Distillation dewatering set and its dewatering process using it

A dehydration device and distillation column technology, which is applied in the fields of hydrocarbon oil dehydration, chemical instruments and methods, and containers for laboratory use, can solve problems such as bumping easily, and achieve the effect of avoiding bumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

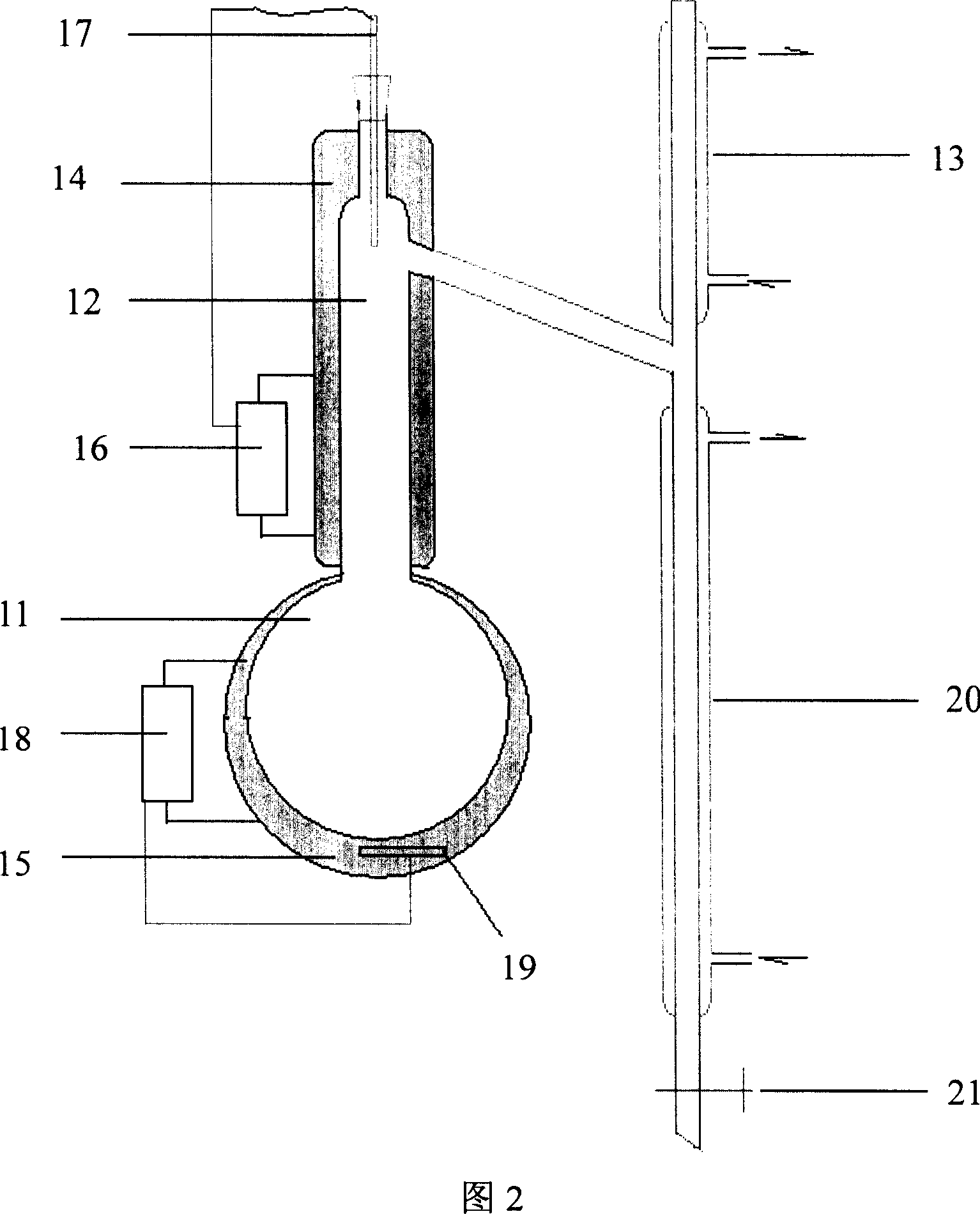

[0032] This embodiment is used to illustrate the distillation dehydration device and method provided by the present invention.

[0033] Water was added to anhydrous crude oil to obtain an aqueous sample with a water content of 5% by weight. As shown in FIG. 2 , a water-containing sample having a water content of 5% by weight was put into a retort 11 . Open distillation column heater 14, open distillation bottle heater 15 simultaneously, control distillation column heater 14 and distillation bottle heater 15 respectively by distillation column temperature controller 16 and distillation bottle temperature controller 18, make distillation bottle 11 at 2 ℃ The temperature is raised at a rate of 1 / min, and when the temperature of the distillation column 12 detected by the distillation column temperature sensor 17 is 135° C., the temperature of the distillation column 12 is maintained at 135° C. Continue to heat the retort 11, and when the temperature of the retort 11 detected by t...

Embodiment 2

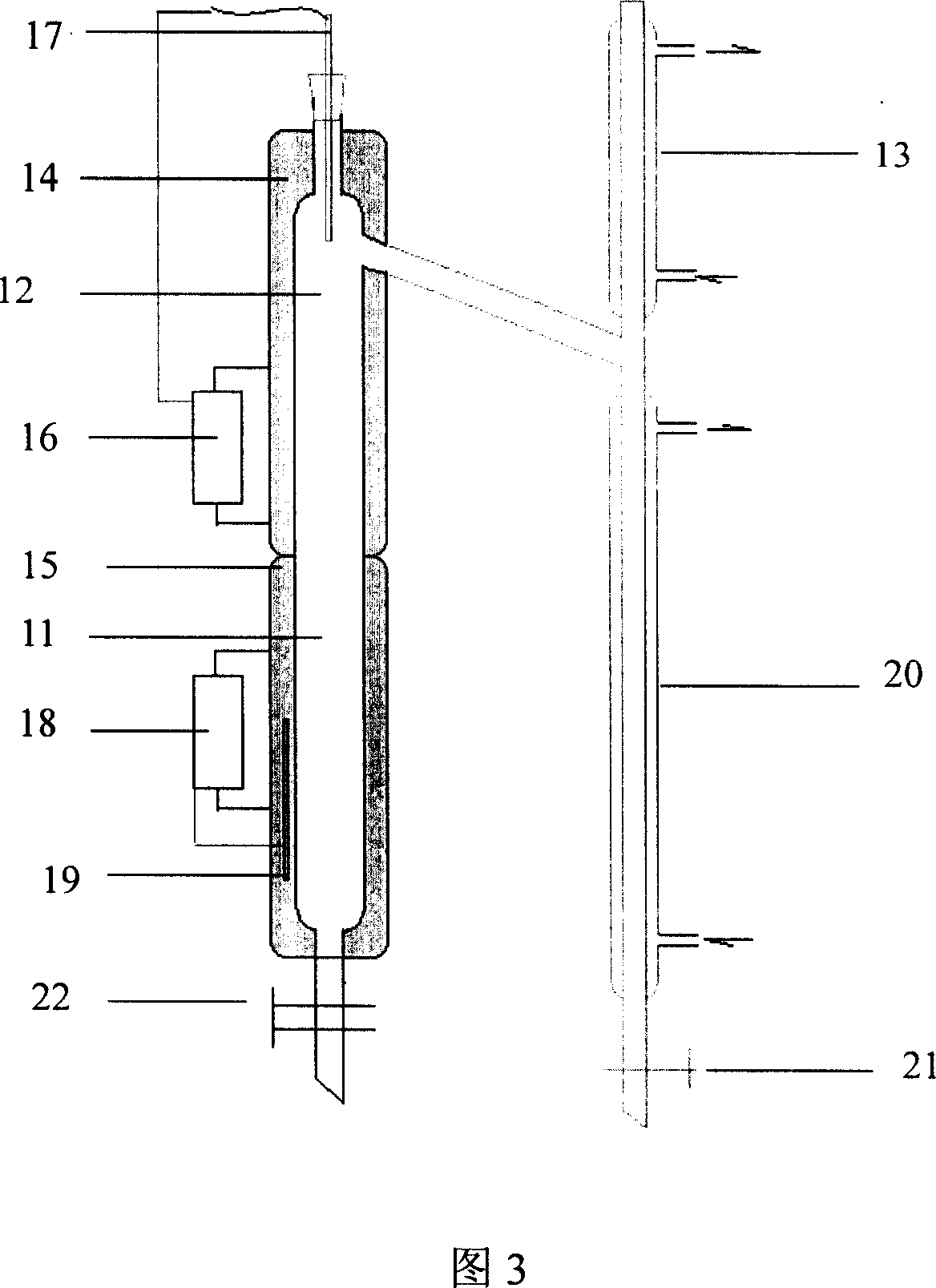

[0037] This embodiment is used to illustrate the distillation dehydration device and method provided by the present invention.

[0038] Water was added to anhydrous heavy oil to obtain an aqueous sample with a water content of 5% by weight. As shown in FIG. 3 , the above-mentioned water-containing sample obtained from anhydrous heavy oil and having a water content of 5% by weight was put into a distillation flask 11 . Open distillation column heater 14, open distillation bottle heater 15 simultaneously, control distillation column heater 14 and distillation bottle heater 15 respectively by distillation column temperature controller 16 and distillation bottle temperature controller 18, make distillation bottle 11 at 2 ℃ / min rate of heating. When the distillation column temperature sensor 17 detects that the temperature of the distillation column 12 is 130° C., the temperature of the distillation column 12 is maintained at 130° C. Continue to heat the distillation bottle 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com