Computerized flat knitting machine press wheel assembly

A computerized flat knitting knitting machine and cloth pressing wheel technology, applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of uneven force, large fabric pressure, inability to adjust the fabric pressure, etc. The effect of the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

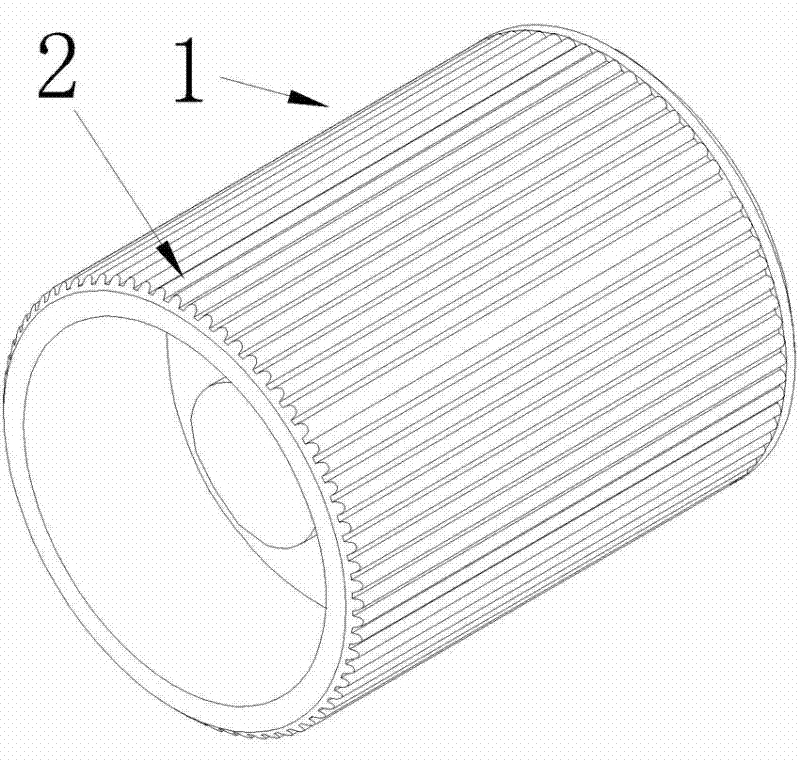

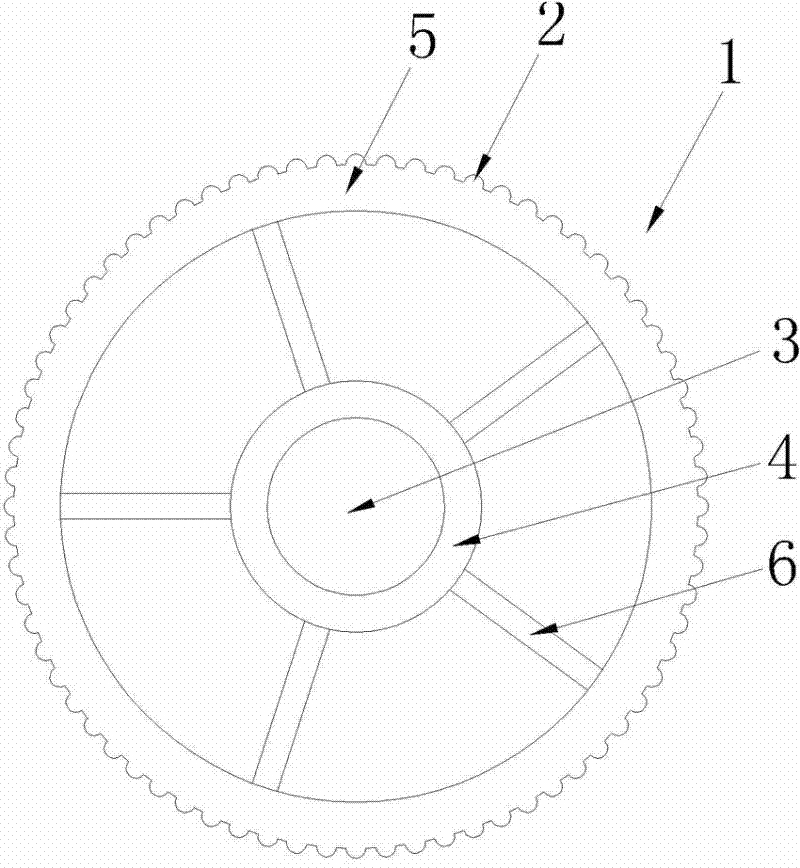

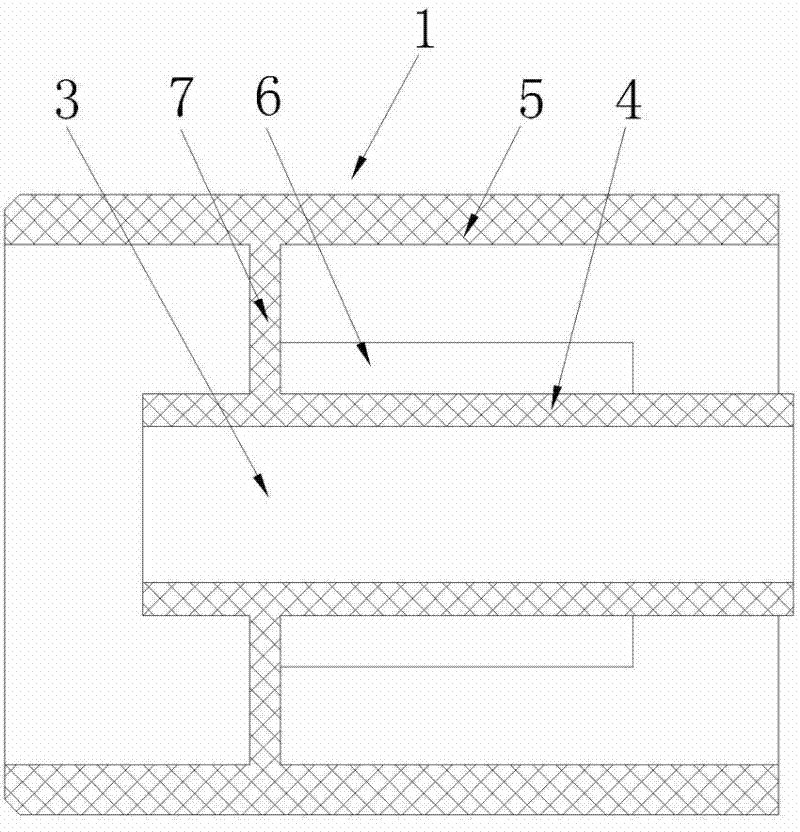

[0023] see figure 1 , figure 2 and image 3 , the press wheel 1 is cylindrical, the axial length is 25% larger than the diameter, and its outer surface has uniformly distributed axial friction ribs 2. These friction ribs 2 can increase the friction coefficient of the outer surface of the press wheel 1. Provides enough friction to the fabric with light pressure. The shaft hole 3 is shorter than the cloth pressing wheel 1, and the shaft hole 3 and the surface of the cloth pressing wheel 1 are hollowed out to form the shaft hole wall 4 and the outer wall 5, which can effectively reduce the cloth pressing without affecting the useful size and shape. Wheel 1 weight. One end of the shaft hole wall 4 protrudes outside the cloth pressing wheel 1, and the other end of the shaft hole wall 4 is in the cloth pressing wheel 1 because the length of the shaft hole 3 is less than the length of the cloth pressing wheel 1. There are five supporting ribs 6 between the shaft hole wall 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com