An electric turning mechanism

A flipping mechanism, electric technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of restricting assembly quality and production efficiency, high energy consumption of hydraulic components, and large equipment space, and achieve the Small change, optimized force performance, stable change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

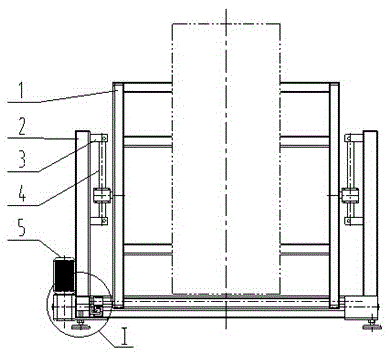

[0041] Such as figure 1 and 3 As shown, except for the reduction motor 5, all other devices are arranged symmetrically along the center line of the bottom edge of the U-shaped installation frame, wherein:

[0042] Such as figure 1 As shown, in a preferred embodiment of the present invention, the shown electric turning mechanism includes a fixed and turning workpiece 15 (such as Figure 4 As shown), the flip frame 1, the U-shaped mounting frame 2, the vertical guide rod 4 fixed on the U-shaped mounting frame 2 through the guide rod seat 3 and the outside of the U-shaped mounting frame 2 And be positioned at the deceleration motor 5 of any one in two vertices.

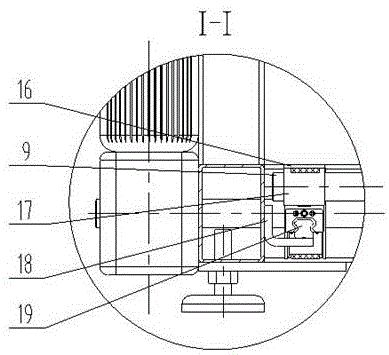

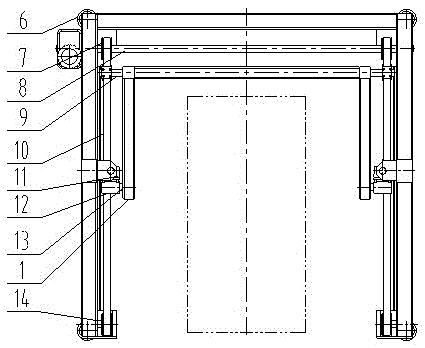

[0043] Such as figure 2 As shown, in another prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com