Crude oil ultrasonic emulsion breaking dehydrating device and emulsion breaking dehydrating method thereof

A dehydration device, crude oil technology, applied in the direction of mechanical dehydration/demulsification, dehydration/demulsification adjustment/control, etc., can solve problems such as damage and complex chemical composition, and achieve the effect of strengthening overpressure protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0168] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0169] The crude oil ultrasonic emulsion dehydration device and the demulsification dehydration method thereof of the present invention respond to the characteristics of the ultrasonic wave, and with the help of the chemical activity of the chemical demulsifier, cooperate cooperatively to destroy the stable structure of the crude oil emulsion, and promote the rapid structural change of the crude oil emulsion. Realize efficient oil and water separation of crude oil.

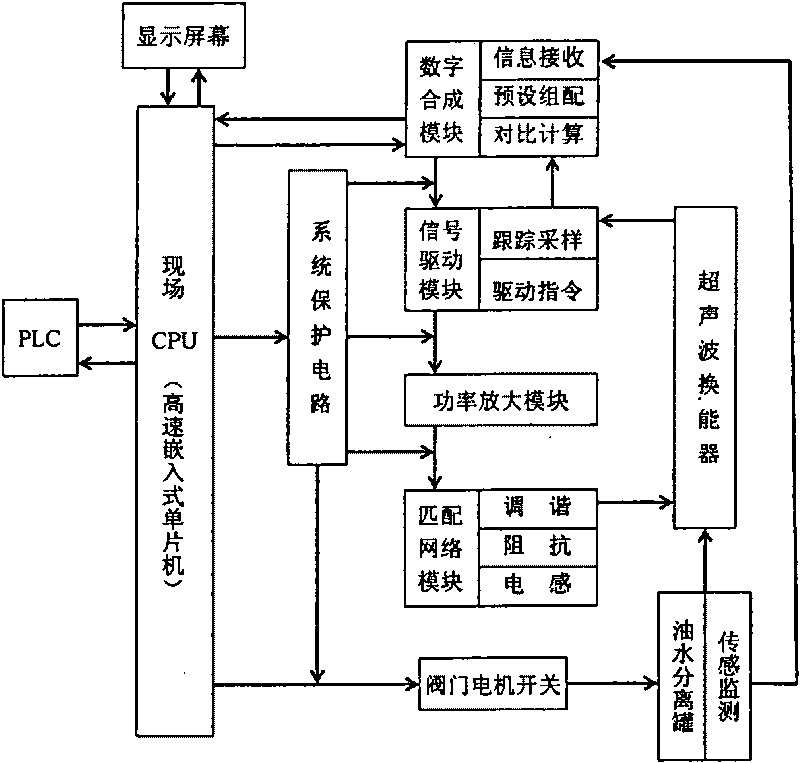

[0170] figure 1 The present invention is a schematic block diagram of the overall structure of the ultrasonic generator; it is composed of a human-computer interactive digital display, an AVR high-speed embedded single-chip microcomputer, a digital synthesis module, a signal drive module, a power amplification module, a matching network module, and a generator housing. And other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com