Transmission mechanism for stamping die

A technology of transmission mechanism and stamping die, which is applied in the field of stamping die accessories, can solve the problems of scratches on the cover, lower yield rate, inability to maximize the contact surface between the car cover and the belt, etc., and achieve the effect of stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

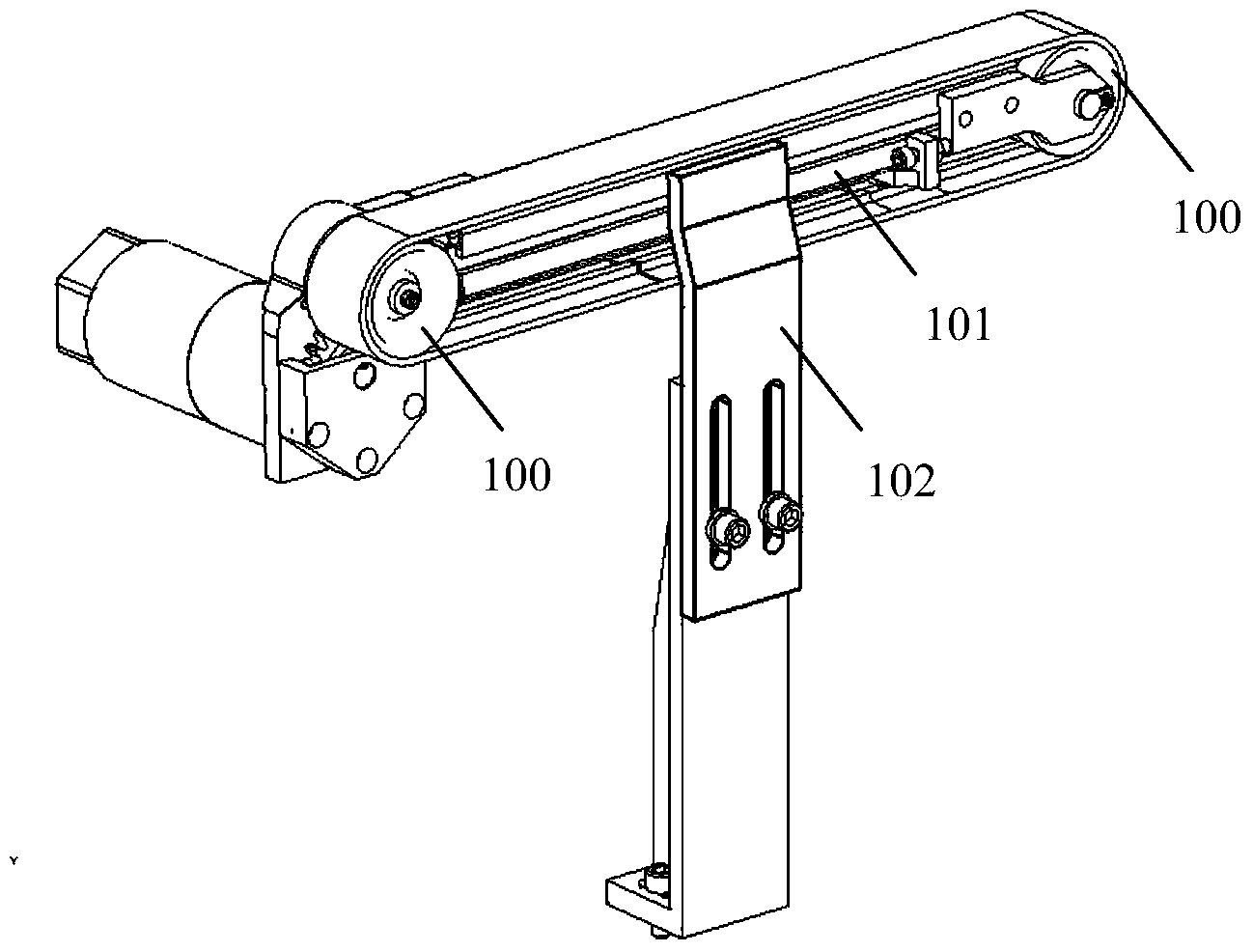

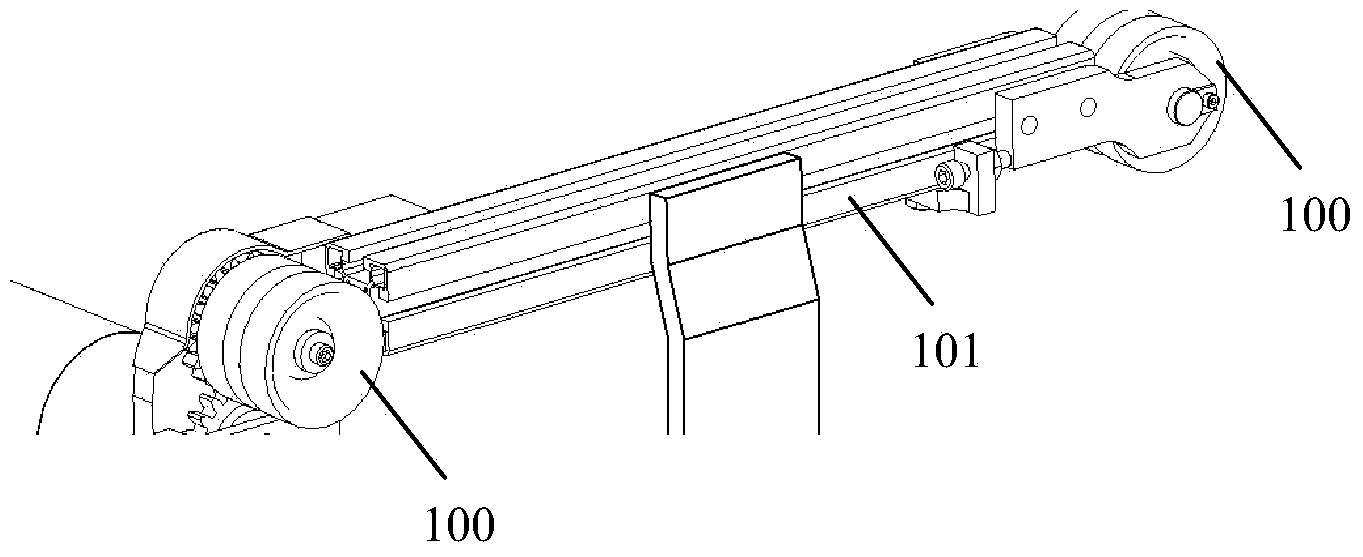

[0035] Such as Figure 4 As shown, a transmission mechanism for stamping dies, which is mainly used in stamping dies for automobile stamping parts, including driving wheel 1, driven wheel 2, belt 3, motor 4, round shaft 5, open clamp 6, connecting plate 7.

[0036] Belt 3 Tensioned belt 3 on driving pulley 1 and driven pulley 2.

[0037] The circular shaft 5 is arranged between the driving wheel 1 and the driven wheel 2, and its axis is parallel to the working surface of the belt 3.

[0038] Four open clamps 6 are clamped on the round shaft 5 , two of which are respectively arranged at both ends of the round shaft 5 , and a motor 4 is mounted on the open clamp 6 close to the driving wheel 1 .

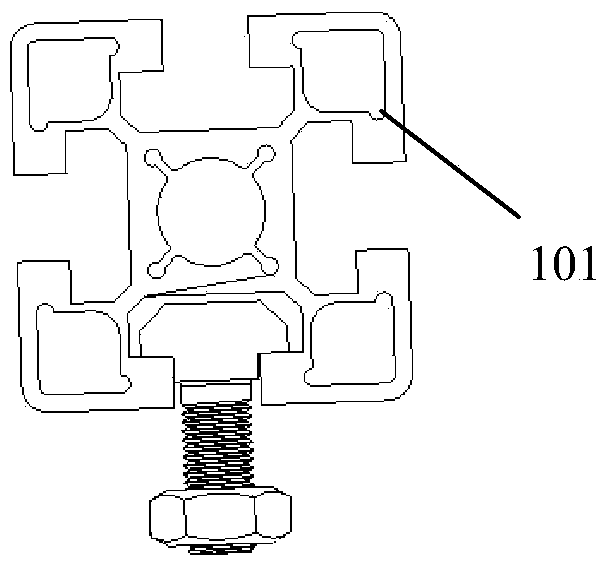

[0039] The non-open ends of two opening clamps 6 on the circular shaft 5 middle part are installed on this connecting plate 7 in a vertically adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com