Hydraulic self-induced vibration subsoiler

A technology of self-excited vibration and subsoiler, applied to agricultural machinery and implements, applications, plows, etc., can solve the problems of poor consistency of tillage depth, large shaft length, discomfort, etc., to ensure consistency of tillage depth and reduce traction resistance Small, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

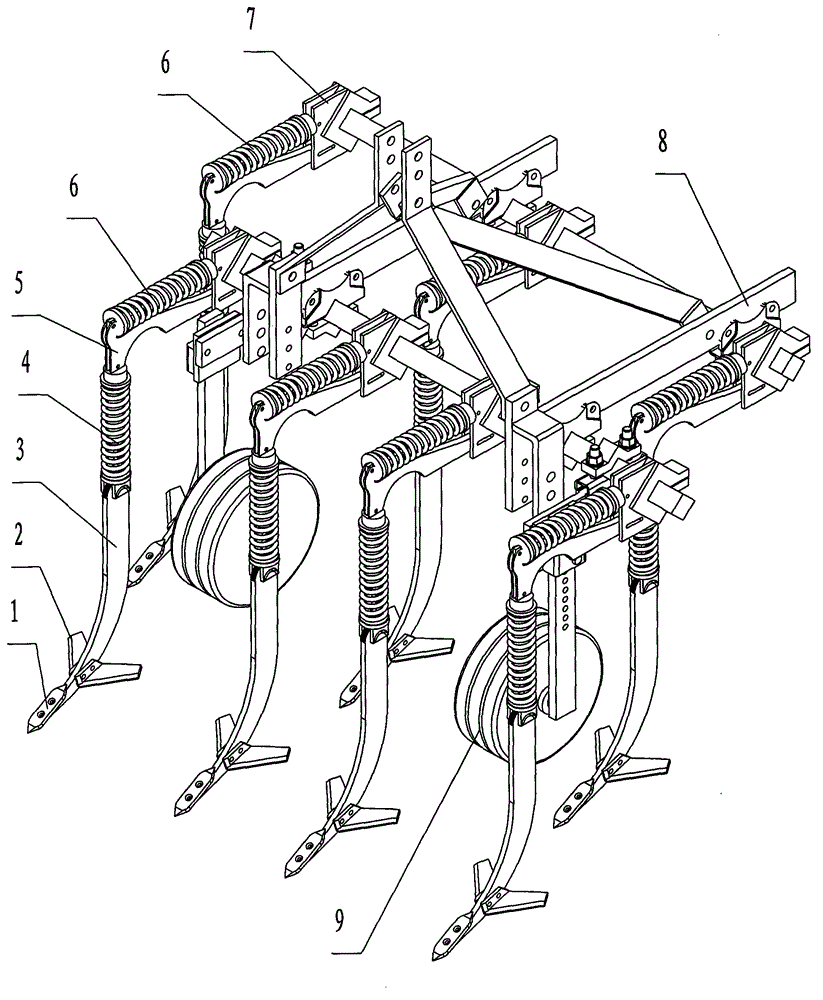

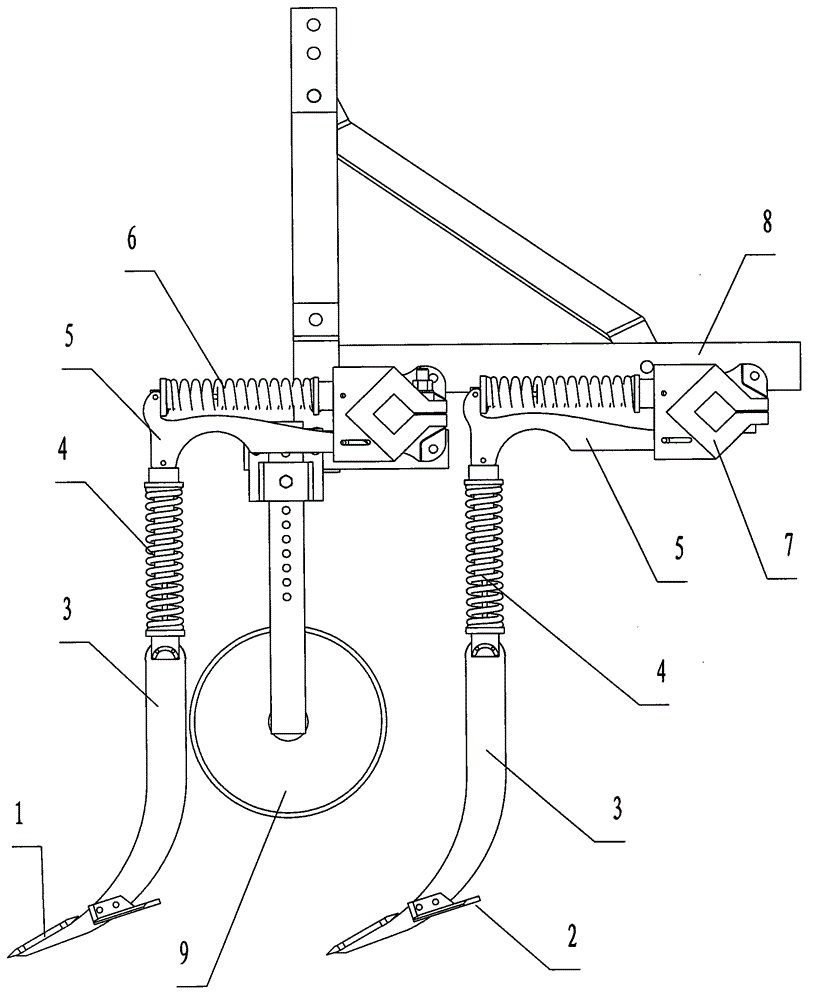

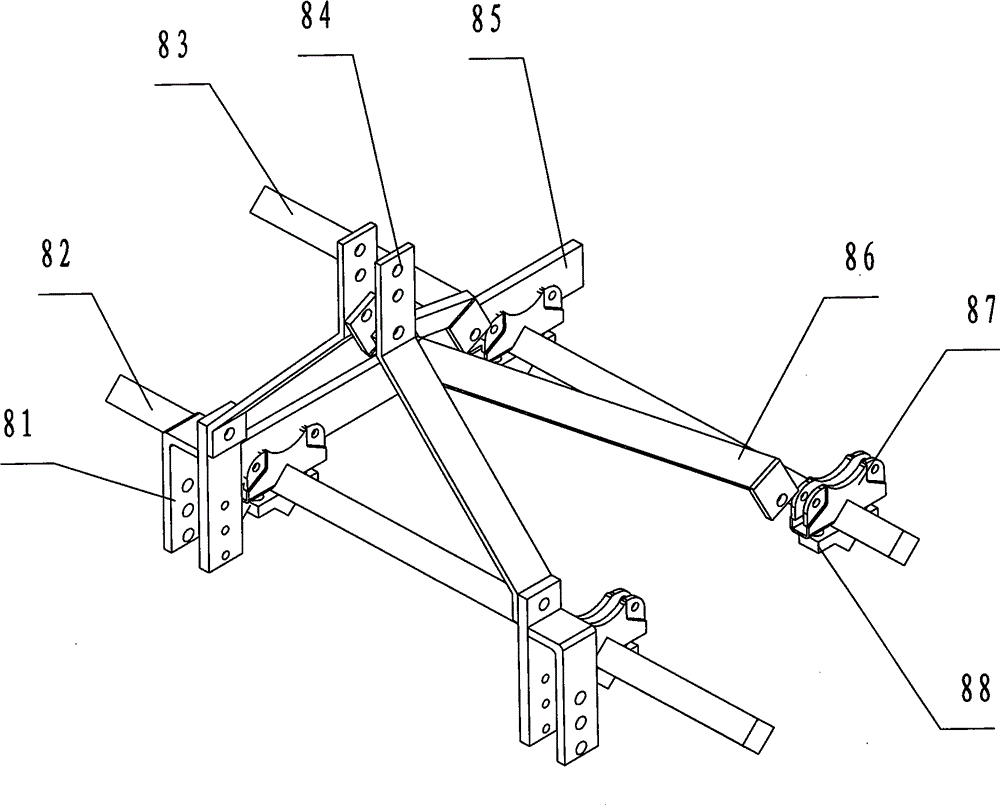

[0032] Embodiment 1: with reference to attached Figure 1-12, the present invention comprises frame 8 and subsoiling device, and described subsoiling device is arranged under frame 8, and described frame 8 is composed of suspension sub-board 81, front beam 82, rear beam 83, inclined draw bar 84, crossbeam 85. A transverse drawbar 86, a "U" groove fixing piece 87 and a "V" lock piece 88 are formed. The suspension sub-board 81 is connected to the beam 85, and the upper end of the inclined drawbar 84 is connected to the transverse The inner side of the upper end of the drawbar 86, the lower end of the transverse drawbar 86 is connected to the inner side of the suspension sub-board 81, the lower end of the inclined drawbar 84 is connected to the inner side of the crossbeam 85, and the crossbeam 85 is connected in the groove of the "U"-shaped groove fixture 87, "U" ""-shaped groove fixing piece 87 and "V"-shaped locking piece 88 embrace the front beam 82 and rear beam 83 and fasten...

Embodiment 2

[0033] Embodiment 2: The difference from Embodiment 1 is that the front beam 82 and the rear beam 83 of the frame 8 are arranged in alignment, and the subsoiling shovel is arranged symmetrically with the front four and the rear four. This setting is suitable for inter-plant subsoiling and crop growth period In addition, the subsoiling device can be arranged on the front beam 82, and the subsoiling device can be removed on the rear beam 83, and the rotary tiller can be installed to realize joint operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com