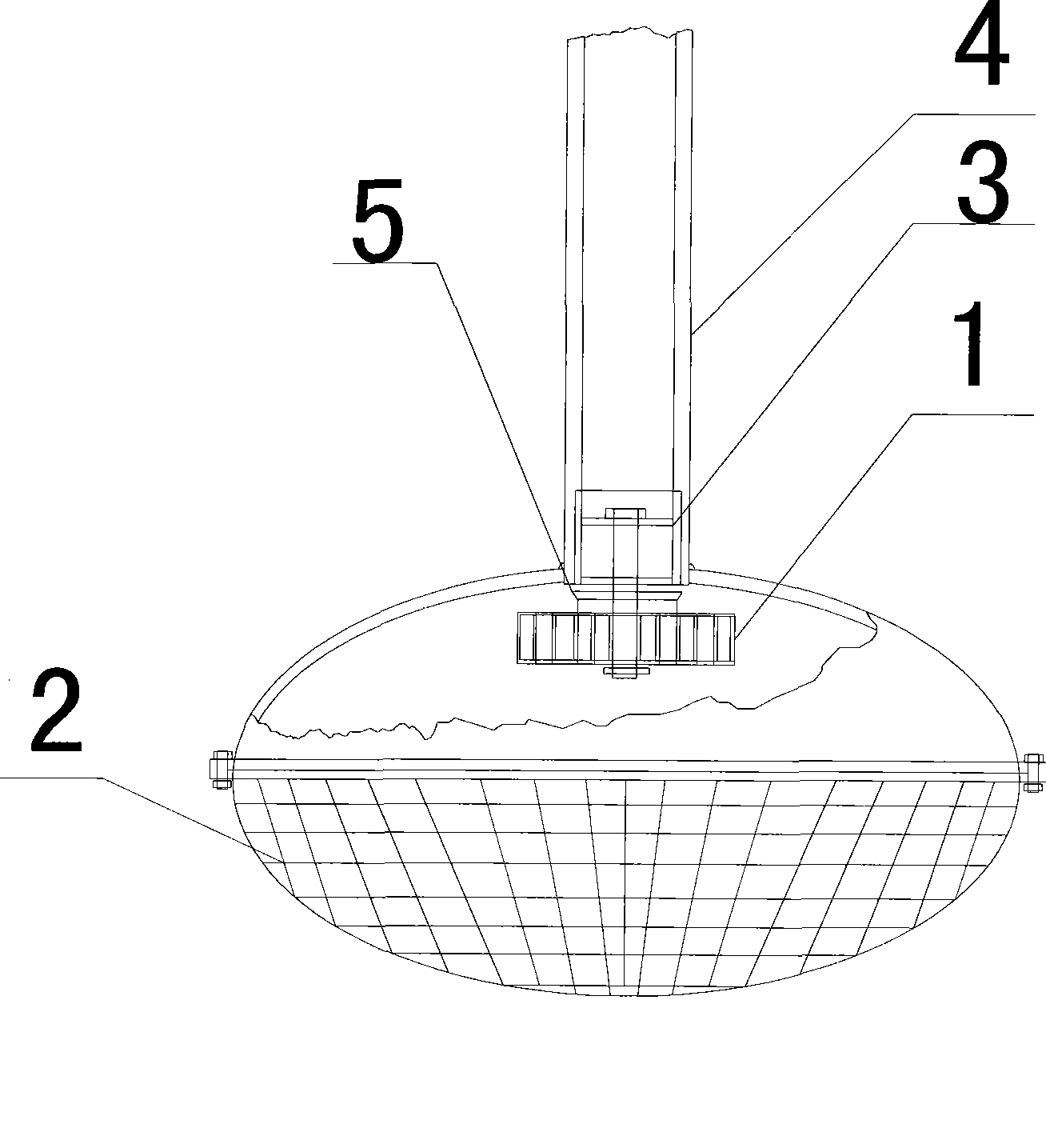

[0008] The rotary atomizing spray device of the present invention comprises a rotating impeller 1, a sprayer nozzle 2, an impeller fixing seat 3, an oil guide pipe 4, and an impeller guide cover 5; the outlet of the oil guide pipe 4 is provided with an impeller guide cover 5, The impeller fixing seat 3 is located in the impeller guide cover 5, the rotating impeller 1 is located under the impeller guide cover 5 and the impeller fixing seat 3, the rotating shaft of the rotating impeller 1 is located in the impeller fixing seat 3, and the spray hole 2 is located in the rotating impeller 1. below. The blades of the rotary impeller 1 have an inclination angle with the axial direction of the rotary impeller 1 .

[0009] The oil heated by the far-infrared heater enters the impeller guide cover 5 through the oil guide pipe 4, and the oil is directly introduced into the middle hole of the rotating impeller 1 by the impeller guide cover 5, and is emitted to the surroundings through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com