Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

A carbon nanotube and carbon fiber technology, applied in the field of carbon fiber reinforcement and its preparation, can solve the problems of increased interface rigidity, decreased material toughness, unable to improve the performance of fiber resin matrix, etc., achieves less interface defects, improved performance, and promotes popularization and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

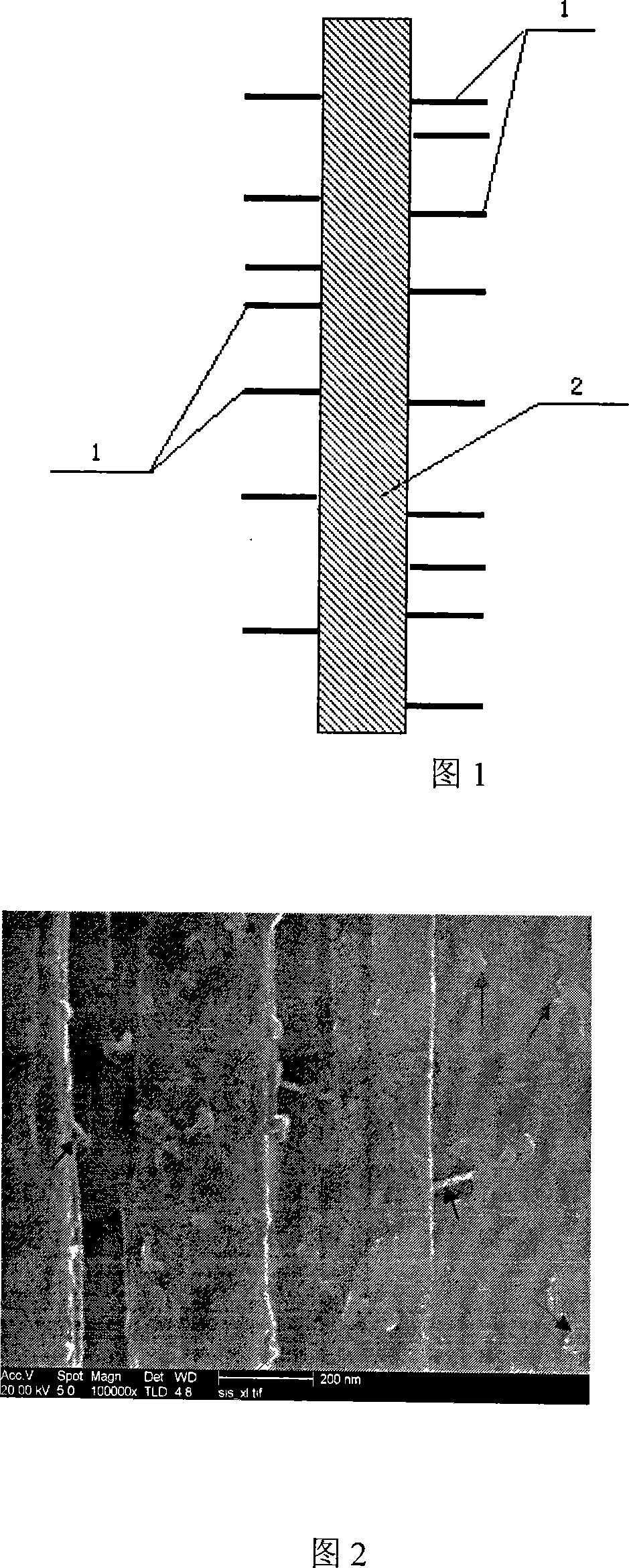

[0012] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1. In this embodiment, the carbon nanotube-connected carbon fiber multi-scale reinforcement is composed of 2 to 6 parts by weight of carbon nanotubes 1 and 100 modified by 1,6 hexamethylenediamine. carbon fiber 2 with acid chloride functional groups on the surface; the carbon nanotube 1 is connected to the surface of the carbon fiber 2 through a chemical bond.

[0013] In this embodiment, the carbon nanotubes modified by 1,6 hexamethylenediamine are made according to the following steps: 1. Pretreatment of carbon nanotubes: putting the carbon nanotubes into a mixed solution of sulfuric acid and nitric acid for 1s pulse ultrasonic treatment for 8-12min , and then reflux at 95-105°C for 4±0.1h, then filter and wash the solid phase until neutral, then dry and grind; 2. Put the pretreated carbon nanotubes into SOCl 2 Medium 1s pulse ultrasonic treatment for 8-12min, then add N,N-dimethylformamide a...

specific Embodiment approach 2

[0016] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the carbon nanotube-connected carbon fiber multi-scale reinforcement consists of 3 to 5 parts by weight of carbon nanotubes modified by 1,6 hexamethylenediamine and 100 carbon fibers with acid chloride functional groups on the surface are combined. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: The difference between this embodiment and specific embodiment one is: the carbon nanotubes connected carbon fiber multi-scale reinforcement is composed of 4 parts by weight of carbon nanotubes modified by 1,6 hexamethylenediamine and 100 parts It is made by combining carbon fibers with acid chloride functional groups on the surface. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com