Patents

Literature

56results about How to "Stable transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

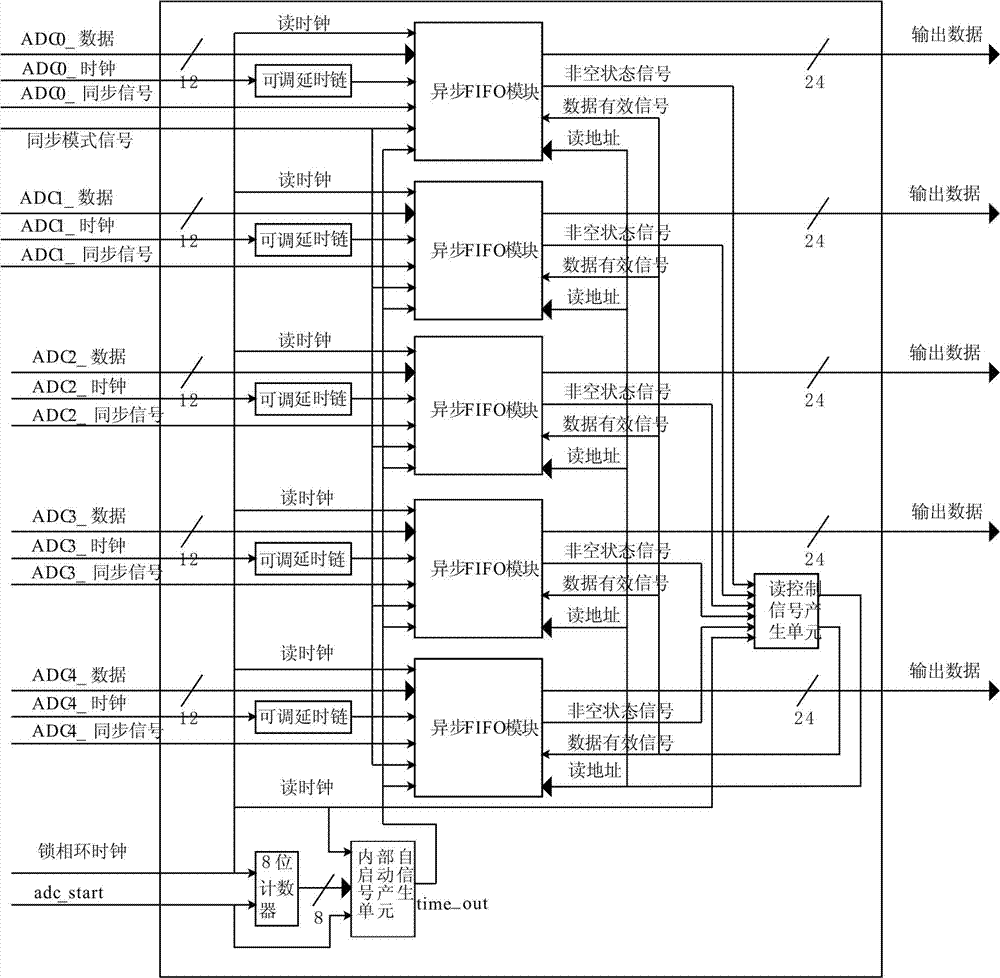

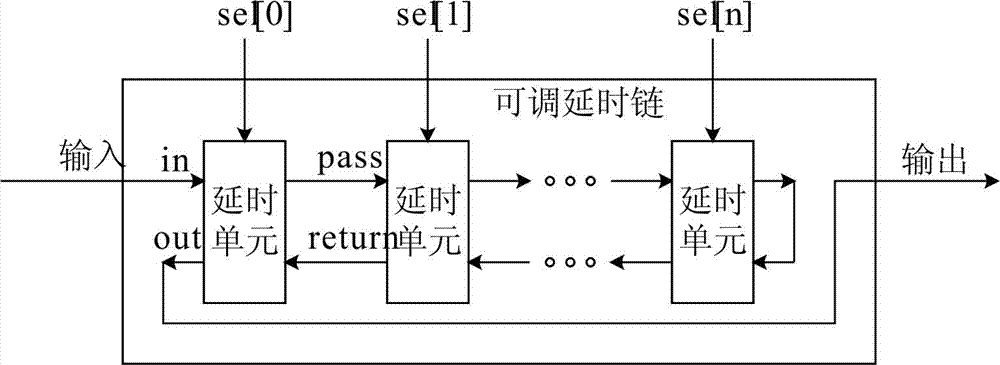

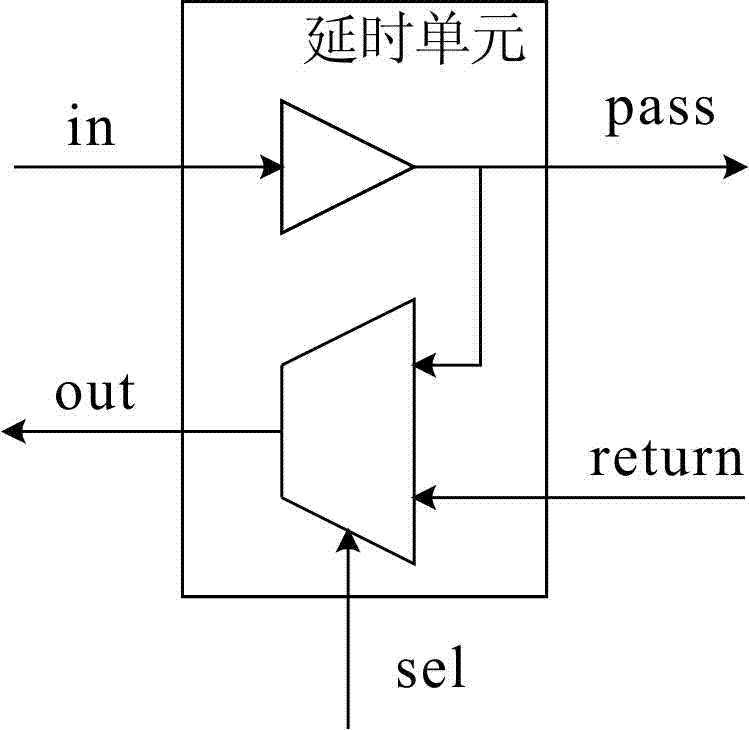

High-speed signal sampling and synchronizing framework and method applied to signal processing chip

ActiveCN102931994AAchieve stabilityStable transmissionAnalogue/digital conversionElectric signal transmission systemsSynchronismStart signal

The invention discloses a high-speed signal sampling and synchronizing framework applied to a signal processing chip. The framework is characterized by comprising an adjustable delay chain module, an asynchronous FIFO (First In and First Out) module connected with the adjustable delay chain module, a read control signal generating unit connected with the asynchronous FIFO module, a first counter used for receiving a starting signal and starting to count, and an internal self-starting signal generating unit connected with the first counter, wherein the internal self-starting signal generating unit is connected with the asynchronous FIFO module. The framework can be used for finishing the adjustable delay processing on ADC (Analog to Digital Conversion) clock signals, performing the asynchronous writing and the synchronous reading by the asynchronous FIFO module, and realizing the stability of signal-path signal sampling and the synchronism among multiple paths of signals, so that high-speed signals can be transmitted stably and reliably.

Owner:CHENGDU GANIDE TECH

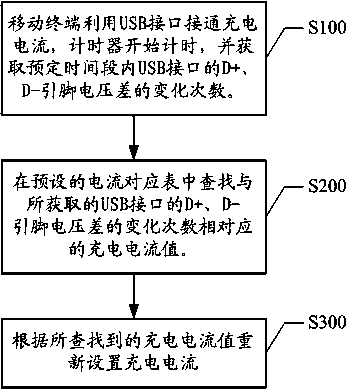

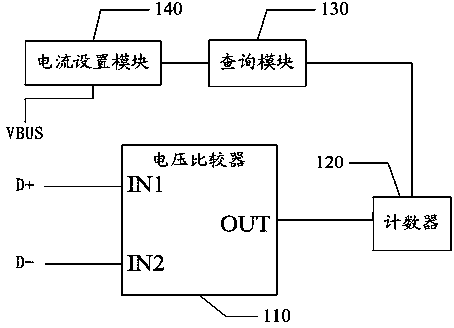

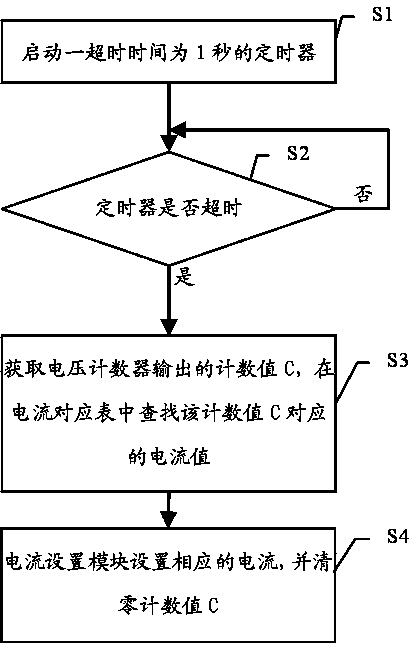

Method and system for setting charging current in USB data transmission of mobile terminal

ActiveCN104167789AAvoid Data Transfer FailuresStable transmissionBatteries circuit arrangementsSecondary cells charging/dischargingData transmissionTransfer procedure

The invention discloses a method and system for setting the charging current in USB data transmission of a mobile terminal. The method includes the following steps that first, the mobile terminal is connected with the charging current through a USB interface, and the number of changes of difference between the voltage of a D+ pin and the voltage of a D- pin of the USB interface in a preset period of time is acquired; second, a charging current value corresponding to the acquired number of changes of difference between the voltage of the D+ pin and the voltage of the D- pin of the USB interface is searched for in a preset current corresponding table; third, the charging current is reset according to the found charging current value. According to the method and system, by acquiring the number of changes of difference between the voltages of the USB pins in the data transmission process, the charging current in the data transmission process is adjusted according to the preset current corresponding table, so that the problem that when the mobile terminal performs USB data transmission, data transmission fails because of unstable voltage is avoided, and stable data transmission is guaranteed while the mobile terminal is charged through the USB.

Owner:威海区域创新中心有限责任公司

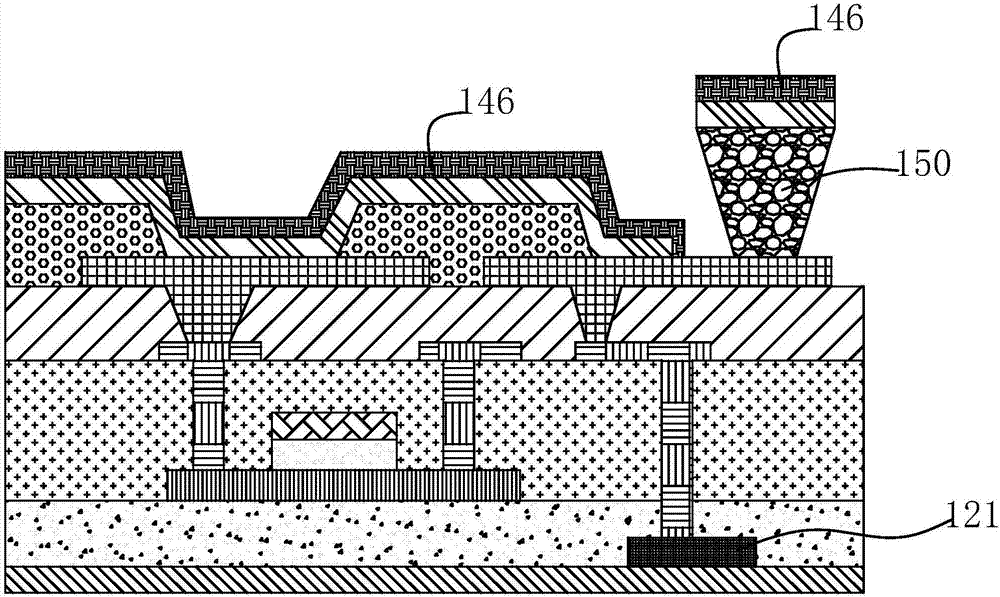

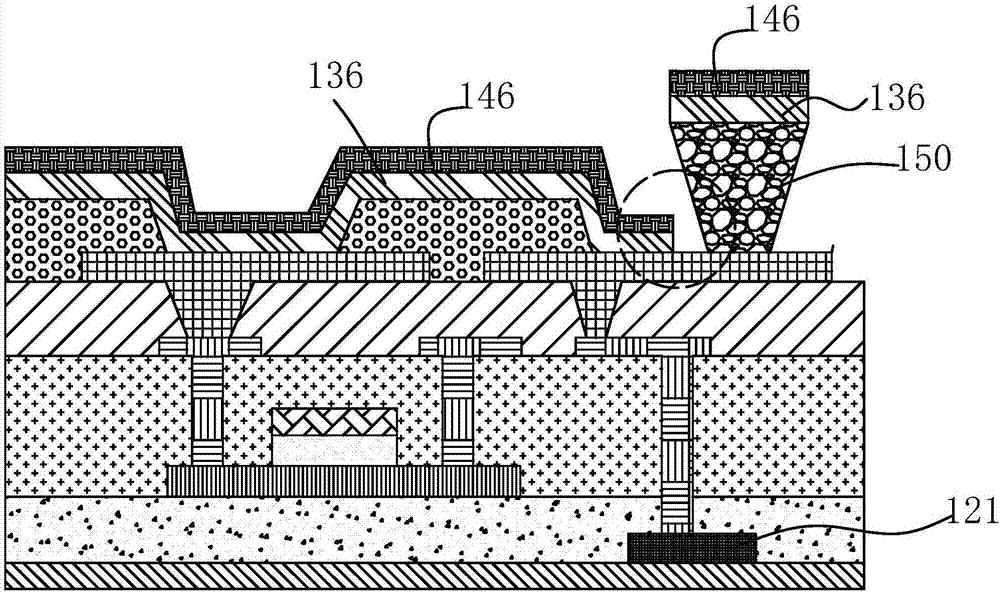

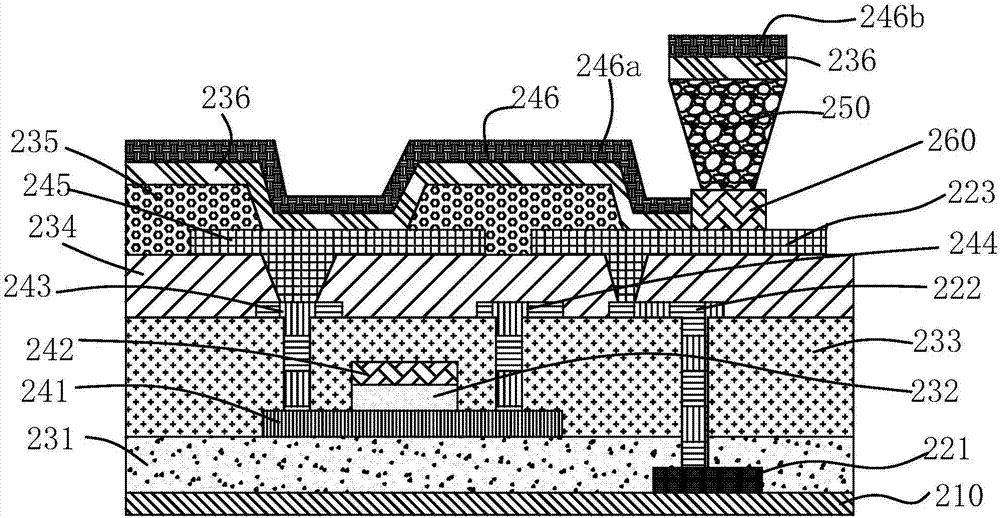

OLED display panel and manufacturing method thereof

ActiveCN108010943AStable transmissionSmooth transmissionSolid-state devicesSemiconductor/solid-state device manufacturingAuxiliary electrodeVoltage

The embodiment of the invention discloses an OLED display panel, which comprises a first substrate, a flat layer, an auxiliary electrode, an anode, a pixel definition layer, a cathode isolation column, an organic light-emitting layer, a cathode and an electrode table, wherein the flat layer is formed on the first substrate; the auxiliary electrode is formed on the first substrate; the anode is formed on the flat layer; the cathode is formed on the organic light-emitting layer and comprises a light-emitting cathode and an isolation cathode; the light-emitting cathode is located on the pixel definition layer and a pixel region; the isolation cathode is located on the cathode isolation column; the light-emitting cathode is separated from the isolation cathode through the cathode isolation column; the electrode table is electrically connected with the auxiliary electrode directly or indirectly; the cathode isolation column is formed on the electrode table; and the electrode table is electrically connected with the light-emitting cathode for the light-emitting cathode to receive voltage on the auxiliary electrode. The embodiment of the invention further discloses a manufacturing methodof the OLED display panel. The OLED display panel has the advantage that the cathode is electrically connected with the auxiliary electrode stably.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

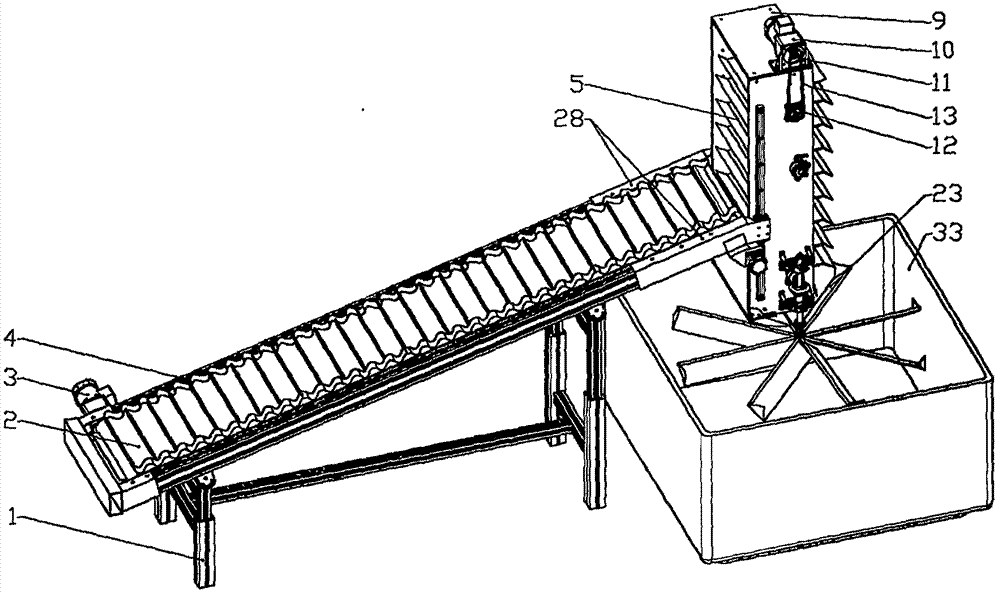

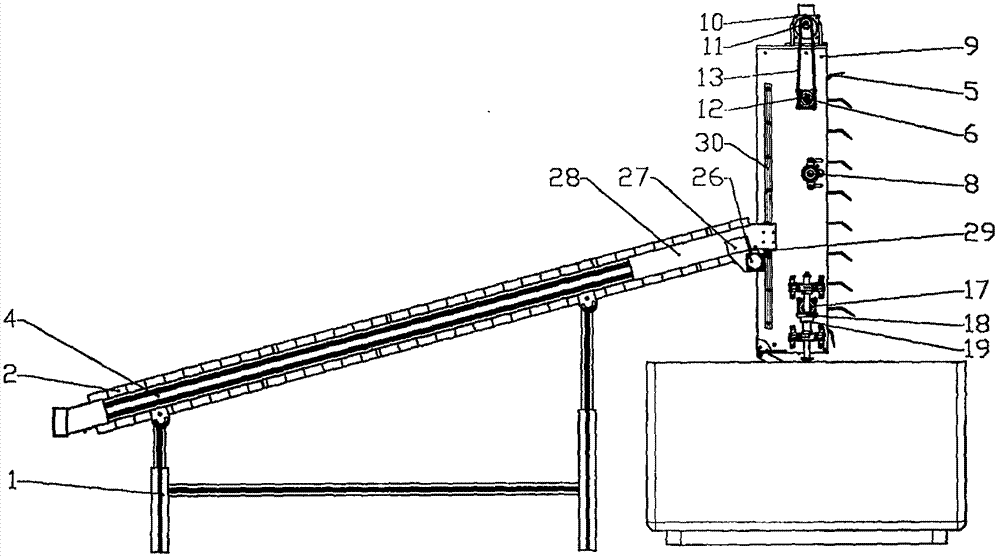

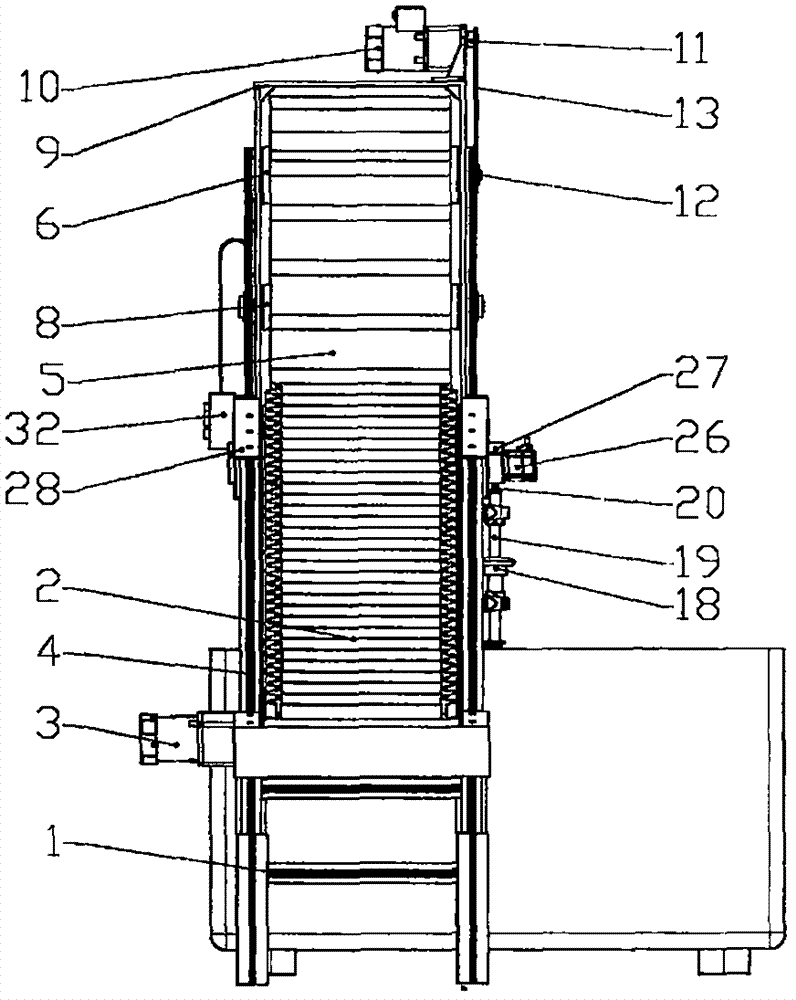

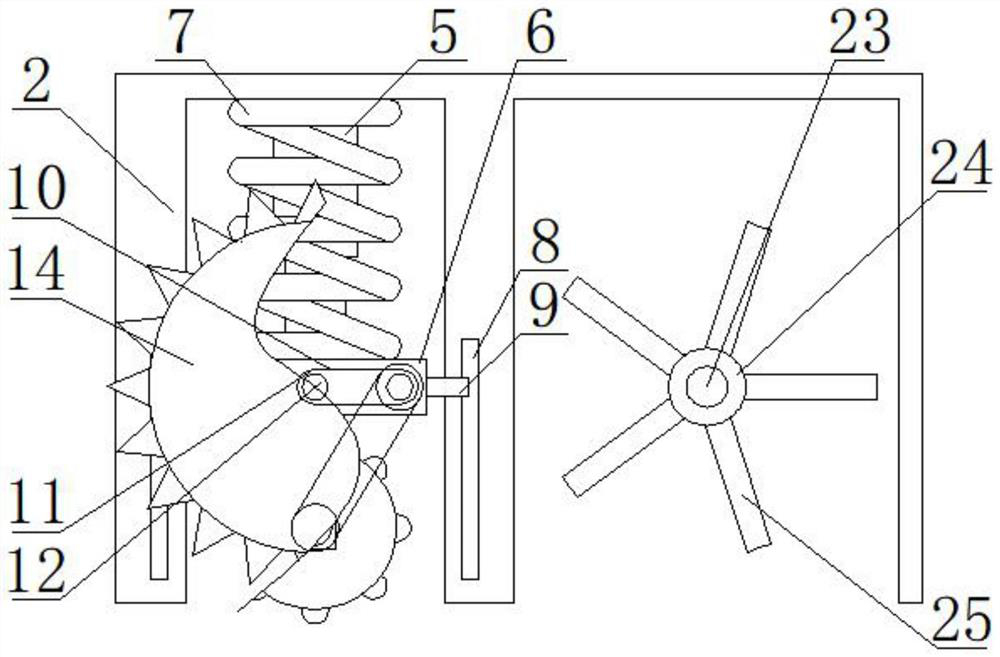

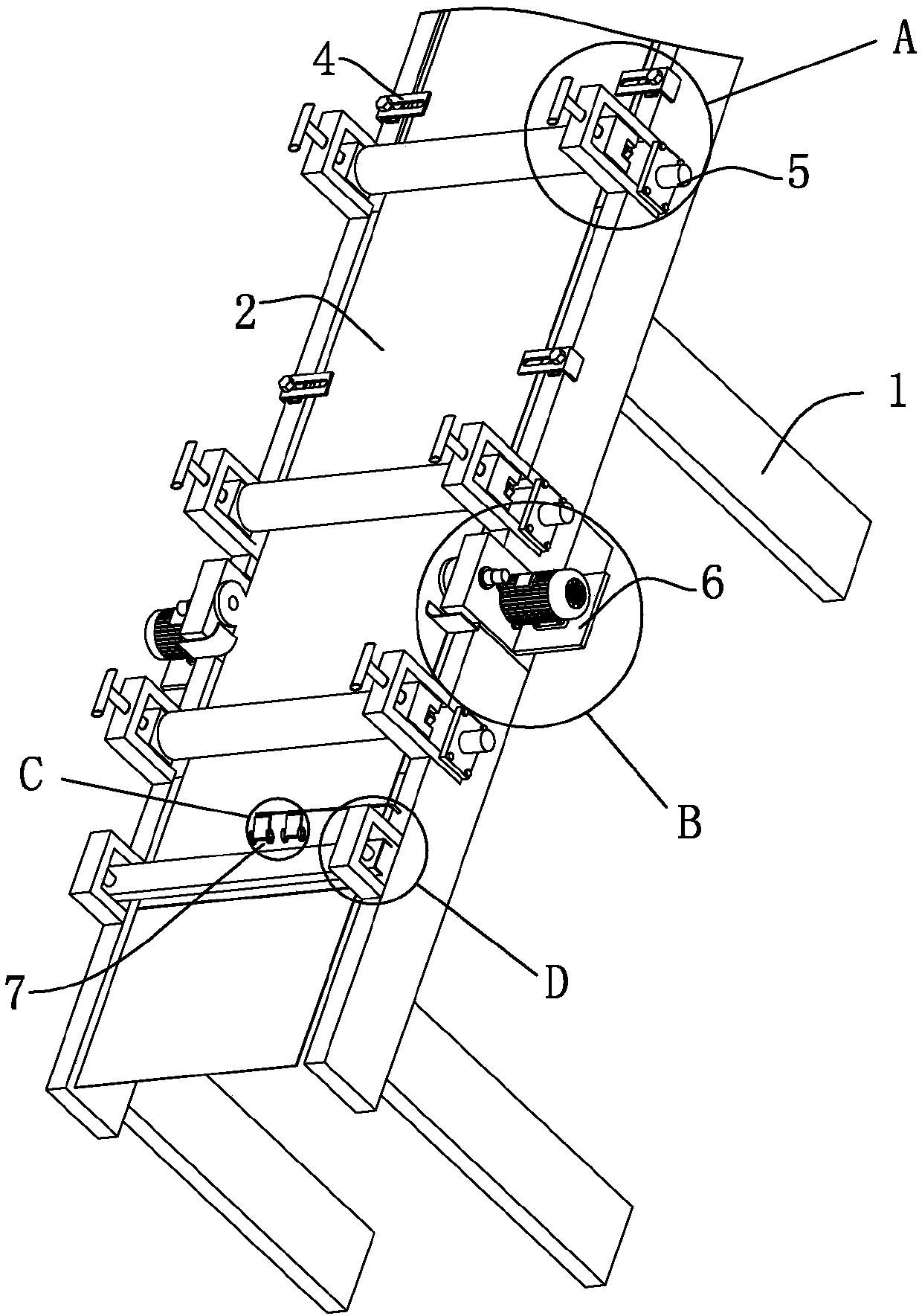

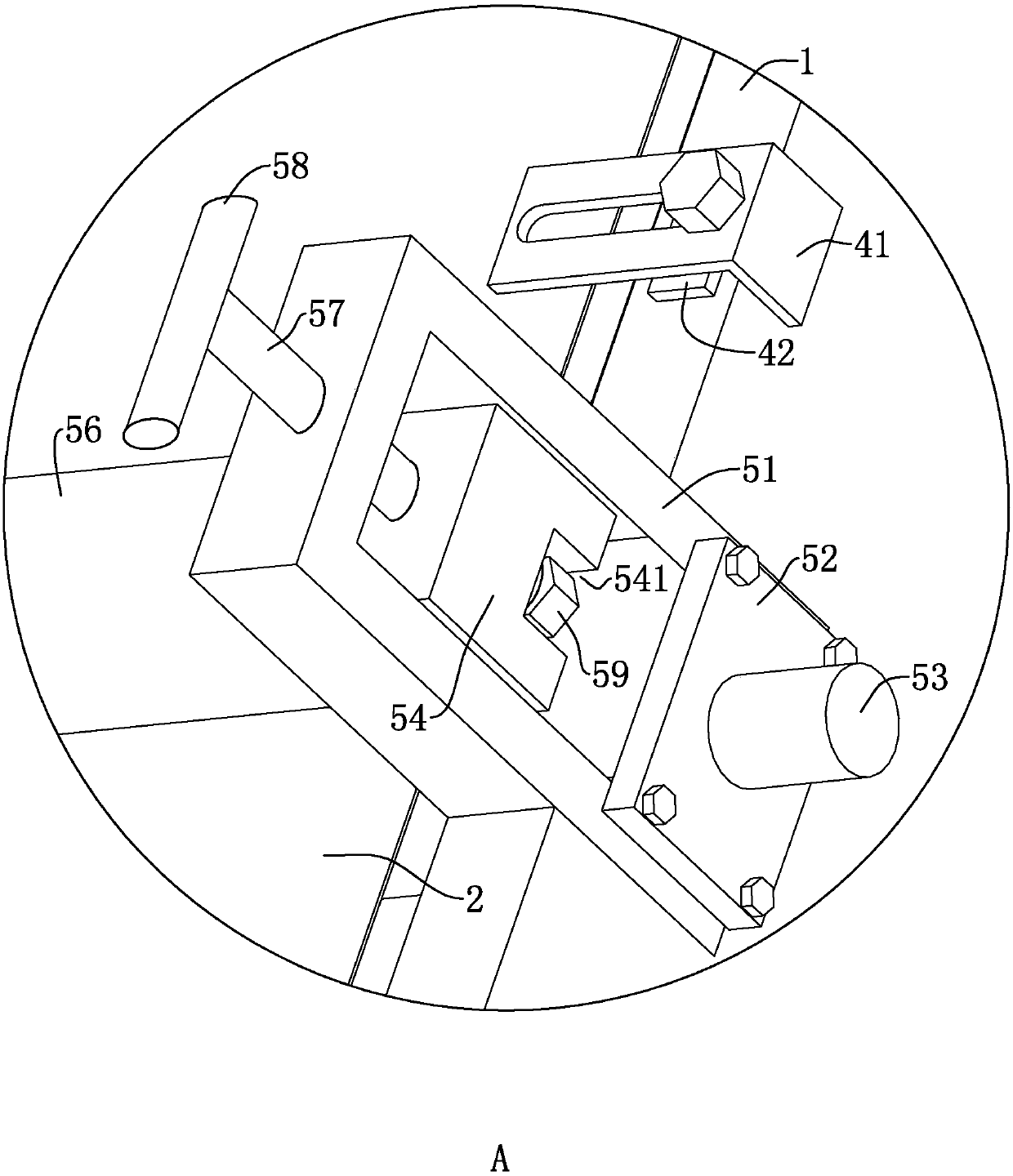

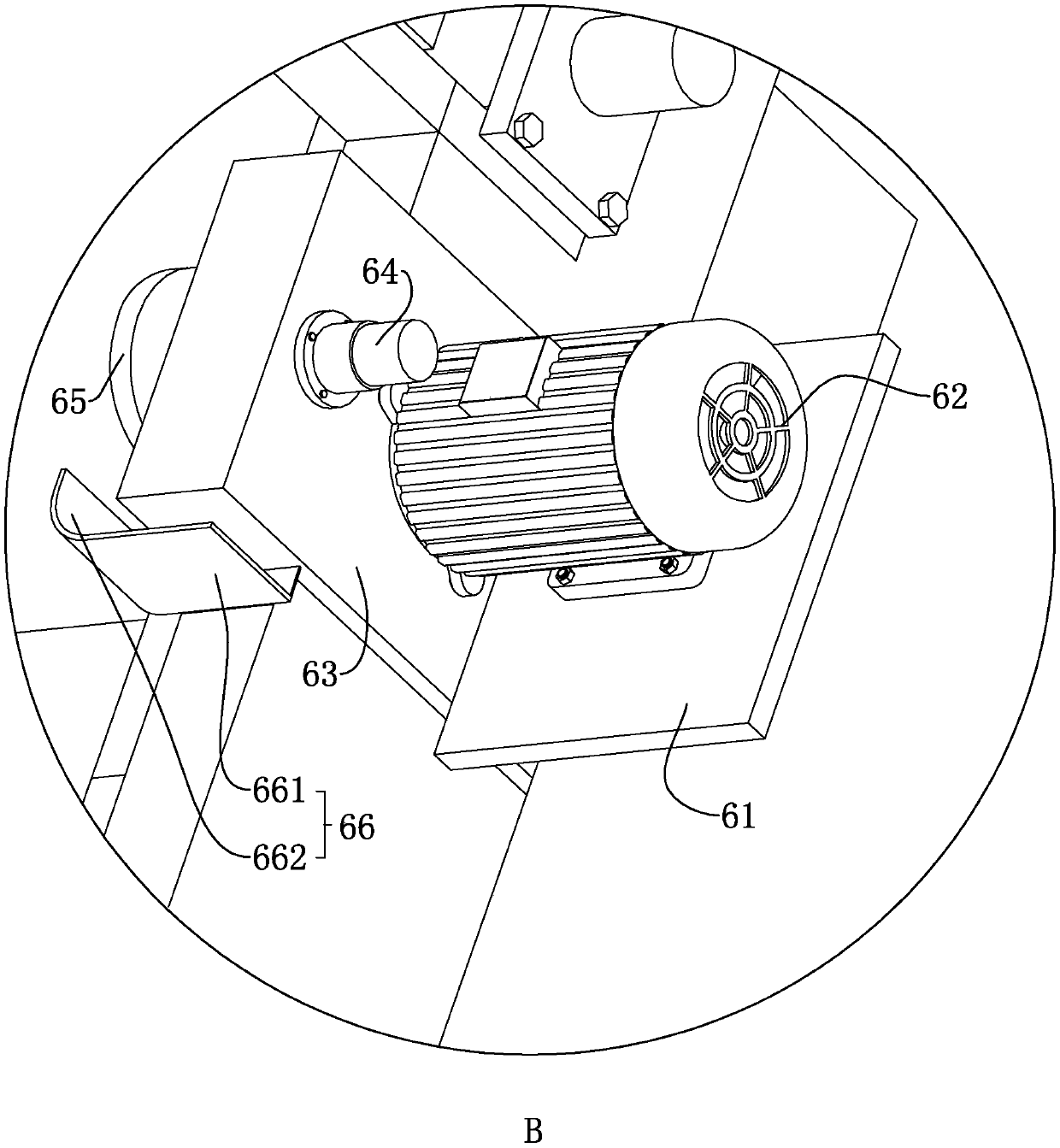

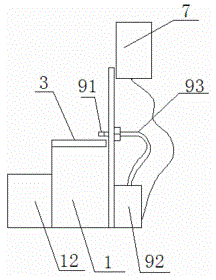

Fruit boxing device

InactiveCN107416264AStable transmissionAvoid violent collisionsPackaging automatic controlPackaging fruits/vegetablesEngineeringControl system

The invention discloses a fruit boxing device which mainly comprises a supporting frame, a main conveying mechanism, a vertical conveying mechanism, a rotating mechanism, a lifting mechanism and a fruit box. The supporting frame achieves a supporting effect, the main conveying mechanism is fixed to the supporting frame and conveys fruits to the boxing device, the vertical conveying mechanism is installed at the tail end of the main conveying mechanism, the rotating mechanism is installed on the side face of the vertical conveying mechanism, the lifting mechanism is installed on the main conveying mechanism and the vertical conveying mechanism, and the fruit box is placed under the rotating mechanism. The fruit boxing device is characterized in that with the fruit boxing process carried out, the fruit stacking height is changed, the vertical conveying mechanism can be lifted by the certain height under the effect of a control system and the lifting mechanism, fruit boxing continuity is ensured, violent collision is prevented from being caused when fruits are conveyed into the box, and the purposes that the boxing efficiency is improved and the fruit damage rate is lowered are achieved.

Owner:NORTHWEST A & F UNIV

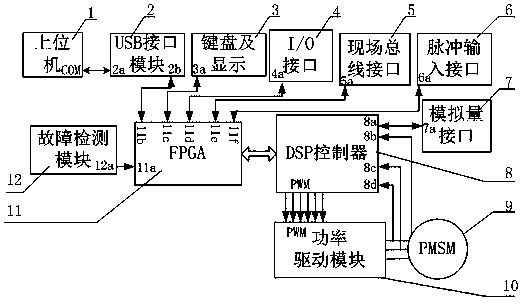

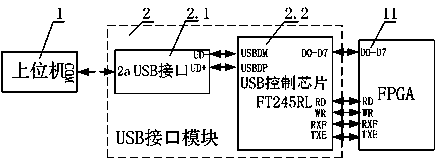

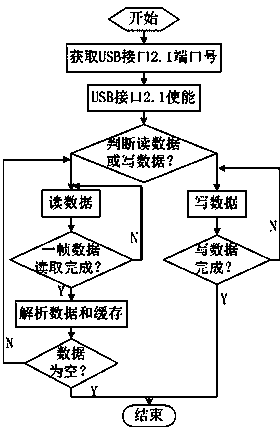

Servosystem high-speed data interactive communication unit based on USB

InactiveCN104238420AIncrease transfer rateStable transmissionProgramme controlComputer controlTransmission ratePermanent magnet synchronous motor

The invention relates to a servosystem high-speed data interactive communication unit based on a USB. According to the technical scheme, the COM end of an upper computer (1) is connected with the input and output end 2a of a USB interface module (2); the data end and the control end 2b of the USB interface module (2) are connected with the data end and the control end 11b of an FPGA (11) respectively; a data bus and an address bus of the FPGA (11) are correspondingly connected with a data bus and an address bus of a DSP controller (8); the PWM output end of the DSP controller (8) is connected with the PWM input end of a power drive module (10); two current feedback ends of a permanent magnet synchronous motor (9) are correspondingly connected with the input end 8c and the input end 8d of the DSP controller (8); the position feedback end of the permanent magnet synchronous motor (9) is connected with the input end 8b of the DSP controller (8); the output end of the power drive module (10) is connected with the input ends of the permanent magnet synchronous motor (9). The servosystem high-speed data interactive communication unit based on the USB has the advantages of being simple in structure, high in transmission rate, stable in transmission and convenient to use.

Owner:WUHAN UNIV OF SCI & TECH

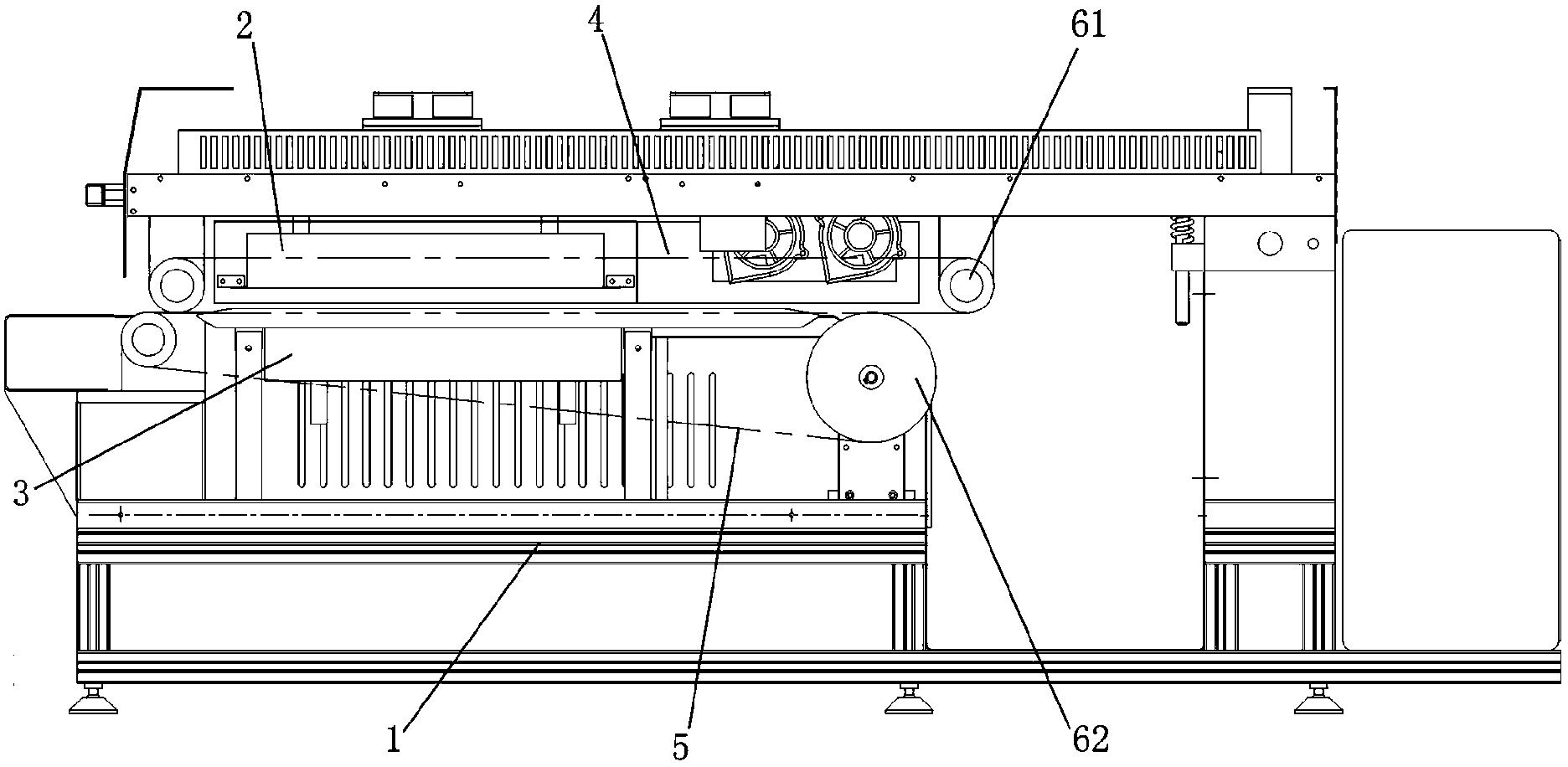

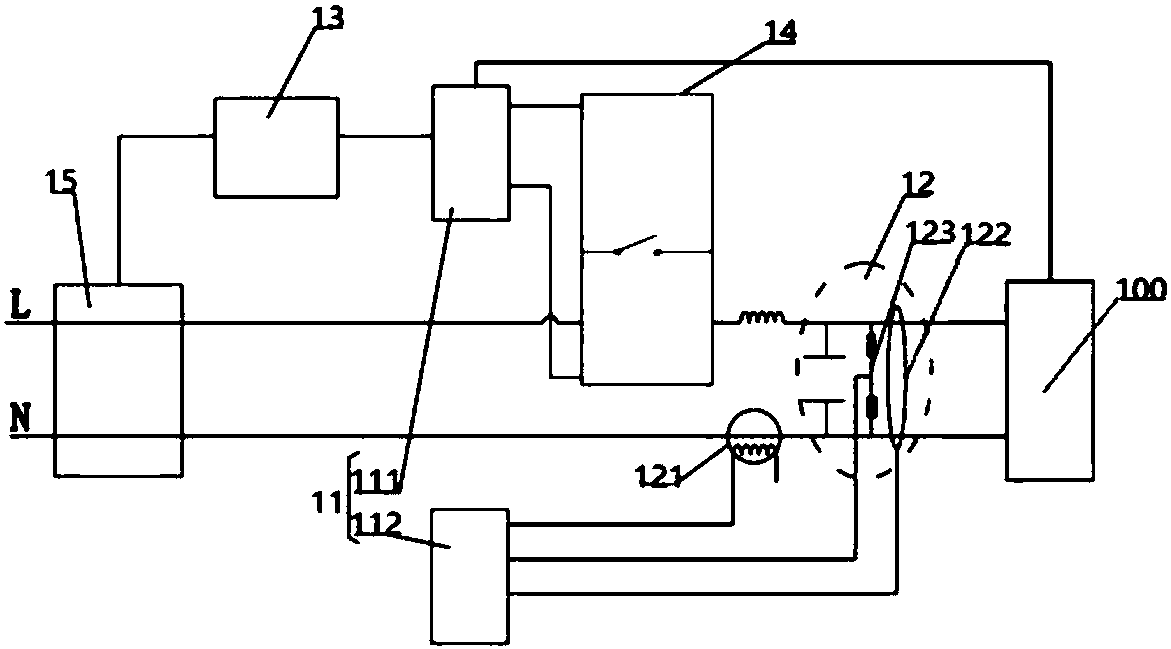

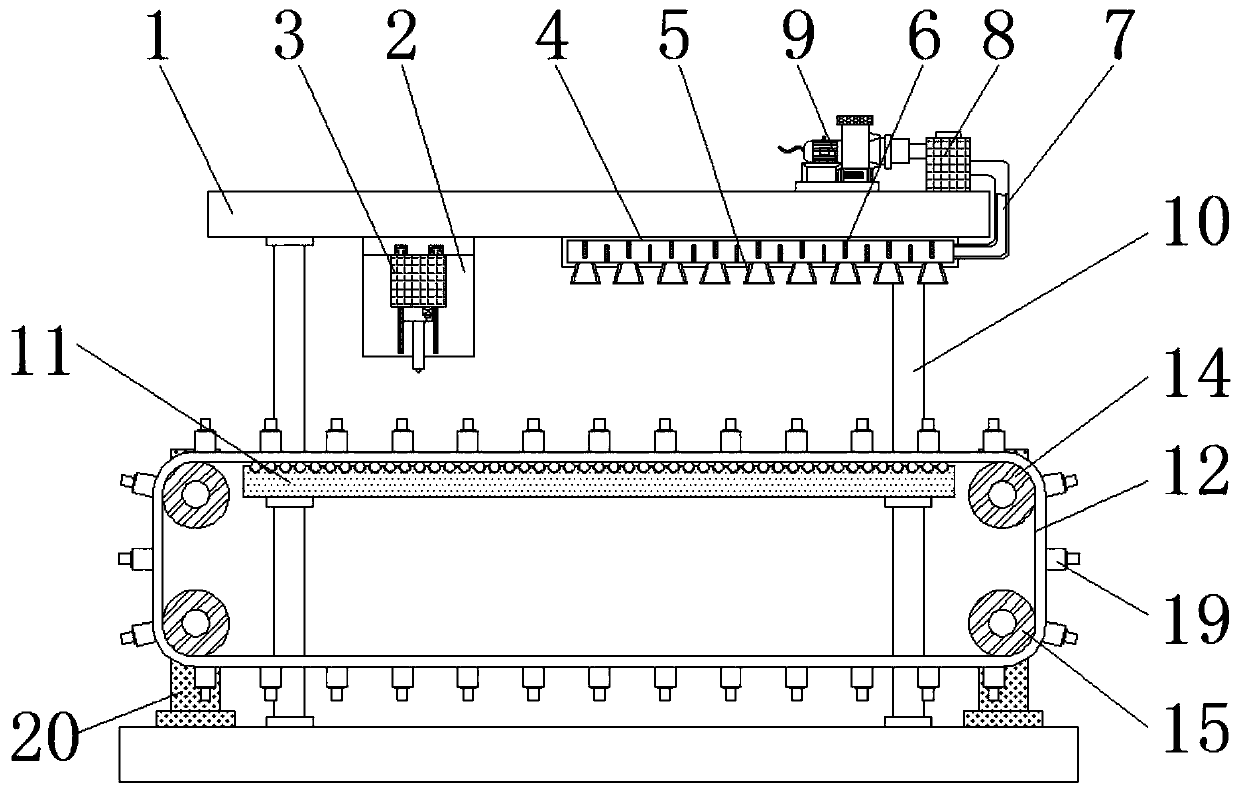

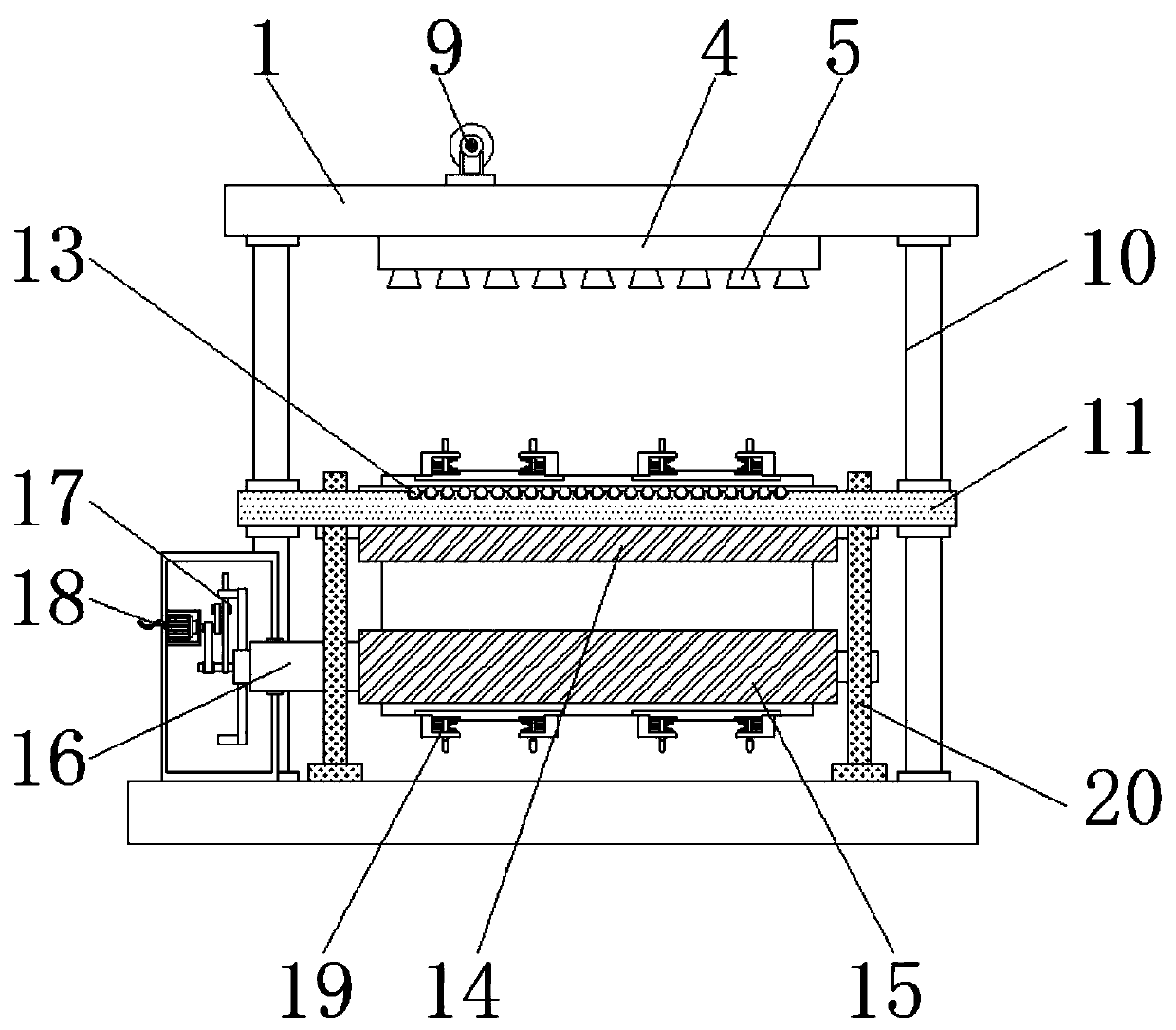

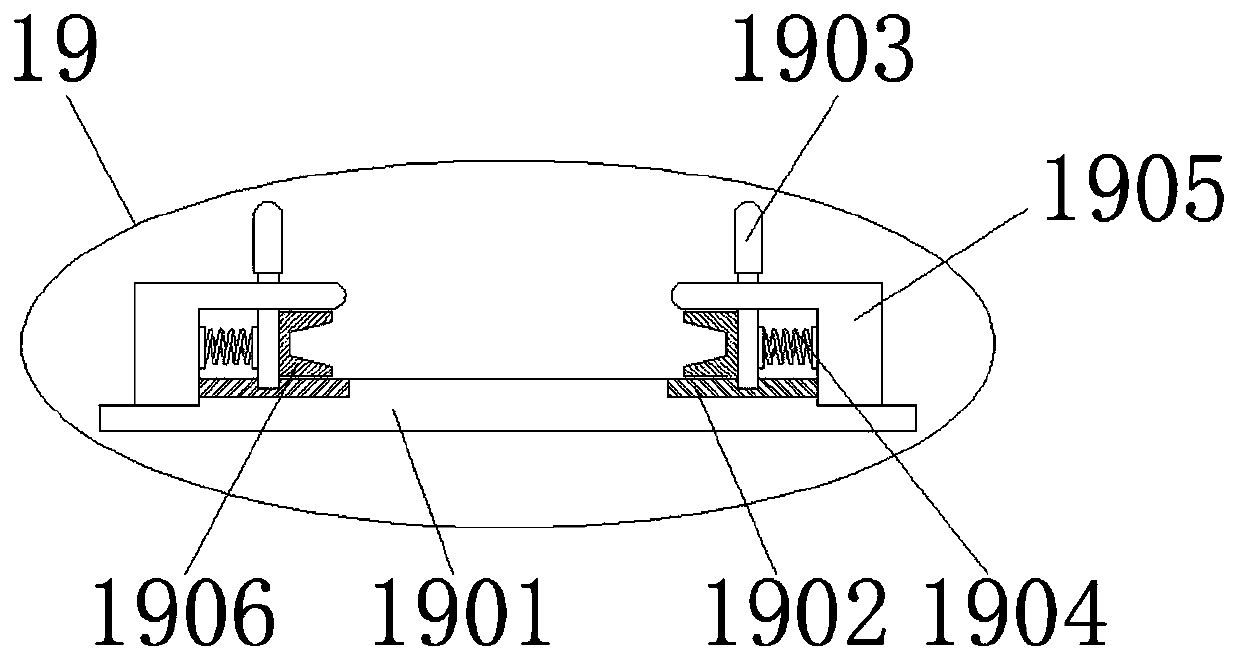

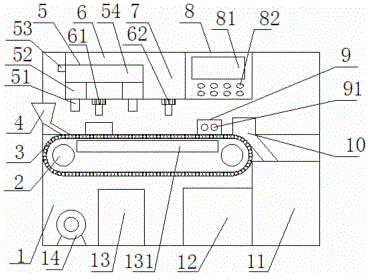

Double-driven crawler type heat shrinkable tube heater

The invention discloses a double-driven crawler type heat shrinkable tube heater comprising a frame, an upper heating module, a lower heating module, upper synchronous conveyor belts and lower synchronous conveyor belts, wherein the upper heating module and the lower heating module are arranged inside the frame; the upper heating module and the lower heating module are oppositely folded up and down; a heating cavity is arranged between the two heating modules; the upper synchronous conveyor belts are arranged at two sides of the upper heating module; the lower synchronous conveyor belts are arranged at two sides of the lower heating module; and the double-driven crawler heat shrinkable tube heater also comprises an electric control device. A heat shrinkable tube is clamped and conveyed by two groups of electric and mechanical combined synchronous conveyor belts via the heating cavity; the upper and lower synchronous conveyor belts are electrically controlled to move actively and independently; deadlock of purely mechanical linkage and mechanism damage caused by the deadlock are avoided; and step failing out is dynamically finely adjusted by the characteristics of meshing of the upper and lower synchronous conveyor belts and slipping of a single-tooth synchronous belt. The double-driven crawler heat shrinkable tube heater is simple and reliable, and can achieve stable delivery of large-size and large-batch heat shrinkable tubes.

Owner:如冈自动化控制技术(上海)有限公司

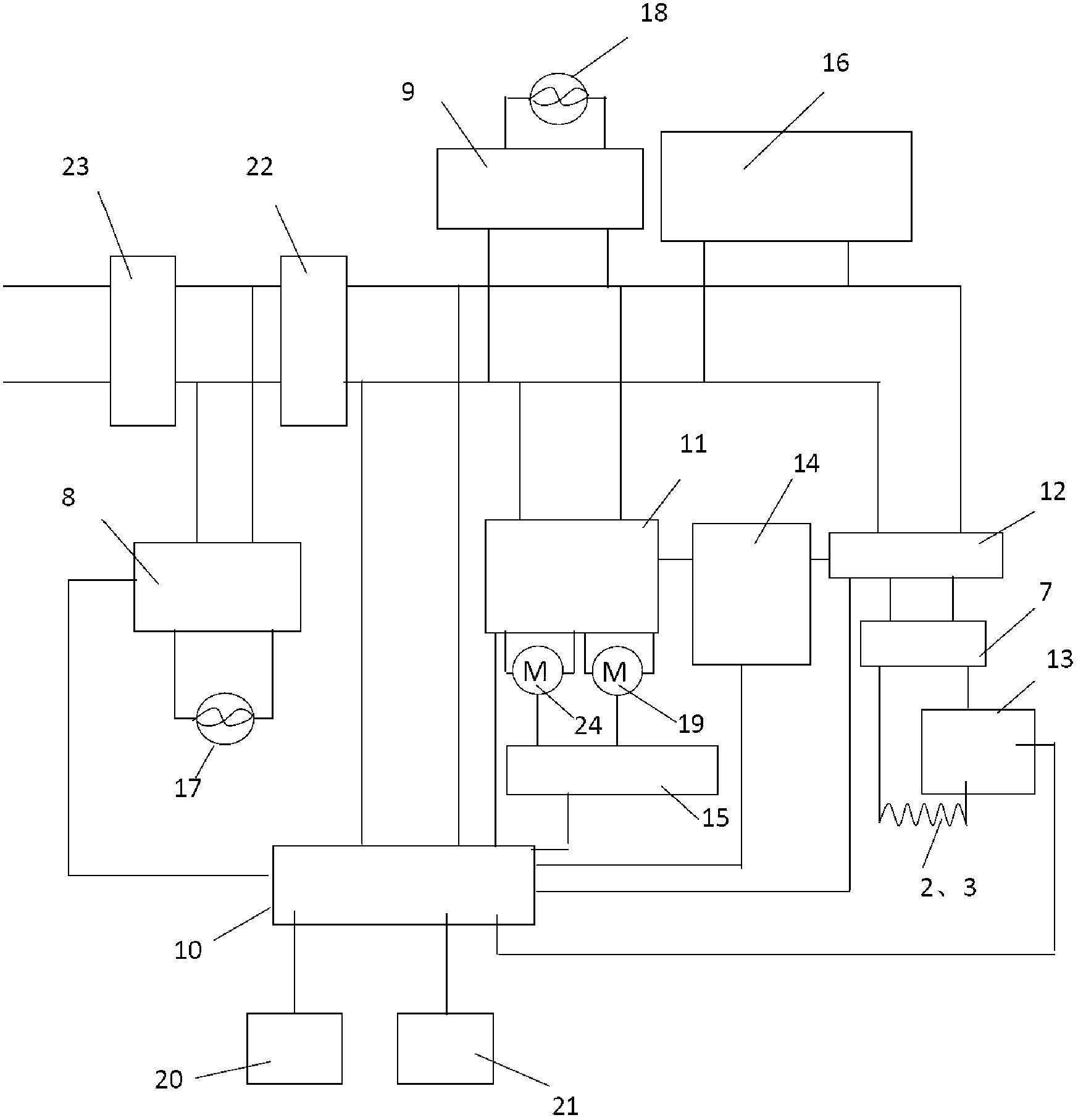

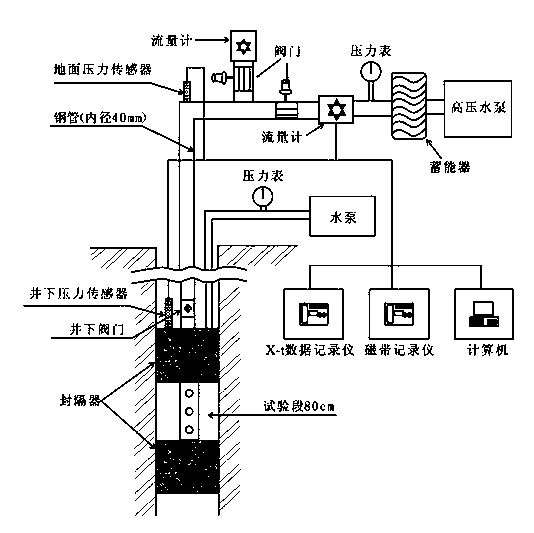

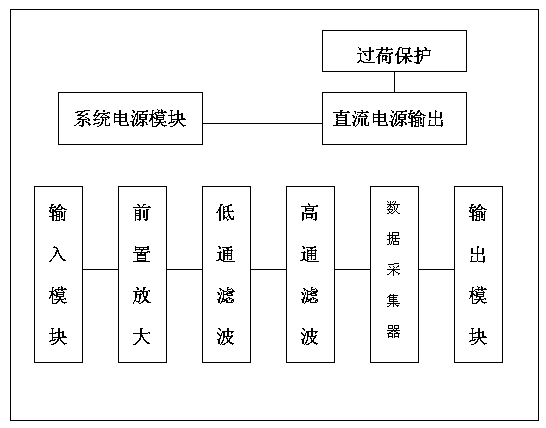

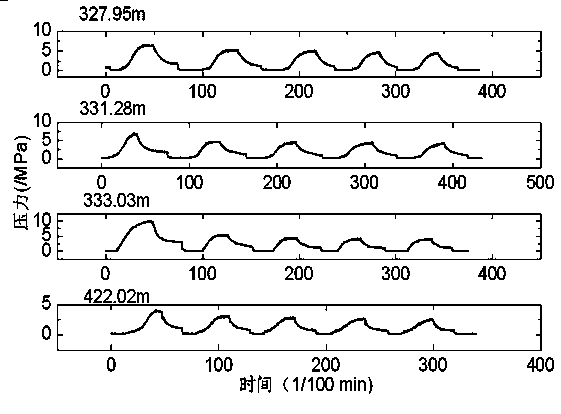

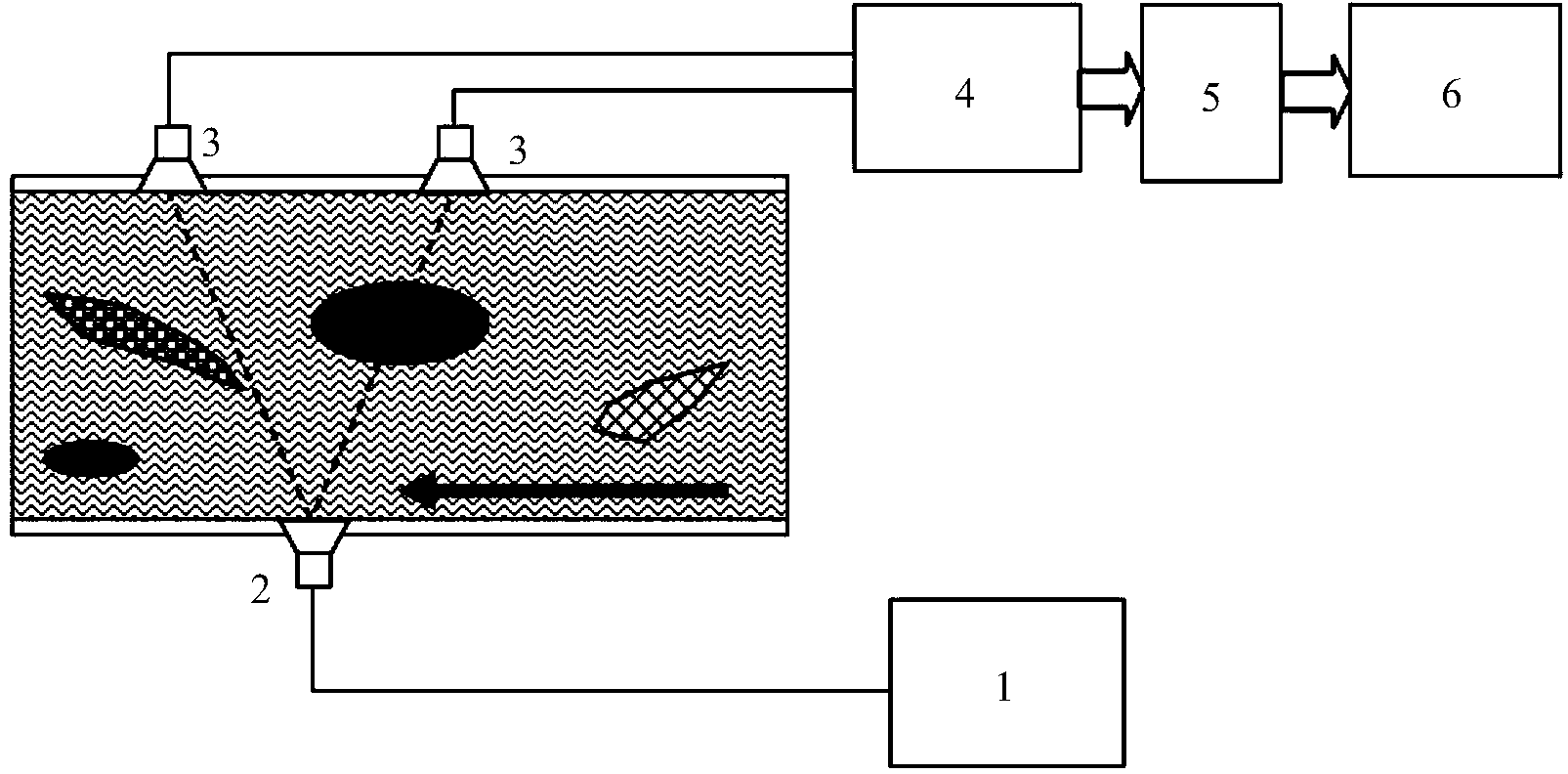

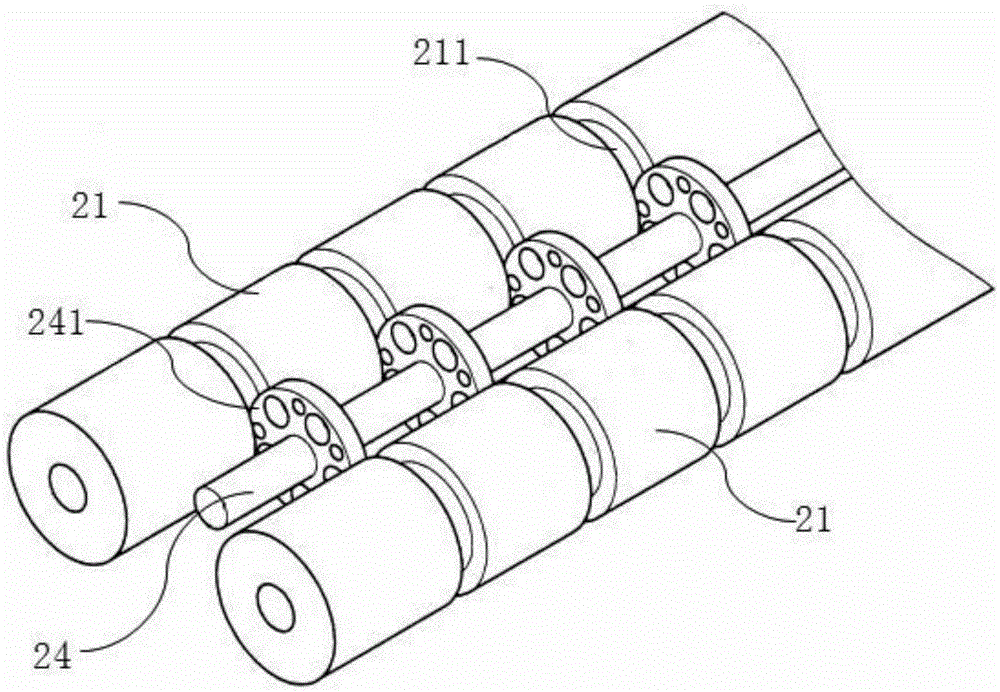

System for collecting in-situ stress measurement data by using hydraulic fracturing

ActiveCN103527180AStable transmissionThe recording curve has little noiseSurveyFluid removalCollections dataGeophysics

The invention discloses a system for collecting in-situ stress measurement data by using hydraulic fracturing. Test section pressure data, packer monitoring pressure data and test section flow data can be simultaneously collected in the process of in-situ stress measurement by using the hydraulic fracturing, the collecting frequency of the system can reach 5-10Hz, and therefore smooth and steady transmission of data collection is achieved.

Owner:NAT INST OF NATURAL HAZARDS MINISTRY OF EMERGENCY MANAGEMENT OF CHINA

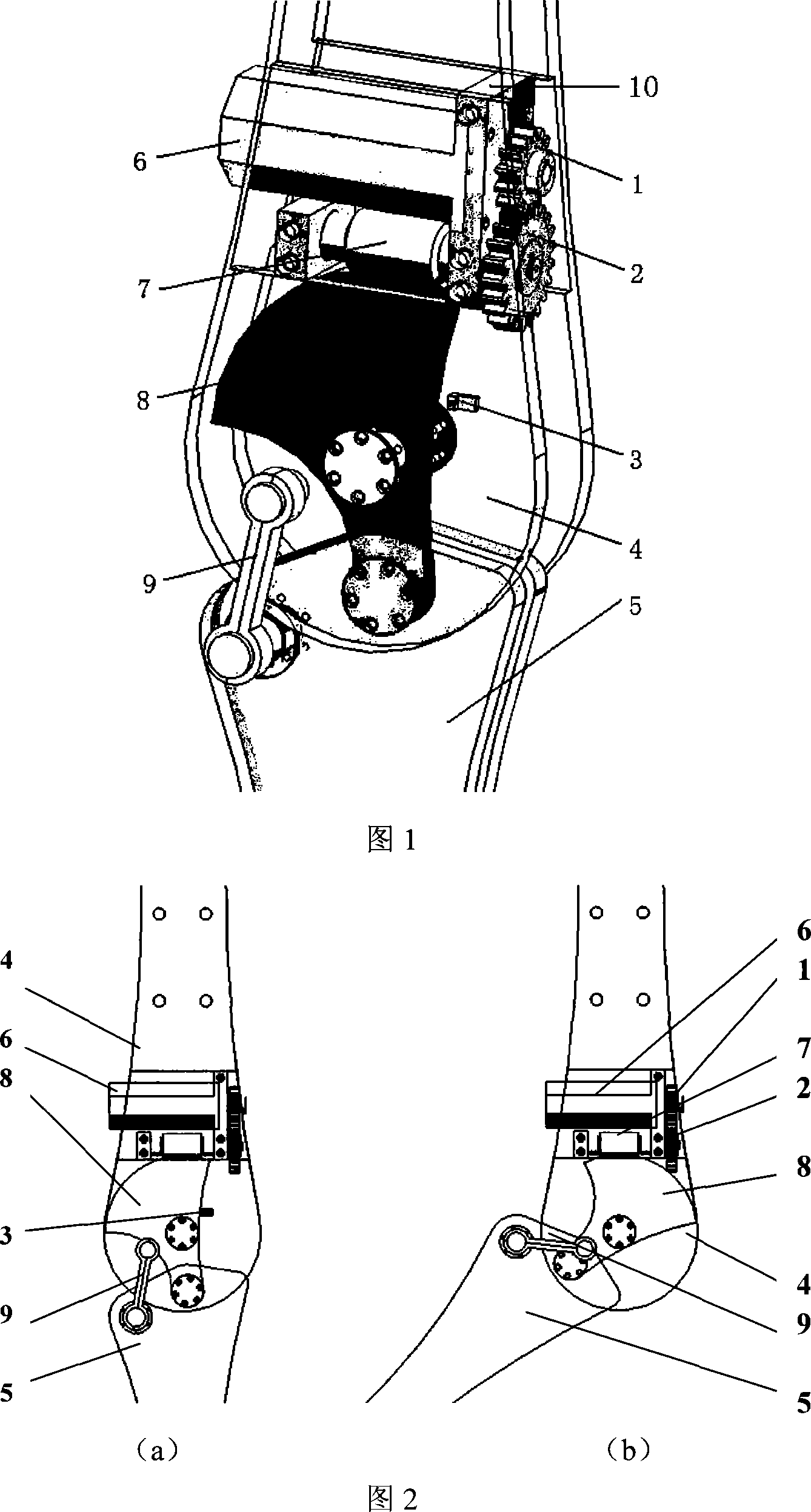

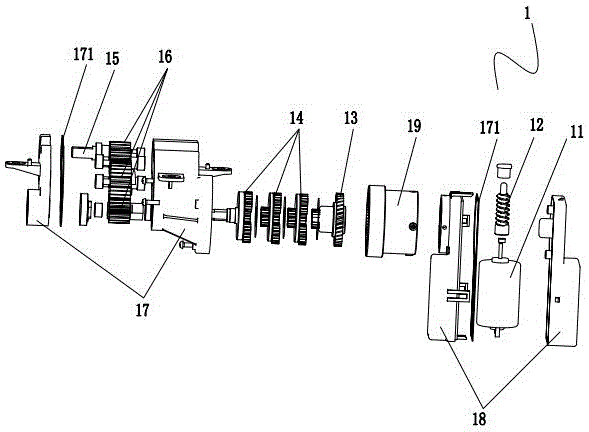

Artificial limb exoskeleton knee joint

InactiveCN101234044ACompact layoutStable transmissionChiropractic devicesWalking aidsKnee JointExoskeleton

The invention relates to an ectoskeleton knee joint of artificial limb, pertaining to a rehabilitation engineering technical field, which comprises a servo motor, a drive mechanism and a four-bar linkage. The four-bar linkage comprises a thigh ectoskeleton, a crus ectoskeleton, a back link and a worm wheel; the drive mechanism comprises a main drive gear, a driven gear and a worm; the thigh ectoskeleton consists of two plates (an inner plate and an outer plate) between which the servo motor is fixed; the main drive gear is fixedly connected with an output shaft of the servo motor and meshed with the driven gear; the driven gear is positioned on one shaft end of the worm; the worm is fixed between the two plates of the thigh ectoskeleton; the worm is meshed with the worm wheel; the other end of the worm wheel is connected with the crus ectoskeleton through a bearing; a rotation centre of the worm wheel is connected with the thigh ectoskeleton through a support shaft of the worm wheel; the back link is connected with the thigh ectoskeleton and a support shaft of the crus ectoskeleton. The ectoskeleton knee joint of artificial limb of the invention has compact structure and the whole drive system is completely positioned in interior sides of the crus ectoskeletons in two thighs, thus preventing suffers from the impact of mechanical structure.

Owner:SHANGHAI JIAO TONG UNIV

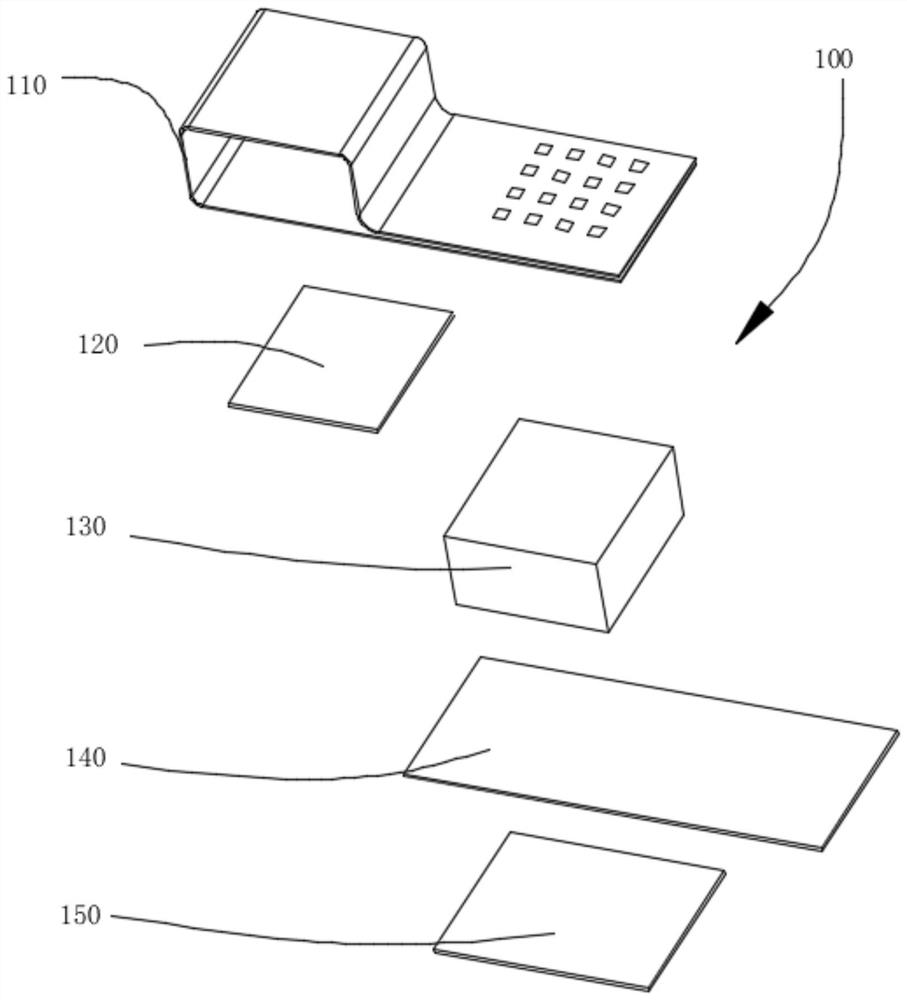

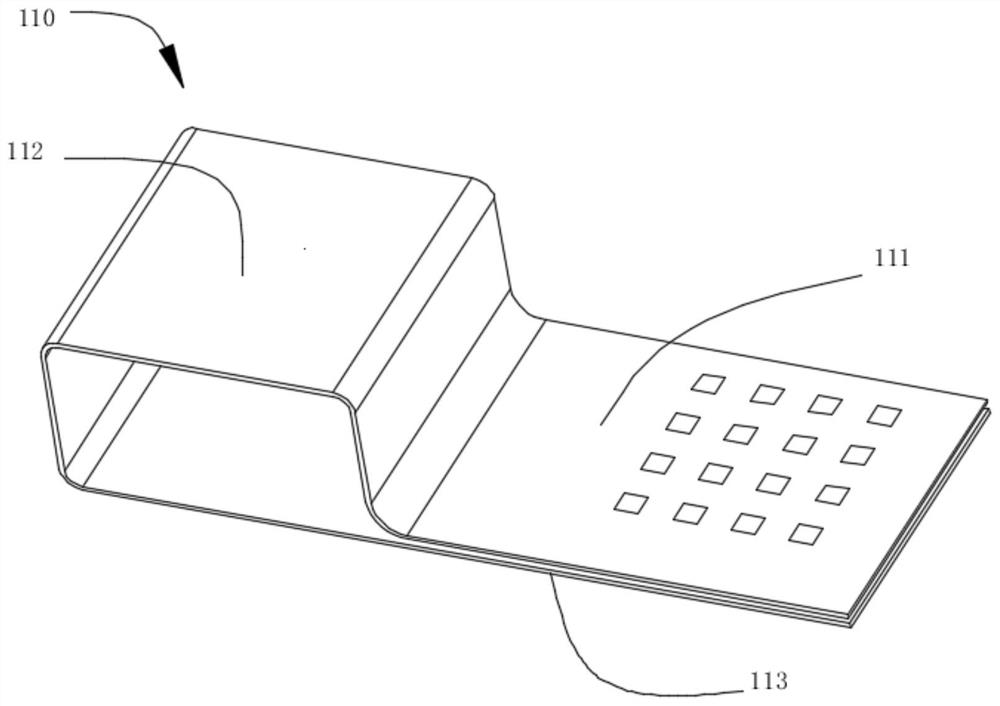

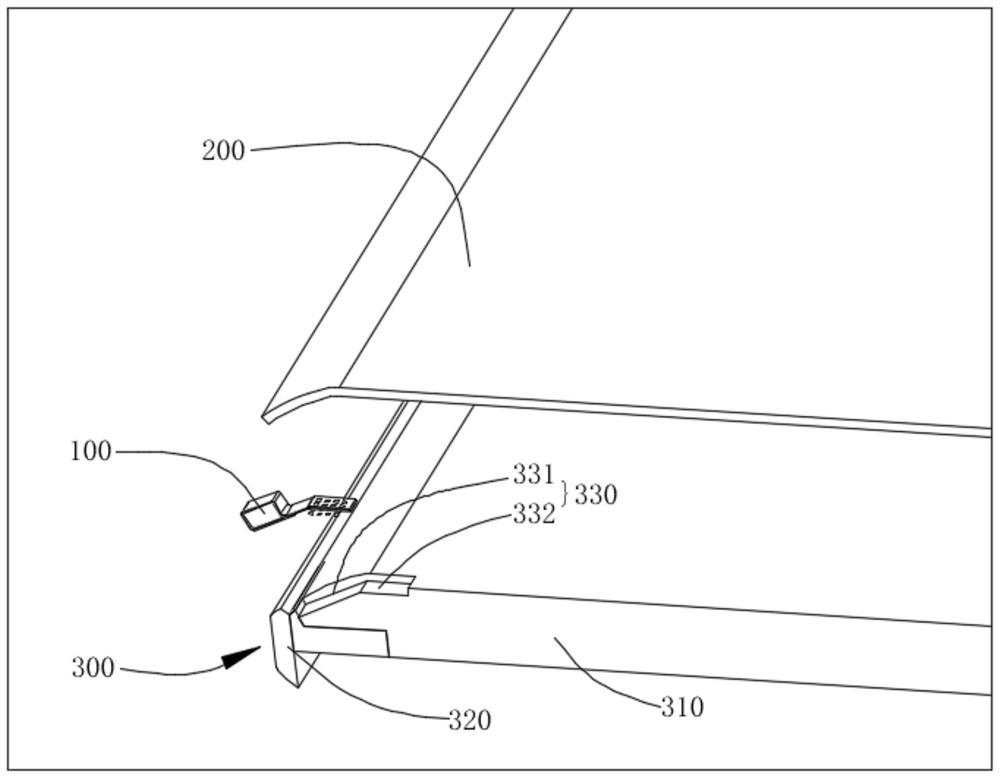

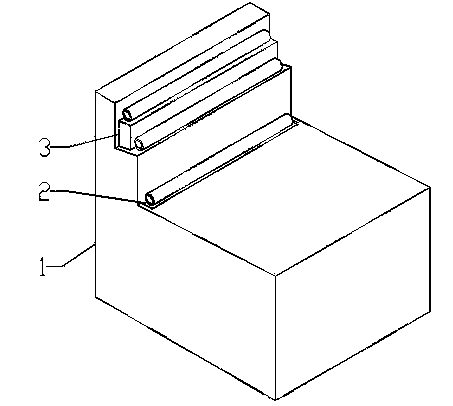

Electronic equipment and production method of elastic grounding assembly

ActiveCN112993606AGuaranteed stabilityStable transmissionContact member manufacturingCasings/cabinets/drawers detailsPhysicsElectrically conductive

The invention discloses electronic equipment which comprises a display screen, an equipment shell and an elastic grounding assembly. The display screen is arranged on the equipment shell, the elastic grounding assembly comprises an elastic body and a metal conductive sheet, the metal conductive sheet comprises a first section, a second section and a third section which are connected in sequence, the second section is bent to form a cylindrical structure part, the elastic body is arranged in the cylindrical structure part, the first section and the third section are overlapped with each other and are connected to one side of the cylindrical structure part, the cylindrical structure part is elastically supported between the display screen and the equipment shell, the equipment shell comprises a grounding area, and the first section and the third section are electrically connected with the grounding area so that two mutually independent conductive paths are formed. In order to ensure the stability of the grounding conductive process and further ensure the effective transmission of signals, the invention also discloses a production method of the elastic grounding assembly.

Owner:VIVO MOBILE COMM CO LTD

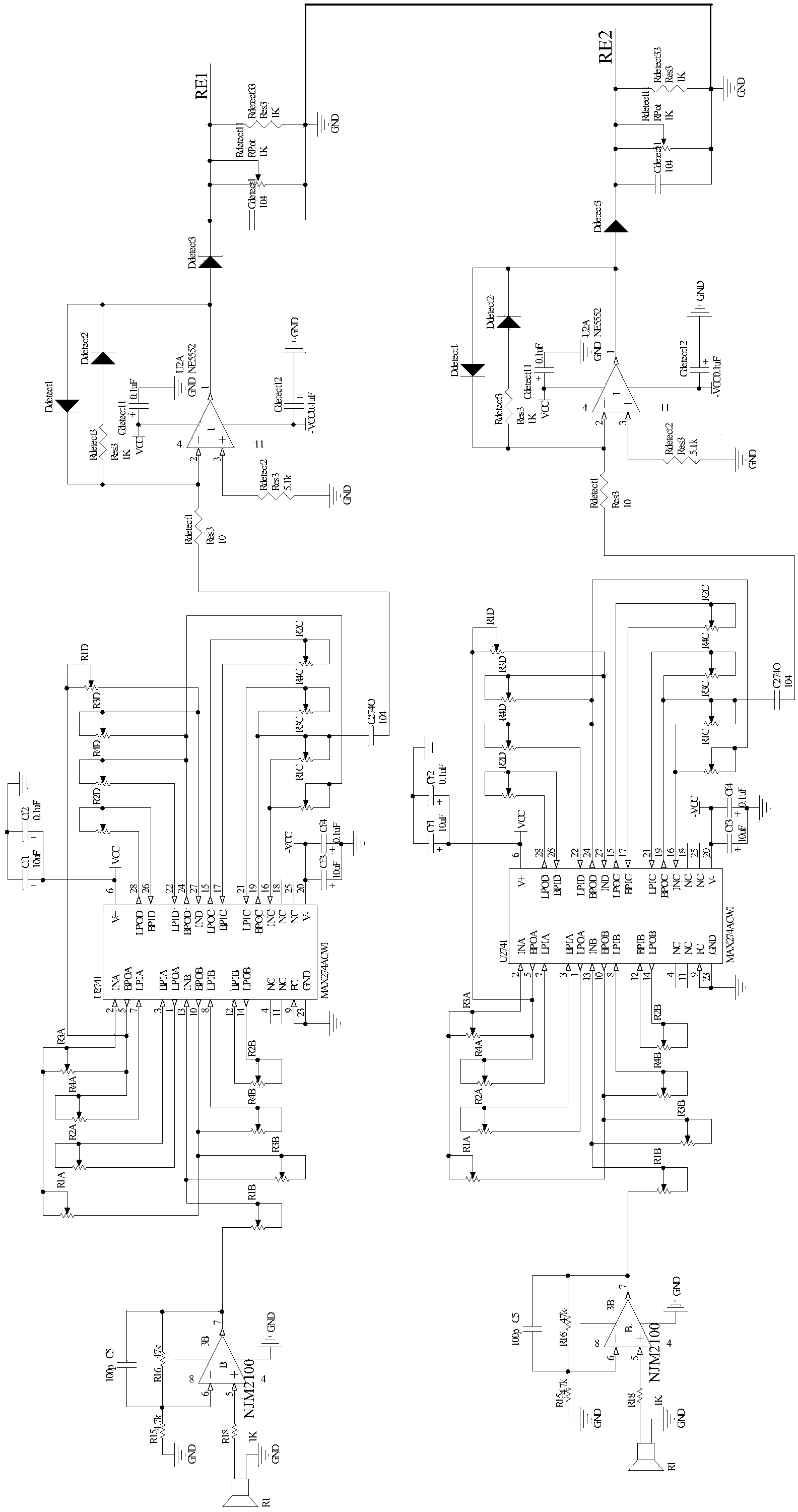

Flow measuring device for sewage containing solid garbage

InactiveCN104296814AAvoid the problem that it cannot be applied to sewage containing a large amount of solid wasteStable reflectionVolume/mass flow measurementSanitary sewerUltrasound

The invention discloses a flow measuring device for sewage containing solid garbage, and relates to sewage flow measurement. The flow measuring device comprises an ultrasonic wave emitting circuit, an ultrasonic wave emitter, two ultrasonic wave receiving sensors, an ultrasonic wave receiving circuit, an analog-digital conversion circuit and a flow calculation module, wherein the output end of the ultrasonic wave emitting circuit is connected with the input end of the ultrasonic wave emitter; the ultrasonic wave emitter is mounted at the bottom of a sewage discharge pipeline; the two ultrasonic wave receiving sensors are mounted at the top of the sewage discharge pipeline; the input end of the ultrasonic wave receiving circuit is connected with the output ends of the two ultrasonic wave receiving sensors; the ultrasonic wave receiving circuit is used for amplifying, filtering and performing envelope detection treatment on a received ultrasonic wave signal; the output end of the ultrasonic wave receiving circuit is connected with the input end of the analog-digital conversion circuit; the output end of the analog-digital conversion circuit is connected with the input end of the flow calculation module; the flow calculation module is used for acquiring envelop of two received signals, used for subsequently performing relevant calculation so as to acquire the relevant peak positions, and used for calculating the flow velocity and the flow of sewage according to the distance between the two ultrasonic wave receiving sensors.

Owner:XIAMEN UNIV +1

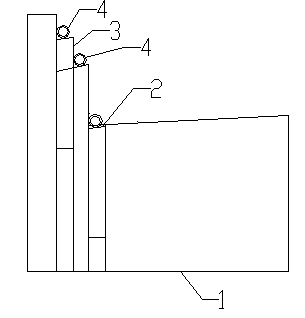

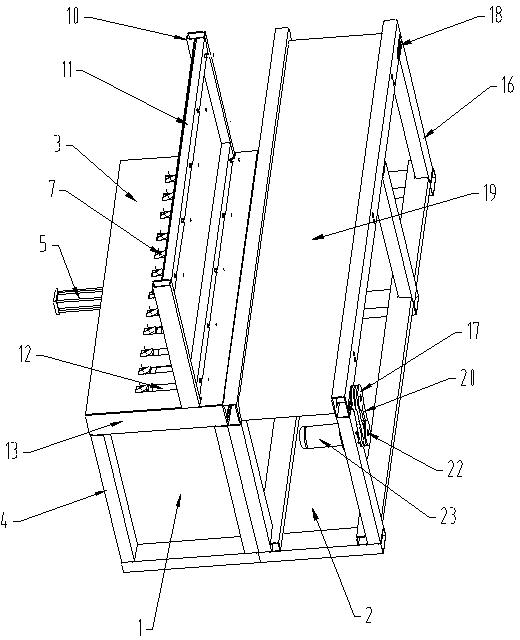

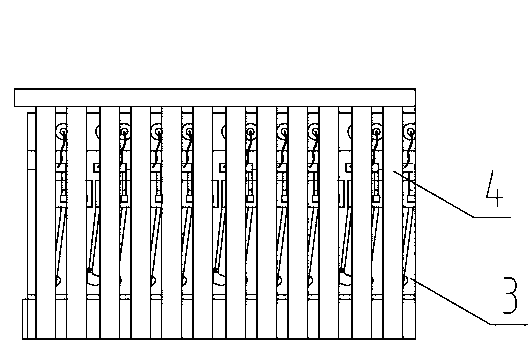

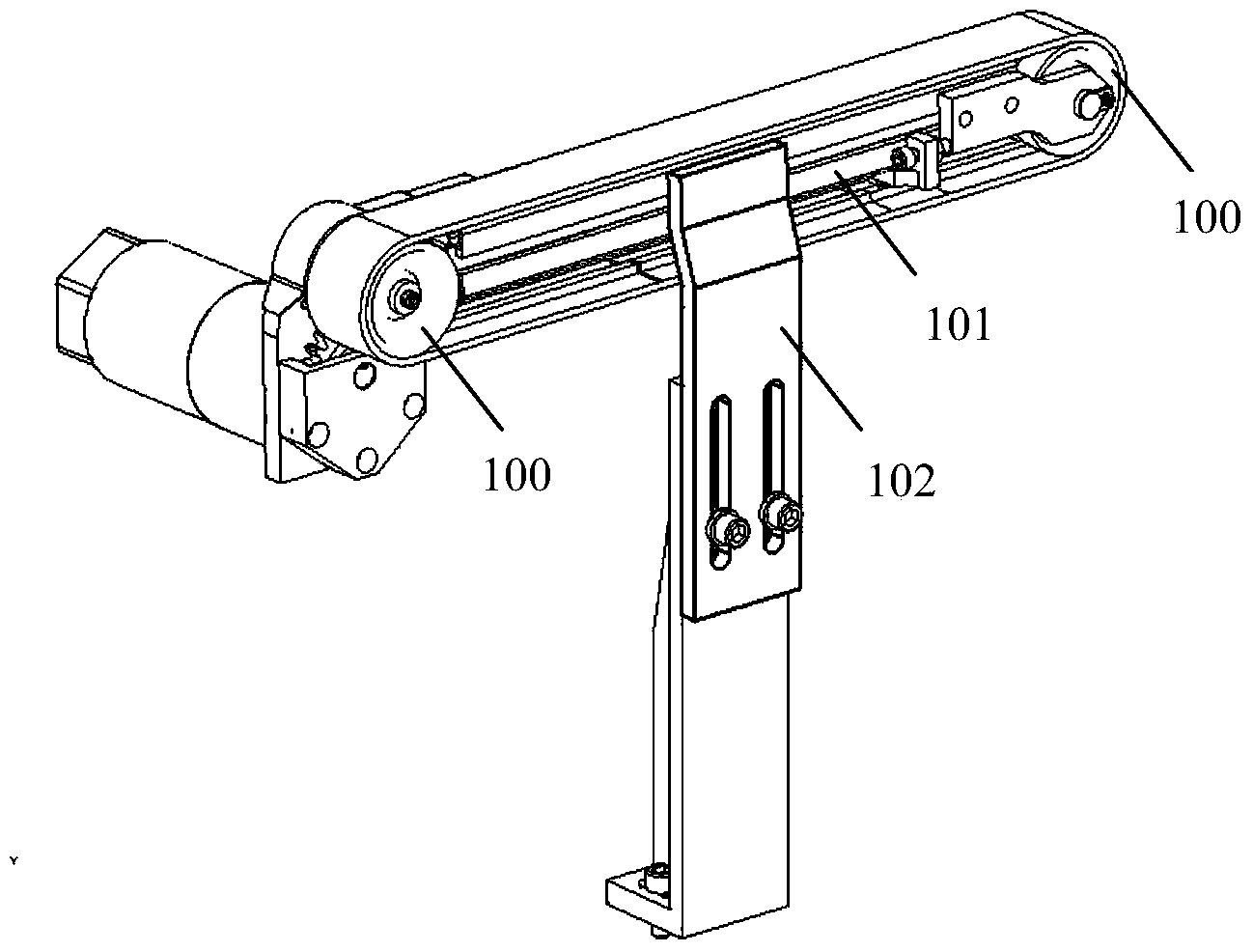

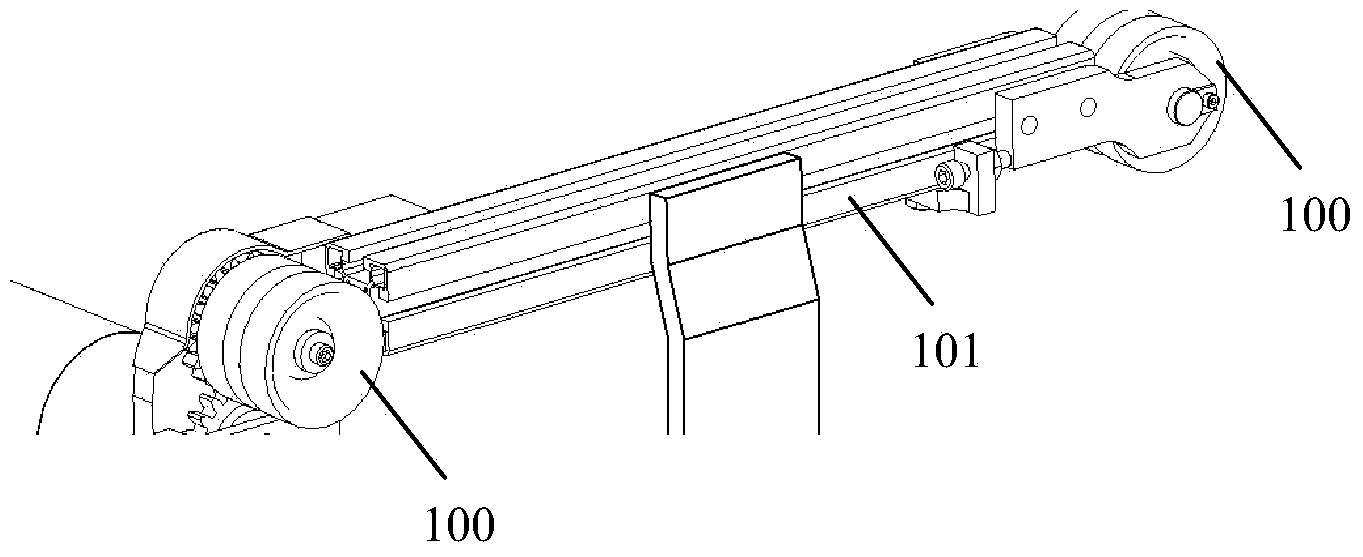

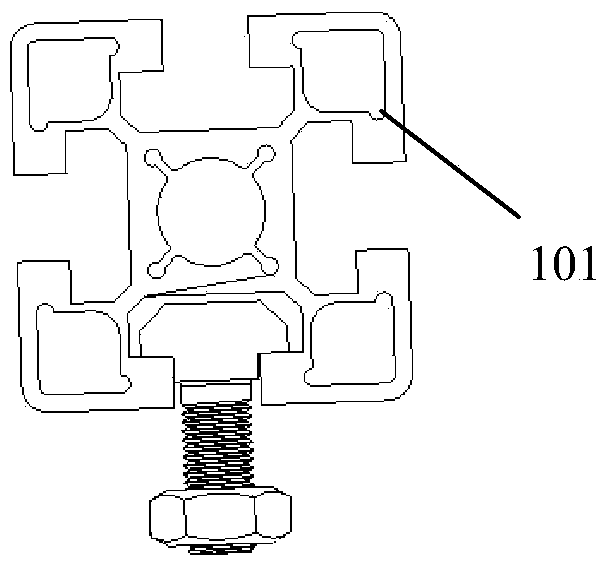

Special feeding device for front fork tubes

InactiveCN103979300AStable transmissionSimple structureConveyor partsSteel tubeElectrical and Electronics engineering

The invention discloses a special feeding device for front fork tubes, which comprises a base, wherein a front fork tube placing station and a work station are arranged on the base, and the upper surface of the work station is higher than the front fork tube placing station. The special feeding device for the front fork tubes also comprises a first feeding plate and a second feeding plate, wherein the first feeding plate and the second feeding plate are slidably connected with the base. The special feeding device for the front fork tubes provided by the invention has the advantages of fixed time and fixed quantity, automatic feeding, stable transmission, simple structure, reliable quality and low cost, and the steel tubes can be conveyed to the work station one by one.

Owner:泰州双羊精密无缝钢管有限公司

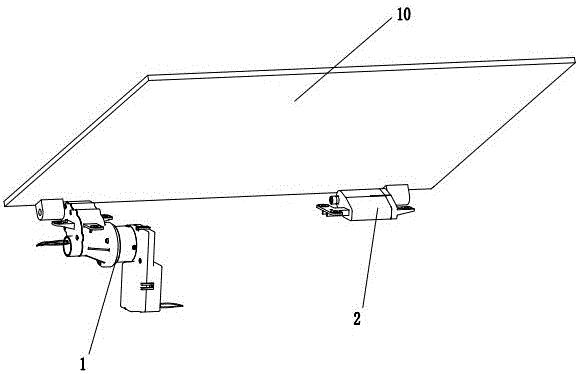

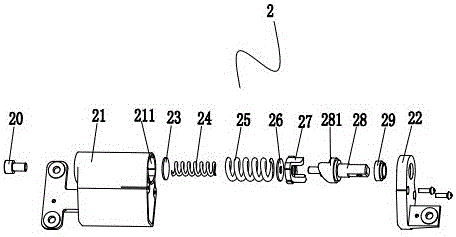

Novel turnover device

PendingCN106481743AReasonable structural designStable transmissionToothed gearingsGearing detailsBevel gearPlanet

The invention relates to a novel turnover device comprising a drive mechanism and a damping mechanism. The drive mechanism comprises a motor, a worm, a bevel gear, a planetary gear bank and an output shaft. The damping mechanism comprises a first shell and a first cover. A first tube seat is horizontally arranged in the first shell. A first gasket, a first compression spring, a second gasket, a damping movable block and a rotating shaft are sequentially arranged in the tube seat. The novel turnover device is reasonable in structural design. The drive mechanism drives the output shaft to stably conduct transmission. The damping mechanism can provide assisting force when a cover plate and other turnover pieces are opened, so that the load of the motor is lightened. The damping mechanism can also provide buffering force when the cover plate and the other turnover pieces are closed, so that the problem that when electrically closed, the cover plate and the other turnover pieces overturn due to sudden acceleration is solved, and the phenomenon that when the cover plate and the other turnover pieces are electrically closed, a sudden change is generated is relieved. In this way, an automatic cover-overturning mechanism has practicability, the use safety performance is improved, and the novel turnover device can be well applied to products and improve the market competitiveness and the brand image of an enterprise.

Owner:仝达产品开发(惠州)有限公司

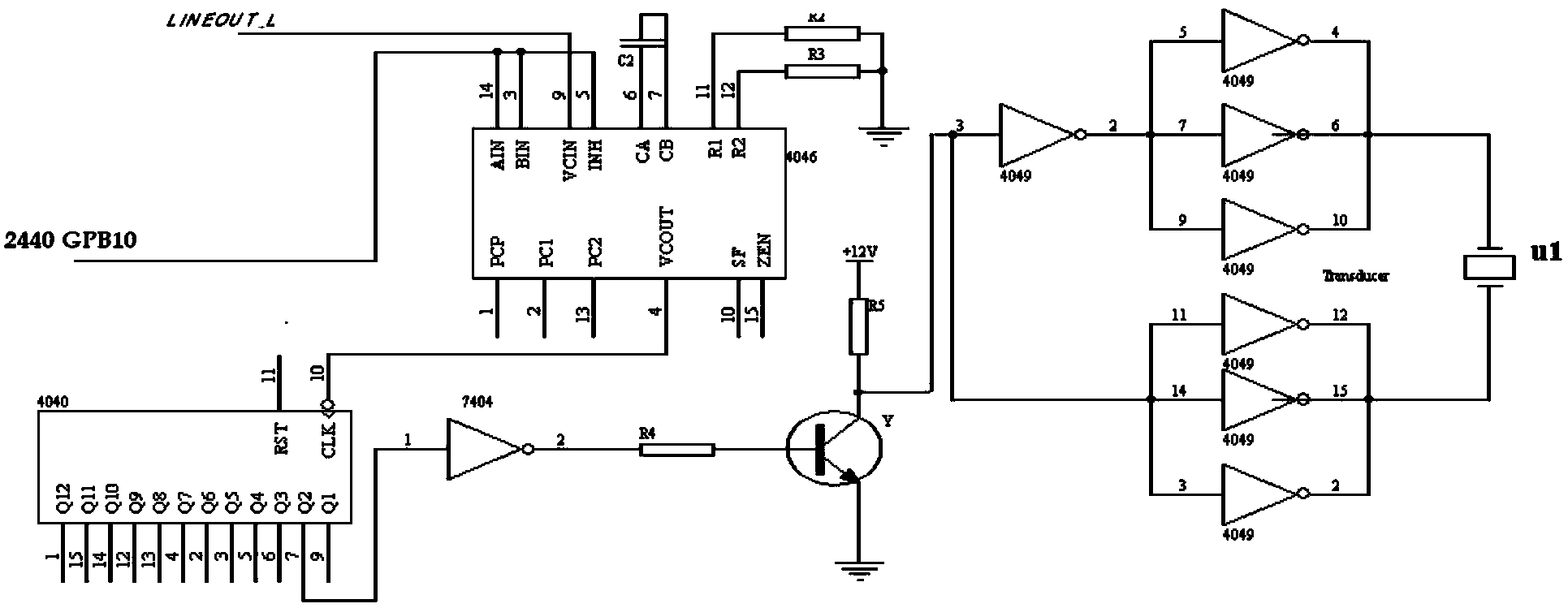

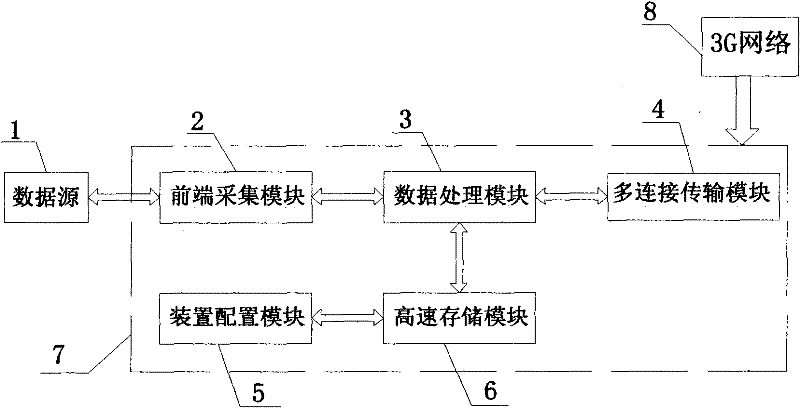

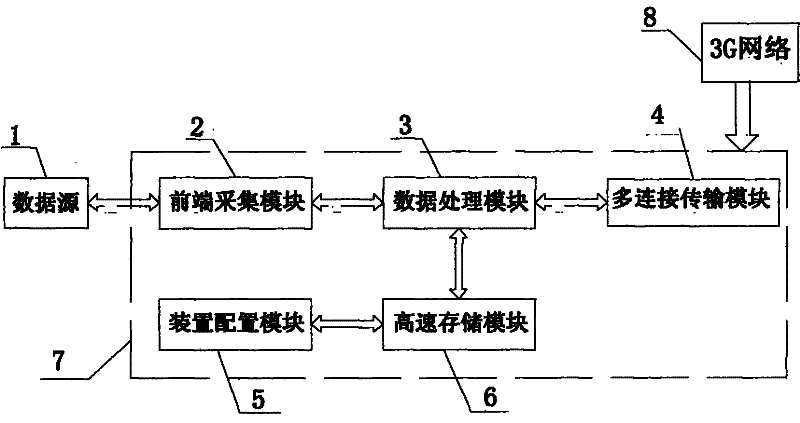

3G multi-card multi-mode high speed wireless acquiring and transmitting apparatus

InactiveCN102346957AIncrease transfer rateStable transmissionElectric signal transmission systemsWireless communicationAcquisition apparatusTransmission rate

The invention discloses a 3G multi-card multi-mode high speed wireless acquiring and transmitting apparatus comprising a front acquiring module, a data processing module, a multi-connection transmitting module, a high speed storing module and an apparatus configuring module. The front acquiring module is connected with a data source positioned outside the wireless acquiring module through signal wires. The front acquiring module is used for acquiring data from the data source. The data processing module is respectively connected to the three functional modules, which are the front acquiring module, the multi-connection transmitting module and the high speed storing module through signal wires. The data processing module is used for analyzing and de-packing received data, and for transmitting the data to the multi-connection transmitting module. The apparatus configuring module is connected to the high speed storing module through signal wires. The high speed storing module is used for managing and storing the acquired data according to apparatus configurations. According to the invention, simultaneous transmission of the data is realized with a 3G card and the modules, such that the transmission speed of the wireless 3G acquisition apparatus is greatly improved, and multi-card multi-mode simultaneous transmission is realized.

Owner:孙勉

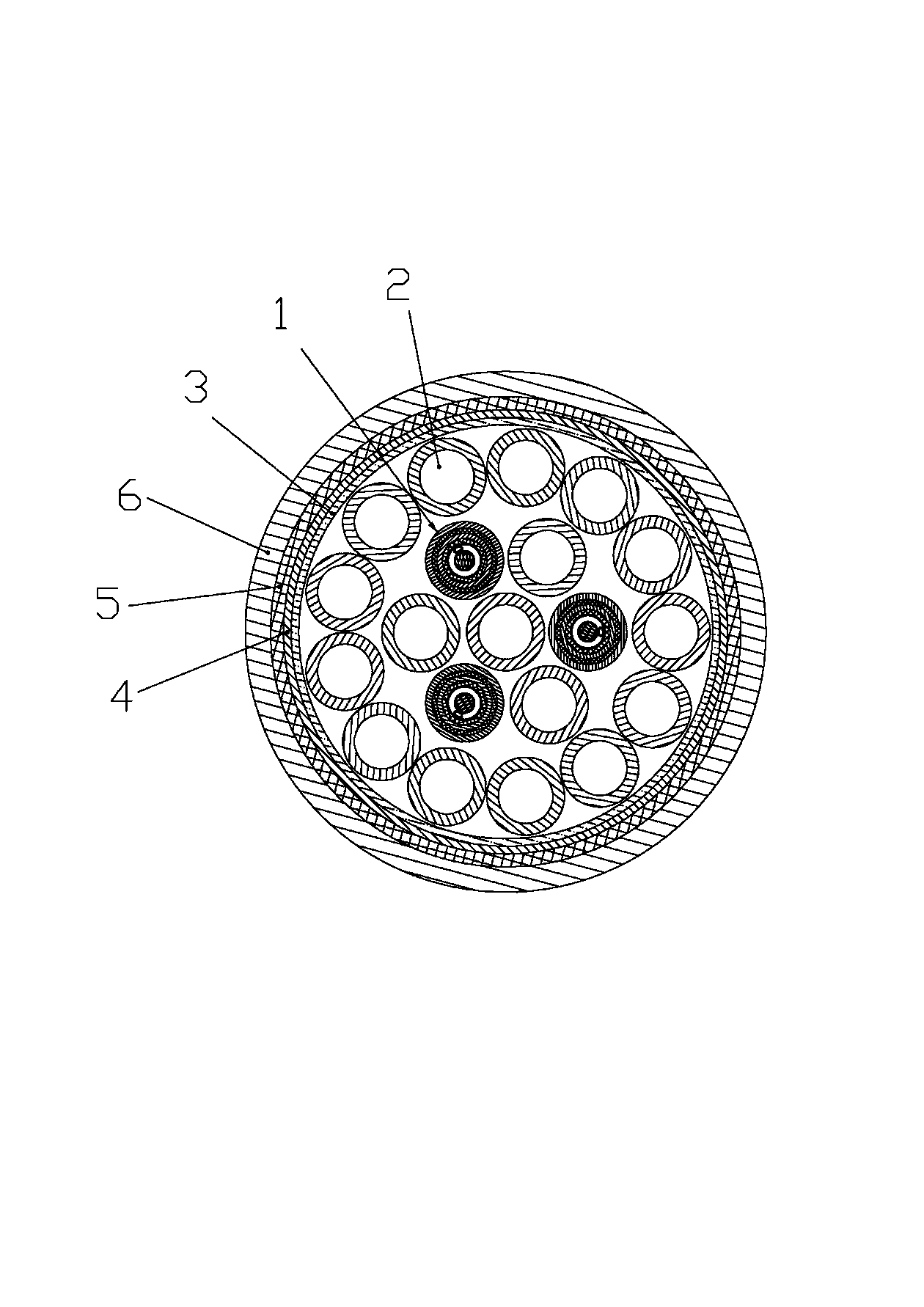

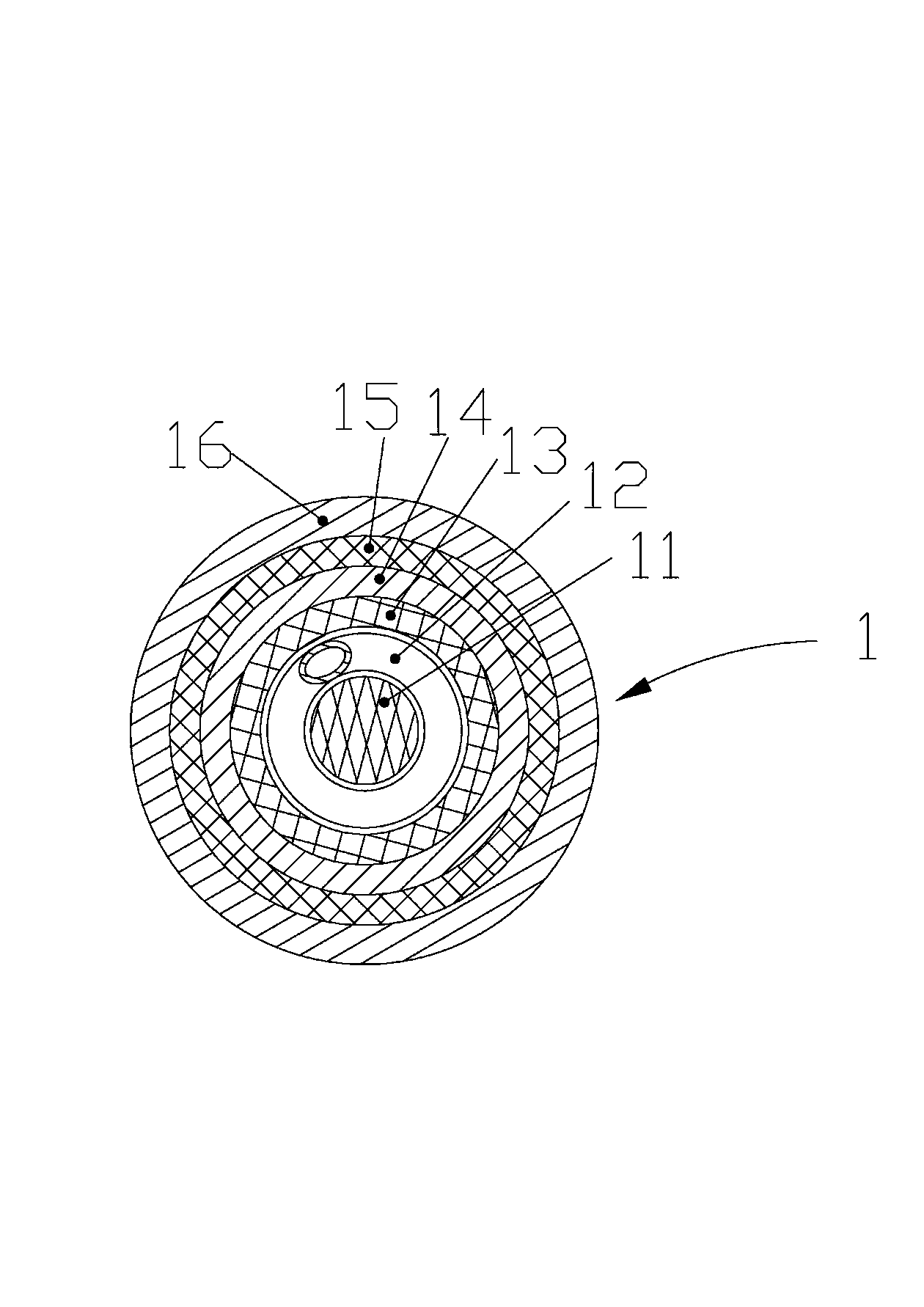

Communication cable and production process thereof

ActiveCN102856001AStable transmissionStrong anti-interferenceCable/conductor manufactureCables with twisted pairs/quadsCopper wireYarn

The invention discloses a communication cable. The communication cable comprise a cable core which comprises a conductor, a spiral hollow pipe, an insulation pipe, a silver belt layer, a sliver wire weaving layer and a protecting bush pipe are wrapped outside the conductor. The invention also discloses a production process of the cable. The production process comprises the following steps of: (A) extruding and stretching the insulation hollow pipe; (B) twisting the stretched insulation hollow pipe by pairs; (C) wounding the twisted insulation hollow pipe by pairs on the conductor by butting joint; (D) pushing and extruding a PTFE (Polytetrafluoroethylene) insulation layer outside the insulation hollow pipe; (E) lapping a single crystal silver-plated copper belt and shielding; (F) weaving the single crystal silver-plated copper wires; (G) extruding a plastic protecting bush layer; (H) stranding and cabling the cable core and the hollow pipe; (I) lapping a PTFE film outside the formed cable; (J) lapping a total shielding crystal silver-plated copper belt on the cabled yarns; (K) weaving the total shielding single crystal silver-plate copper wire by the cabled yarns; and (L) extruding an outer protecting bush by the cabled yarns, namely forming the cable. The communication cable disclosed by the invention not only prevents interference, but also is stable in transmission signals.

Owner:清远市合意氟塑电线有限公司

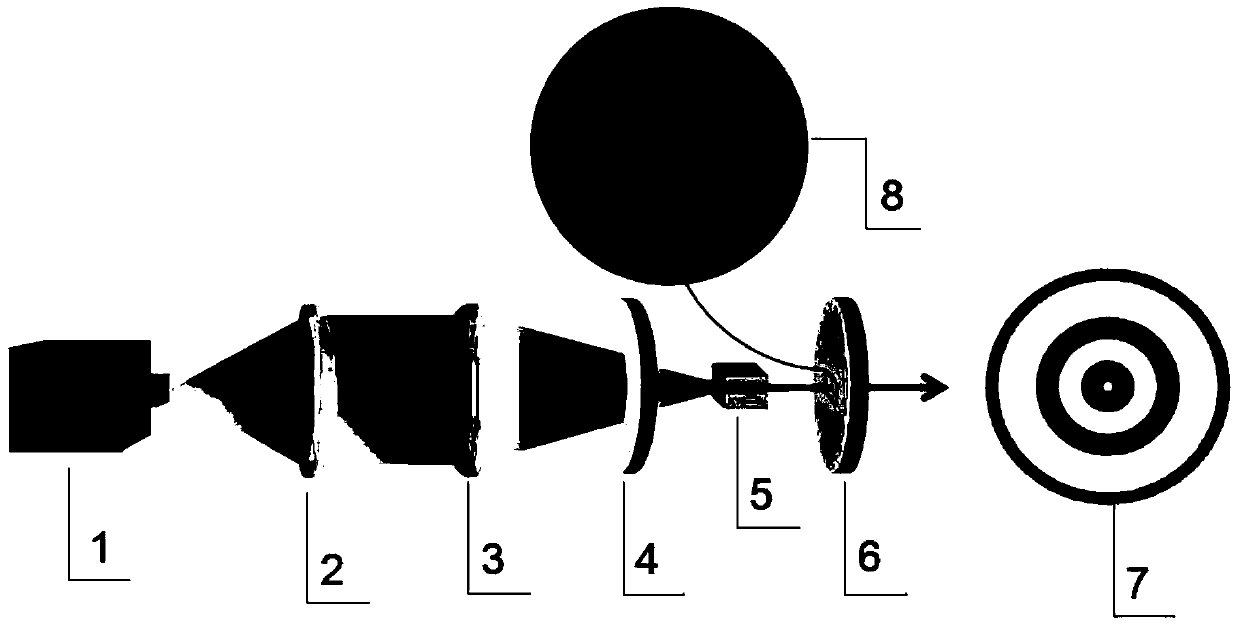

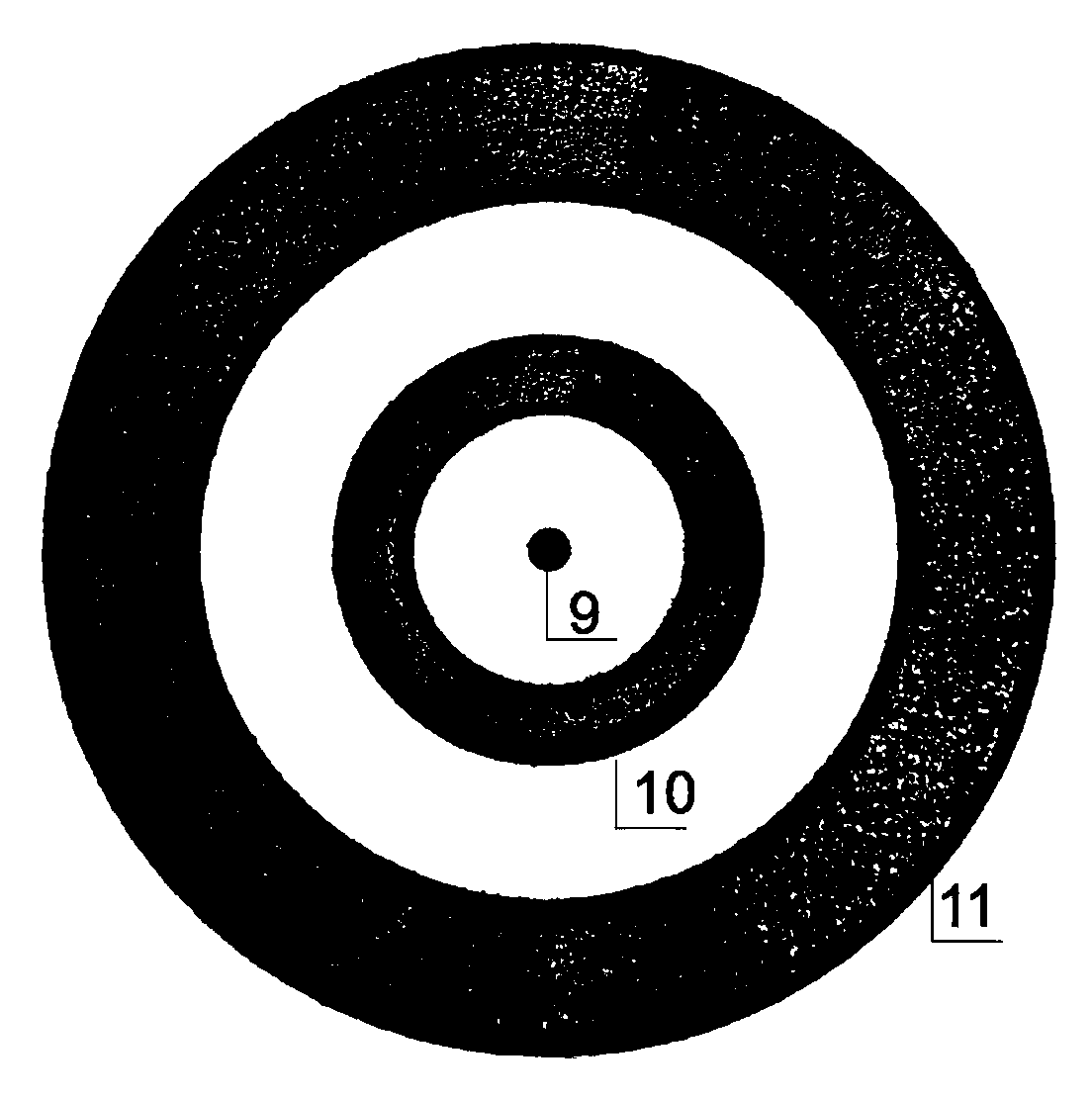

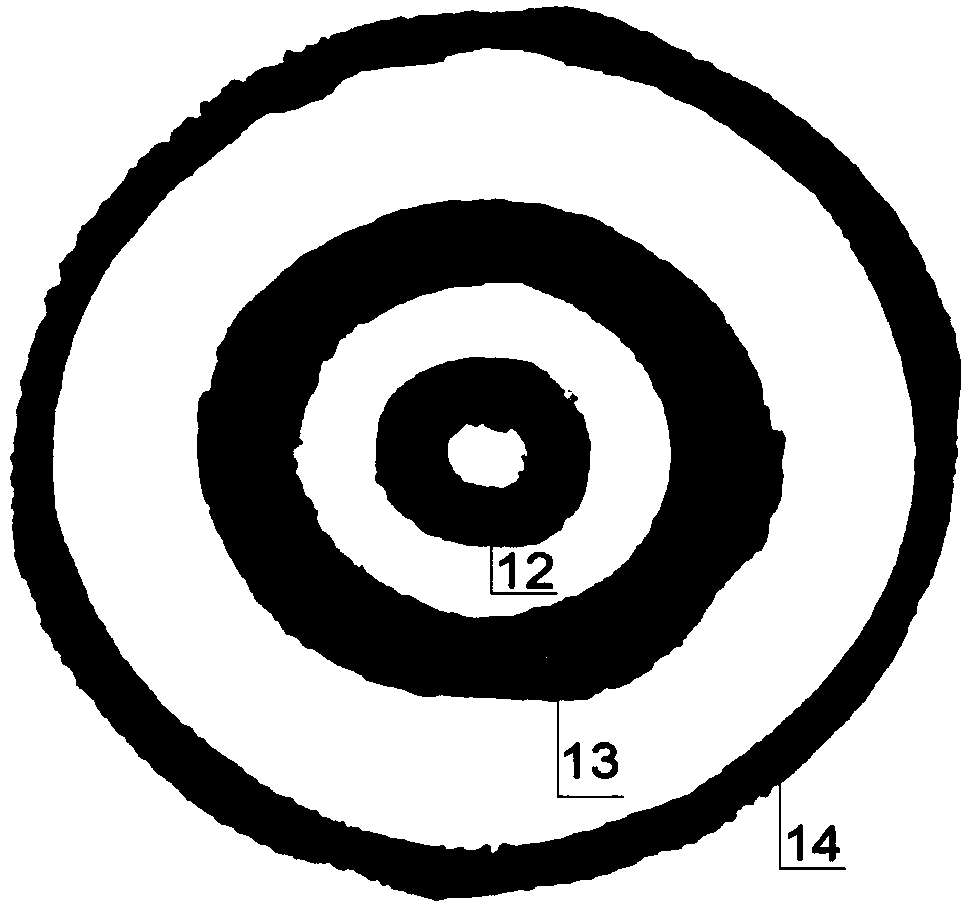

Method for directly generating multiple vortex beams in a cavity

A method for directly generating multiple vortex beams in a cavity. The core of the method is that etching circular microholes and concentric rings of different sizes on the surface of the laser end mirror, and adjusting the circular microholes and the concentric rings to the center of the beam to form a circular and a annular spatial loss modulation, so as to form a plurality of annular net gainregions in the laser cavity, so that the vortex beams of different orders oscillate and output, thereby producing multi-vortex beams directly in the laser cavity. Each vortex beam has the characteristics of high purity and stable transmission. The vortex generation method has important application prospects in space division multiplexing optical communication.

Owner:SHANGHAI JIAO TONG UNIV

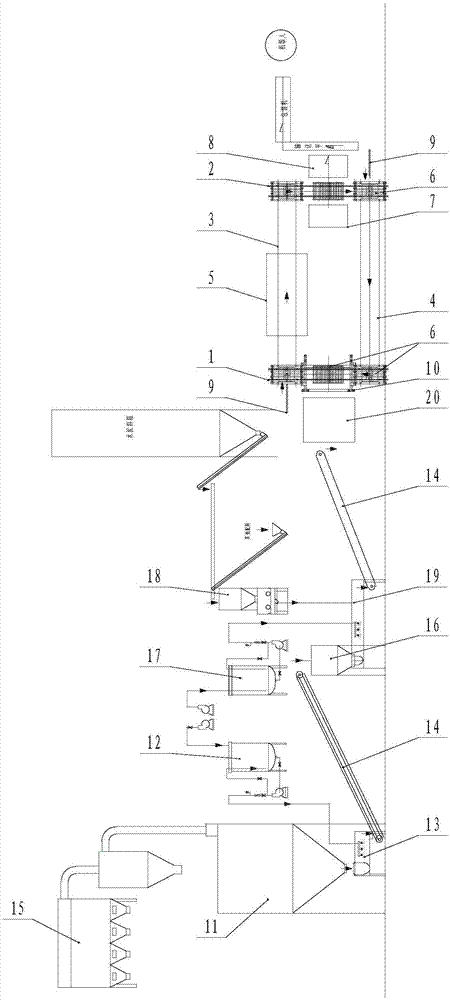

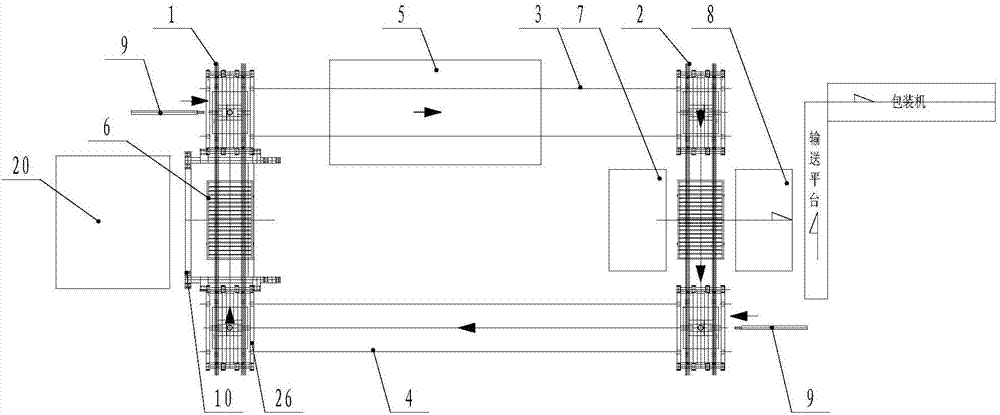

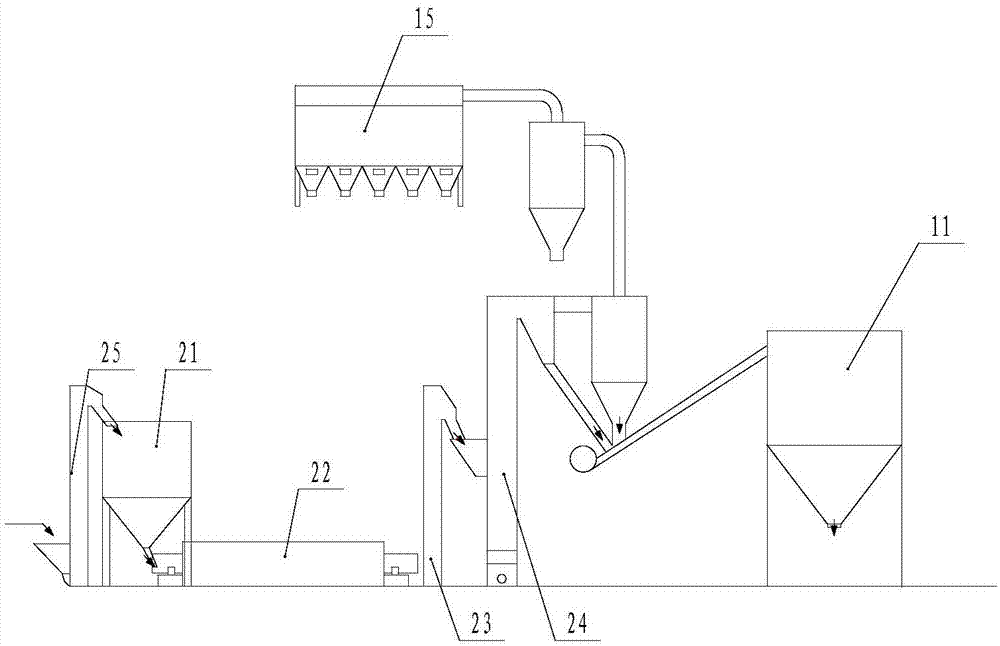

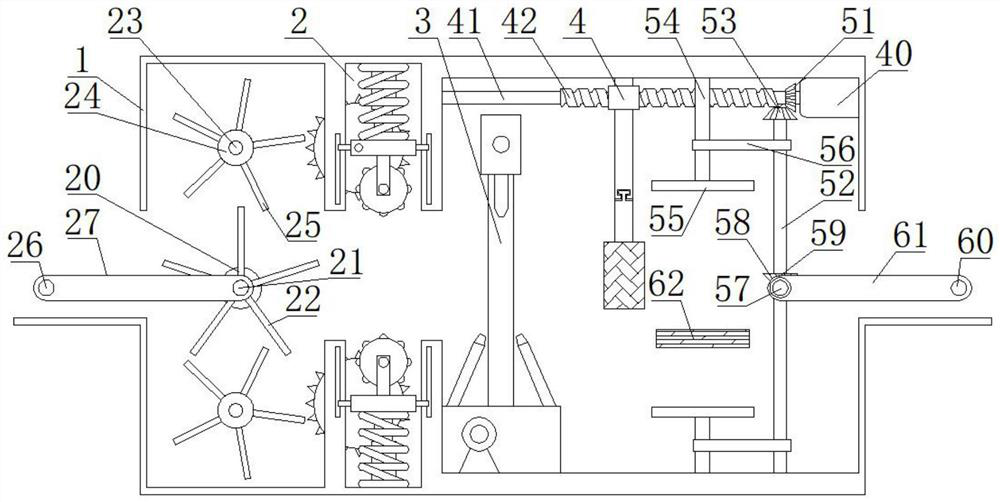

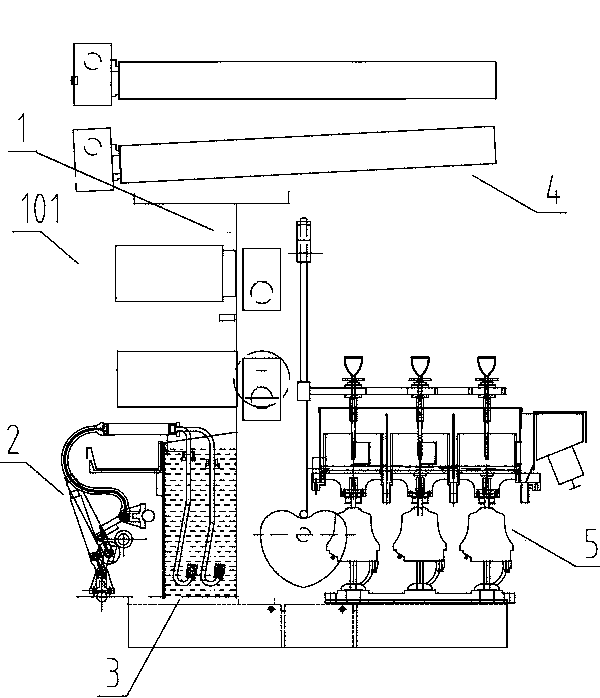

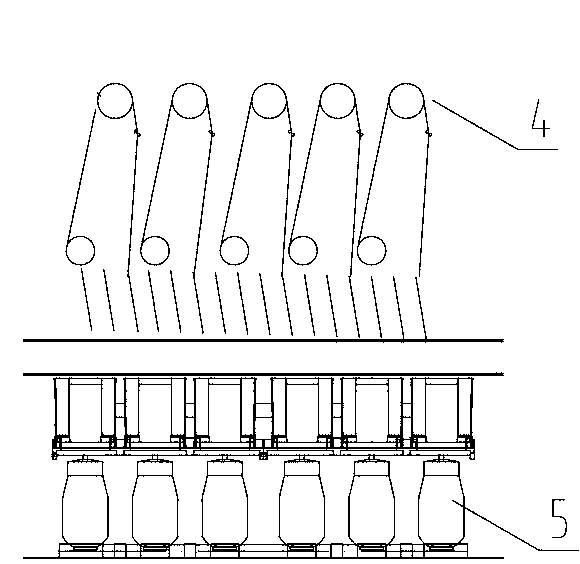

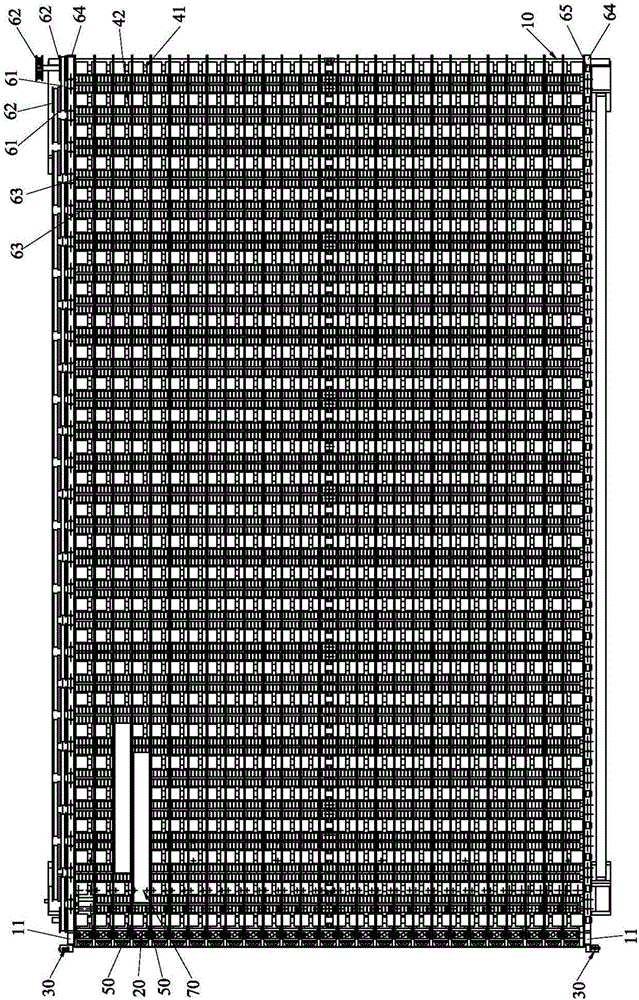

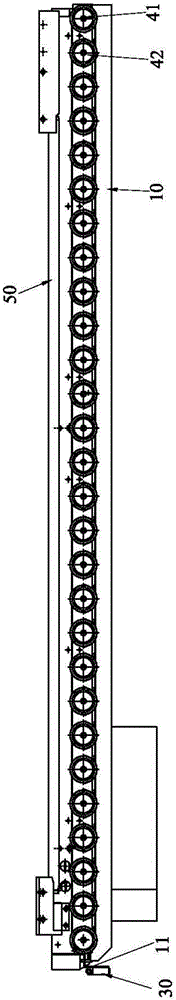

Full-automatic production device for expanded perlite heat preserving board

ActiveCN107571388ASave manpower and investmentStable transmissionCeramic shaping plantsAuxillary shaping apparatusPerliteProcess engineering

The invention discloses a full-automatic production device for an expanded perlite heat preserving board and relates to the field of heat preserving board production devices. The full-automatic production device for the expanded perlite heat preserving board is used for overcoming the defects that in the process of producing the expanded perlite heat preserving board, cost is high, efficiency is low, consumed time is long and assembly line production cannot be achieved. The full-automatic production device for the expanded perlite heat preserving board comprises a material mixing device, a board pressing device, a drying device and a packaging platform; the material mixing device is used for conveying materials to the board pressing device after the materials are mixed uniformly; the boardpressing device is used for pressing the mixed materials into the heat preserving board; the drying device is used for drying the heat preserving board; and then the dried heat preserving board enters the packaging platform to be packaged. The full-automatic production device for the expanded perlite heat preserving board is used for assembly line production of the expanded perlite heat preserving board.

Owner:华亿建材科技有限公司

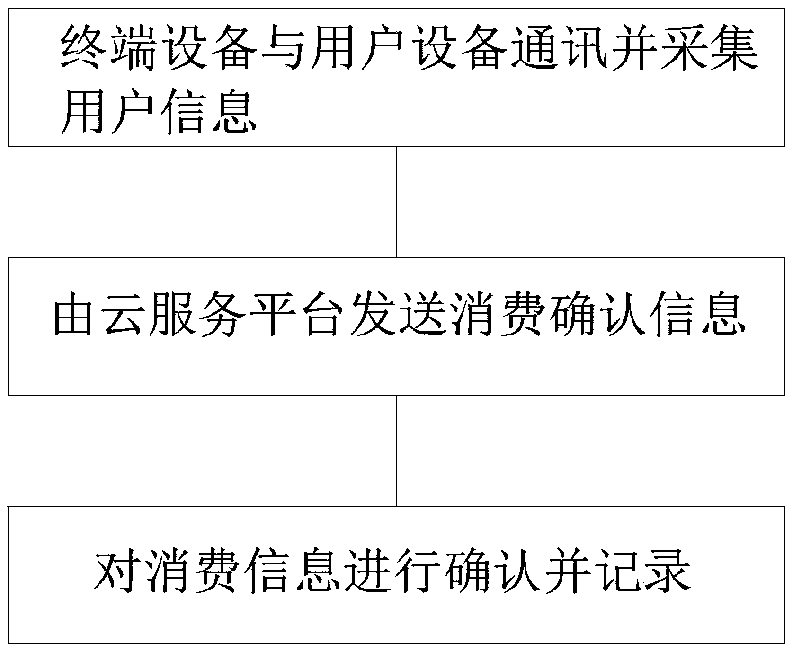

Transaction method

InactiveCN107707617AStable trading environmentStable transmissionPower distribution line transmissionPayment architectureUser informationTerminal equipment

The invention relates to the technical field of business methods, and particularly relates to a transaction method. The transaction method comprises the following steps: a) performing, by terminal equipment of a front end, communication with user equipment to collect user information, and recording the user information; b) sending the user information collected by the terminal equipment of the front end to a cloud service platform that establishes a communication connection with the terminal equipment of the front end, and receiving consumption confirmation information sent by the cloud service platform via terminal equipment, wherein the terminal equipment is in communication connection with the cloud service platform via a PLC; and c) performing, by the user equipment, consumption afterconfirming the consumption confirmation information by clicking the same.

Owner:康体佳智能科技(深圳)有限公司

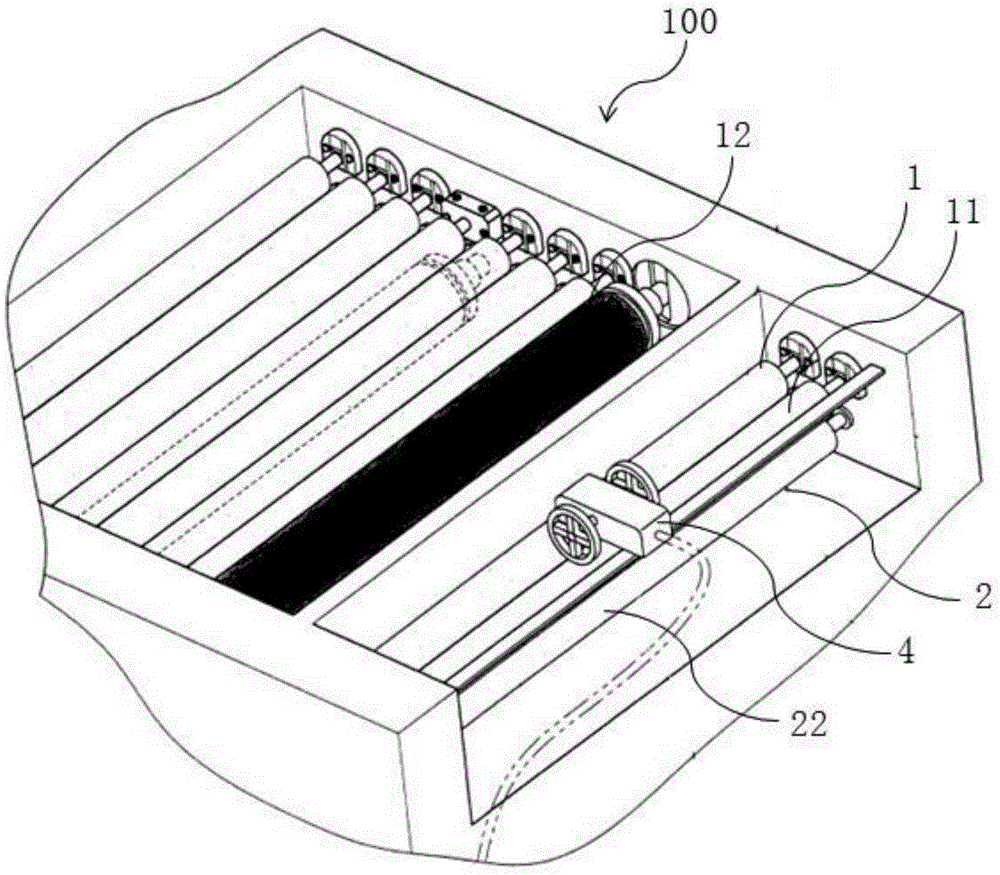

Flexible circuit board rolling cleaning device

InactiveCN105246256AAvoid damageStable transmissionInsulating layers/substrates workingTransfer procedureMechanical engineering

The invention relates to a flexible circuit board rolling cleaning device which comprises a base, a first roller assembly and a second roller assembly. The first roller assembly comprises a number of first rollers which are arranged in parallel. The second roller assembly comprises a number of second rollers which are arranged in parallel. The first rollers and the second rollers are opposite. The device is characterized in that the first roller assembly comprises at least one cleaning roll; bristles are arranged on the surface of the cleaning roll; the second roller assembly comprises a protection wheel and a support wheel; the protection wheel is provided with bristles; the protection wheel is adjacent to the support wheel; and the support wheel is opposite to the cleaning roll. According to the flexible circuit board rolling cleaning device which is provided by the invention, a flexible circuit board is prevented from being involved into the rollers in a transmission process; the flexible circuit board is prevented from being damaged in the transmission process; the transmission of the flexible circuit board is stable and flexible; and the cleaning effect of the cleaning roll is enhanced.

Owner:CHONGQING HANGLING PCB

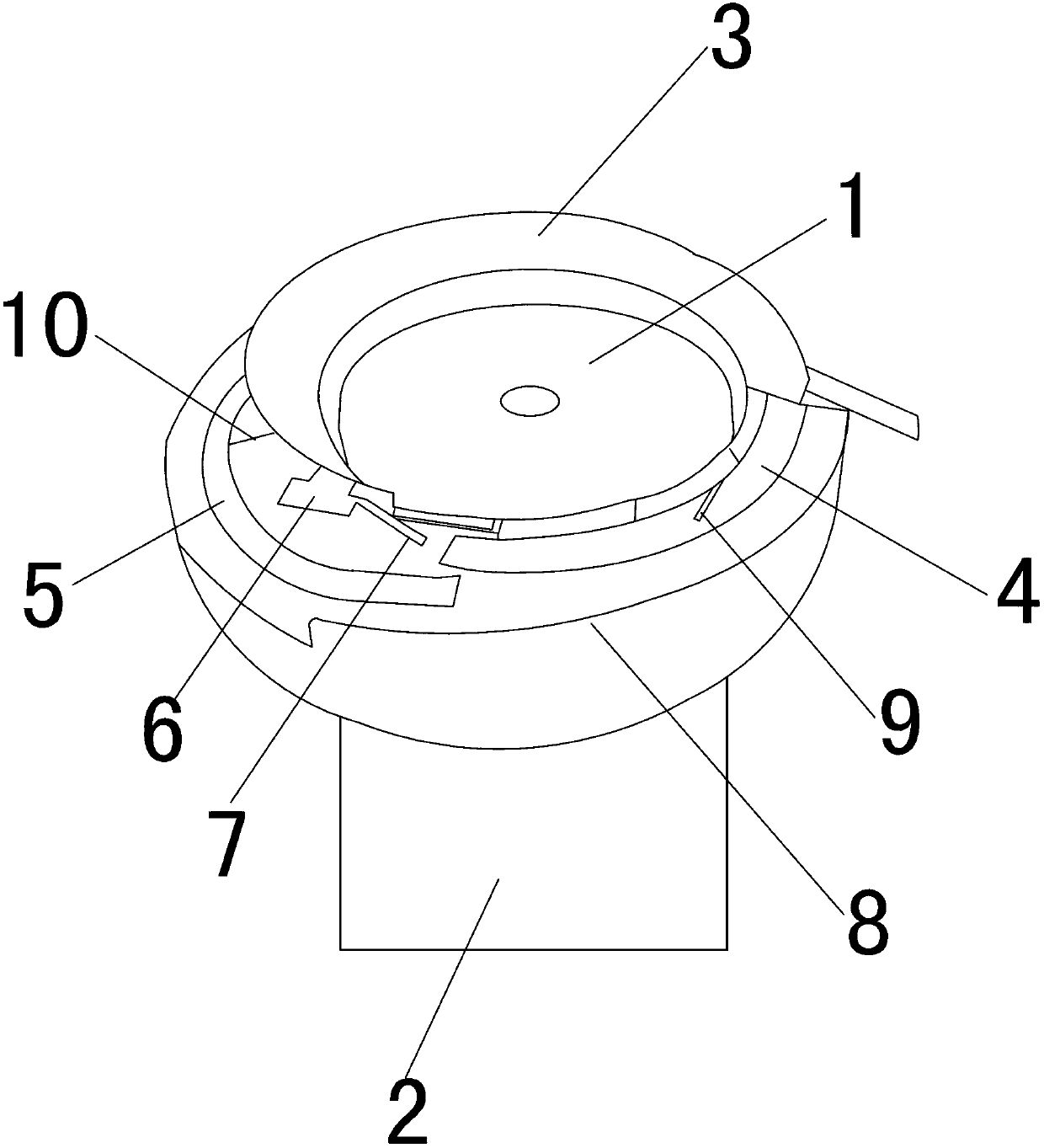

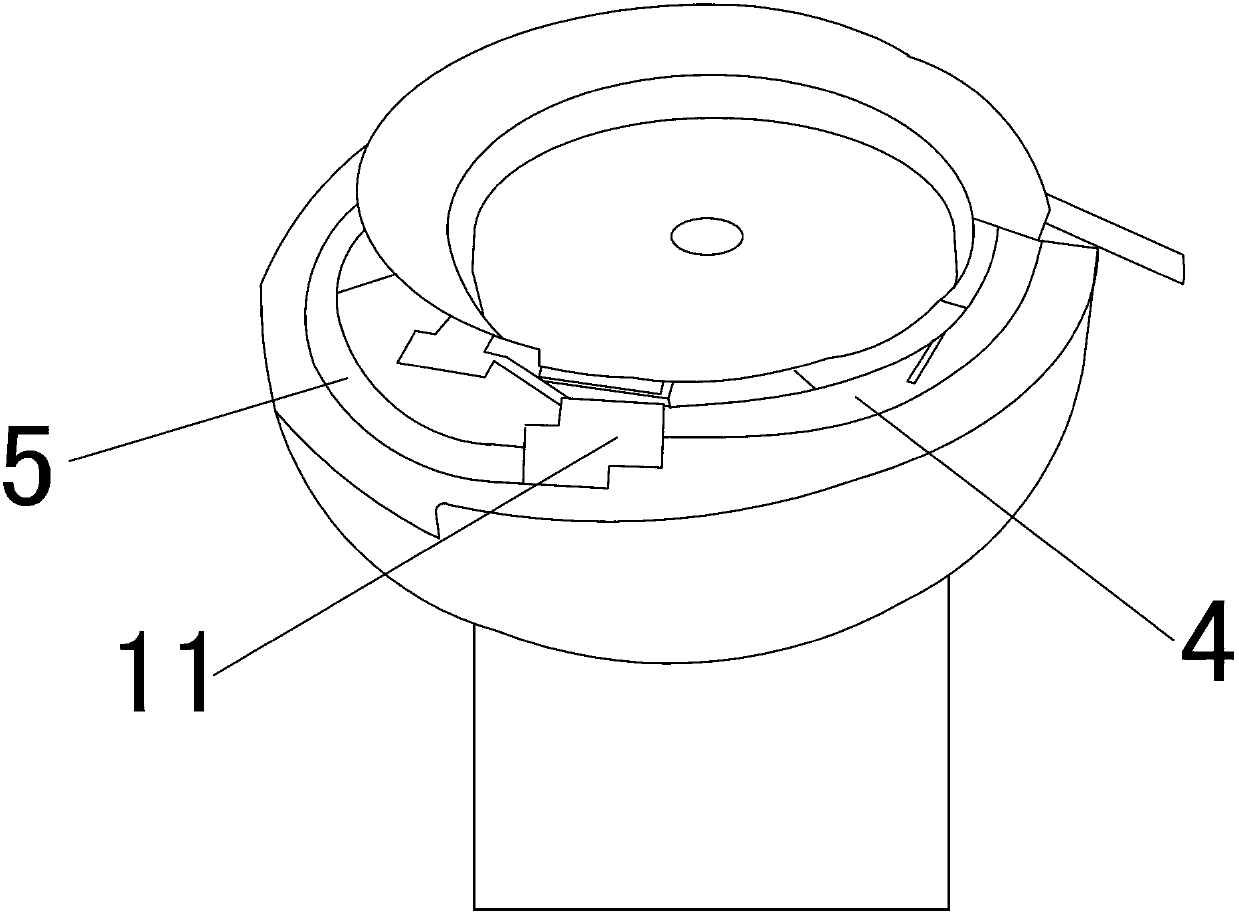

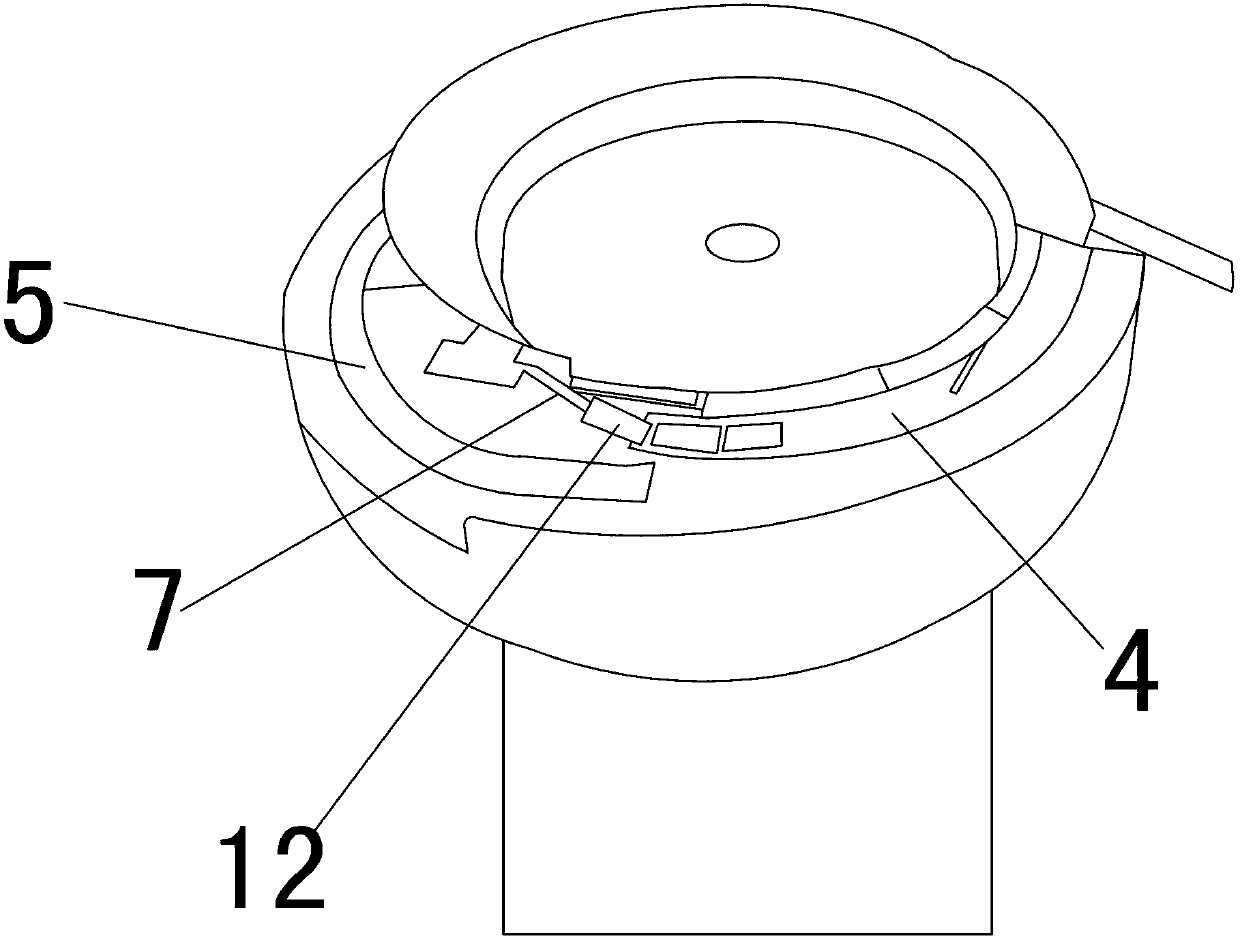

Vibrating disk used for conveying cupping device magnetic caps

InactiveCN103342226AStable transmissionHigh degree of automationJigging conveyorsConveyor partsRegular arrayMechanical engineering

The invention relates to a vibrating disk used for conveying cupping device magnetic caps. The vibrating disk comprises a feed cylinder used for placing the magnetic caps to be conveyed, a driving device is connected to the center of the bottom of the feed cylinder, and more than one circle of spiral feed channel is arranged and extends upward in a spiral shape from the edge of the bottom of the feed cylinder along the inner side of the side wall of the feed cylinder. The vibrating disk is characterized in that a sliding channel is connected with a discharge port of the spiral feed channel and used for enabling the conveyed magnetic caps to be arrayed tidily in an installation state, the sliding channel is divided into a plurality of sections which are disconnected from one another and encircle the outer side of the feed cylinder in a spiral mode from top to bottom, and sliding guiding joints are arranged in the disconnecting positions of the sliding channel and used for adjusting the conveying state of the magnetic caps. The vibrating disk has the advantages of being a smooth magnetic cap conveying device for automatic production of cupping devices and arranging the magnetic caps in a disordered state to be output in a regular array according to the assembly state needed by a host computer.

Owner:北京康祝医疗器械有限公司

Computer production dispensing device with conveying stability controlled

InactiveCN110000049AStable transmissionFacilitate teleportation and pauseLiquid surface applicatorsCoatingsInfrared emitterDrive shaft

The invention discloses a computer production dispensing device with conveying stability controlled. The dispensing device comprises a fixing plate, a refrigerating device, a dispensing head and an infrared emitter, wherein the mounting base is fixedly arranged on the lower surface of the fixing plate, a dispensing machine is arranged on the mounting base, the right side of the dispensing machineis provided with an air pipe, the inner surface of the air pipe is fixedly connected with a baffle, a conveyor belt is arranged above the supporting plate, the front end of a driving shaft is fixedlyconnected with a connecting piece, a motor is arranged at the left end of a transmission part, the upper end of a heating wire is connected with a storage battery, and the infrared emitter is fixedlyarranged on the front side of the upper end of the dispensing head. According to the computer production dispensing device with the conveying stability controlled, stable conveying stability can be realized, the conveyor belt can be conveniently controlled to run or stop, furthermore, blockage of the dispensing head and the mutual adhesion between the dispensing head and a workpiece cannot be caused, and glue can be conveniently dried.

Owner:HUNAN UNIV OF ARTS & SCI

Wood processing paint spraying device

PendingCN113426605AIncrease coefficient of frictionStable transmissionPretreated surfacesCoatingsElectric machineryManufacturing engineering

The invention discloses a wood processing paint spraying device. The wood processing paint spraying device comprises a paint spraying box, wherein a conveying mechanism, a spraying mechanism, a clamping mechanism and a drying mechanism are arranged in the paint spraying box; and the conveying mechanism is characterized in that first electric push rods are fixedly connected to the top and the bottom of the inner wall of the paint spraying box, the bottoms of the first electric push rods are fixedly connected with bearing plates, the outer walls of the first electric push rods are sleeved with first springs, and limiting grooves are formed in the two sides of the conveying mechanism. According to the wood processing paint spraying device, transmission rollers are arranged, a motor is started to drive driving blades to rotate around a first rotating shaft, the driving blades knock driven blades when rotating so that the driven blades can rotate around a transmission rod, then a spur gear meshed with the driven blades can rotate, a first rotating rod can rotate, a first fixing rod enables the transmission rollers to rotate under the action of a first belt, protrusions arranged on the outer walls of the transmission rollers increase the friction coefficient of the device, so that wood plates can be conveyed more stably, meanwhile, the distance between the two rotating rollers can be conveniently adjusted through the limiting grooves, and then the wood plates can be transmitted more accurately.

Owner:谢辉

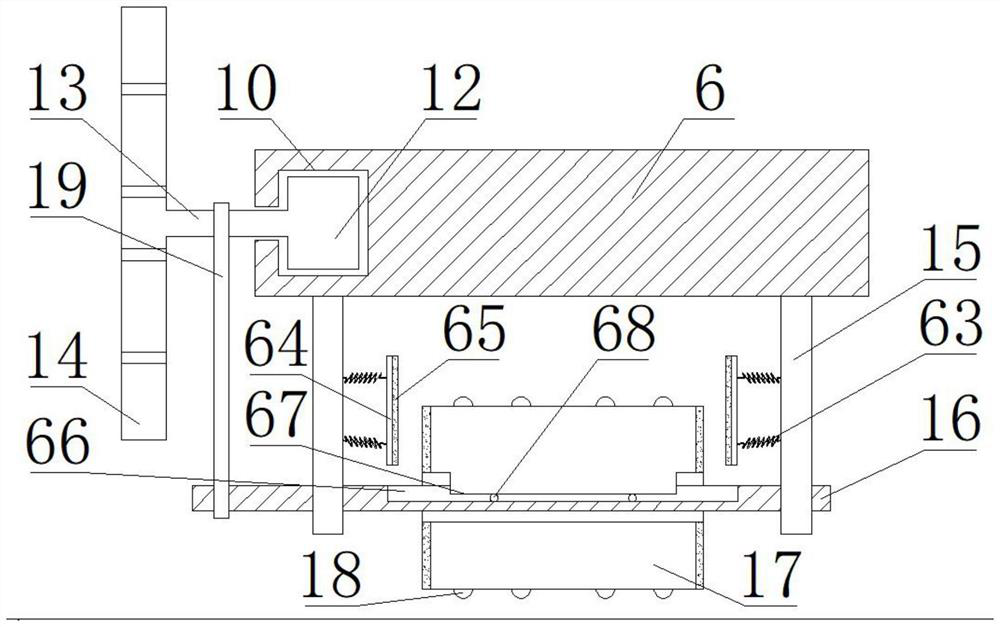

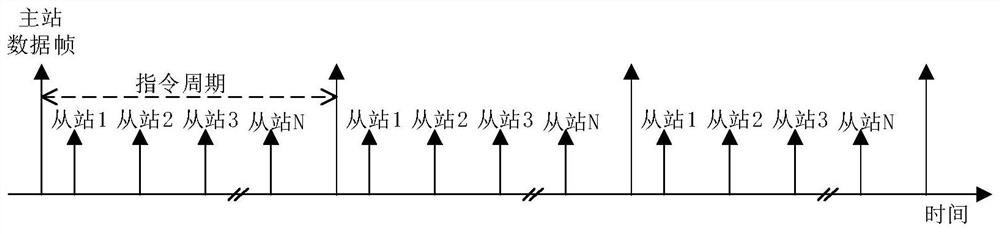

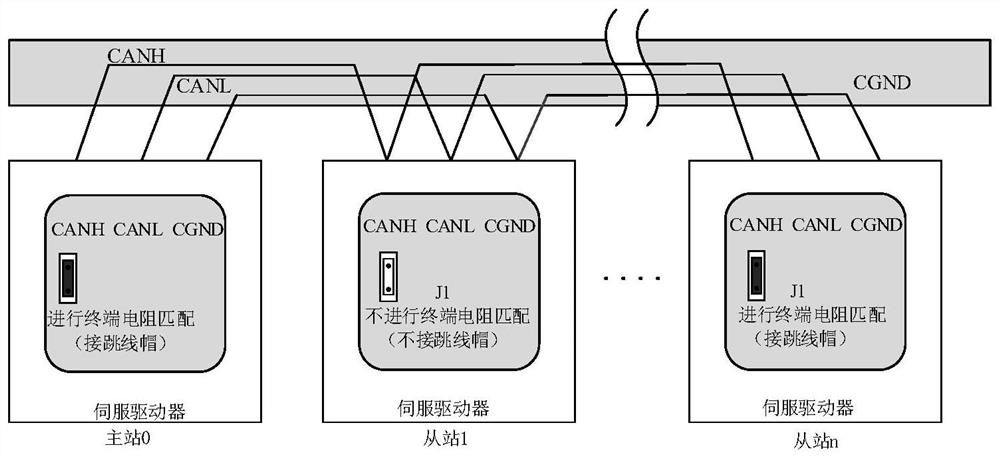

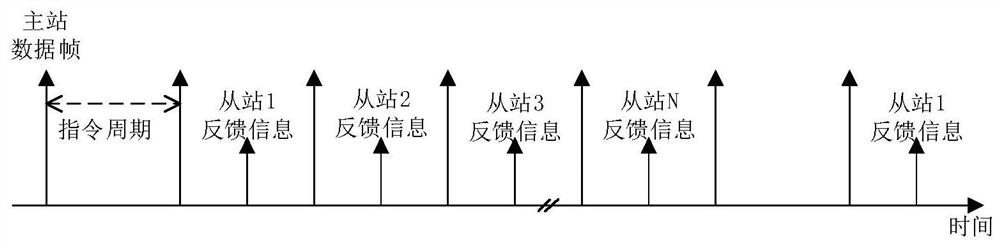

Method for transmitting process data between master driver and slave driver based on CAN bus

ActiveCN113259217AStable transmissionShorten the communication cycleBus networksLink layerReal-time computing

The invention discloses a method for transmitting process data between a master driver and a slave driver based on a CAN bus. A master station servo driver periodically broadcasts a frame through the CAN bus to add a data frame of a 1-byte counter, the initial value of the counter is 0, and 1 is added to the value of the counter after the data frame broadcasted by the master station servo driver is successfully sent; each slave station servo driver receives the data frame broadcasted by the master station servo driver, analyzes the data frame, performs remainder operation processing on the obtained value of the counter, and further determines whether to feed back updated state information to the master station servo driver according to the remainder. The method has the advantages that the situation that a plurality of slave station servo drivers feed back state information at the same time does not exist, the phenomenon of data collision does not occur, frame synchronization of a CAN link layer is not affected, arbitration failure of a certain slave station servo driver with a low priority is not caused all the time. Therefore, the master station servo driver loses the state information of the slave station servo driver with the low priority for a long time.

Owner:NINGBO ANXIN CNC TECH

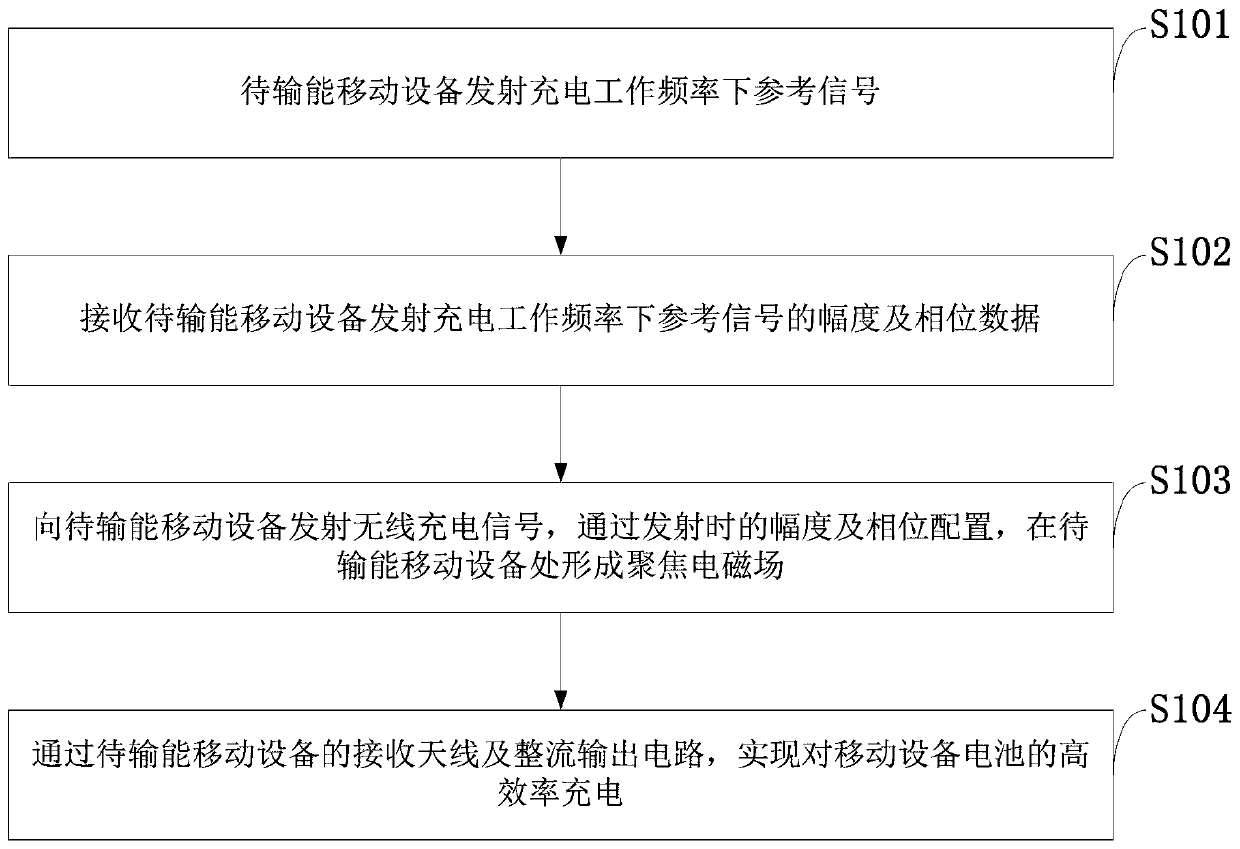

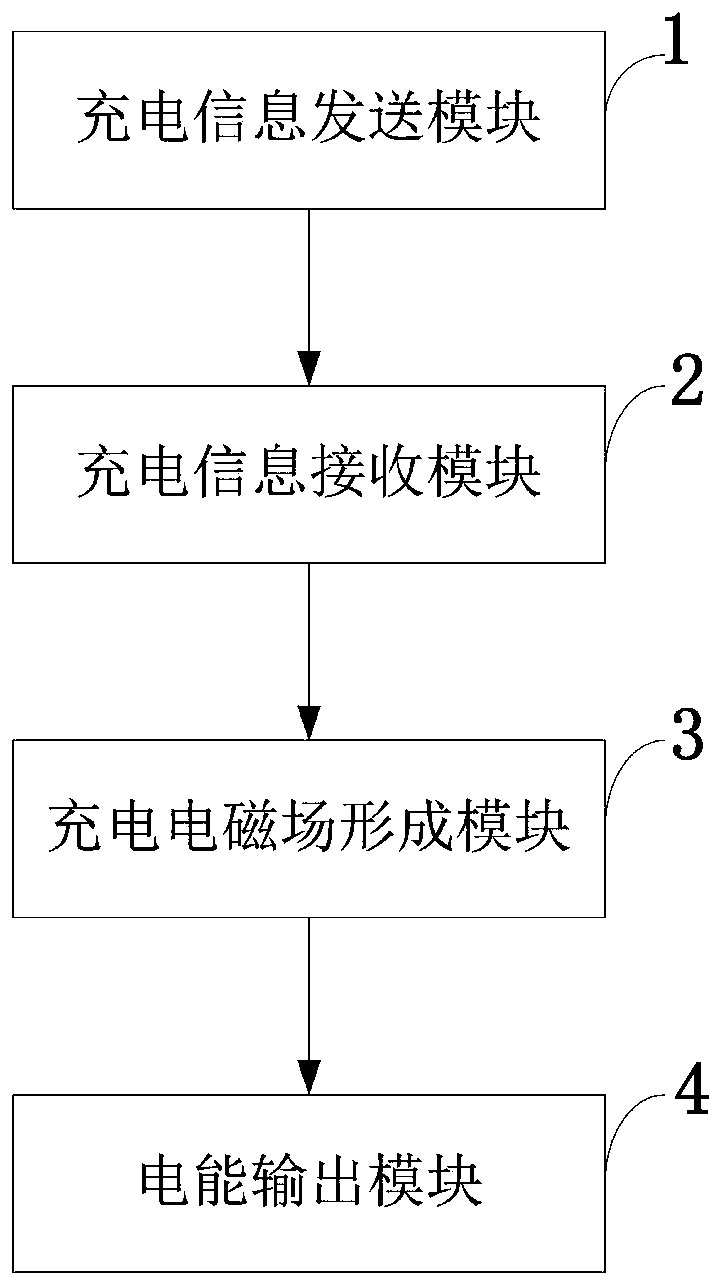

Wireless charging device, system and method, mobile terminal and storage medium

ActiveCN111293756AImprove transmission efficiencyStable transmissionNear-field transmissionBatteries circuit arrangementsTelecommunicationsInductive charging

The invention belongs to the technical field of wireless charging, and discloses a wireless charging device, system and method, a mobile terminal and a storage medium. The wireless charging device comprises an internal charging system which is installed in an external metal frequency selection box body and used for achieving wireless charging. The four side faces and the top face of the metal frequency selection box body are all band-pass type frequency selection surfaces. A multi-antenna subsystem of the internal charging system comprises N antenna units, wherein N is an integer greater than1. The antenna unit adopts an oscillator antenna, a microstrip patch antenna, a waveguide slot antenna, a spiral antenna or a dielectric resonator antenna; and the N antenna units of the multi-antennasubsystem are uniformly arranged on the inner sides of the four side surfaces of the metal frequency selection box body in a two-dimensional annular manner or are arranged on the three-dimensional curved surface of the whole inner side of the metal frequency selection box body. According to the invention, simultaneous wireless charging of a plurality of mobile communication devices with differentbrands, different device types and different placement modes can be realized, normal communication can be realized, and the device has the advantages of high transmission efficiency, stable transmission, environmental protection and the like.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Roll type plastic cutting machine

PendingCN107932583ALittle change in forceStable transmissionMetal working apparatusArticle deliveryEngineeringMechanical engineering

The invention discloses a roll-type plastic cutting machine, which belongs to the field of plastic production equipment, and aims to improve the cutting dimension accuracy of plastic flooring and ensure the laying effect. The key points of the technical scheme include a bracket and a driving mechanism, and the driving mechanism drives objects to be cut. Moving along the length direction of the bracket, the roll-type plastic cutting machine includes a cutting mechanism, the cutting mechanism includes two gearboxes fixedly arranged on both sides of the bracket, and an AC motor for driving the gearbox is arranged outside the gearbox, so The opposite ends of the output shafts of the two gearboxes are fixed with cutting pieces. The invention solves the problem of low cutting dimension accuracy when manually cutting the plastic floor.

Owner:BEIJING ANDATAI RUBBER & PLASTIC PROD CO LTD

Capsule detecting device

InactiveCN104880467AGuaranteed detection accuracyStable transmissionOptically investigating flaws/contaminationSortingElectric machinerySprocket

The invention relates to a capsule detecting device. The capsule detecting device is characterized in that a motor is installed in a rack, chain wheels are installed on the rack, the motor is connected with the chain wheels through a transmission device, a roller type conveying belt is installed on the chain wheel, a feeding port is formed in one end of the roller type conveying belt, and a discharging port is formed in the other end of the roller type conveying belt; a destaticizing ion wind device, a controller, an operation displayer and a rejecting device are sequentially installed on the rack, the controller is located above the roller type conveying belt, an image detecting device is installed at the bottom of the controller, and the controller is connected with the image detecting device, the rejecting device and the operation displayer. The capsule detecting device can comprehensively and accurately detect internal and appearance defects of capsules to reject the unqualified capsules and collect the qualified capsules; the capsules roll at the detection position so that complete capsule images can be shot, and detection accuracy is ensured.

Owner:XINCHANG WUPENG MACHINERY

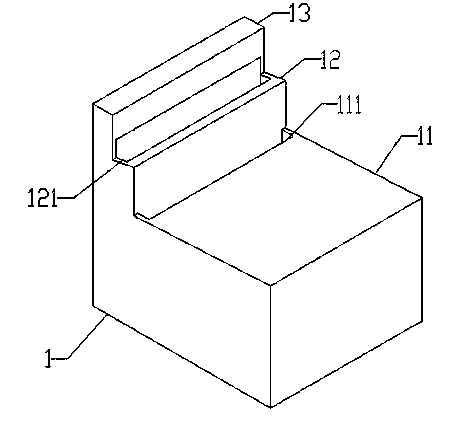

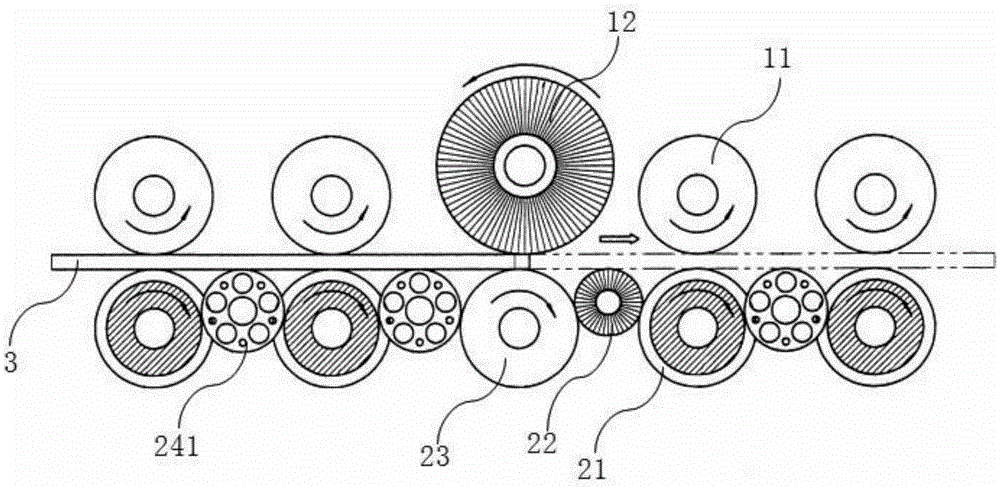

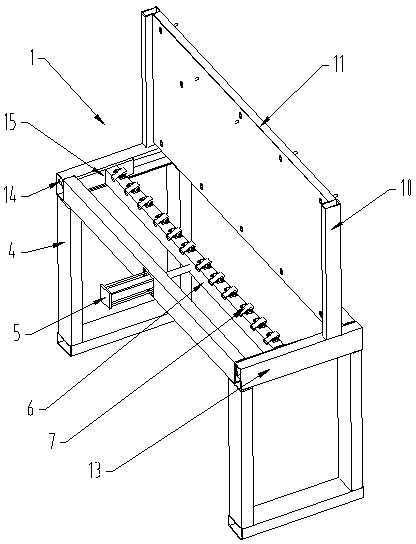

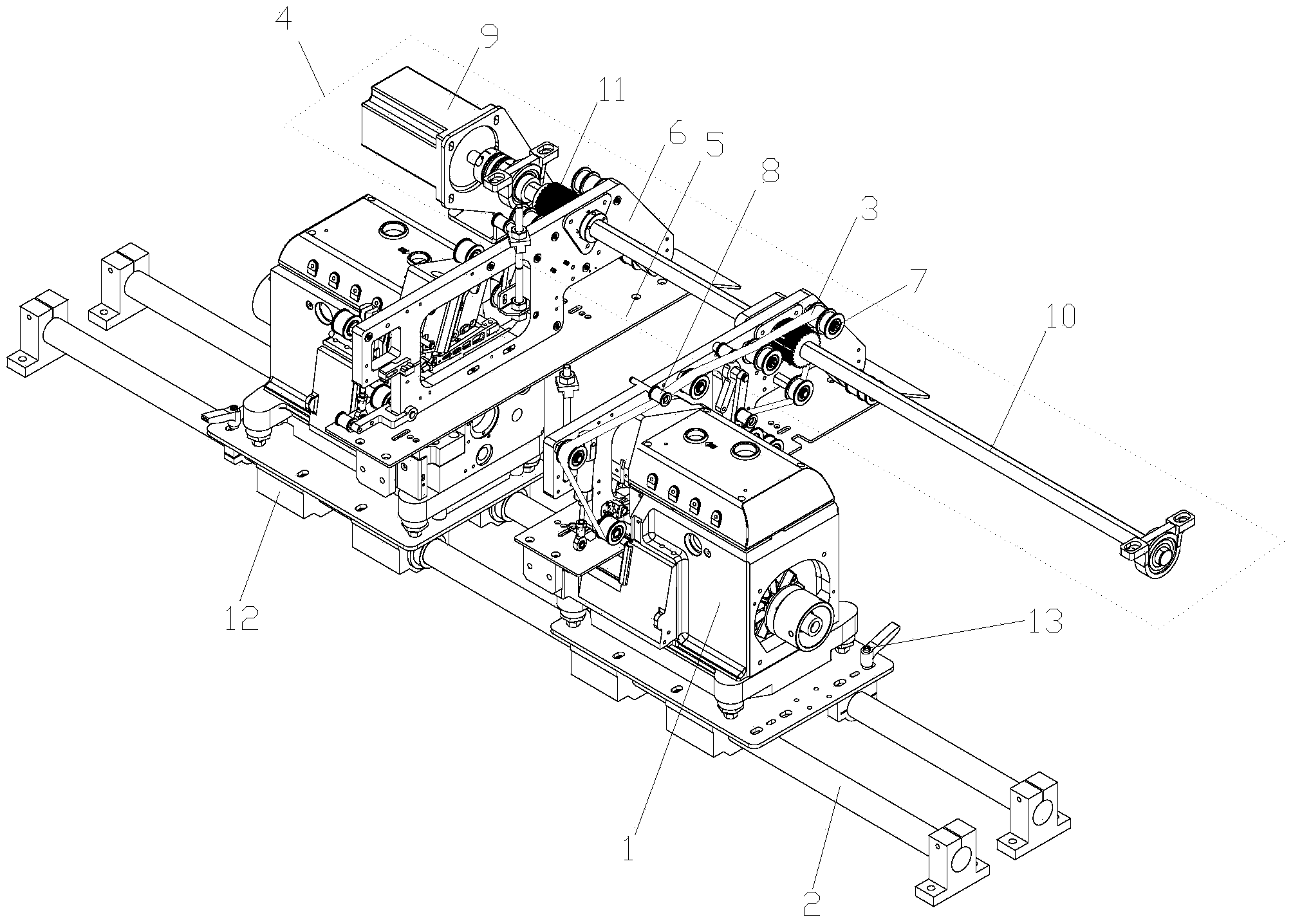

Feeding device used for machining of wood floors

InactiveCN103508182AStable transmissionHigh degree of automationConveyorsConveyor partsEngineeringMaterial supply

The invention discloses a feeding device used for machining of wood floors. The feeding device used for machining of wood floors comprises an automatic material supply mechanism (1) and a feeding mechanism (2), wherein the automatic material supply mechanism (1) comprises a material supply worktable (3) and a material supply support (4), an air cylinder (5) is installed on the material supply support (4), a piston rod at the front end of the air cylinder (5) is connected with a pushing frame (6) which is movably connected with the material supply support (4), a plurality of pushing blocks (7) arranged in the extending direction of the piston rod are embedded in the pushing frame (6), a cylindrical pin (8) penetrating through each pushing block (7) is fixed on the pushing frame (6) through a positioning block (9), a baffle support (10) is further arranged on the material supply support (4), and a transverse baffle (11) which can be vertically adjusted is installed on the baffle support (10). Through intelligent reset of the pushing blocks and the adjustment of the transverse baffle, the feeding device used for machining of wood floors achieves automatic feeding, has the advantages of being simple in structure, convenient to use, stable in operation and high in work efficiency, and is suitable for being popularized and used.

Owner:YANCHENG INST OF TECH

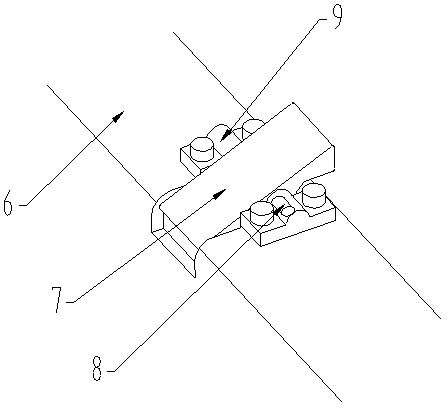

Twin-needle machine binding off mechanism

InactiveCN104250884AOptimize structureStable transmissionSewing-machine control devicesElectric machineryEngineering

The invention relates to a twin-needle machine binding off mechanism which comprises a pair of twin-needle machines, a slide rail, object carriers, belts and a synchronous rotating component fixed on the object carrier. The pair of twin-needle machines sleeves the slide rail to perform double-edge binding off on fabric passing between the two twin-needle machines. The object carriers are disposed at the noses of the twin-needle machines. Each object carrier comprises as carrier plate and a fixing rack, the height of the fixing rack is identical with the sewing height of the twin-needle machines, the fixing rack is vertically connected to the carrier plate, and a plurality of belt guide wheels are disposed on the fixing rack. The belts sleeve the belt guide wheels, the belt guide wheels roll the belts on the surfaces of the carrier plates. The synchronous transmission component comprises a motor, a rotary shaft and a belt pulley, wherein the rotary shaft is fixed on the fixing racks through shaft sleeves, the rotary shaft is connected with the belt pulley, the belt pulley drives the belts to roll around the belt guide wheels, and one end of the rotary shaft is connected with a motor. By the arrangement, the twin-needle machine binding off mechanism has the advantages that synchronous binding off is performed by the two opposite twin-needle machines, the structure for tightening or rolling fabric is improved, stable transmission is achieved, and production efficiency can be effectively increased.

Owner:SUZHOU JUKANG SEWING ROBOT

Spinning technology of novel spinning machine

InactiveCN103628158AStable strengthStable transmissionNew-spun product collectionArtificial thread manufacturing machinesEngineeringControl system

The invention relates to a spinning technology of a novel spinning machine. The spinning technology comprises the steps of supplying glue, molding threads, spinning and winding, wherein during spinning, independent drying drawing rollers are arranged among spinning rollers; a molding part of a winding device is arranged at the outer side of the area between wall boards at the two sides of a stand and at the other side opposite to the spun surfaced; after the steps of supplying glue, molding the threads and spinning, the obtained threads pass through the drying drawing rollers and are wound by the winding device, so that the wound threads can be obtained. According to the spinning technology of the novel spinning machine, the winding device is externally arranged, so that the corrosivity to the threads, the winding device and a control system of the winding device is low in the acid environment, and the winding device is convenient to maintain and operate by a worker; the independent drying drawing rollers are arranged among the spinning rollers, so that the threads pass through the drying drawing rollers when walking at the rear sections of the spinning rollers; at the moment, the drying drawing rollers are independent of the spinning rollers, so that the drying temperature and the drying time can be effectively controlled when the threads are dried.

Owner:YIBIN GRACE GROUP CO LTD +1

Transmission mechanism for stamping die

ActiveCN104014678AStable transmissionMaximize exposureMetal-working feeding devicesPositioning devicesLeather beltEngineering

The invention discloses a transmission mechanism for a stamping die. The transmission mechanism comprises a driving wheel, a driven wheel, a belt arranged on the driving wheel and the driven wheel in a tensioning mode, a circular shaft arranged between the driving wheel and the driven wheel, a plurality of opened clamps which are arranged on the circular shaft in a clamping mode, and a joining plate, wherein the axis of the circular shaft is parallel to the working face of the belt, and the non-opened end of at least one opened clamp is adjustably installed on the joining plate relative to the perpendicular direction of the joining plate. According to the transmission mechanism for the stamping die, the circular shaft in the transmission mechanism can rotate in the opened clamps so that normal adjustment of the circular shaft and the upper potion of the joining plate can be achieved, the opened clamps and the joining plate can be adjusted in the perpendicular direction so that the working face on the belt can be adjusted according to the molded surface of a covering part of an automobile, contact maximum of the covering part of the automobile and the conveying belt is achieved, and fast and stable conveying is ensured under the premise that the covering part is not damaged.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

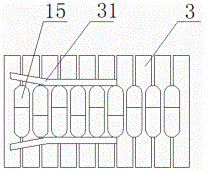

Medicine dispensing layer assembly mechanism

The invention discloses a medicine dispensing layer assembly mechanism which comprises a supporting frame, a medicine stirring box mechanism, sensors, driving rollers, a plurality of driven rollers and a plurality of partition plates. The medicine stirring box mechanism and the sensors are arranged on the front edge of the supporting frame. The driving rollers and the multiple driven rollers are sequentially arranged in a front-and-back spaced manner. Each roller and the adjacent corresponding driven roller are connected through cooperative mounting of a synchronous belt and a synchronous belt wheel, and every two adjacent driving rollers are connected through cooperative mounting of a synchronous belt and a synchronous belt wheel. According to the medicine dispensing layer assembly mechanism, power is conveyed through a motor, the synchronous belts and the synchronous belt wheels cooperate to drive the driving rollers and all the driven rollers to synchronously rotate in the same direction, and medicine boxes are placed on the driven rollers to move forwards along with rotation of the driven rollers; and the partition plates achieve the guide function, traditional belt conveying and self-gravity sliding are replaced, the medicine dispensing layer assembly mechanism can be suitable for conveying the medicine boxes of various specifications and sizes, and is good in universality, stable in conveying, low in noise and convenient to maintain, and the integrity of the medicine boxes in the medicine dispensing process is guaranteed.

Owner:迈为医疗技术(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com