A new type of high-performance reinforced concrete beam and its manufacturing method

A technology for reinforced concrete beams and concrete beams, which is applied to joists, girders, trusses and other directions to achieve the effects of saving construction costs, improving flexural bearing capacity and strong repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

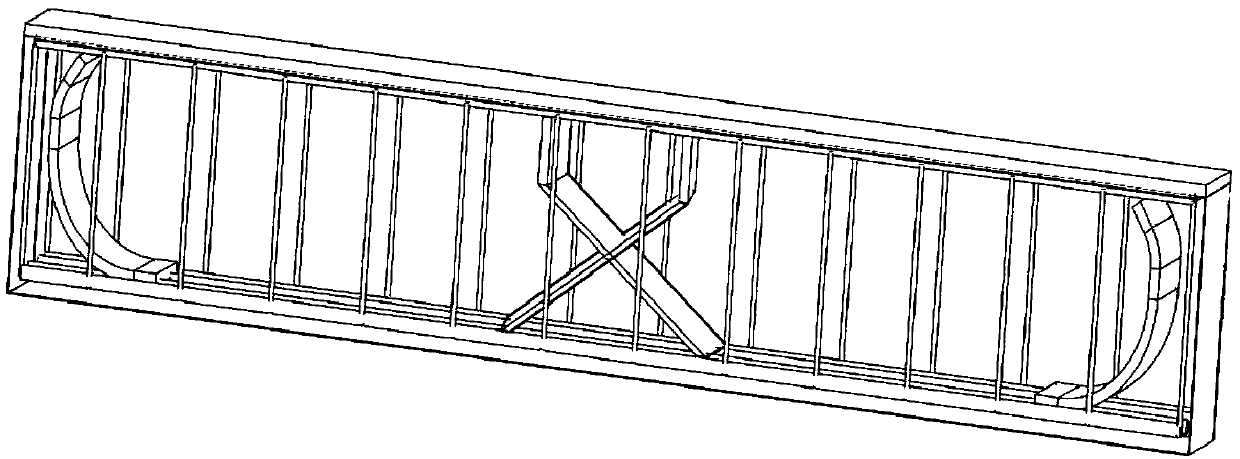

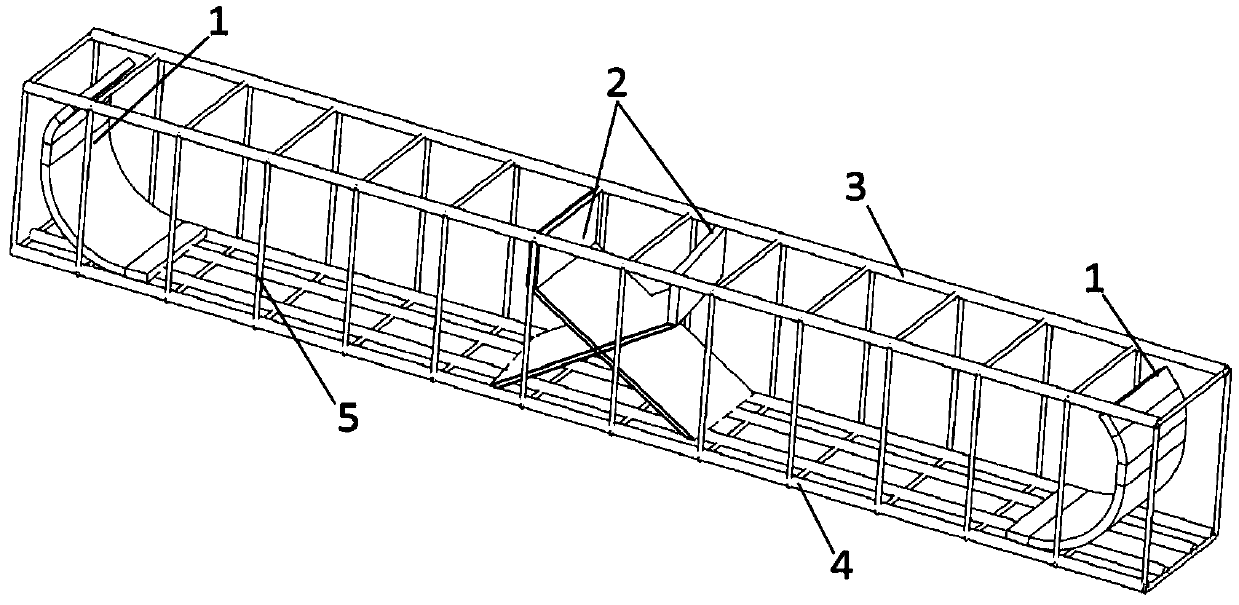

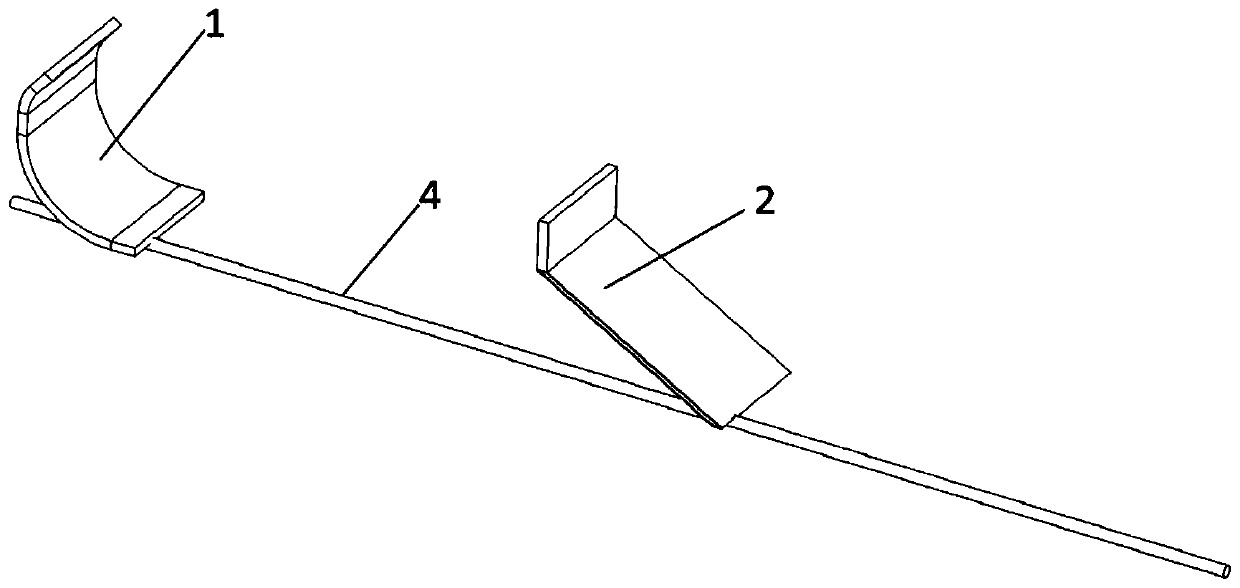

[0018] Embodiment of the present invention: a novel high-performance reinforced concrete beam, as attached Figure 1-4 As shown, it includes the concrete beam body and the reinforcement cage pre-cast in the concrete beam body. The two ends of the reinforcement cage are symmetrically arranged with arc-shaped steel plates 1 and the lower ends of the arc-shaped steel plates are fixedly connected with the lower longitudinal bars 4 respectively. There are two types of plates for shaped steel plate 1: steel plate with ribs and steel plate without ribs. A mid-span cross-folded rotatable steel plate 2 is set in the middle of the steel cage, and the lower end of the mid-span cross-folded rotatable steel plate 2 and the lower longitudinal rib 4 Fixed connection, the arc-shaped steel plate 1, the mid-span cross-folding rotatable steel plate 2 and the lower longitudinal rib 4 are fixedly connected by welding or mechanical connection.

[0019] Wherein the mid-span cross folded rotatable st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com