Roll type plastic cutting machine

A cutting machine and cutting mechanism technology, applied in the direction of winding strips, metal processing, sending objects, etc., can solve the problems of easy occurrence of burrs or crooked edges, inaccurate operation, waste of materials, etc. The effect of transmission and conveying is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

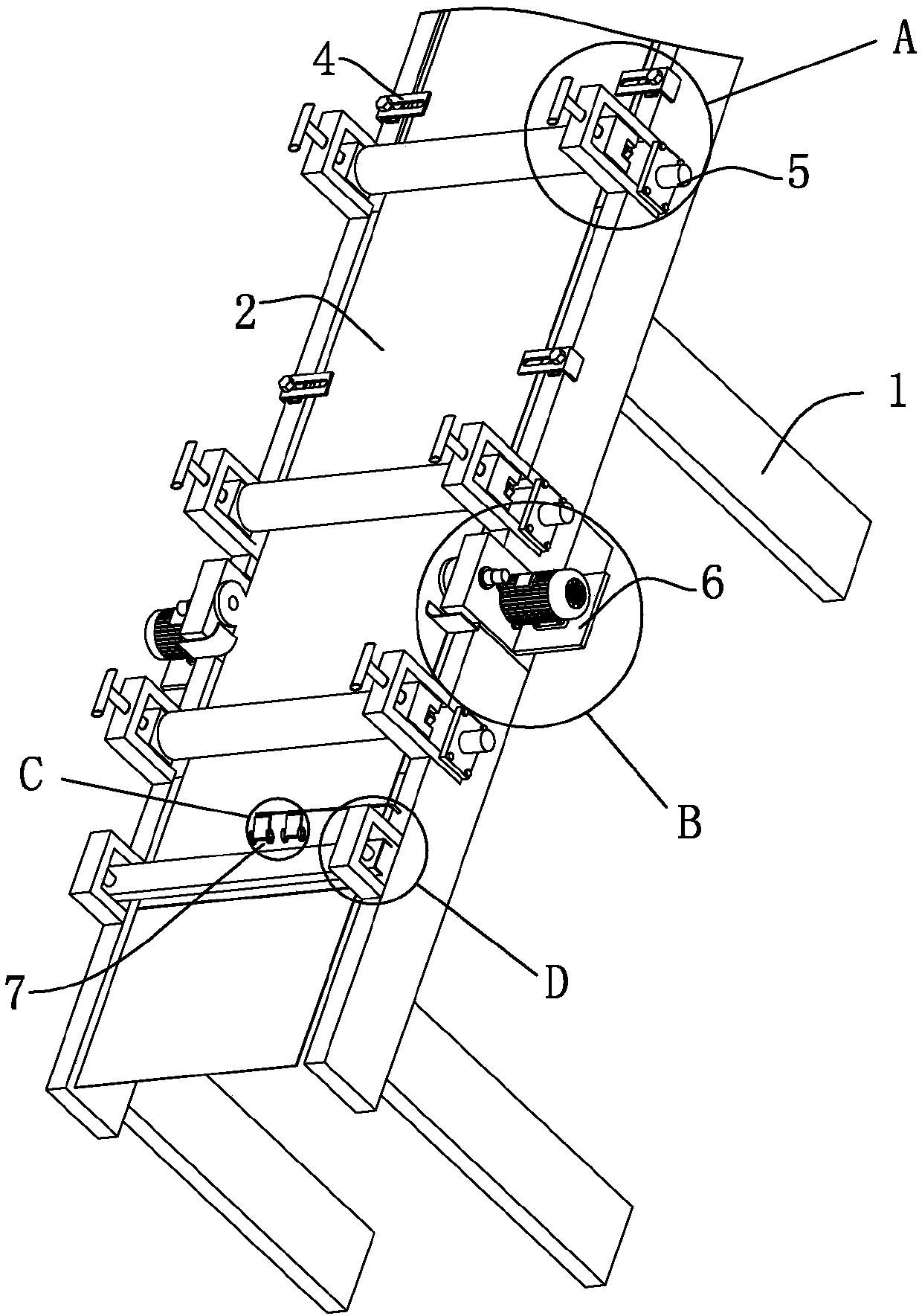

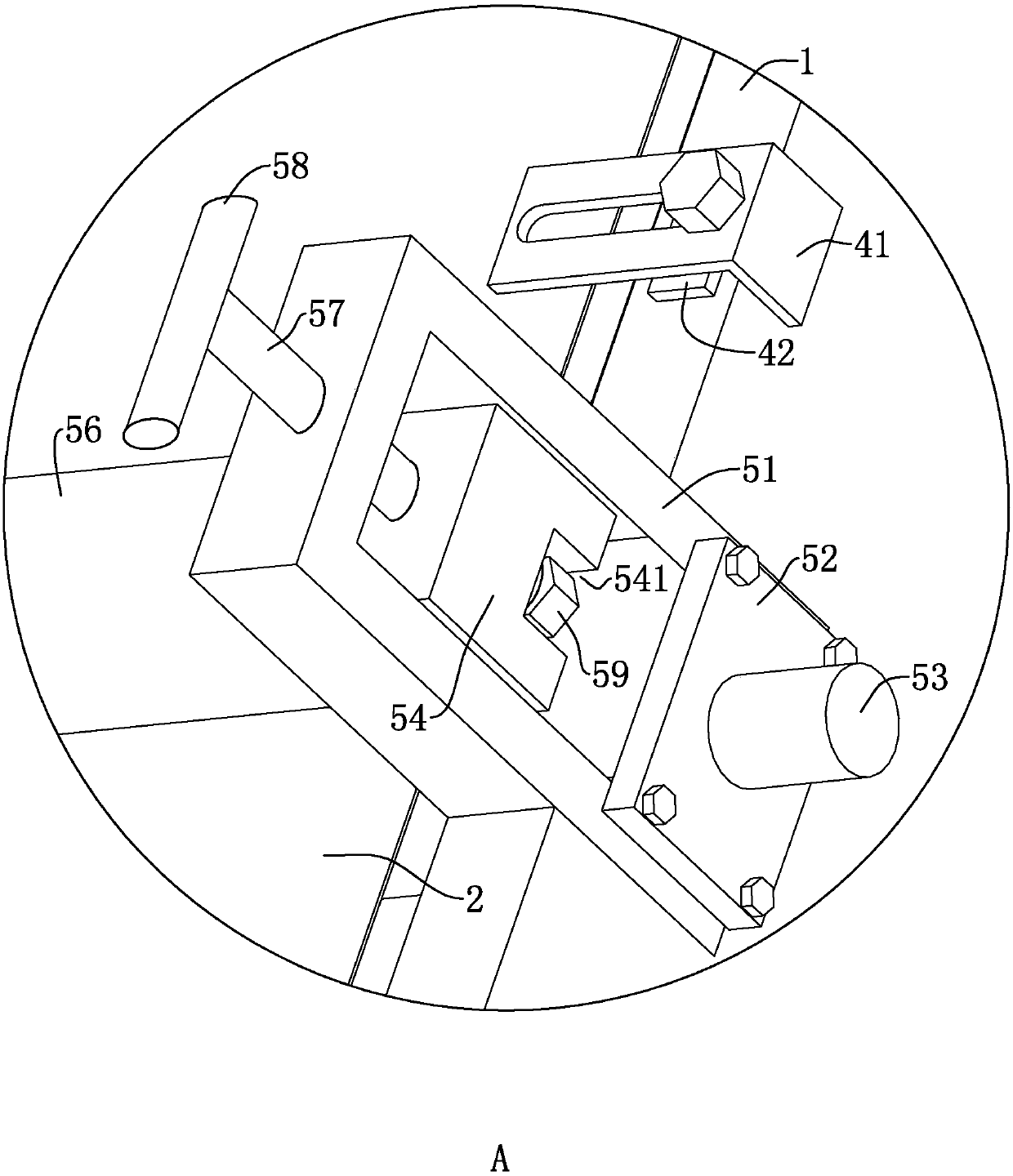

[0038] A roll-type plastic cutting machine, such as figure 1 and figure 2 As shown, the roll-type plastic cutting machine includes a bracket 1 on which a plastic floor 2 is placed. The upper surface of the bracket 1 is provided with several clamping mechanisms 4 along the length direction for preventing the plastic floor 2 from lifting. The clamping mechanism 4 includes Screws are used to fix the pressure plate 41 with an L-shaped structure on the bracket 1. The part of the pressure plate 41 extending between the brackets 1 is located above the plastic floor 2. The height between the lower surface of the pressure plate 41 and the upper surface of the plastic floor 2 is adjusted below the pressure plate 41. Backing plate 42.

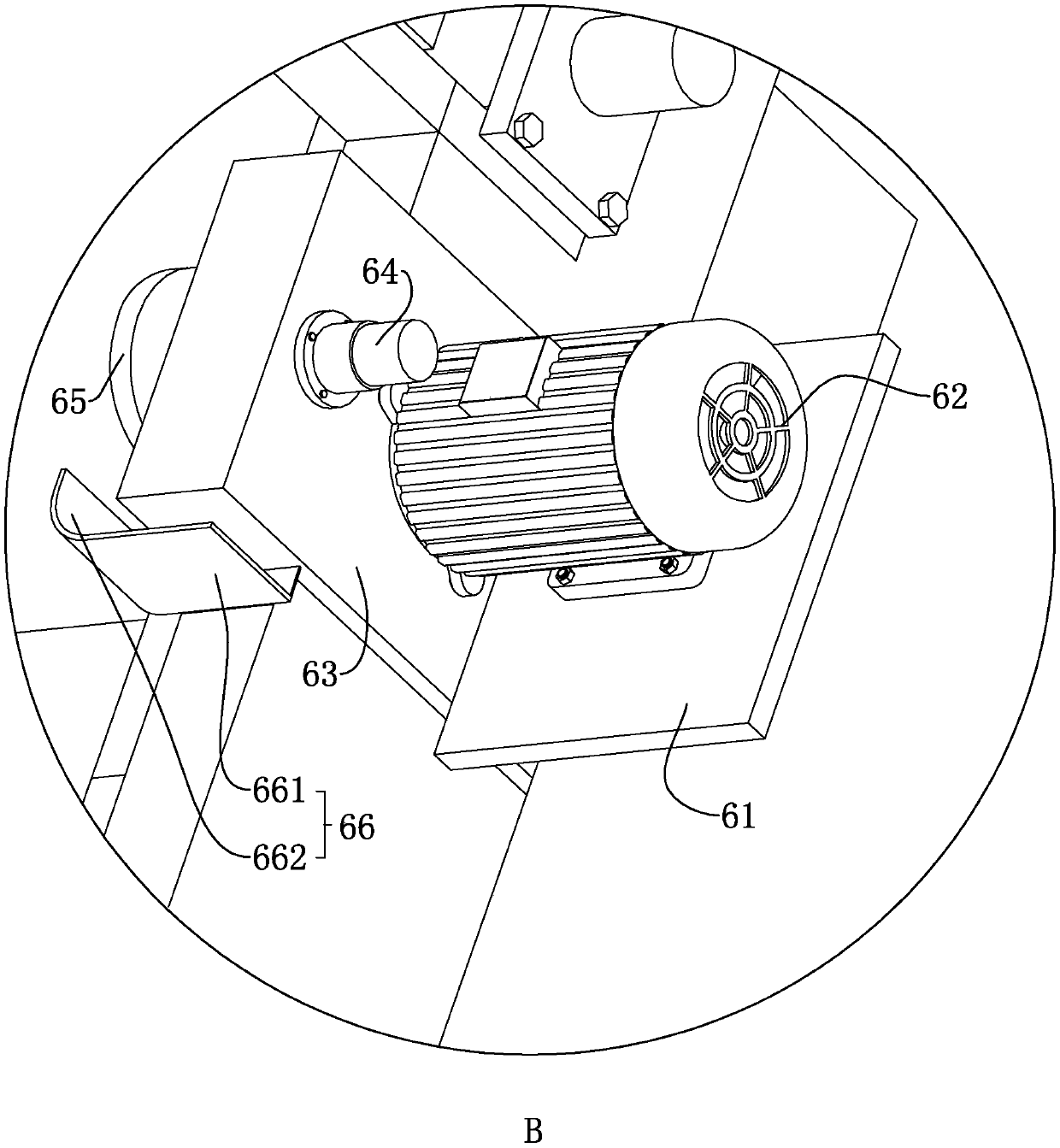

[0039] Such as figure 1 and figure 2As shown, three sets of driving mechanisms 5 for driving the movement of the plastic floor 2 are arranged on the support 1 . The driving mechanism 5 includes a driving frame 51 welded and fixed on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com