Medicine dispensing layer assembly mechanism

A component and medicine dispensing technology, applied in the directions of transportation, packaging, roller table, etc., can solve problems such as poor versatility and inability to dispense medicine, and achieve the effects of good versatility, convenient maintenance and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

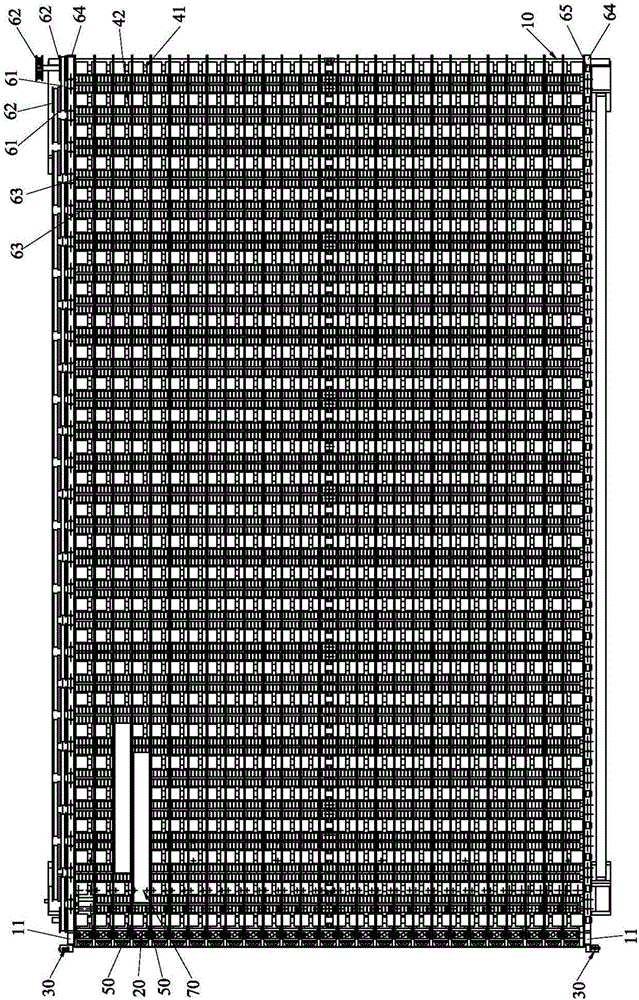

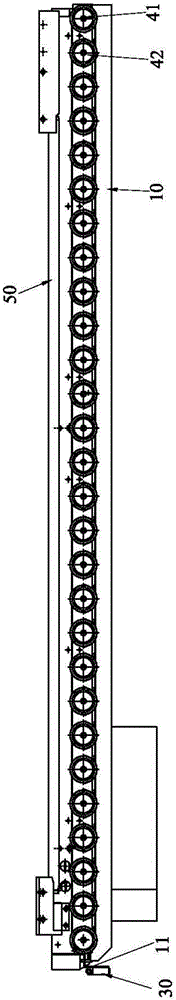

[0022] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a support frame 10, a pill box mechanism 20, a sensor 30, a driving roller 41, a plurality of driven rollers 42 and a plurality of partitions 50.

[0023] The medicine box mechanism 20 and the sensor 30 are all arranged on the front side edge of the support frame 10; One aforementioned sensor 30 is installed, and the two sensors 30 face each other.

[0024] The driving roller 41 and a plurality of driven rollers 42 are arranged at intervals in sequence. The driving roller 41 and each driven roller 42 extend left and right. The ends are rotatably installed on the left and right side edges of the support frame 10 respectively, between the driving roller 41 and the adjacent driven roller 42 and between the adjacent two driven rollers 42 through the synchronous belt 61 and the synchronous belt The wheels 62 are fitted and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com