Red mud treatment system for hollow brick production

A processing system and hollow brick technology, applied in the direction of mixed material pretreatment, chemical/physical process, mixer, etc., can solve the problems of poor adaptability of crushing devices, general mixing effect, low mixing efficiency, etc., to improve the mixing effect and improve Water control effect and efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

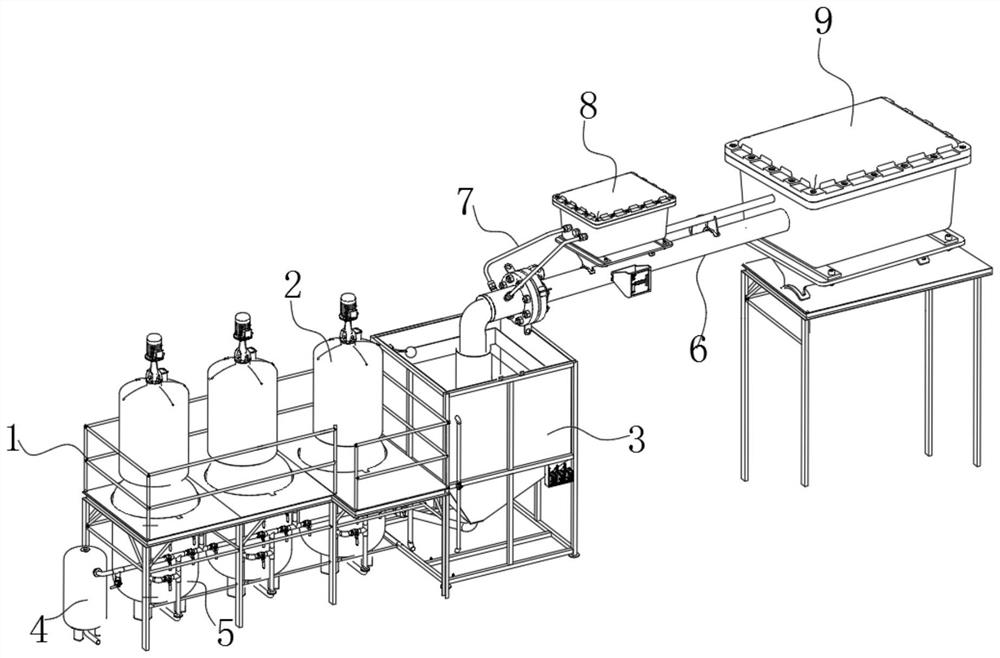

[0030] see Figure 1~4 , in an embodiment of the present invention, a red mud treatment system for hollow brick production, which includes an installation frame 1, a mixing tank 2, a screening machine 3 and a feeding assembly 6, wherein the feeding assembly 6 can carry out Continuous feeding, the sieving machine 3 can send the sieved material body to the mixing tank 2, and the mixing tank 2 is fixed on the mounting frame 1;

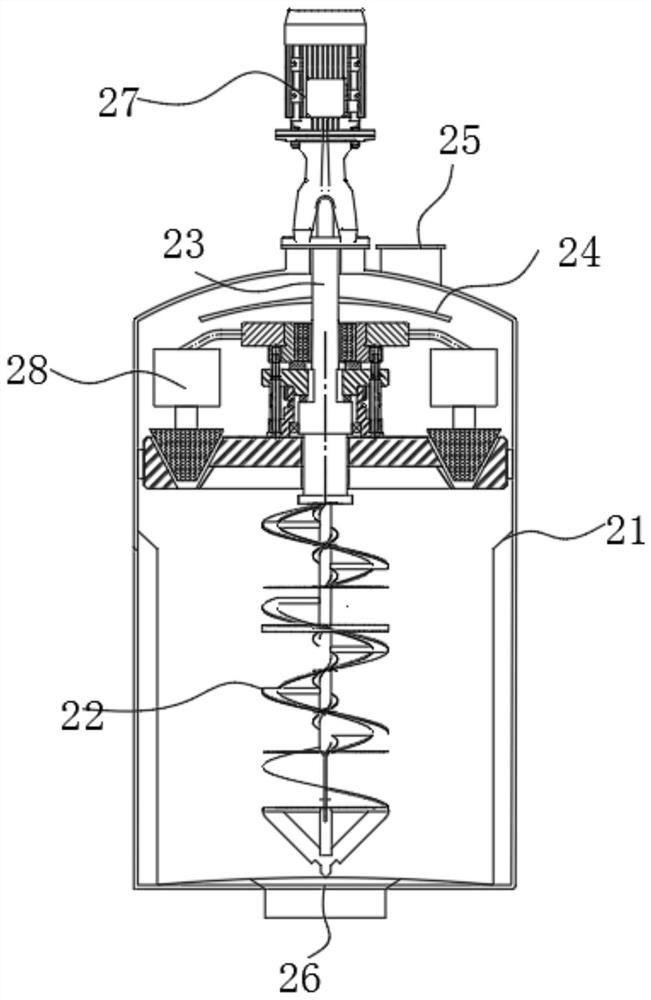

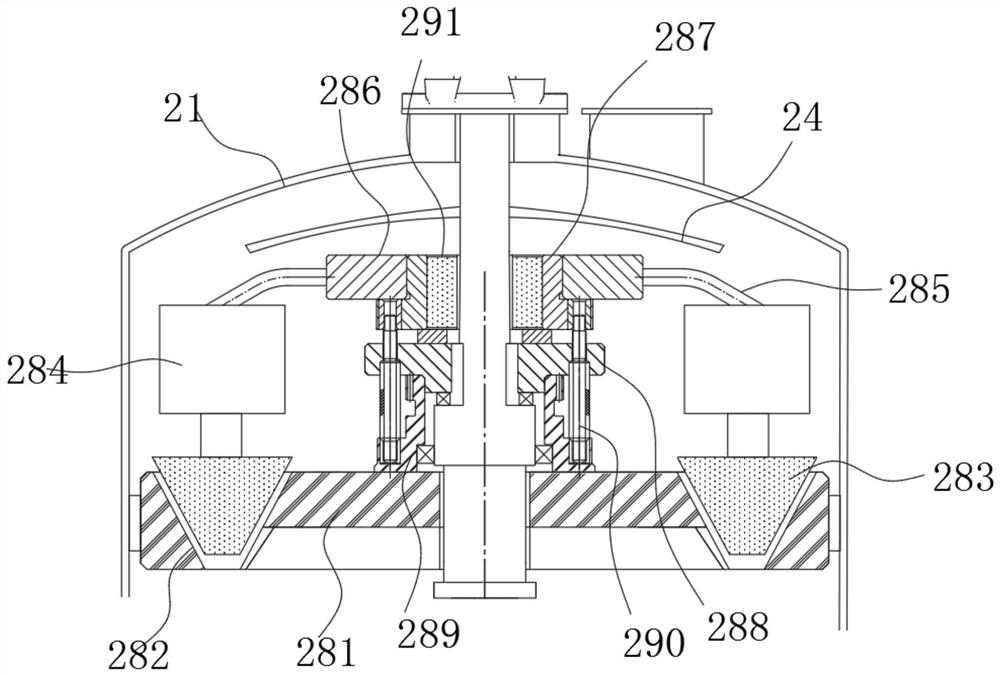

[0031] The top of the mixing tank 2 is provided with a feed port 1 25 for connecting to the discharge end of the screening machine 3, and the side of the mixing tank 2 is provided with a feed port 2 for connecting with the feed tank , it should be explained that there are multiple feeding tanks (not shown in the figure), and the multiple feeding tanks can respectively add reducing agent, cosolvent and other materials to the mixing tank 2, wherein the reducing agent can The iron oxide in the iron-containing red mud is reduced, and the co-solvent is used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com