Simulation test device for surface friction resistance of braided fabric

An inspection device and friction-resistant technology, applied in the direction of testing wear resistance, etc., can solve the problems of large error in inspection conclusions, inconsistent friction effects of the tested objects, and different friction paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

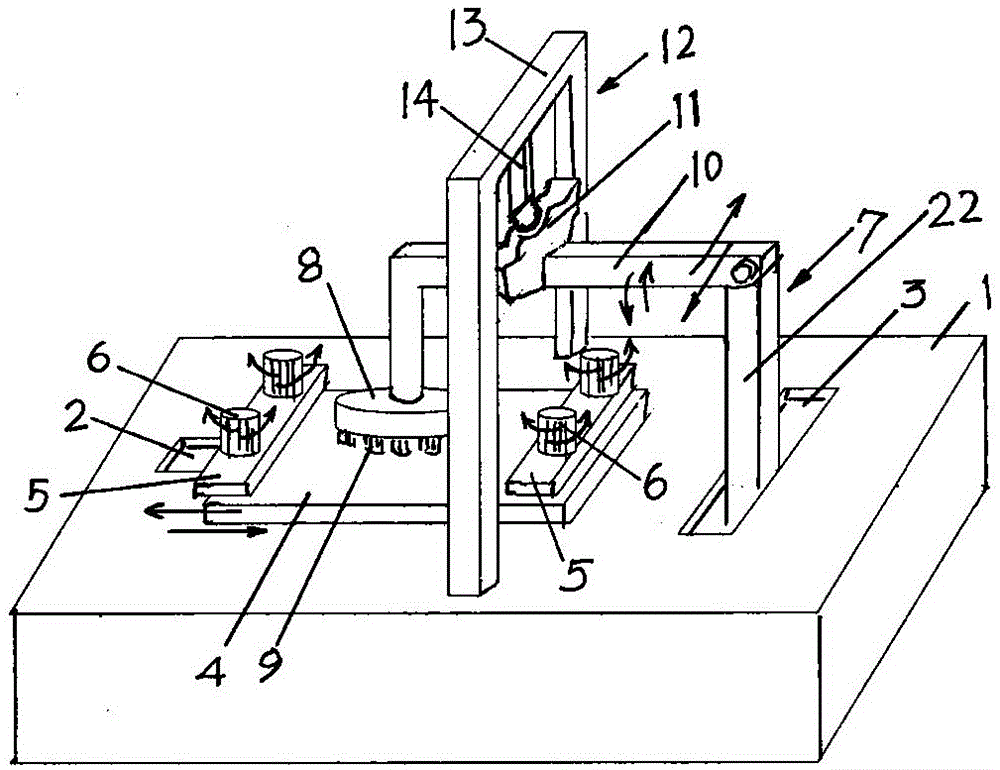

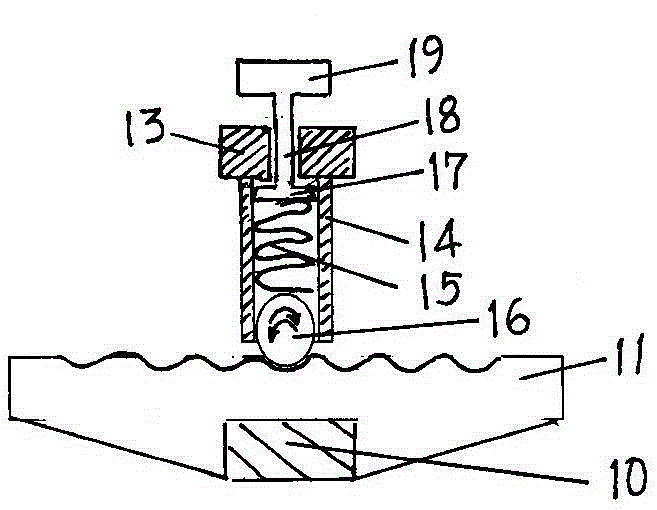

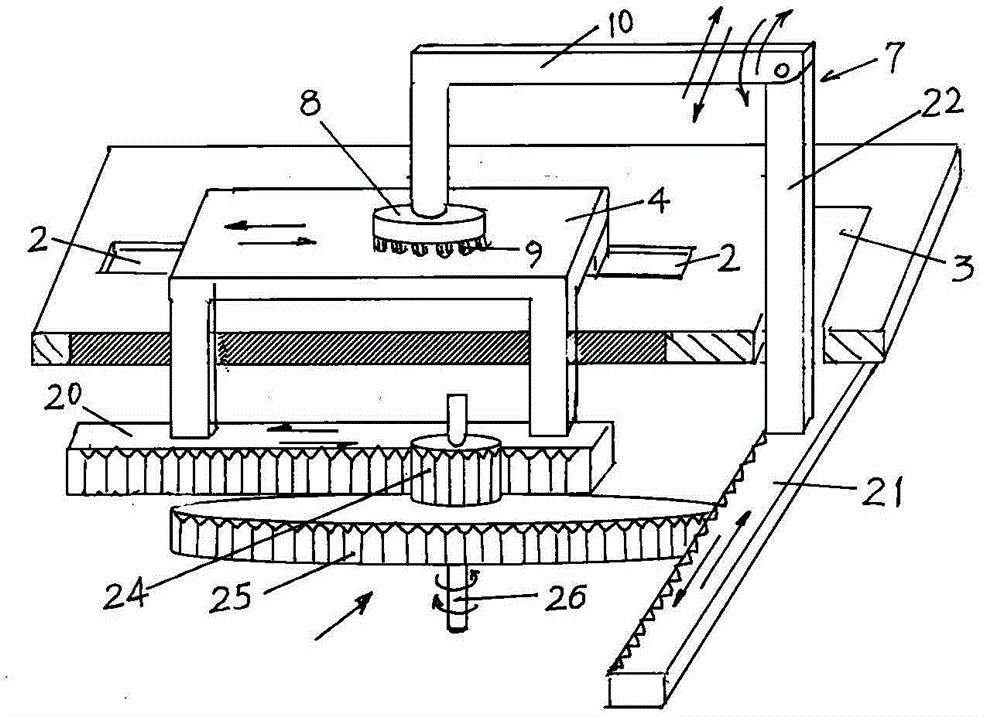

[0020] Embodiment 1, the simulation testing device of braided surface friction resistance

[0021] Such as figure 1 , 2 , 3, including the stage assembly and the friction member assembly that move vertically on the rack platform 1;

[0022] A horizontal long hole 2 and a longitudinal long hole 3 are arranged on the surface of the rack platform 1, and the horizontal long hole 2 and the longitudinal long hole 3 are perpendicular to each other; Lateral movement strip 20, the transverse movement strip 20 with side teeth can do reciprocating lateral movement along the horizontal long hole 2, the transverse movement strip 20 with side teeth is connected with the motor; the frame platform 1 below the longitudinal long hole 3 is provided with The longitudinal movement strip 21 with side teeth, the longitudinal movement strip 21 with side teeth can reciprocate longitudinally along the longitudinal slot 3, the longitudinal movement strip 21 with side teeth is connected with the motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com