Air-floating roller bed type thermal treatment furnace for semiconductor devices

A heat treatment furnace, semiconductor technology, applied in the direction of furnace, furnace type, furnace components, etc., can solve the problem that the atmosphere and environment in the furnace cannot be fundamentally improved, and achieve the effect of consistent force, consistent friction, and prevention of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

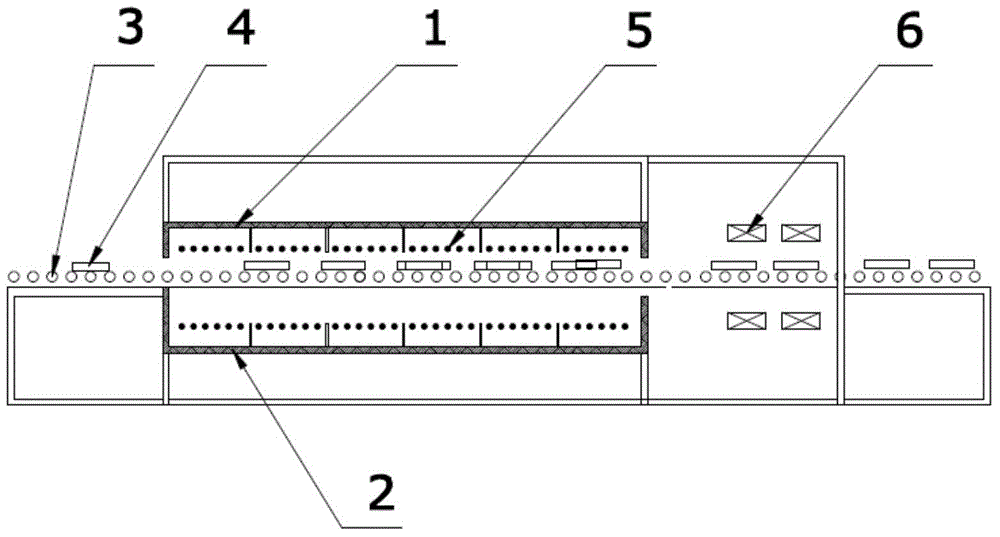

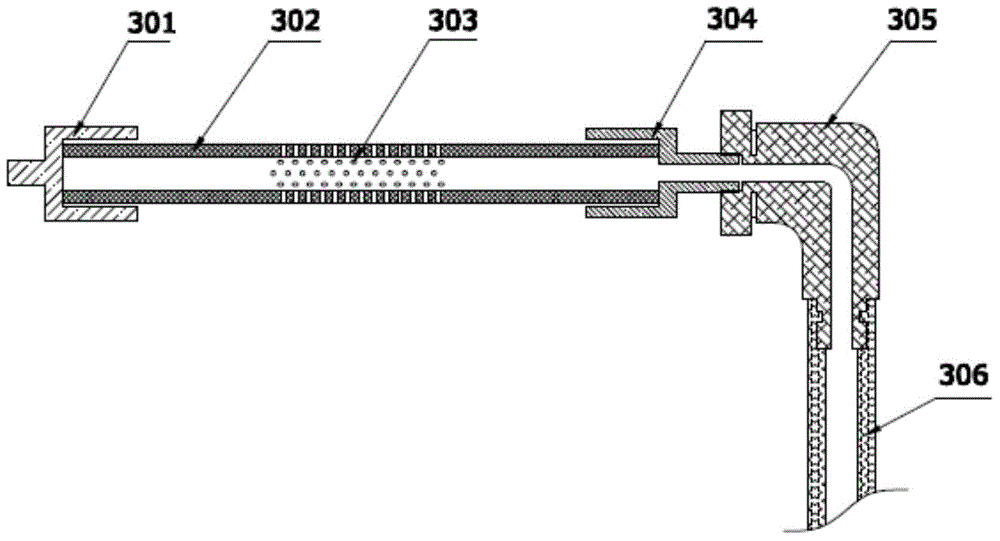

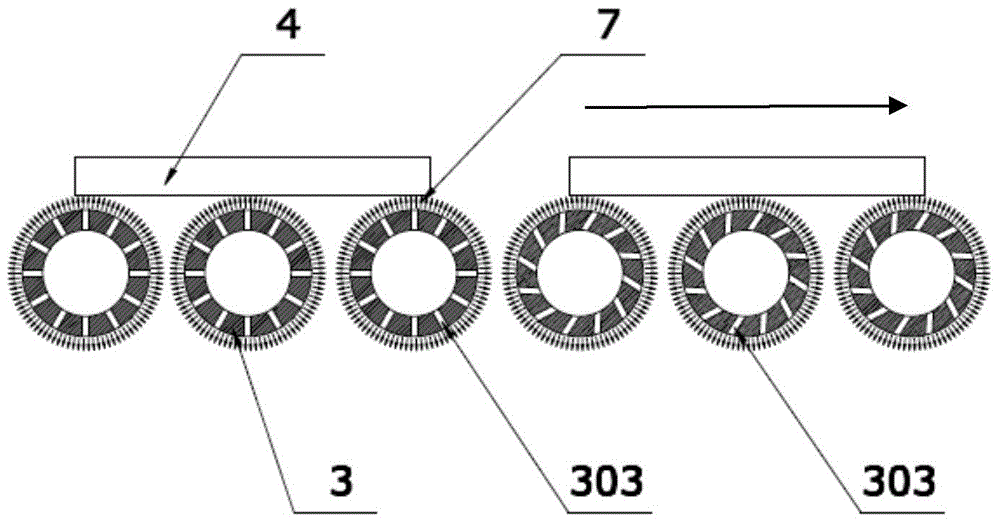

[0023] Such as figure 1 As shown, the present invention discloses an air flotation roller type semiconductor device heat treatment furnace, which is composed of basic units such as an upper furnace body 1, a lower furnace body 2, a transmission roller shaft 3, a heating lamp tube 5, and a cooling fan 6. figure 2 The structure of its vented hollow roller shaft 302 is disclosed. As shown in the figure, the roller table for transporting semiconductor devices 4 is composed of several horizontally arranged rollers 3 that can reciprocate along their own axes. The rollers in the furnace are hollow rollers 302, on which the semiconductor devices 4 There are several ventilation holes 303 along the radial direction at the passing position, and a ventilation shaft head 304 is installed at one end of the hollow roller shaft 302. Clean compressed air or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com