Patents

Literature

35results about How to "Save on-site space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

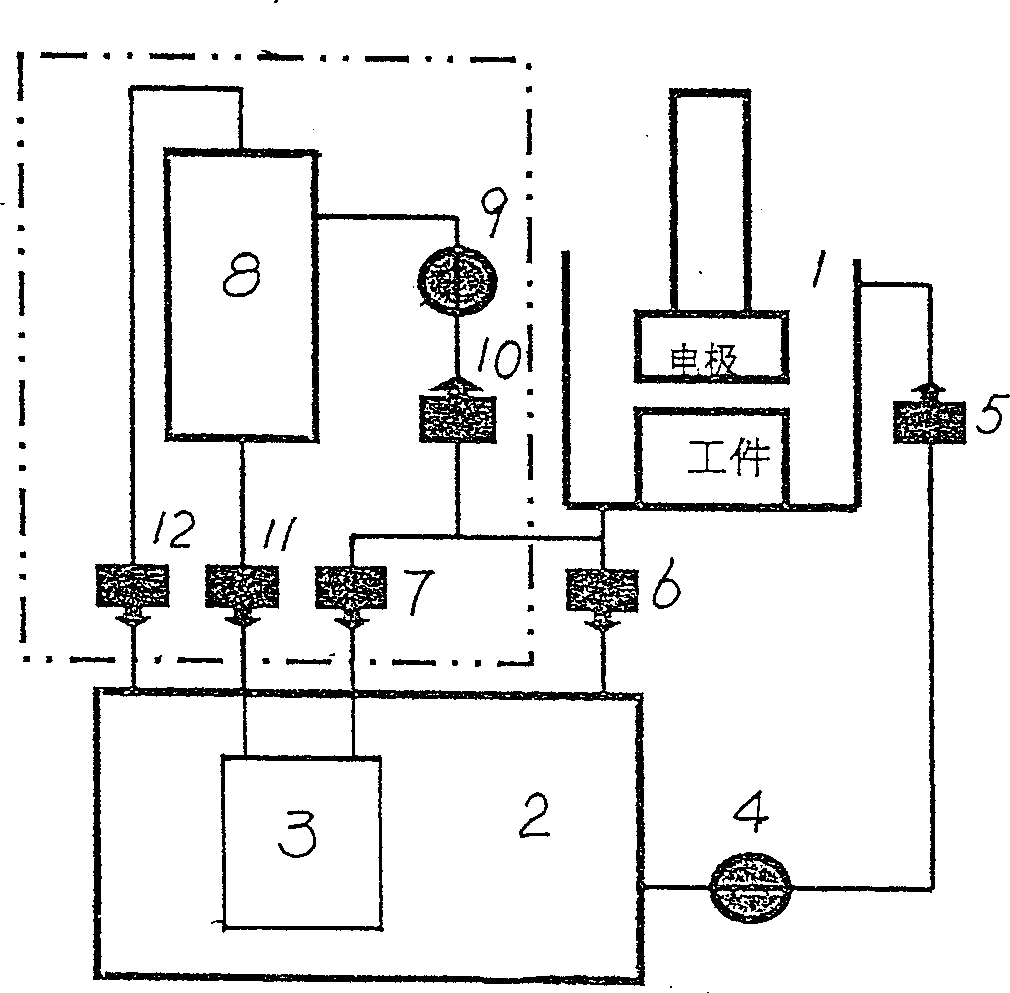

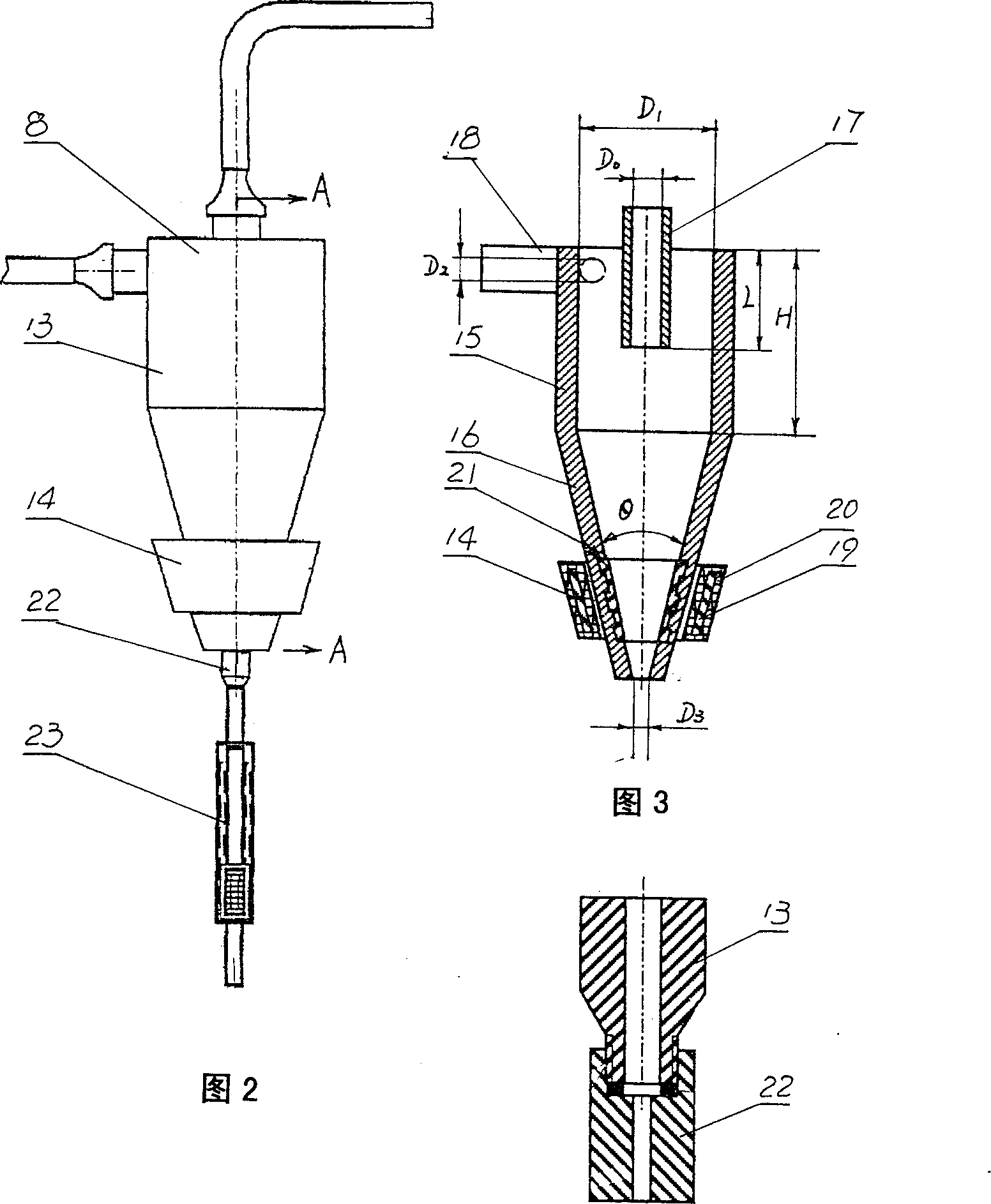

Cyclic treating system of working liquid for electrospark machining

A cyclic treating system for the working liquid used for electrospark machining is composed of liquid tank, oil tank, filter, connecting pipelines, and the pumps and control valves in the pipelines, and features that an under-flowing magneto-hydraulic cyclone separator is parallelly connected with the pipeline between liquid tank and filter. It can separate out more than 85% of ferromagnetic or non-ferromagnetic scrap from said working liquid in in-line mode.

Owner:SHENZHEN UNIV +1

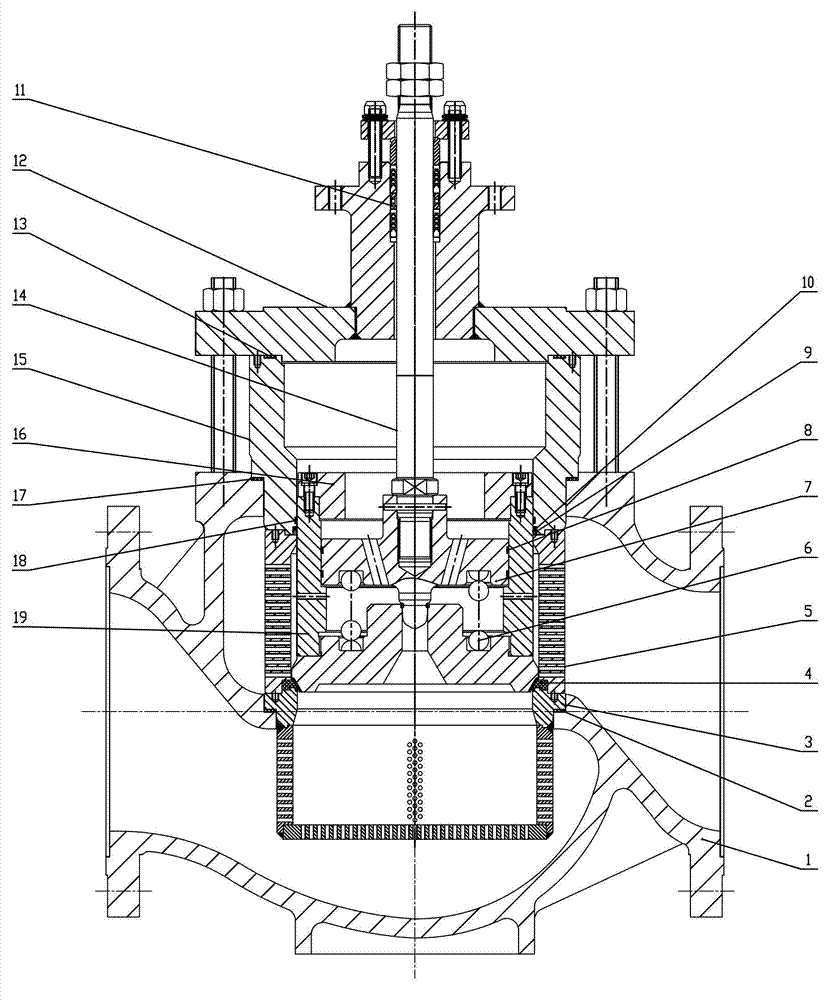

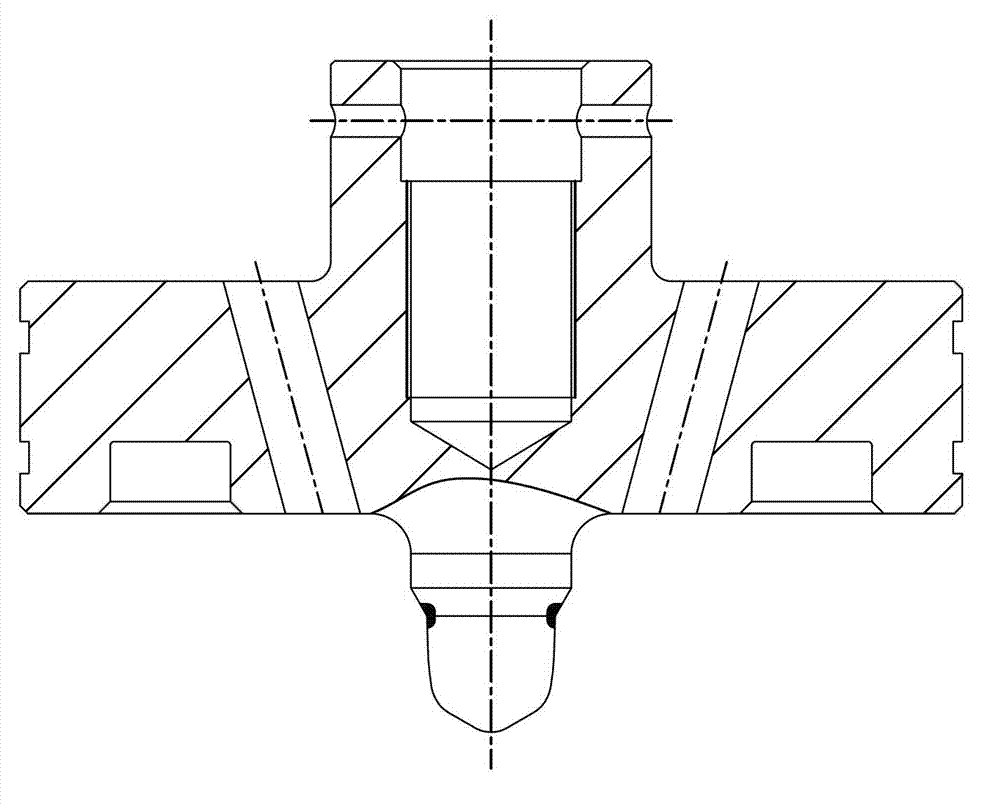

Pilot-operated double-spool split-range adjusting valve

InactiveCN102927336ASimple designCompact structureValve members for absorbing fluid energyEqualizing valvesEngineeringNoise reduction

The invention relates to a pilot-operated double-spool split-range adjusting valve which is characterized in that a valve base is arranged in a valve body, a Teflon valve base is arranged on the valve base, a main spool is assembled on the Teflon valve base to form flexible sealing, a valve rod is integrally connected with a pilot-operated spool, and the valve rod and a compression spring are assembled in an inner cavity of the main spool. A first Teflon guide tape is arranged in a trough of the pilot-operated spool, a thrust ring is used for being connected with the main spool, and the sealing surface of the pilot-operated spool is attached to the sealing surface in the inner cavity of the main spool. A noise reduction sleeve and a balancing ring base are sequentially arranged on the valve base. A stuffing assembly is assembled in an upper cover stuffing box, and an upper cover is fixed on the valve body. By adopting the pilot-operated double-spool split-range adjusting valve, a bypass parallel-connection valve is not used for flow adjusting, and accordingly the use quantity of the valves is saved. The pilot-operated spool can meet requirement of equal percentage accurate adjusting under small opening, and the main spool can meet requirement of equal percentage accurate adjusting under large opening and achieve the function of media large flow backflow cutting in the pipeline system failure state. Flow of the pilot-operated double-spool split-range adjusting valve can be adjusted accurately and the pilot-operated double-spool split-range adjusting valve can save pipe distribution space and reduce use cost of clients.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

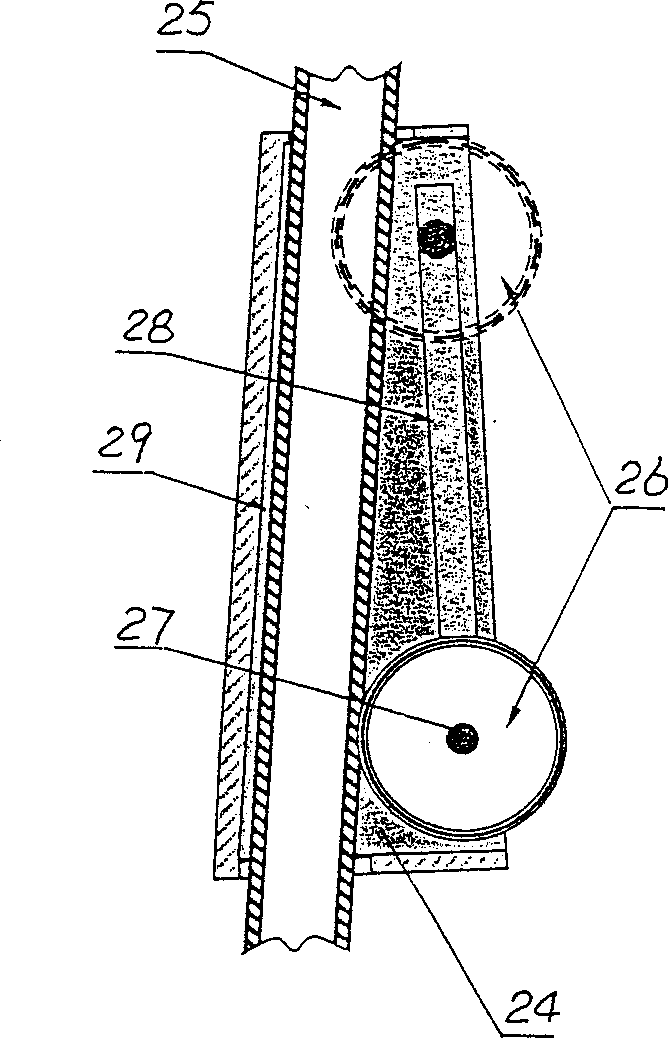

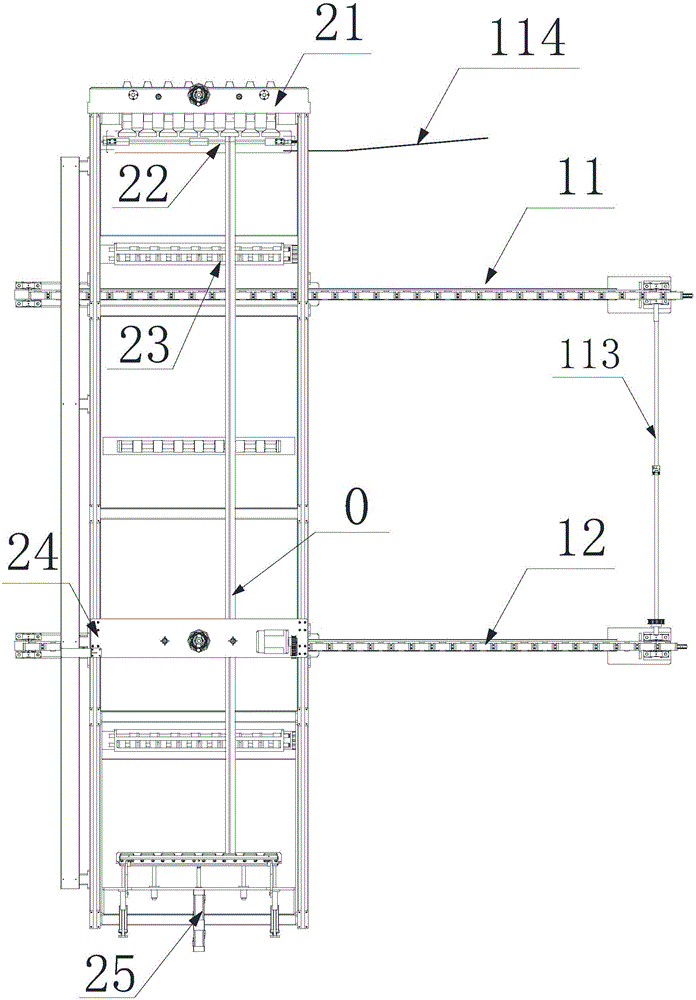

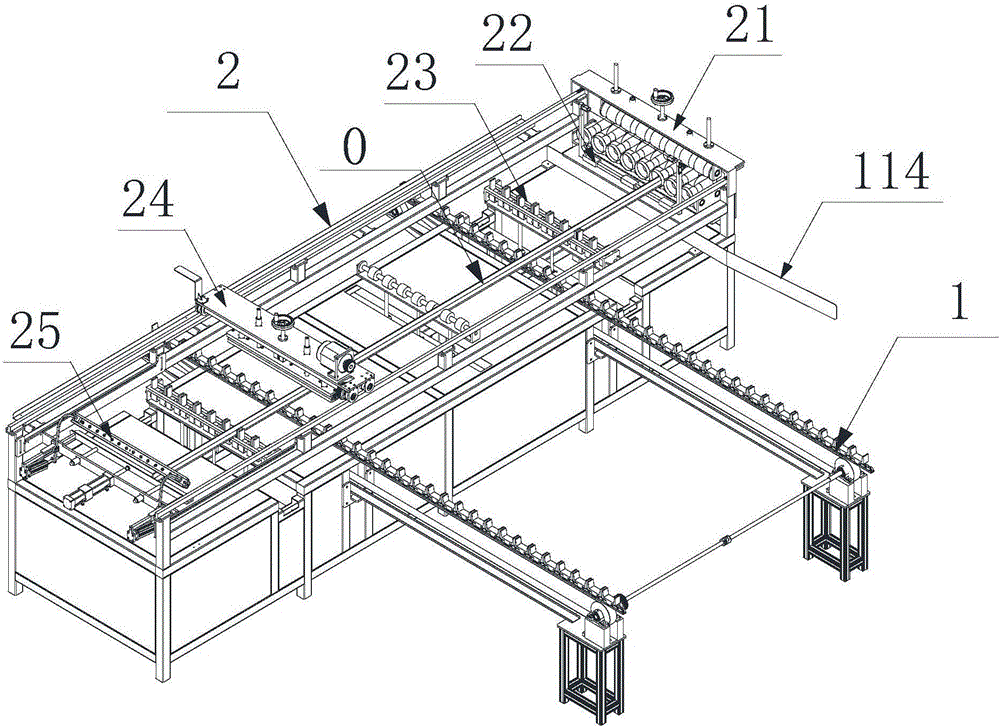

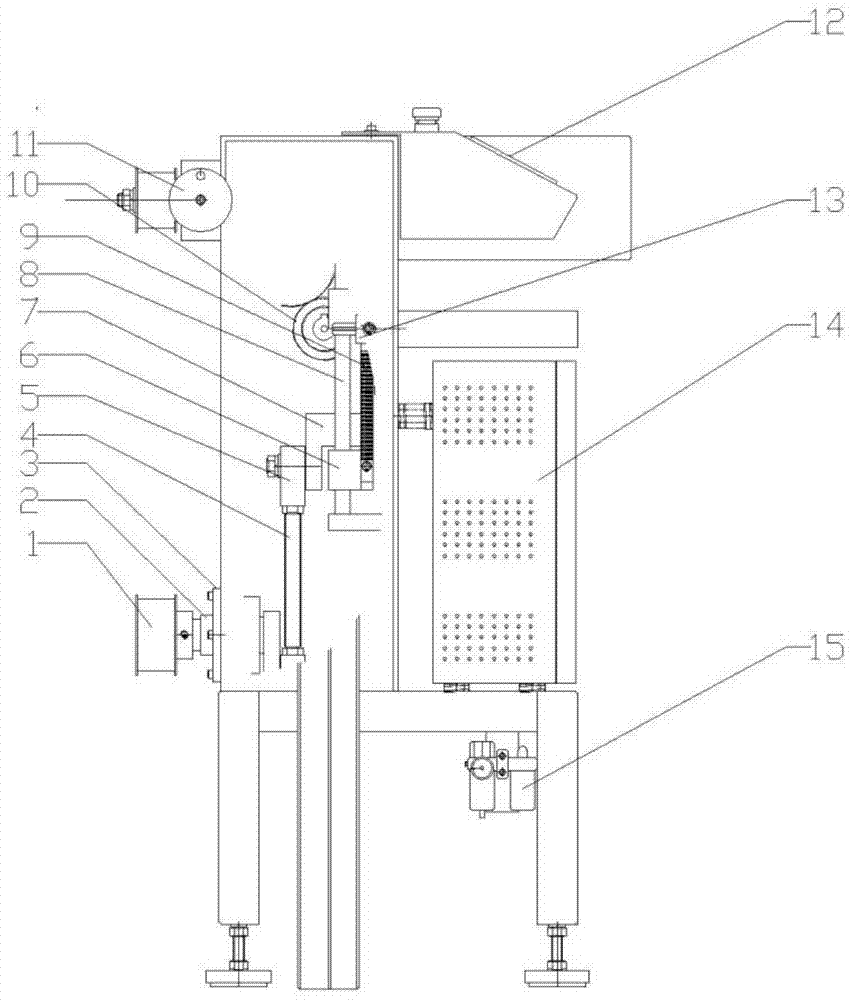

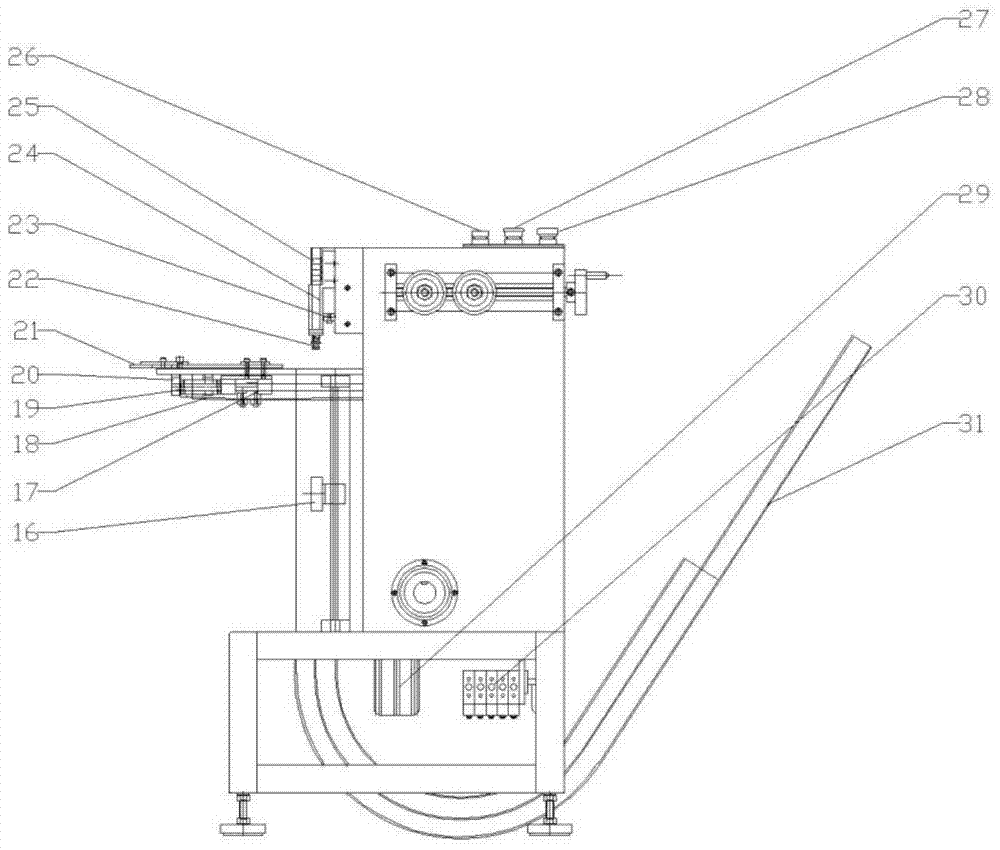

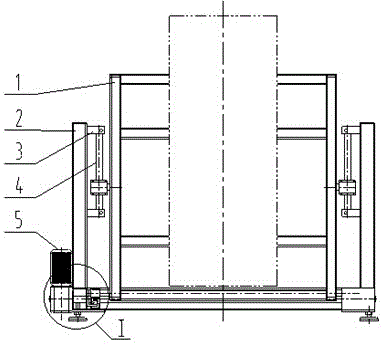

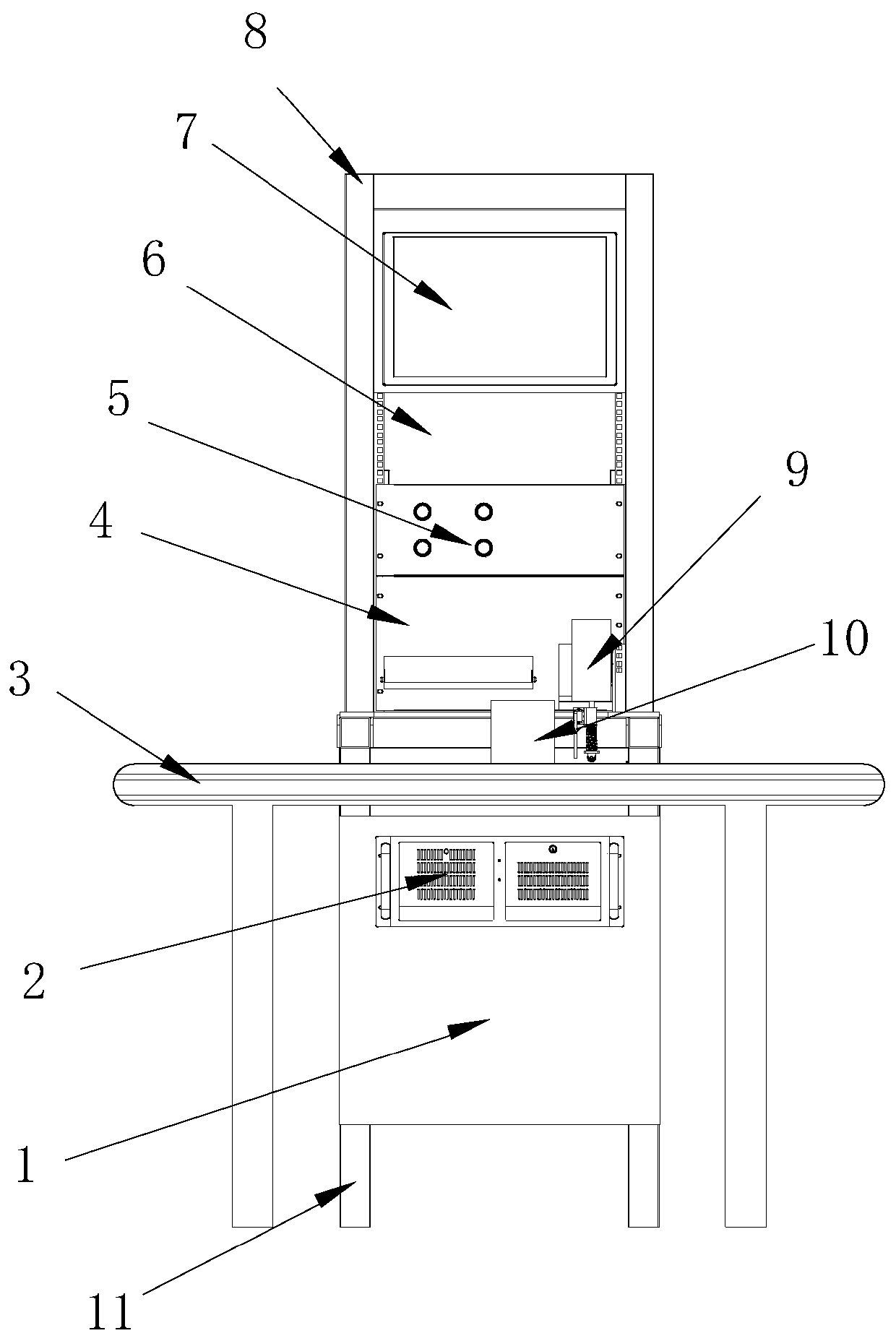

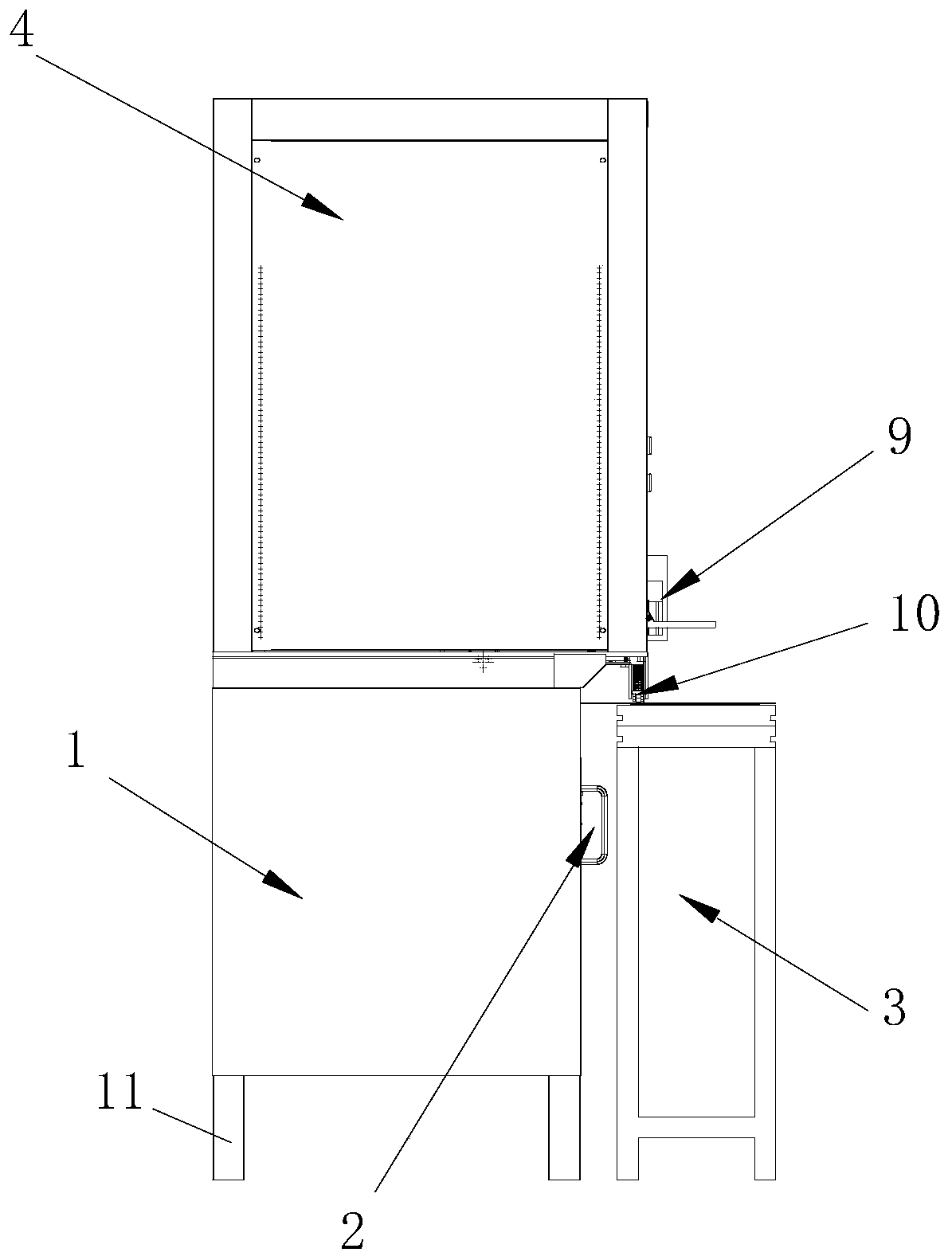

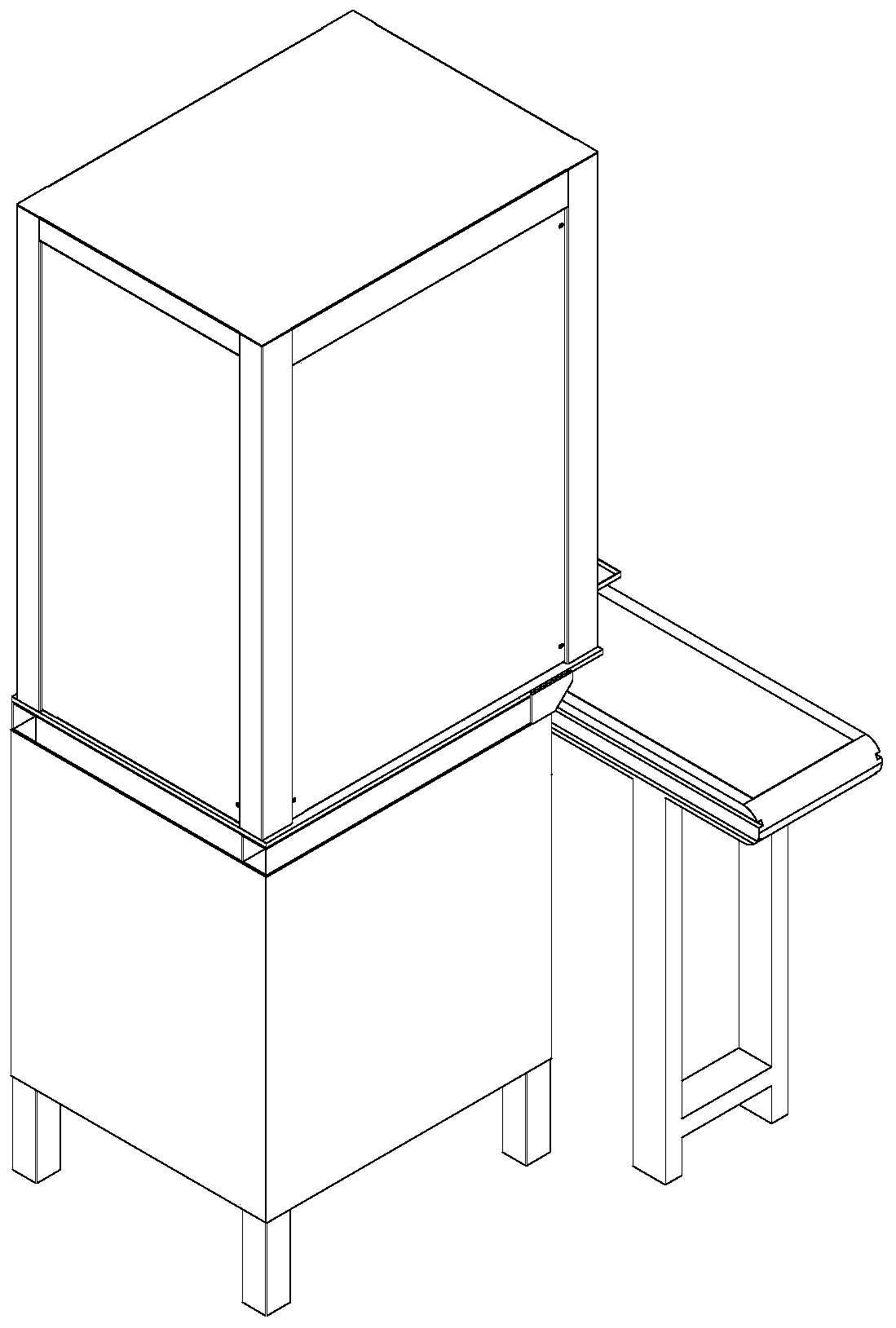

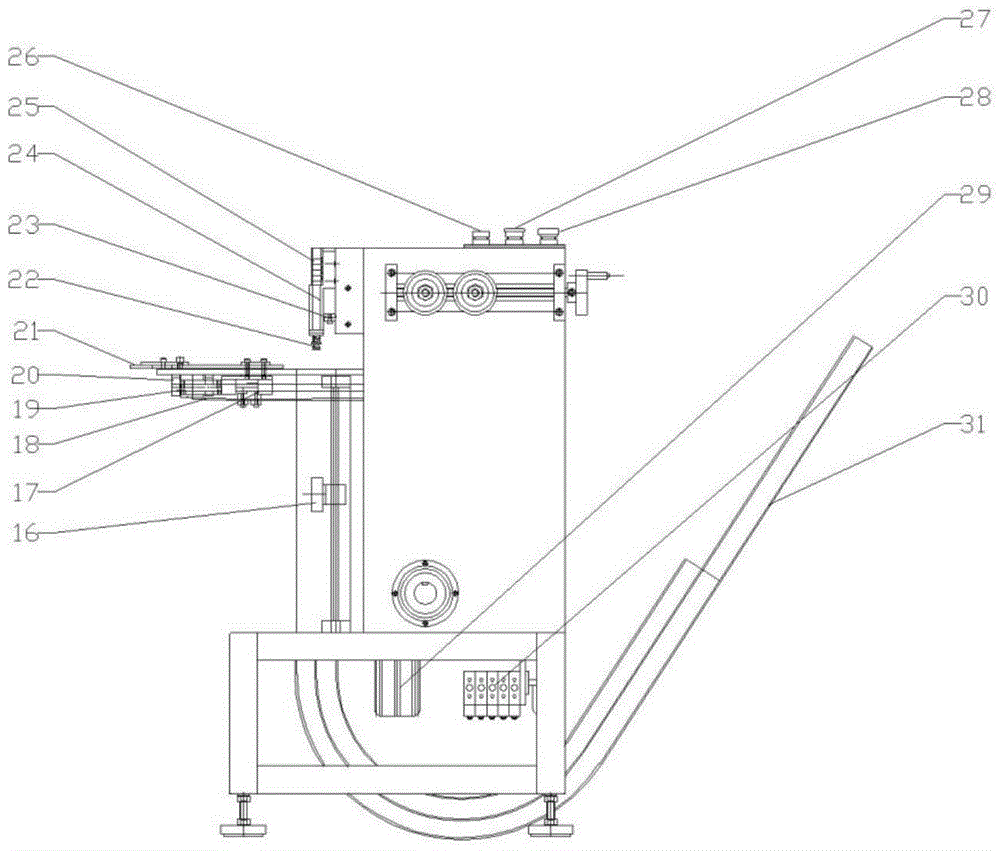

Automatic film sheathing equipment for profile and film sheathing method thereof

ActiveCN106347737AReduce labor intensityImprove stabilityConveyor wrappingRod-shaped articlesEngineeringUltimate tensile strength

The invention discloses automatic film sheathing equipment for a profile and a film sheathing method thereof. The automatic film sheathing equipment comprises a profile charging and discharging conveying unit and an automatic film sheathing unit, wherein the automatic film sheathing unit comprises a sleeve mechanism, a cutting mechanism, a film clamping and translation mechanism, a clamping and pushing-pulling mechanism and a lifting mechanism. The film sheathing method comprises the following steps: the profile charging and discharging conveying unit conveys the profile to the front end of the sleeve mechanism and conveys the profile away from the equipment after the film sheathing is finished, the lifting mechanism lifts the profile from a conveying mechanism in the profile charging and discharging conveying unit, the clamping and pushing-pulling mechanism clamps the end of the lifted profile and push the profile to the sleeve mechanism horizontally, so that the head of the profile extends into a sleeve in the sleeve mechanism; the film clamping and translation mechanism clamps a thin film sheathed outside the sleeve and finishes film sheathing by translation of the thin film along the length direction of the profile to the end part of the profile, and the cutting mechanism is used for carrying out film cutting action after the head of the profile is separated from the sleeve. The automatic film sheathing equipment for profile and the film sheathing method disclosed by the invention have the advantages that the neatness and the quality of the sheathed film can be guaranteed, the film sheathing efficiency can be improved and the labor intensity can be greatly reduced.

Owner:广州市祺兴自动化科技有限公司

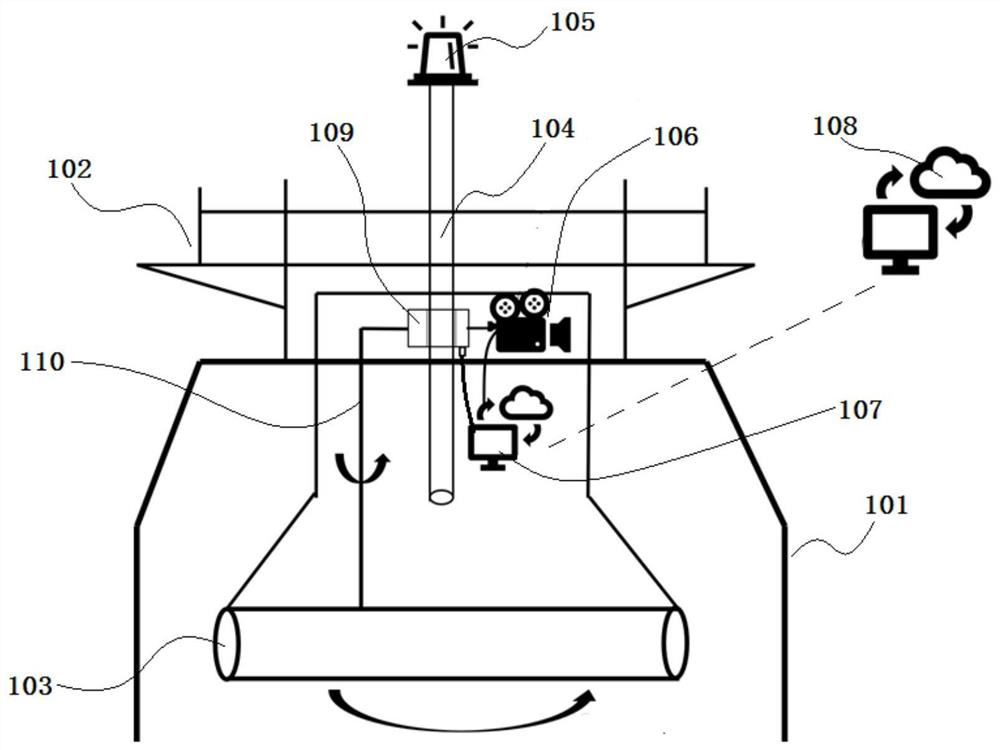

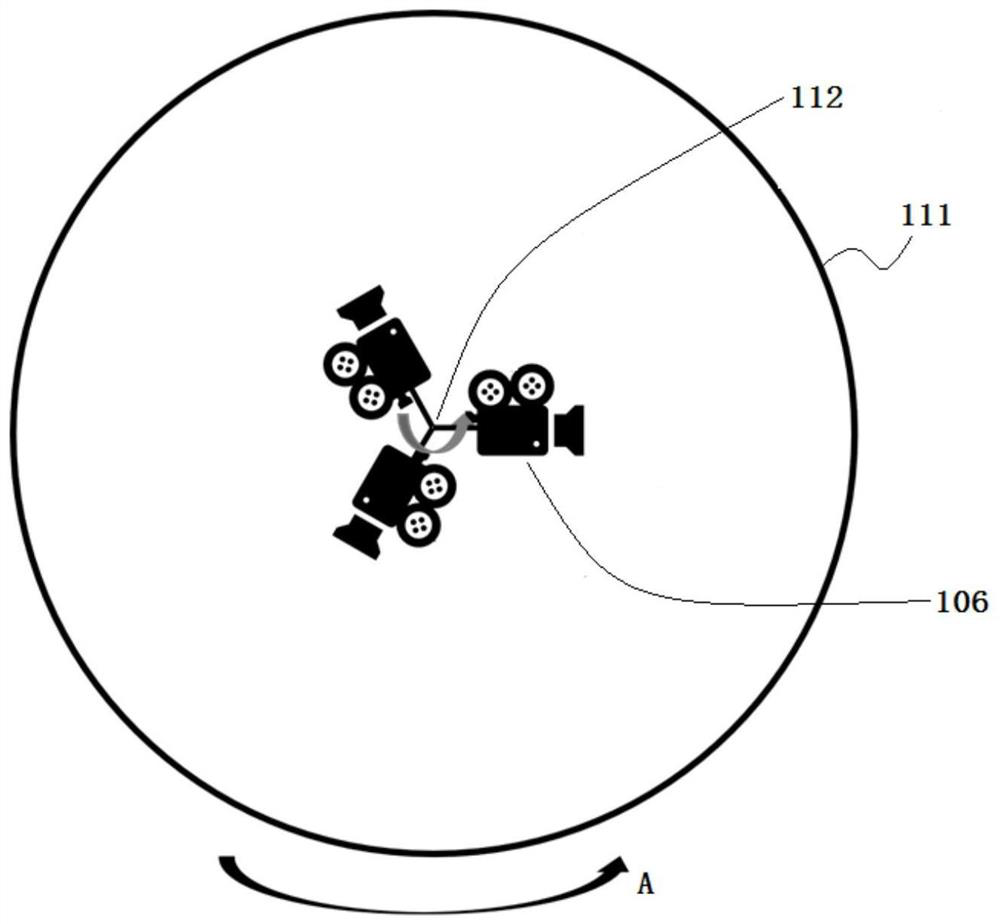

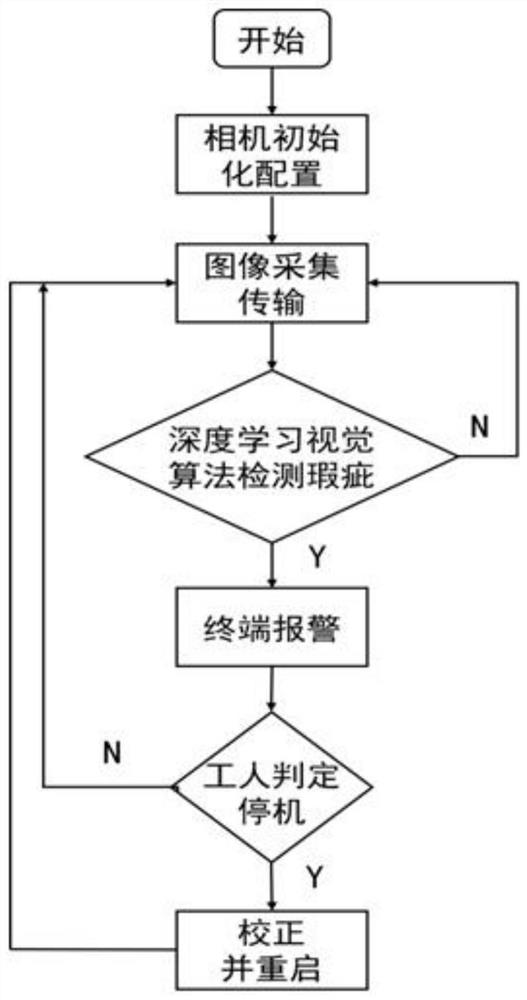

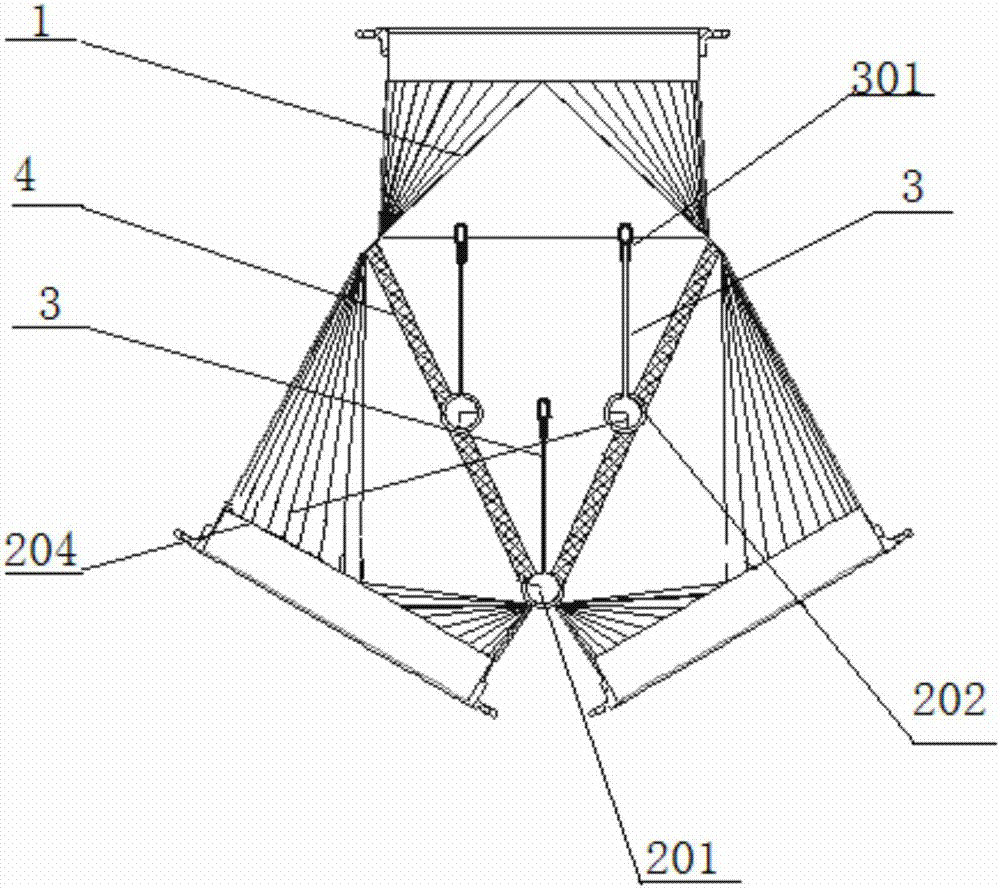

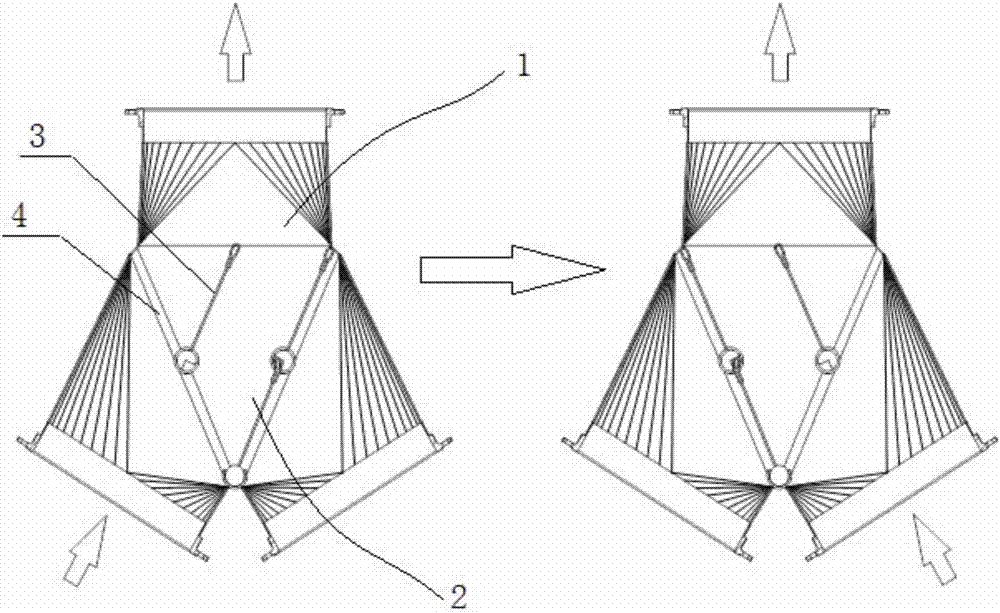

Image acquisition device and fabric defect real-time detection system for circular knitting machine

PendingCN111812108AAchieve a relatively static stateReduce indicator requirementsTelevision system detailsColor television detailsEngineeringImaging data

The invention aims to provide a low-cost, stable and high-quality image acquisition device and a corresponding defect detection system. In order to achieve the purpose, the invention adopts the following technical scheme: the image acquisition device for a circular knitting machine comprises a plurality of cameras which are arranged at intervals in the circumferential direction of a rotating shaftof a circular knitting machine and are used for acquiring real-time images of fabrics in production inside or outside the circular knitting machine, a control transmission module which is electrically connected with the plurality of cameras respectively and is used for controlling shooting actions of the cameras and storing / transmitting image data acquired by the cameras, and a driving / transmission mechanism which is used for driving or enabling the cameras, so that the cameras synchronously rotate with the circular knitting machine when the circular knitting machine runs.

Owner:绍兴织蛛物联科技有限公司

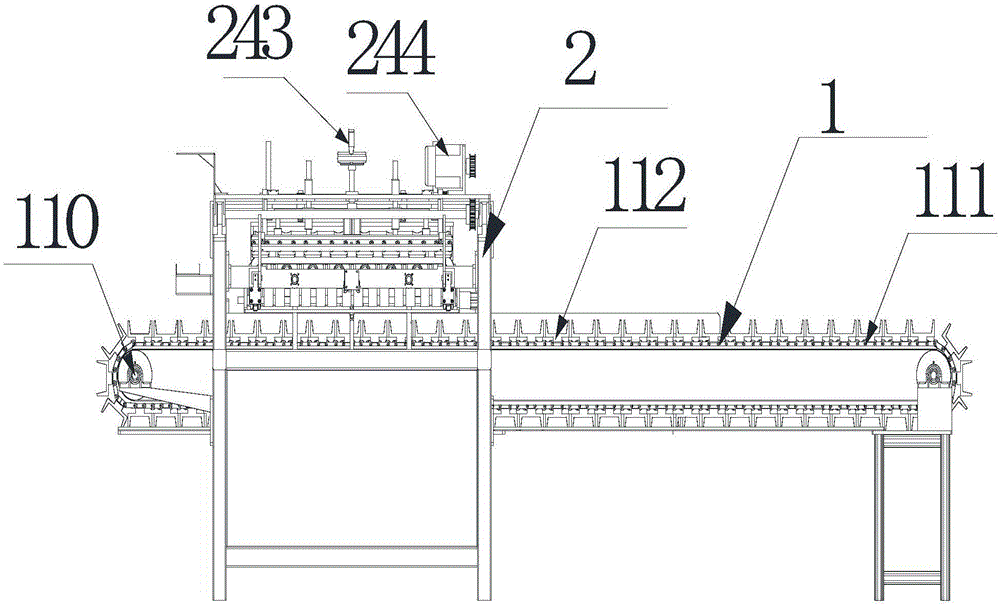

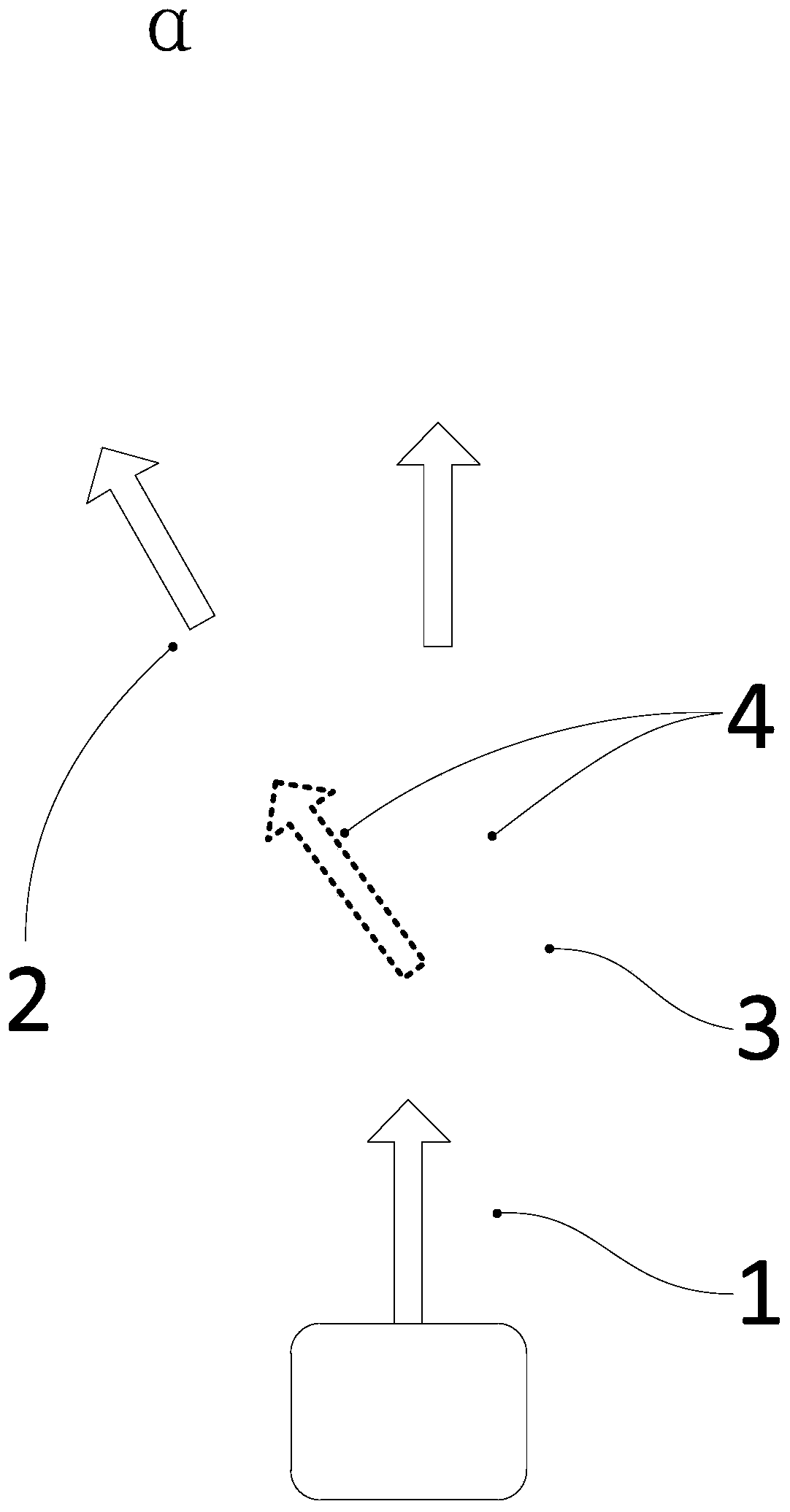

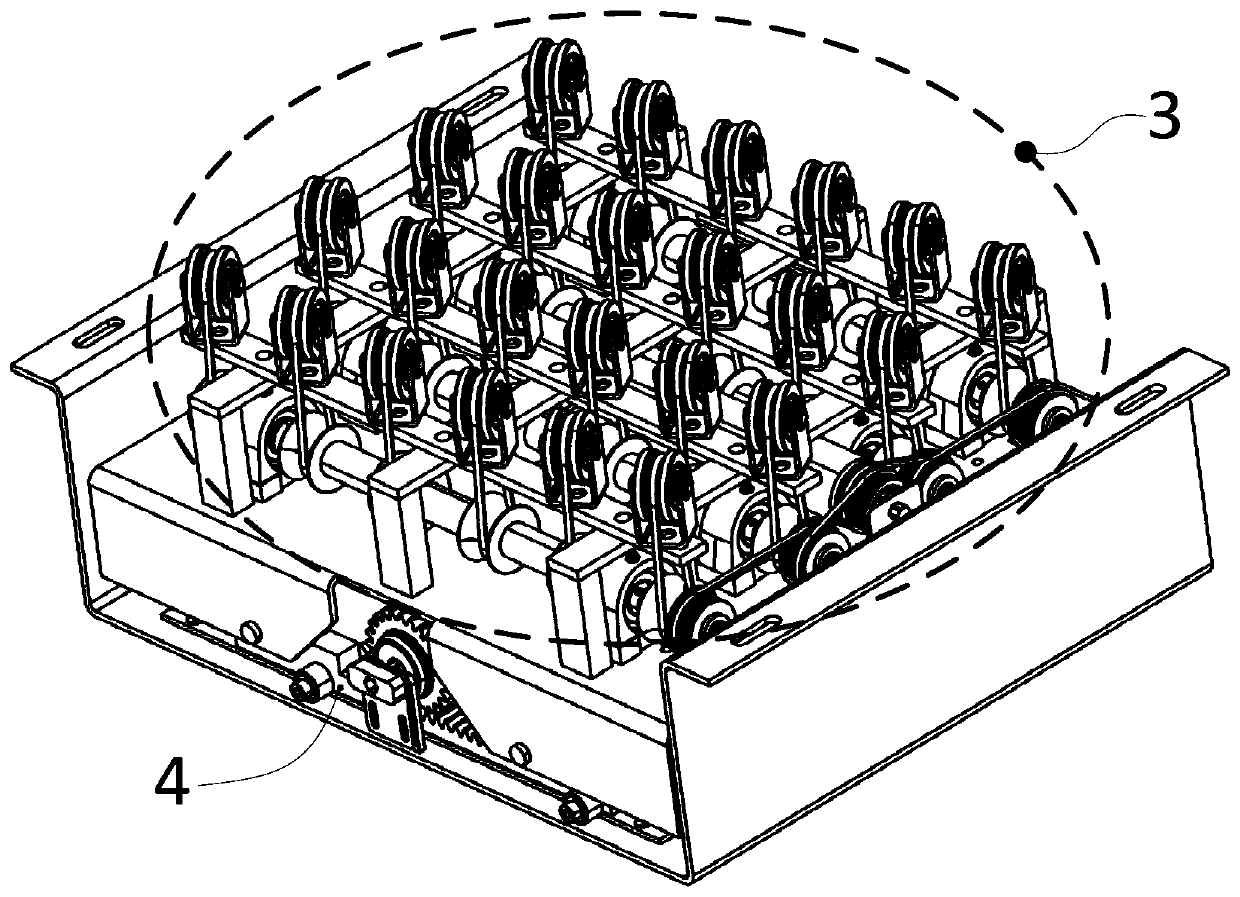

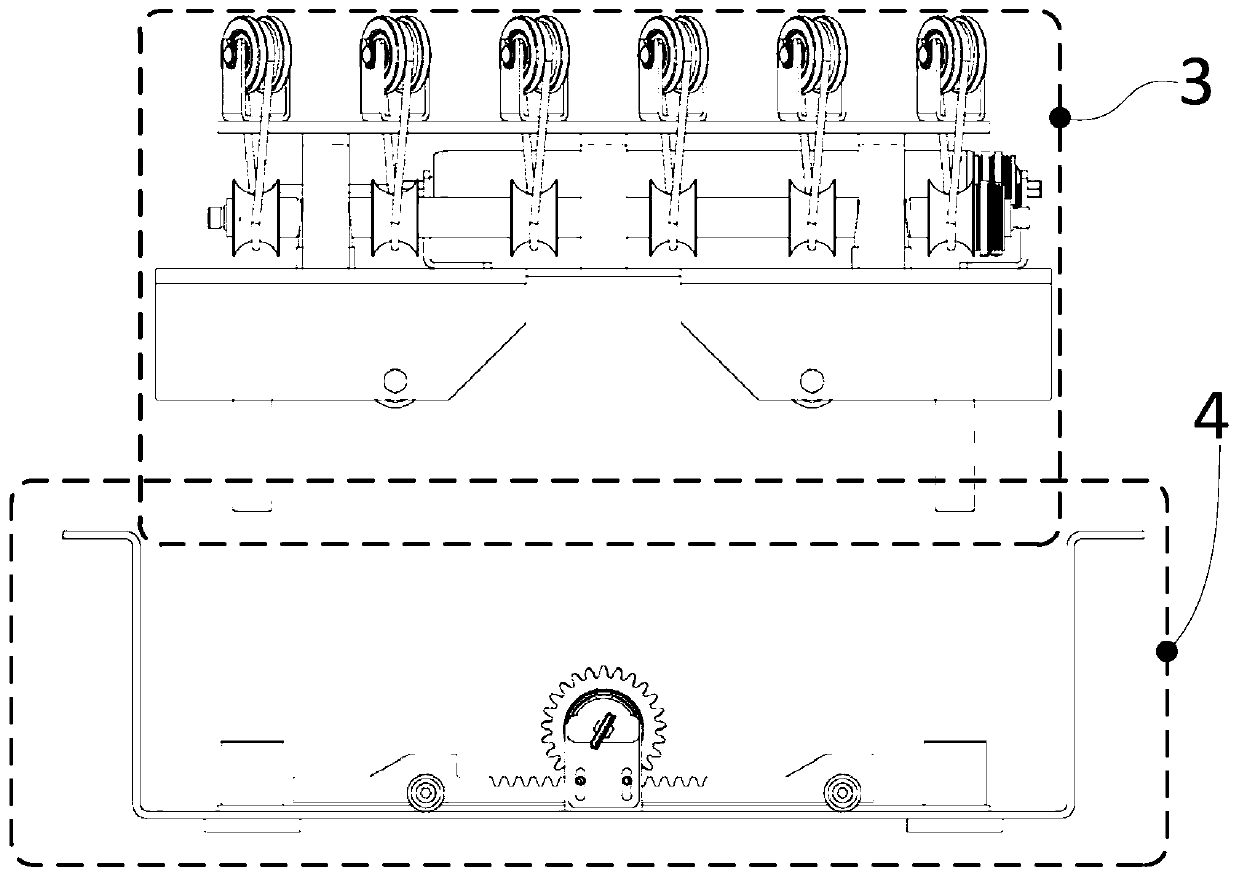

Y-shaped oblique opening sorting machine for high-speed sorting

PendingCN109834065ASmooth sorting and conveyingFast sorting and conveyingSortingModular designEngineering

The invention discloses a Y-shaped oblique opening sorting machine for high-speed sorting. The Y-shaped oblique opening sorting machine for the high-speed sorting comprises a Y-shaped oblique openingchannel composed of a straight-channel roller line and an oblique-joint roller line. According to the improved points of the Y-shaped oblique opening sorting machine for high-speed sorting, oblique wheel sets are arranged at the position, near a cross wire opening of the oblique-joint roller line, under the straight-channel roller line, and the lifting and the lowering of the oblique wheel sets are carried out through jacking driving components; the jacking driving components drive the oblique wheel sets to rise and fall according to requirements; and a plurality of oblique wheels are arrangedon the oblique wheel sets, and the rotating direction of the oblique wheels is consistent with the conveying direction of the oblique-joint roller line, and when the oblique wheel sets are lifted, objects are transported into the oblique-joint roller line. According to the Y-shaped oblique opening sorting machine for the high-speed sorting, the modular design is adopted by the sorting machine, the structure is compact, the arrangement is convenient and flexible, and the use requirements of high-speed sorting sites can be better met.

Owner:JIANGSU JINMING IND ROBOT AUTOMATION

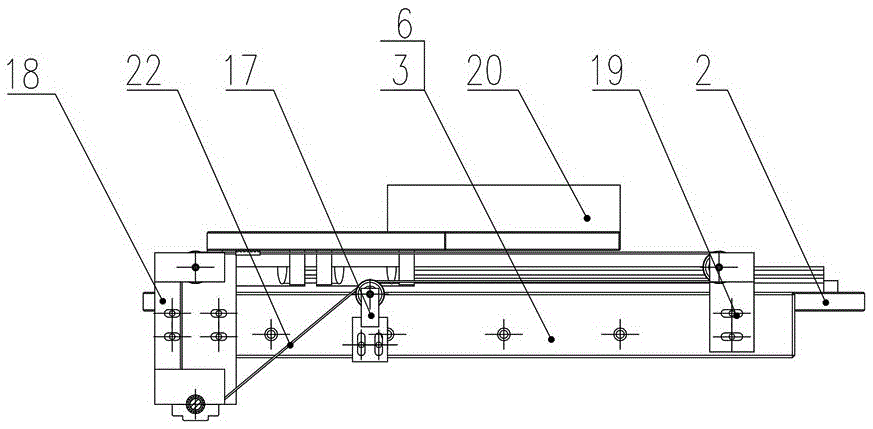

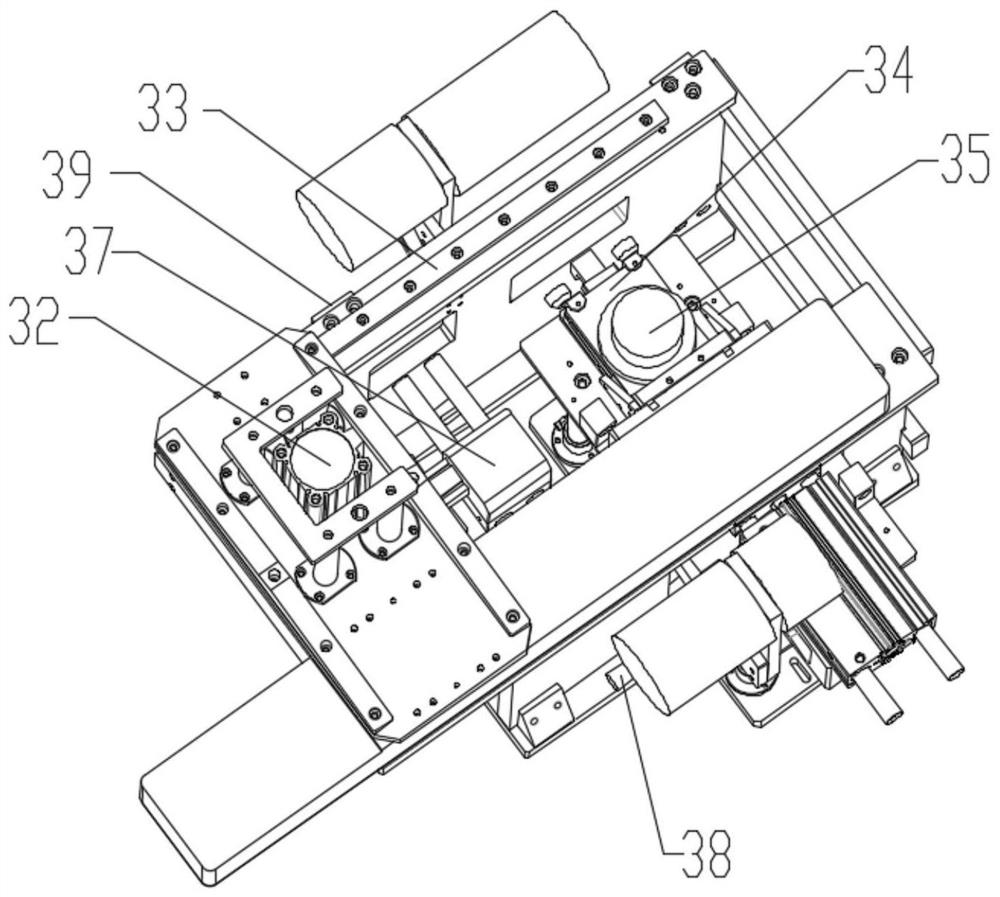

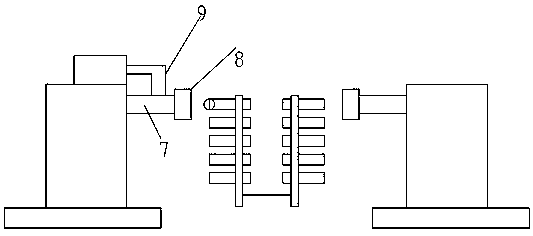

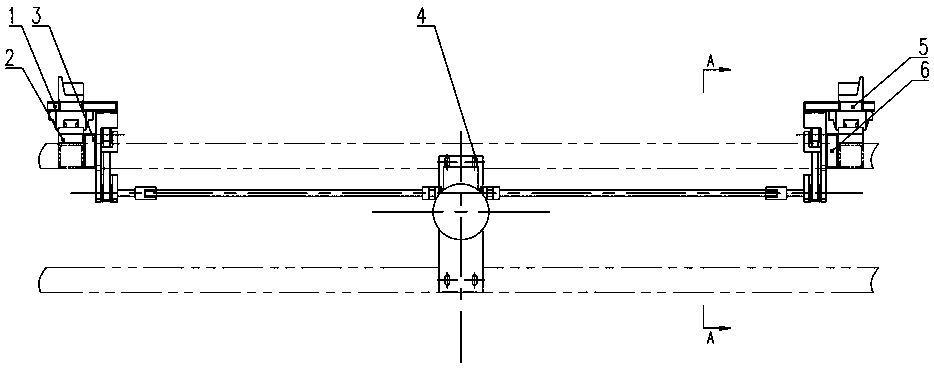

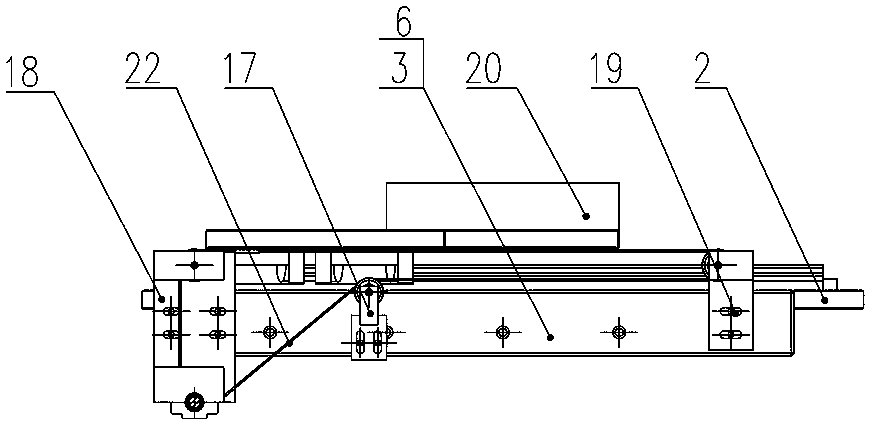

Flexible sliding table device controlled by PLC closed loop

The invention discloses a flexible sliding table device controlled by a PLC closed loop. The flexible sliding table device comprises a sliding part, a drive part, a transmission part and a PLC control part, wherein the sliding part comprises two linear guide rails which are arranged in a direction of movement of a quartz boat seat, and the two linear guide rails are separately positioned on guide rail mounting plates at left and right sides; a slide block for driving the quartz boat seat to move is arranged on the linear guide rails in a sliding mode, and is driven by the drive part; the drive part comprises a step motor and a speed reducer; the transmission part comprises a left drive wheel assembly, a right drive wheel assembly and two connecting rods; the connecting rods are driven by the drive part to further drive the left drive wheel assembly and the right drive wheel assembly; the left drive wheel assembly and the right drive wheel assembly separately drive a left slide block mounting plate and a right slide block mounting plate as well as the slide bock on the two mounting plates to move along the linear guide rails through a synchronous belt; the quartz boat seat is mounted on the slide block; and the PLC control part is used for controlling the drive part. The flexible sliding table device has the advantages of being simple and compact in structure, simple and convenient to operate, high in control precision, good in reliability and the like.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

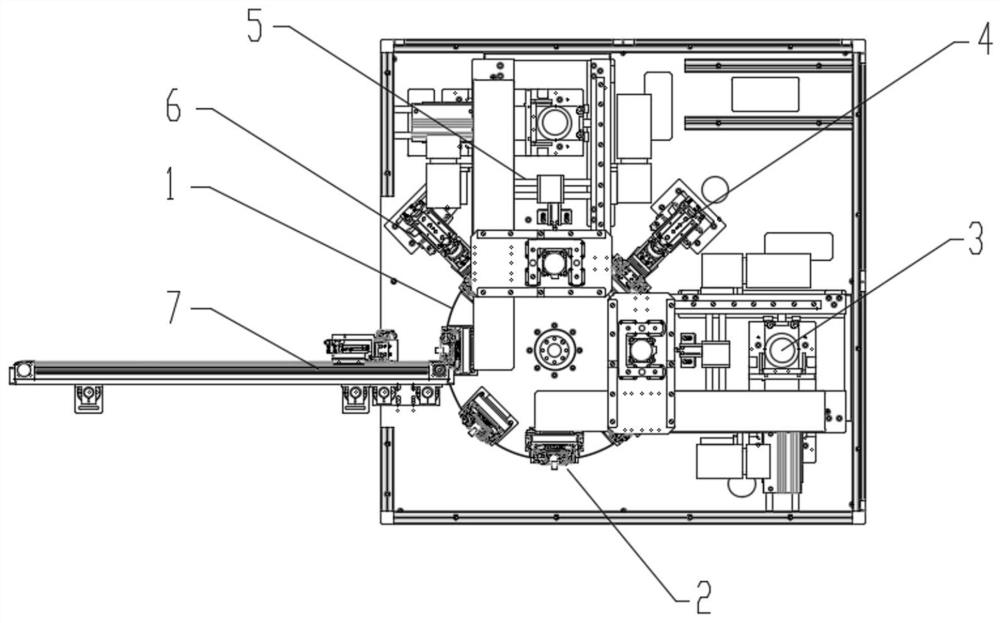

Automatic printing equipment for battery pack

PendingCN113580755ASave human effortImprove efficiencyRotary pressesOther printing apparatusProcess engineeringElectrical and Electronics engineering

The invention provides automatic printing equipment for a battery pack. The equipment comprises an index plate, a plurality of jigs are evenly arranged on the upper end face of the index plate, and a feeding station, a first printing station, a first overturning station, a second printing station, a second overturning station and a discharging station are sequentially arranged on the index plate. By means of the mode, the problems that an existing printing mode is low in efficiency and high in reject ratio are solved.

Owner:江苏乾涌控股有限公司

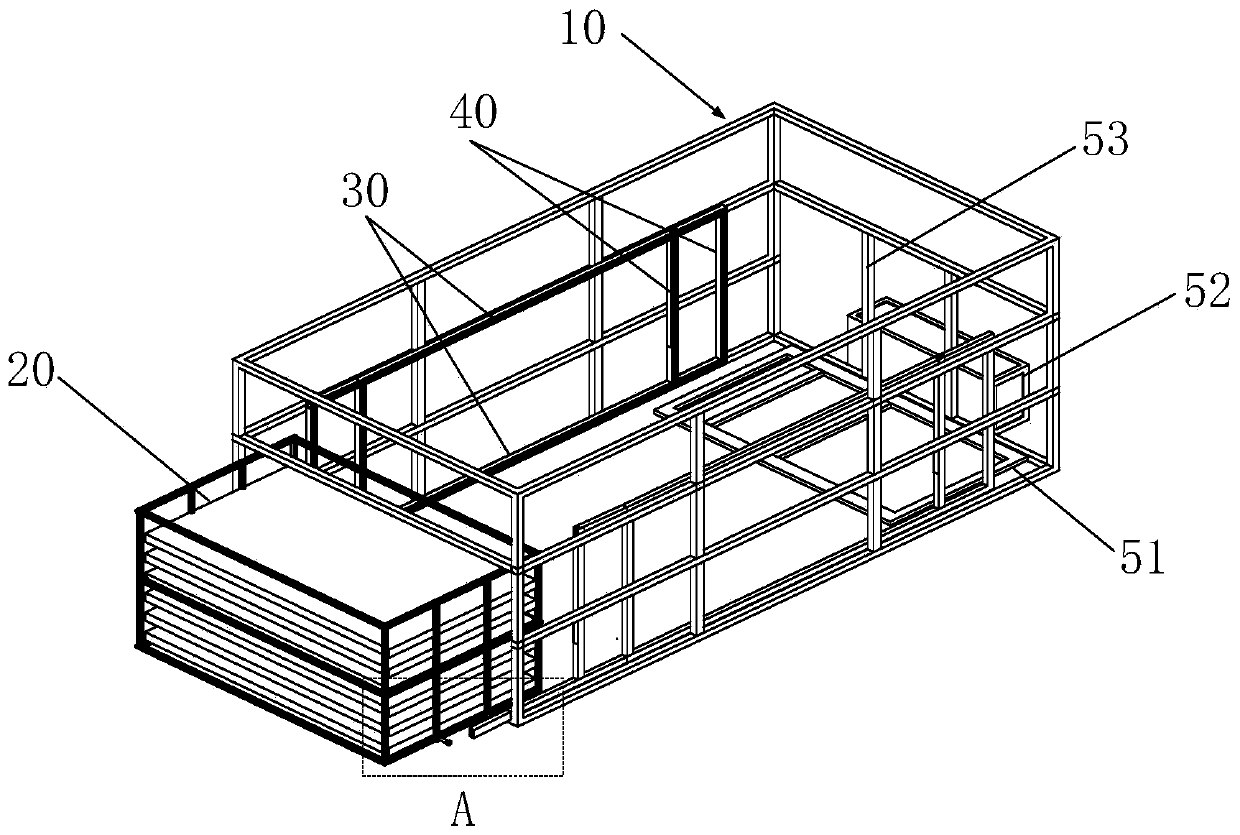

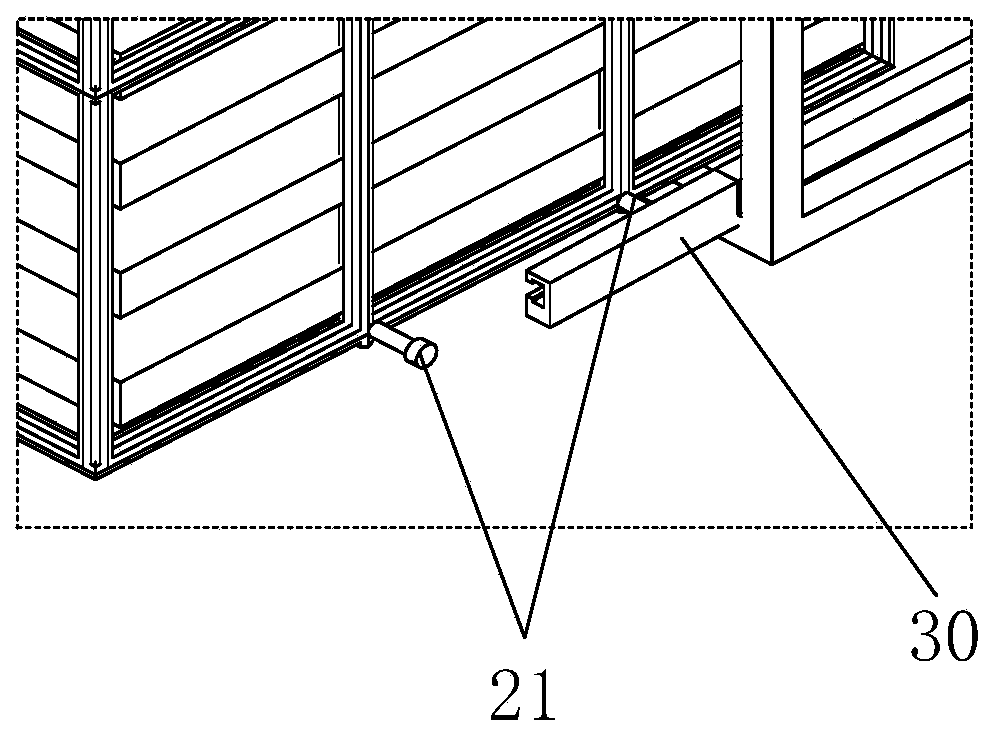

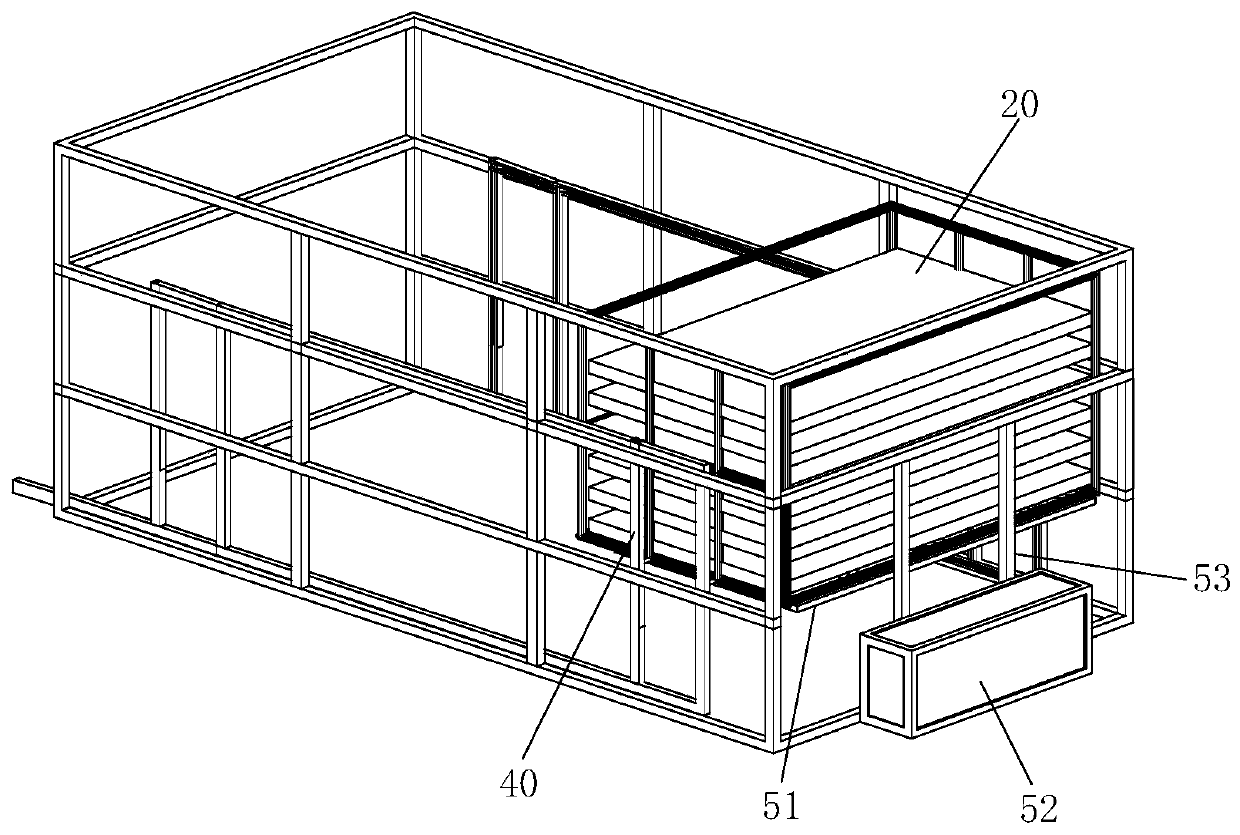

Prefabricated part stacking device

PendingCN110125896ARealize multi-dimensional storageEasy to moveWork tools storageEngineeringMulti dimensional

The invention relates to a prefabricated part stacking device. The device comprises a steel framework and a plurality of stacking baskets, a plurality of layers of transverse sliding grooves are fixedon the steel framework, a plurality of groups of vertical sliding grooves are formed between two layers of transverse sliding grooves, the ends of the vertical sliding grooves communicate with the transverse sliding grooves, rotating wheels are arranged at the bottom of the stacking baskets, and the rotating wheels can slide in the transverse sliding grooves and the vertical sliding grooves. According to the device, the transverse sliding grooves and the vertical sliding grooves are formed, movement on horizontal position of the stacking baskets can be realized by utilizing sliding of the rolling wheels in the transverse sliding grooves, movement at vertical direction of the stacking baskets is realized by utilizing sliding of the rolling wheels in the vertical sliding grooves, so that multi-dimensional storage of prefabricated parts is realized, the stacking quantity of the prefabricated parts is greatly increased, the field space is saved, the stacking baskets are convenient to move, and the prefabricated parts are convenient to take.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

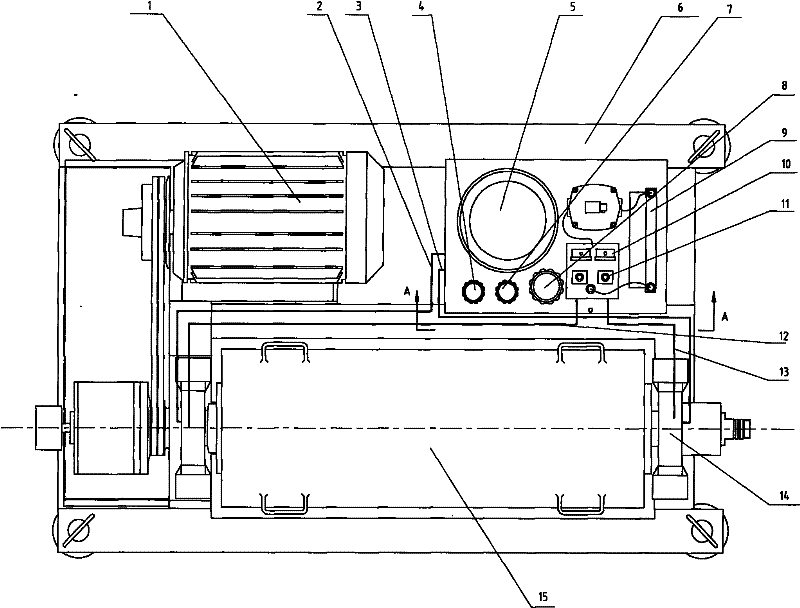

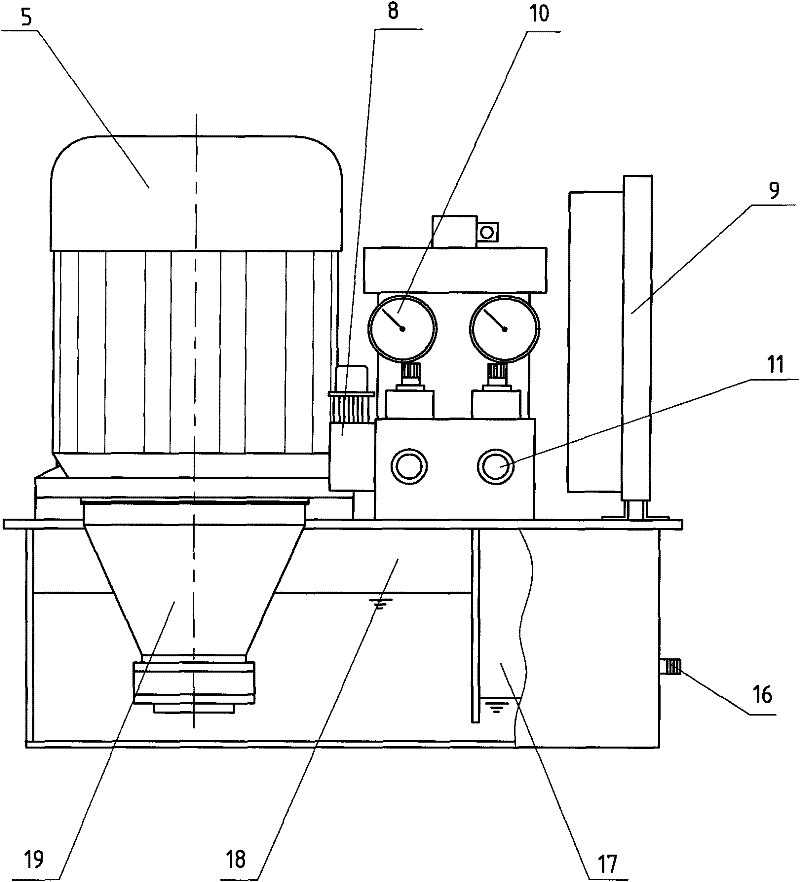

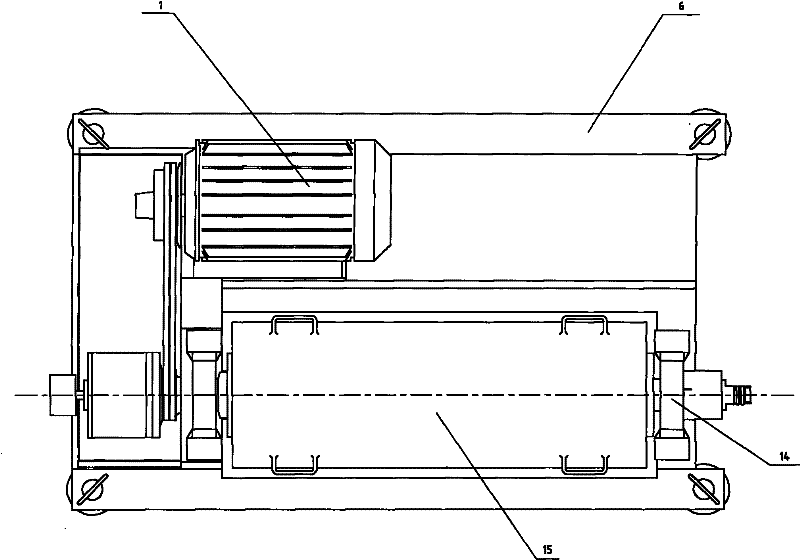

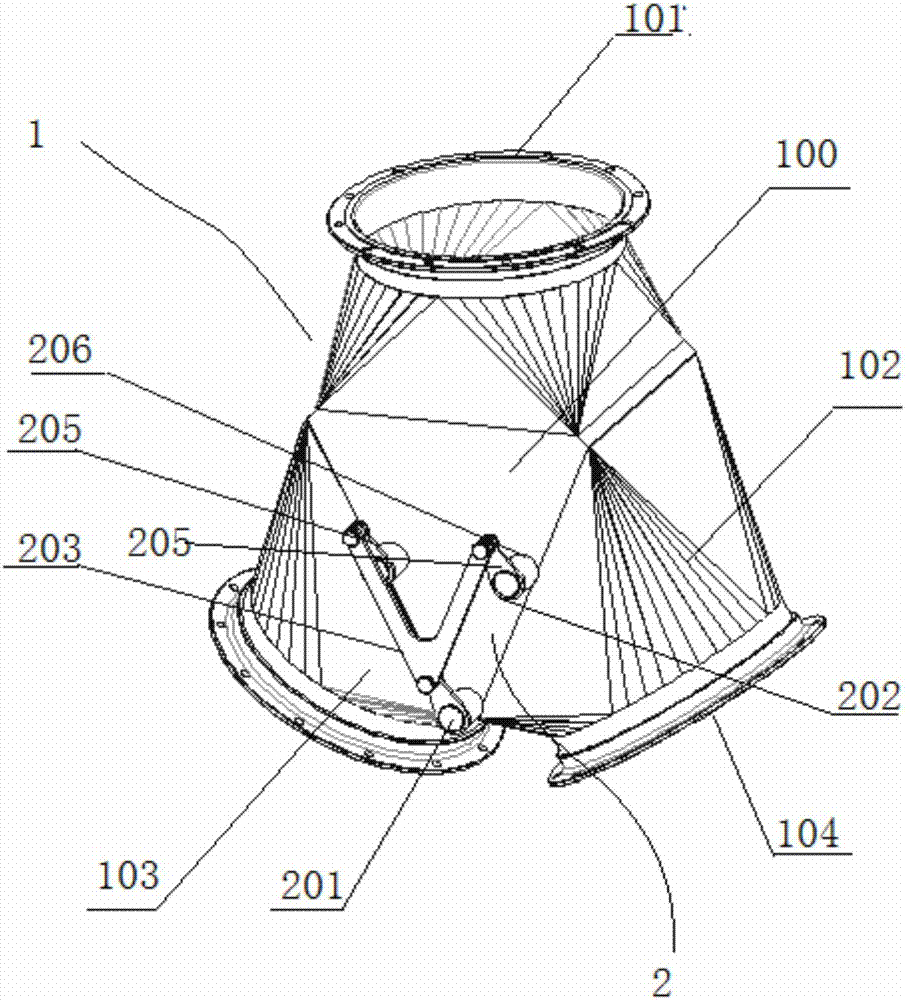

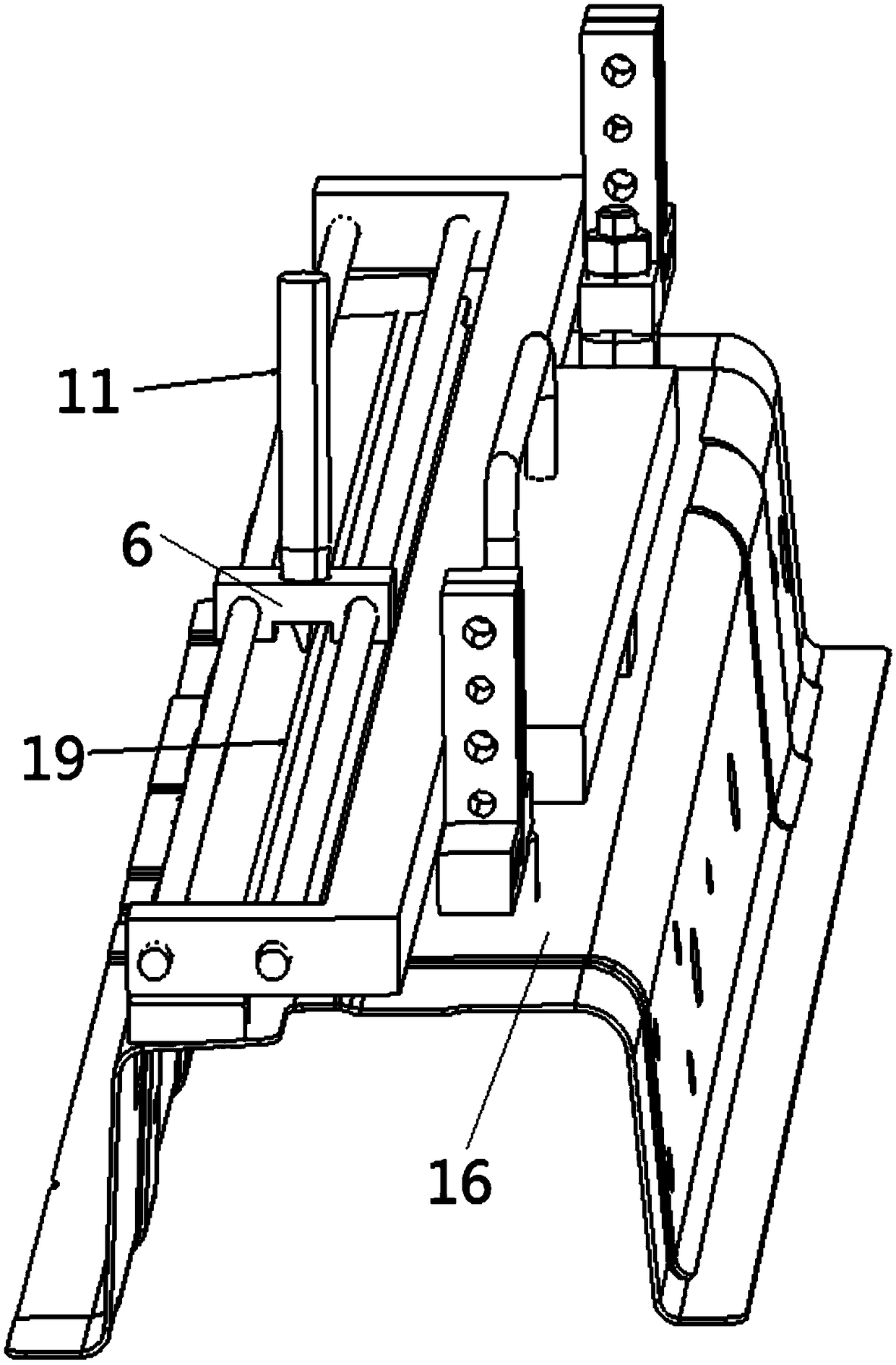

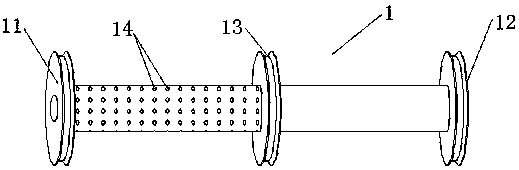

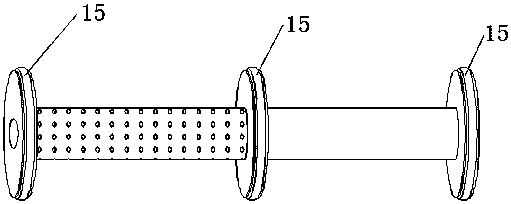

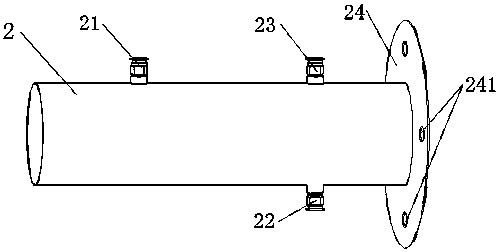

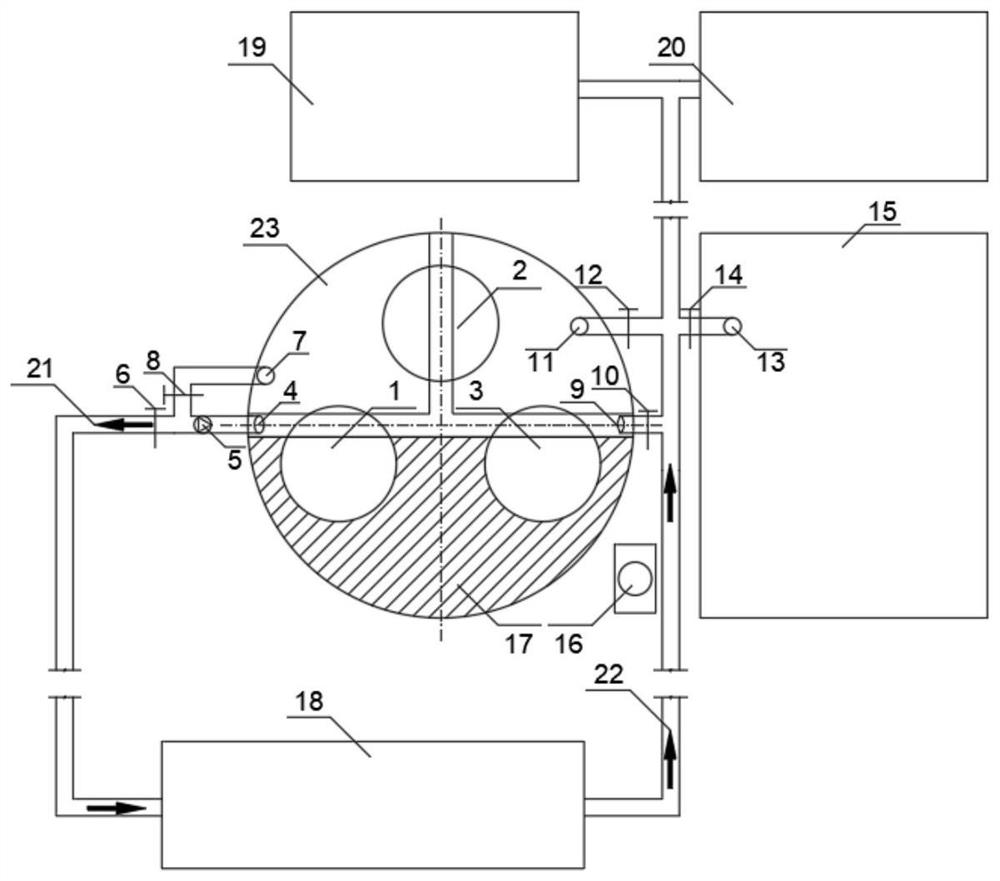

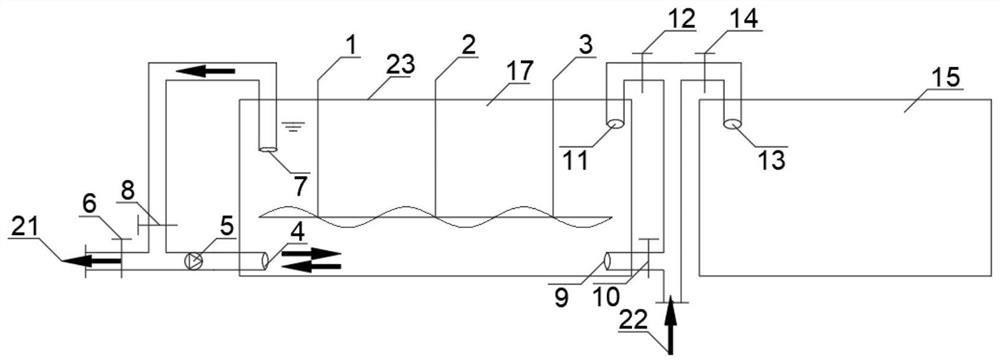

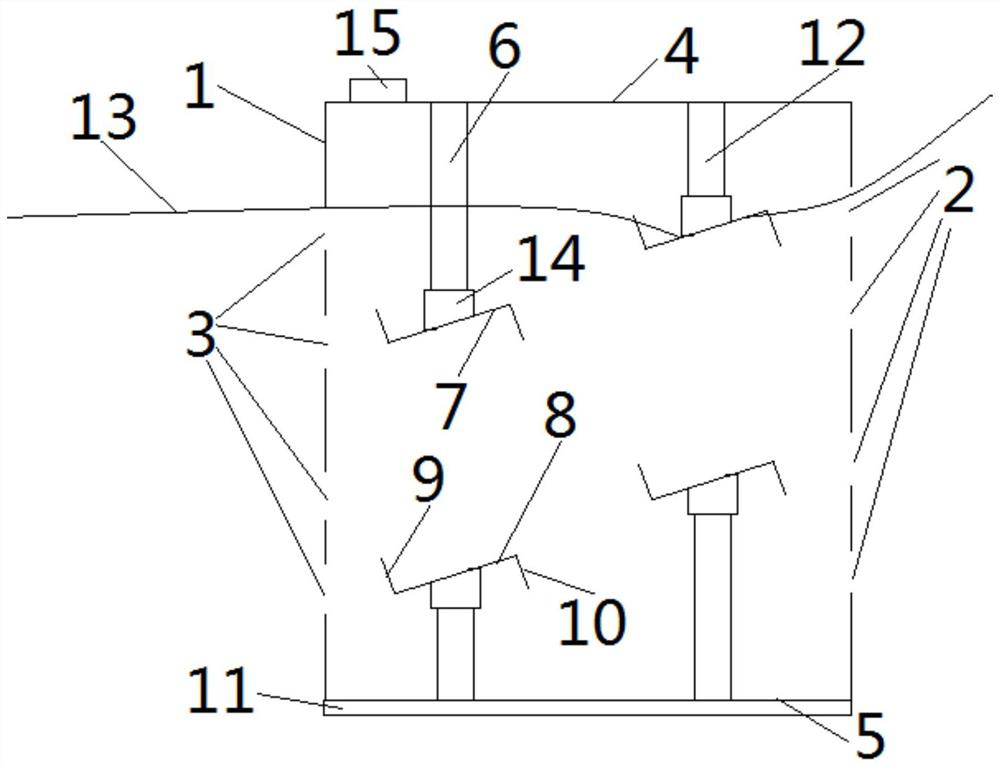

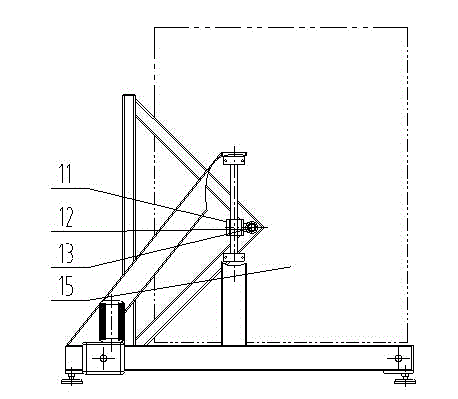

Integrated arrangement structure of decanter centrifuge and hydraulic station

The invention relates to a centrifuge structure in the field of machines, in particular to an integrated arrangement structure of a decanter centrifuge and a hydraulic station. In a rectangular frame (6), one side is provided with an accumbent decanter centrifuge barrel (15), the end of the other side is provided with a motor (1), and power is transmitted to the input shaft end of the centrifuge barrel (15) through a belt. The structure is characterized in that: the hydraulic station is arranged in a rear space of the motor (1) and is a vertically arranged rectangular body; an oil pump motor (5) drives an oil pump (19); the oil pump (19) is respectively connected to the two ends of the centrifuge barrel (15) by front and rear oil inlet pipes (12 and 13) through two oil inlet speed regulating valves (11); an oil supply box (18) and an oil return box (17) are parallelly arranged on the lower part; the lower parts of the two oil boxes are communicated with each other; and the upper part of the oil supply box (18) is connected with a vacuum pump (8). Through the technical scheme, the residual space on the frame (6) is fully utilized, so that the space of a factory building is saved, the problem of transportation and installation inconvenience of a split structure is solved, engineering progress is accelerated, and efficiency is improved.

Owner:SHANGHAI CENTRIFUGE INST

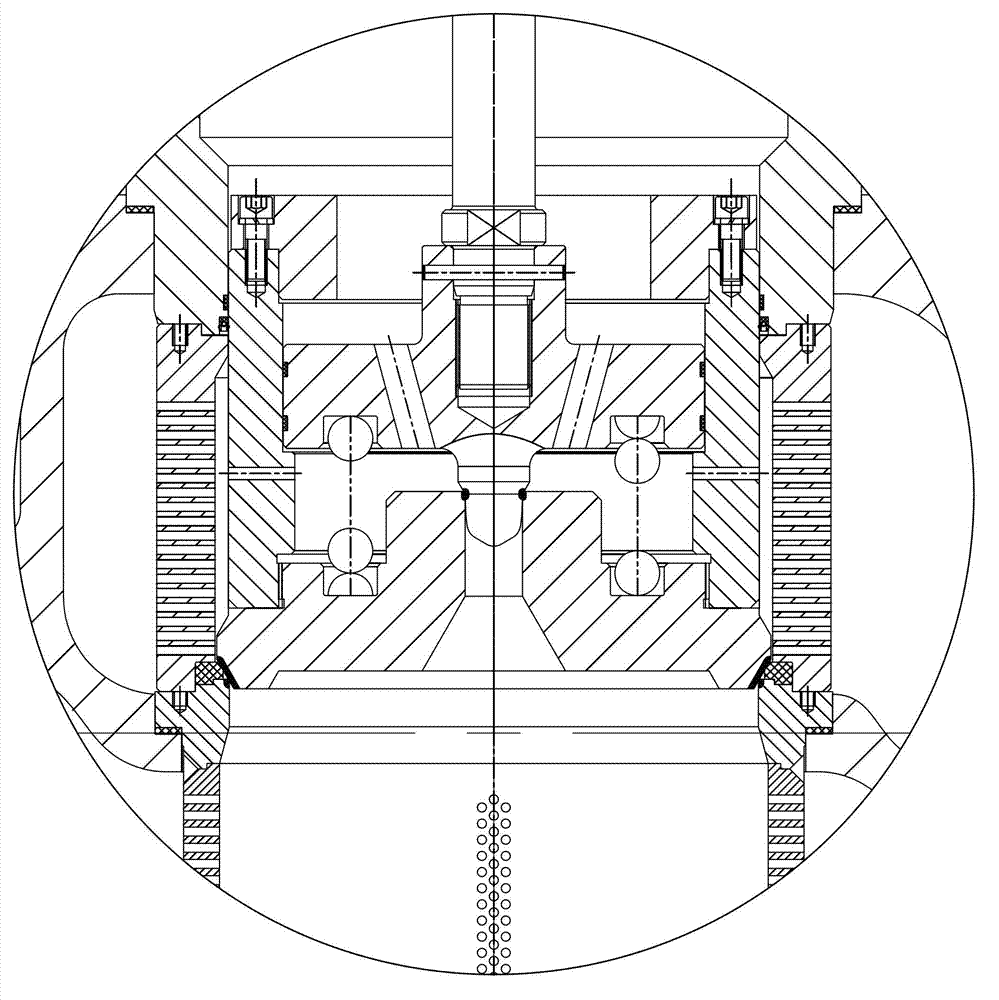

Large-aperture three-way sealed switching valve

ActiveCN106885015ALow costSolve the phenomenon of "grabbing the wind"Multiple way valvesRotational axisVALVE PORT

Owner:ZHIHE ENVIRONMENTAL TECH (JIANGSU) CO LTD

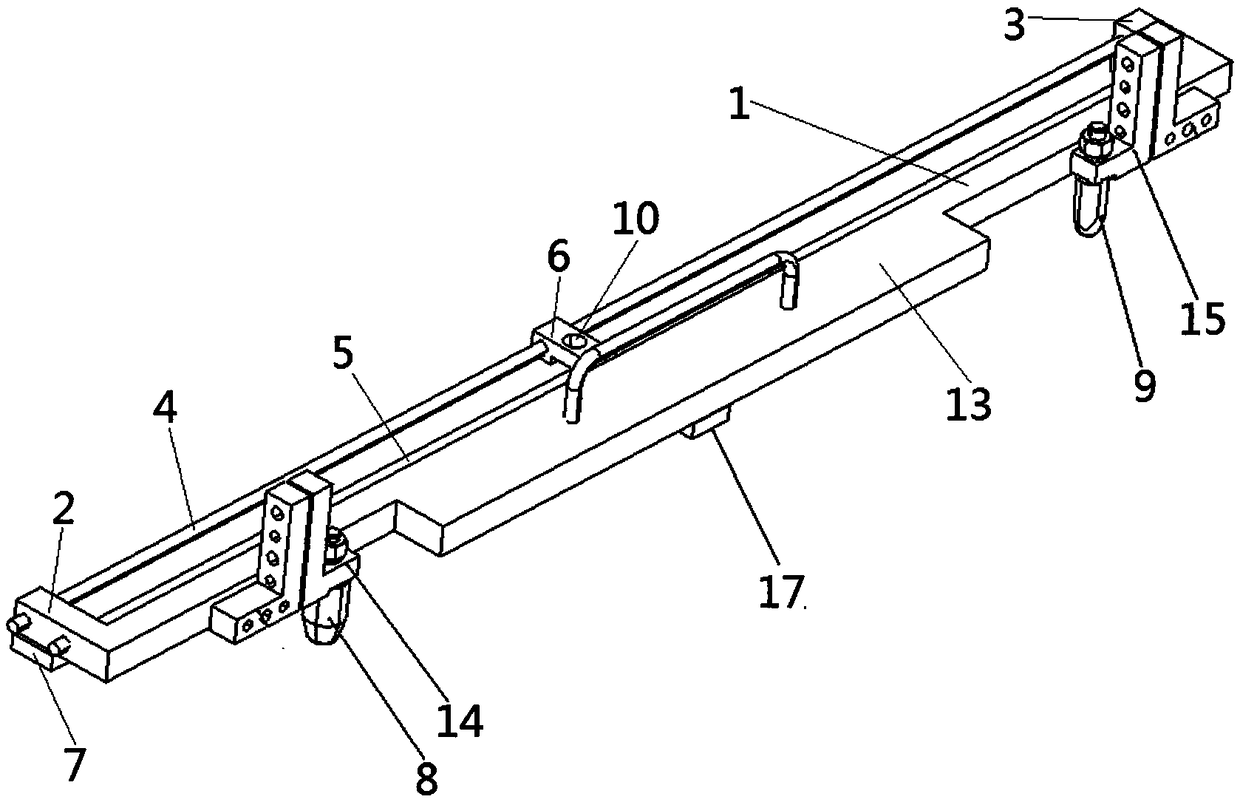

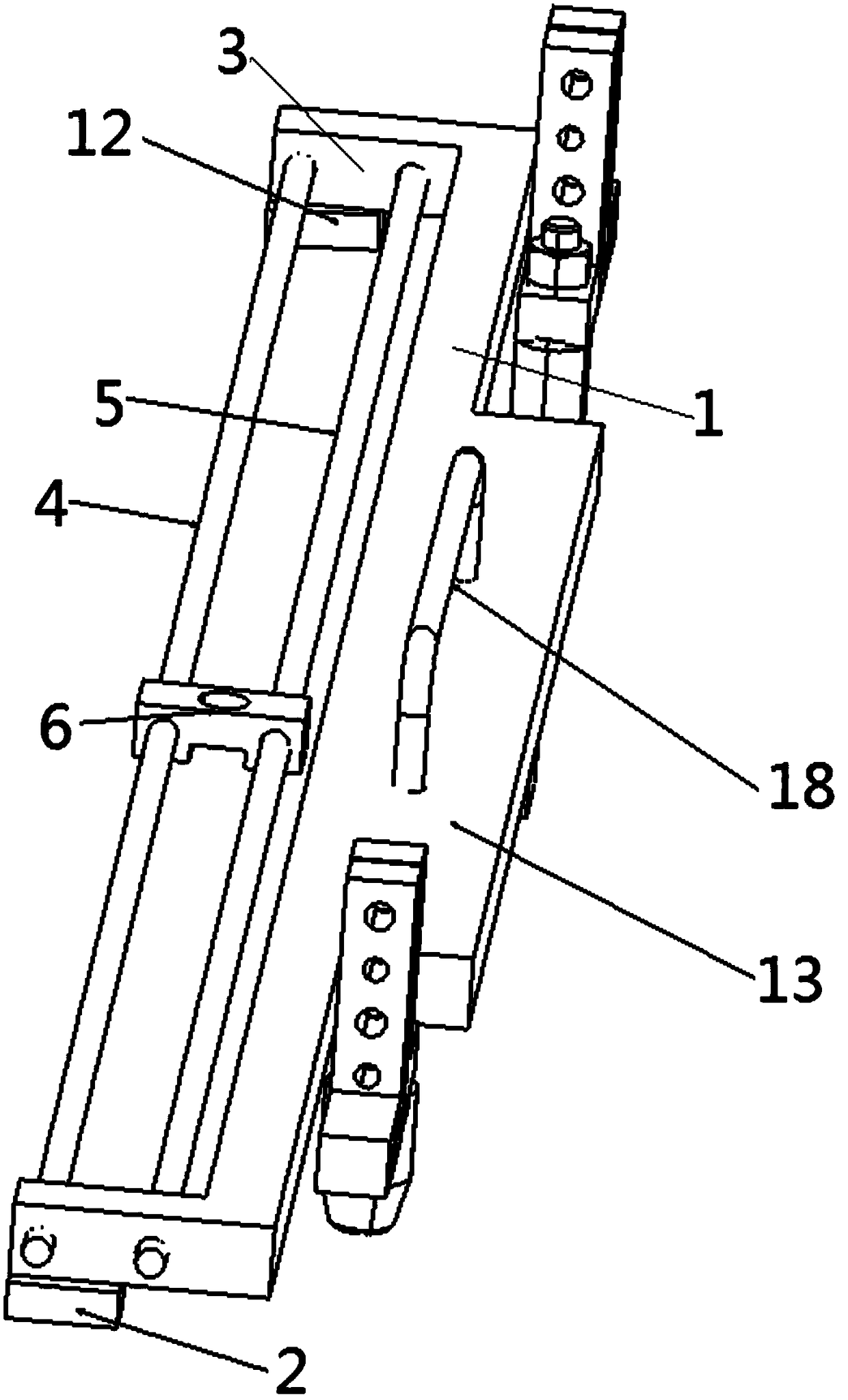

Gluing tool for spot welding of automobile front floor doorsill edge beam through sealant

PendingCN109395970ANo damageNot easy to damageLiquid surface applicatorsCoatingsAssistive device/technologyEngineering

The invention provides a gluing tool for spot welding of an automobile front floor doorsill edge beam through a sealant and applies to the technical field of auxiliary processing equipment for automobile body parts. A slide rail I (4) and a slide rail II (5) are arranged between a bending part I (2) and a bending part II (3) of a tool body (1) of the gluing tool for spot welding of the automobilefront floor doorsill edge beam through the sealant, slide blocks (6) movably sleeve the slide rail I (4) and the slide rail II (5), a regulation block I (7) is arranged on the lower surface of the bending part I (2), and a regulation block II (12) is arranged on the lower surface of the bending part II (3); a positioning pin I (8) is arranged on the side face, close to one end, of the tool body (1), a positioning pin II (9) is arranged at the side face, close to the other end, of the tool body (1), and the slide blocks (6) are provided with gluing gun head positioning holes (10). According tothe gluing tool for spot welding of the automobile front floor doorsill edge beam through the sealant, precision gluing can be effectively conducted according to the gluing theory, the gluing efficiency can also be improved, and the production cost is lowered.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

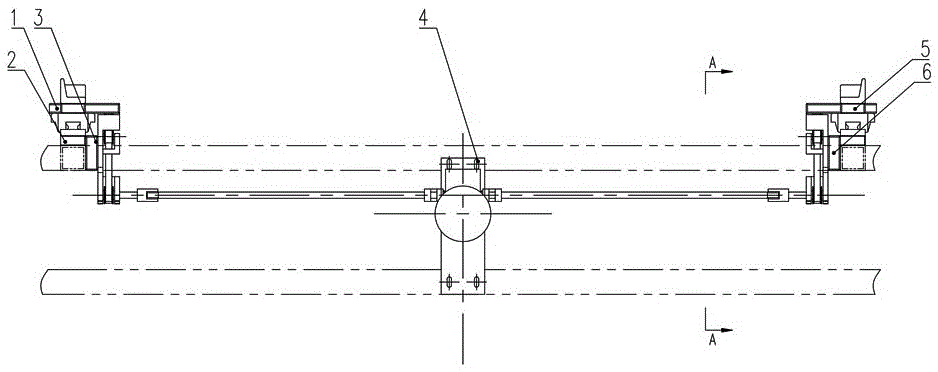

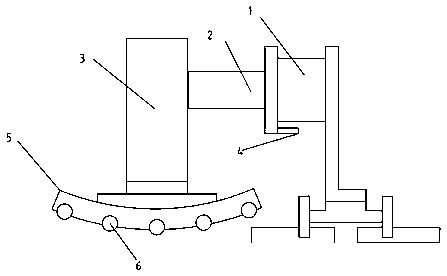

Device and method for replacing half shaft of transmission offline detection bench

PendingCN110118647AImprove efficiencyImprove accuracyVehicle testingMachine part testingDrive shaftTest bench

The invention discloses a device and a method for replacing a half shaft of a transmission offline detection bench. The device comprises a half shaft fixing disc, wherein a plurality of half shafts are arranged in the half shaft fixing disc in parallel, and the half shaft fixing disc is fixedly connected with a connection piece; the connection piece is rigidly connected with a rotor motor, and therotor motor is fixedly connected with a transmission offline detection bench body through a bearing; the half shafts are clamped and fixed with half shaft clamping sleeves, the half shaft clamping sleeves are connected with a cylinder push-pull rod which is connected with a cylinder, and the half shaft clamping sleeves sleeve test bench drive shafts. Through cooperation of the transmission drivehalf shaft and the test bench drive shafts, the half shaft clamping sleeves and the half shaft fixing disc, the half shafts can be automatically switched after test, and a half shaft material base isarranged in the half shaft fixing disc so that the type change efficiency and the accuracy of the device can be improved, and the field space is saved.

Owner:浙江万里扬新能源驱动有限公司

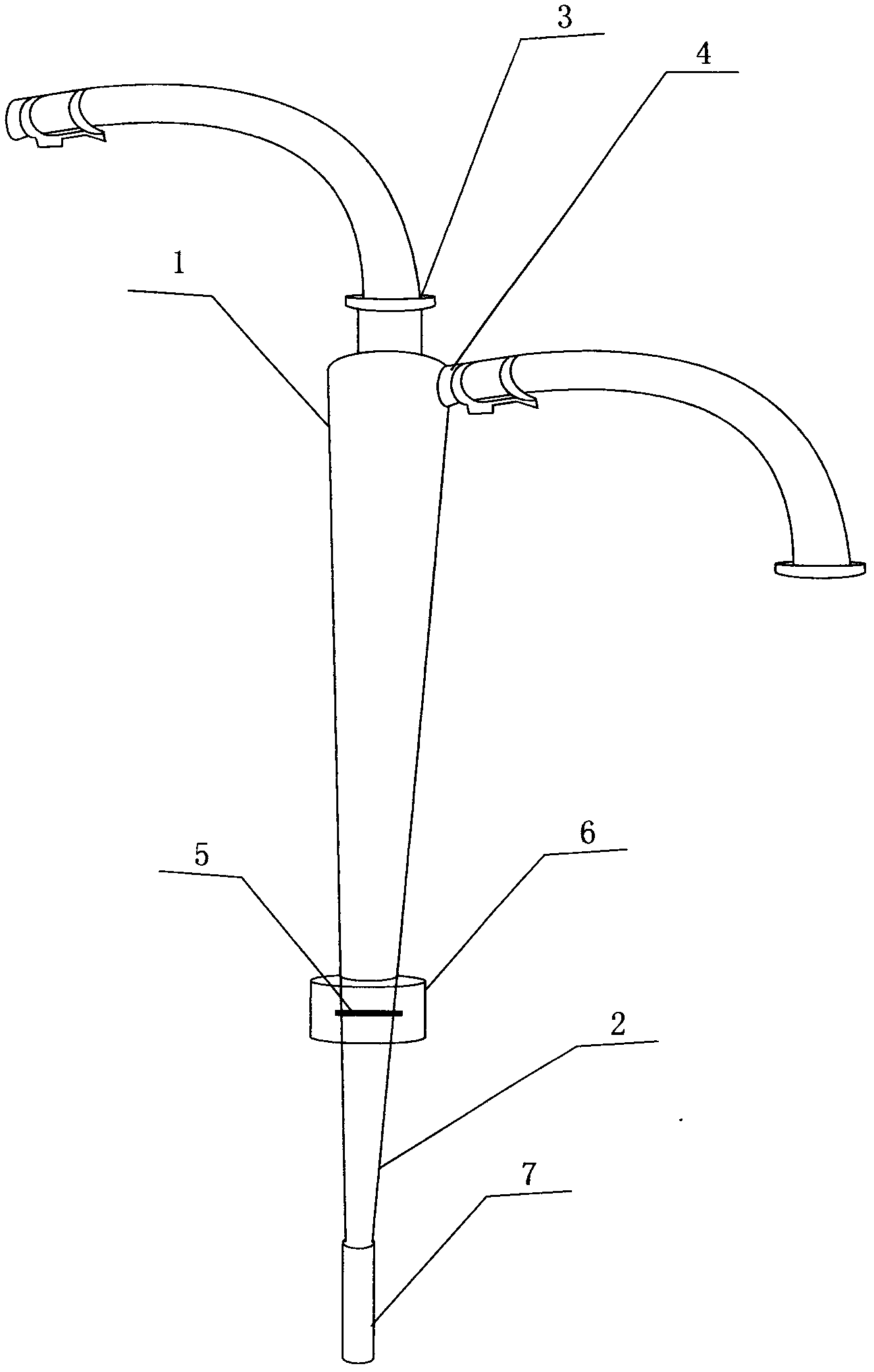

Glass rotational-flow sand-removing device for potato starch production

InactiveCN103381394ASimple structureSimple and fast operationReversed direction vortexPotato starchPulp and paper industry

A glass rotational-flow sand-removing device for potato starch production comprises a rotational-flow cylinder body and a sand settling body, and the rotational-flow cylinder body and the sand settling body are connected through a connecting fastener. The glass rotational-flow sand-removing device for the potato starch production is characterized in that a rubber cushion is disposed between the rotational-flow cylinder body and the sand settling body, and the connecting fastener is used to combine the rotational-flow cylinder body and the sand settling body into a whole; a feed port is disposed at the top end of the rotational-flow cylinder body, a discharge port is disposed on one side of the upper end of the rotational-flow cylinder body; and a sand discharging pipe is connected with the lower portion of the sand settling body. The rotational-flow sand-removing device is made of glass. The glass rotational-flow sand-removing device for the potato starch production has the advantages that the structure is simple, operation is easy and convenient, the glass rotational-flow sand-removing device for the potato starch production is safe and reliable to use, and almost no maintenance is needed; compared with a conventional sand removing device in the prior art, the glass rotational-flow sand-removing device for the potato starch production has the advantages that the size is small, processing ability is great, the space of production site is saved, and the like; grains of sand in slurry fluid can be constantly removed; and the problem of secondary pollution to slurry materials in other sand removing methods is avoided.

Owner:DANGYANG LONGZHIQUAN AGRI DEV

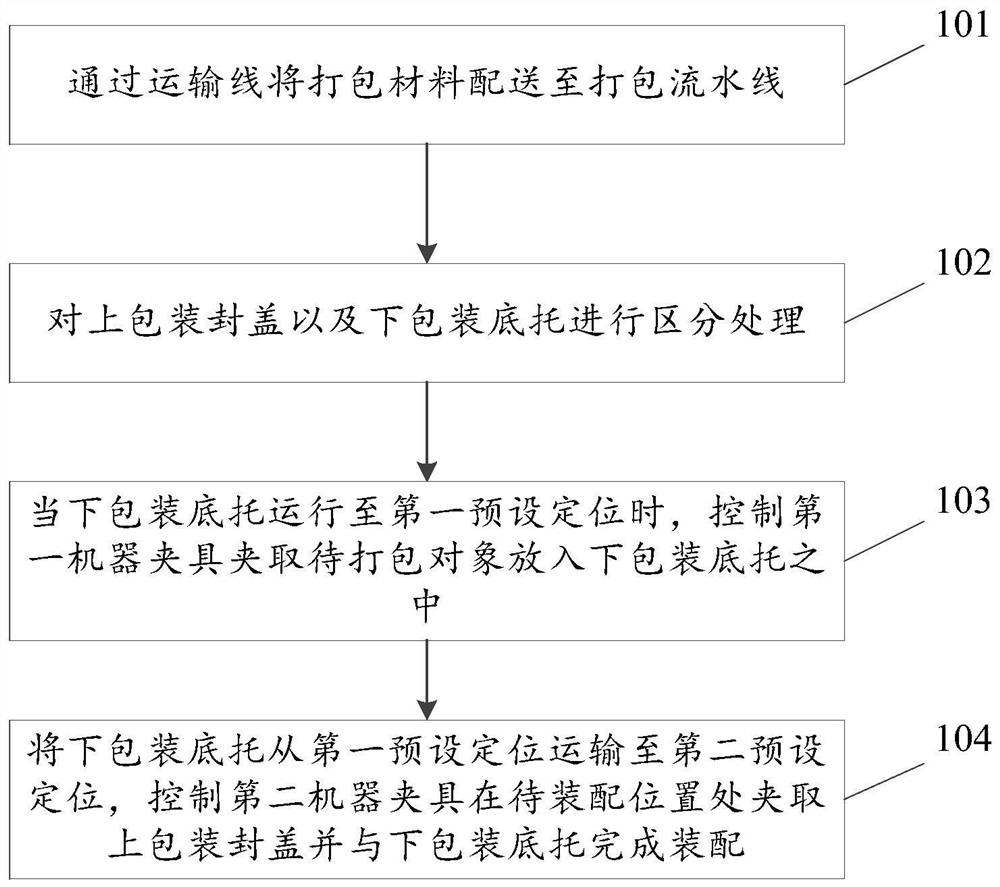

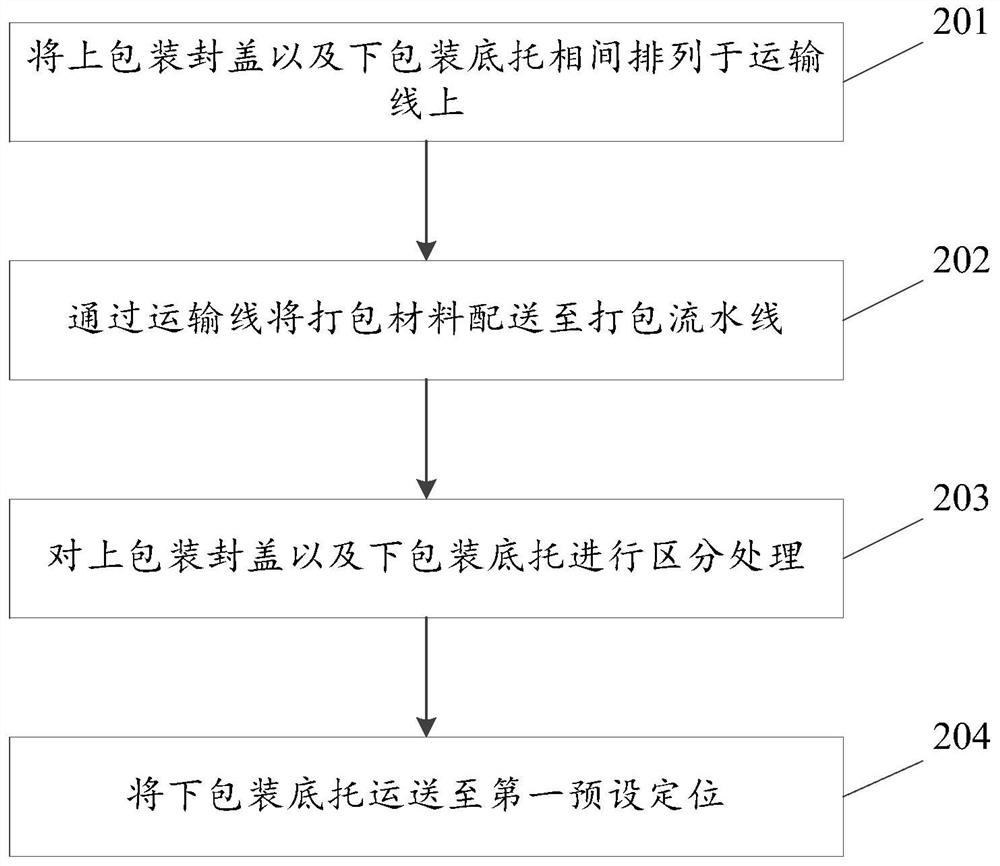

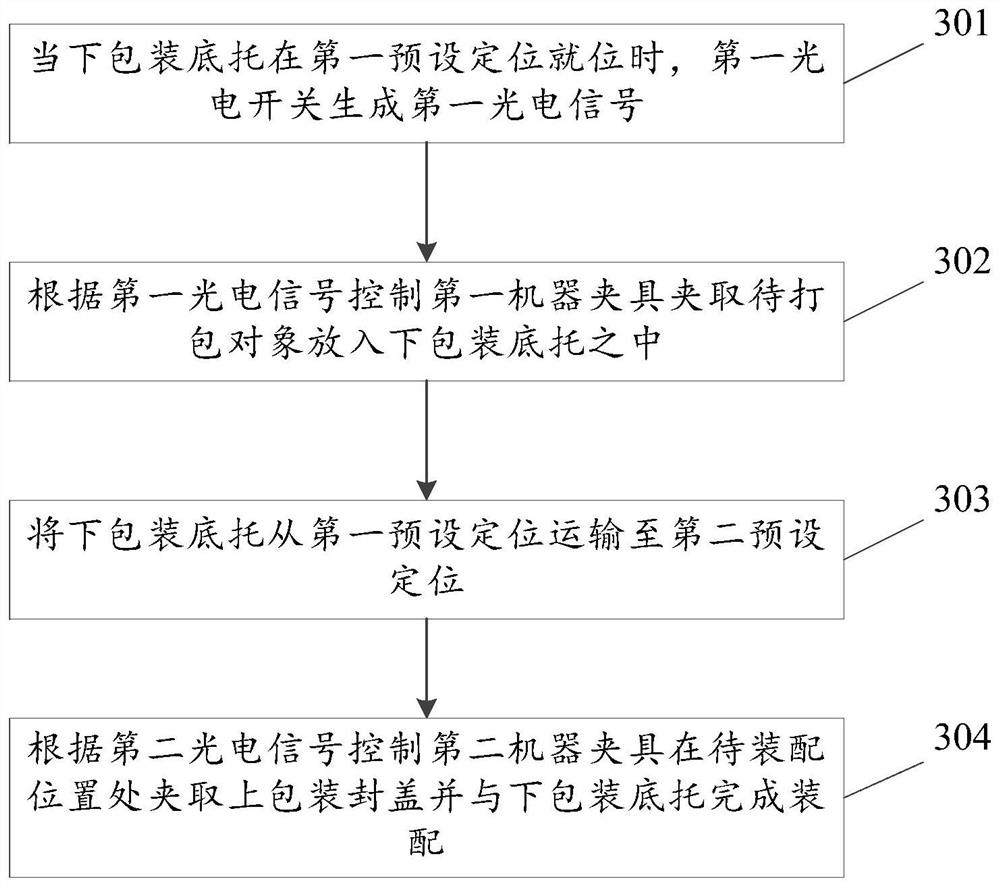

Automatic packaging method, electronic equipment and storage medium

ActiveCN113665916ATroubleshoot breakpointsReduce in quantityPackaging automatic controlPackaging machinesProcess engineeringIndustrial engineering

The invention relates to an automatic packaging method which comprises the following steps: delivering packaging materials to a packaging assembly line through a conveying line, wherein the packaging materials comprise upper packaging seal covers and lower packaging bottom supports; distinguishing the upper packaging seal covers and the lower packaging bottom supports, that is, permitting the passing of the lower packaging bottom supports and leaving the upper packaging seal covers to stay at a to-be-assembled position; when the lower packaging bottom supports move to a first preset fixed position, controlling a first machine clamp to clamp and put to-be-packaged objects into the lower packaging bottom supports; and conveying the lower packaging bottom supports as well as the to-be-packaged objects from the first preset fixed position to a second preset fixed position, controlling a second machine clamp to clamp the upper packaging seal covers at the to-be-assembled position, completing the assembling operation by combining the upper packaging seal covers with the lower packaging bottom supports. According to the provided scheme, the packaging automation can be achieved, the onsite space can be saved, the production environment can be optimized, the packaging procedure can be simplified, the working intensity of production personnel can be relieved, and the production efficiency as well as the production quality can be improved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Multi-wire wiring storage box

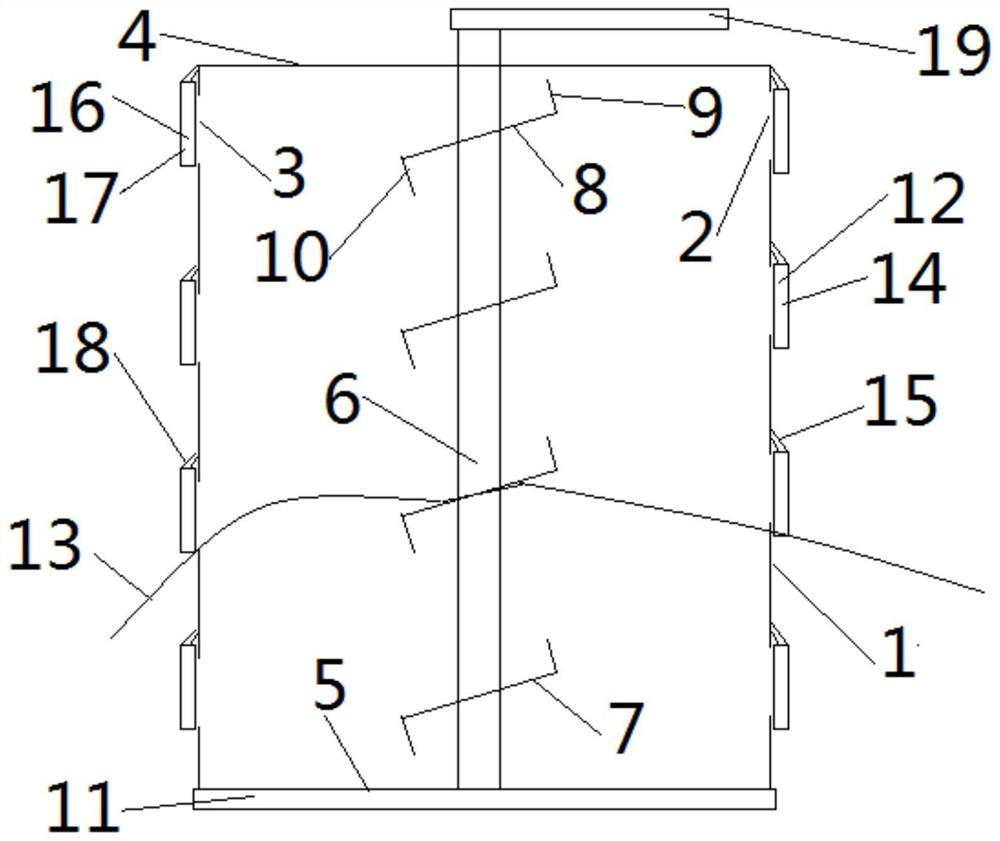

The present invention provides a multi-wire circuit arrangement and storage box applied to the technical field of electrical original auxiliary equipment. The box body (1) of the multi-wire circuit arrangement and storage box is provided with a plurality of wire inlets (2) on the side of the box body. (1) Multiple wire outlets (3) are set on the other side, the upper end of the rotating shaft (6) provided in the box body (1) extends out of the upper end surface (4) of the box body, and the lower end of the rotating shaft (6) is movably installed under the box body On the end face (5), the rotating shaft (6) is provided with a plurality of take-up fan blades (7) according to the gap from top to bottom, and the fan blade rod body (8) of the wire-take-up fan blade (7) is a structure arranged obliquely, and the fan blades are curved. The folding part I (9) is an upward bending structure, and the fan blade bending part II (10) is a downward bending structure. The multi-wire circuit arrangement and storage box of the present invention can conveniently and quickly realize the winding of multiple wires And discharge, avoid the problem of clutter and excessive space occupied by the wire arrangement site, avoid cross-winding of wires, and improve the convenience of use.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

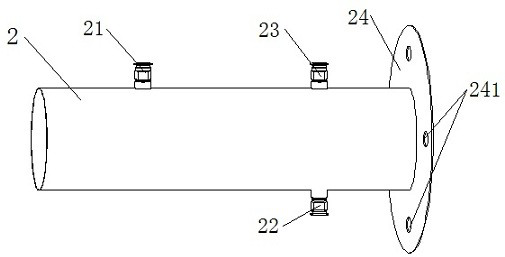

Plastic pipe sizing and cooling production device

ActiveCN108790105AControl deformationSave on-site spaceTubular articlesEngineeringMechanical engineering

The invention provides a plastic pipe sizing and cooling production device. The plastic pipe sizing and cooling production device comprises a circular sizing inner core and a circular sizing outer shell, wherein the circular sizing inner core comprises an inlet and an outlet of a plastic pipe and is concentrically fixed in an inner cavity of the circular sizing outer shell, the two ends of the circular sizing inner core are flush with the two ends of the circular sizing outer shell, an annular space between the circular sizing inner core and the circular sizing outer shell is generally dividedinto a sizing area and a primary cooling area, the sizing area is used for sizing the plastic pipe, and the primary cooling area is used for rapidly cooling the plastic pipe. According to the plasticpipe sizing and cooling production device, the sizing area and the cooling area are integrally designed, so that the plastic pipe sizing and cooling production device is more intensive, the occupiedfield space is smaller, assembly, disassembly and the like are more convenient, the deformation degree of the plastic pipe after extrusion can be controlled, then the plastic pipe can be cooled more uniformly, finally, the easy-to-deform pipe body can be controlled to meet the diameter requirement required to be met, and the quality and the yield of the product are greatly improved.

Owner:SICHUAN NIGALE BIOTECH

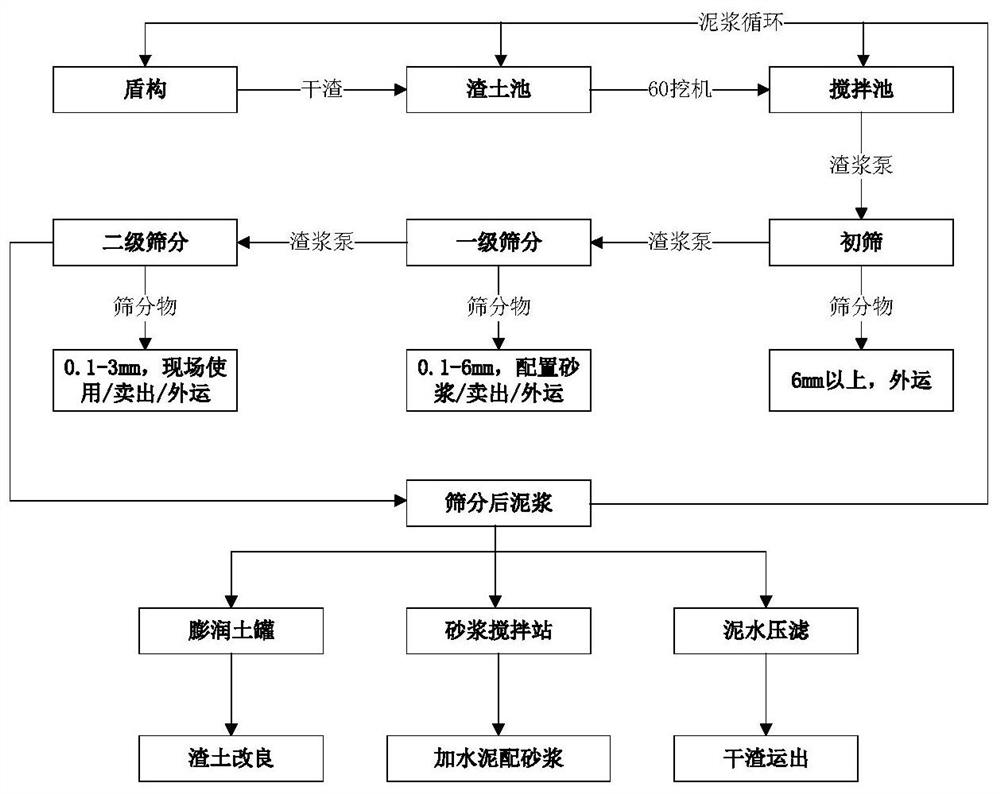

Dual-mode shield waste slag separation system and separation method thereof

PendingCN113482640AStir well to diluteReduce shipping costsMining devicesClimate change adaptationShield tunnelingExcavator

The invention discloses a dual-mode shield waste slag separation system which comprises a shield tunneling machine, a muck pool, a muddy water station and a stirring pool. The stirring pool is arranged close to the muck pool, the stirring pool is communicated with an inlet of the muddy water station through a stirring pool slurry pump and a mud discharge pipe, and a slurry outlet of the muddy water station is communicated with the shield tunneling machine and the stirring pool through a mud inlet pipe; and the muddy water station is provided with a sand grain outlet used for discharging separated particles. A separation method comprises the following steps that shield discharged muck is poured into the muck pool; the muck in the muck pond is transferred into the stirring pond through an excavator arranged beside the muck pond; the muck and slurry are stirred and diluted evenly through a stirrer in the stirring pool, and then the muck and slurry are pumped to the muddy water station through the slurry pump for separation treatment; and slurry formed through separation treatment in the muddy water station is conveyed into the shield tunneling machine, the stirring pool and the mortar stirring station, and sand particles formed through separation treatment in the muddy water station are conveyed into a screening structure to be screened. The waste muck is fully utilized, the material cost is saved, and the environmental pollution is small.

Owner:中交(广州)建设有限公司

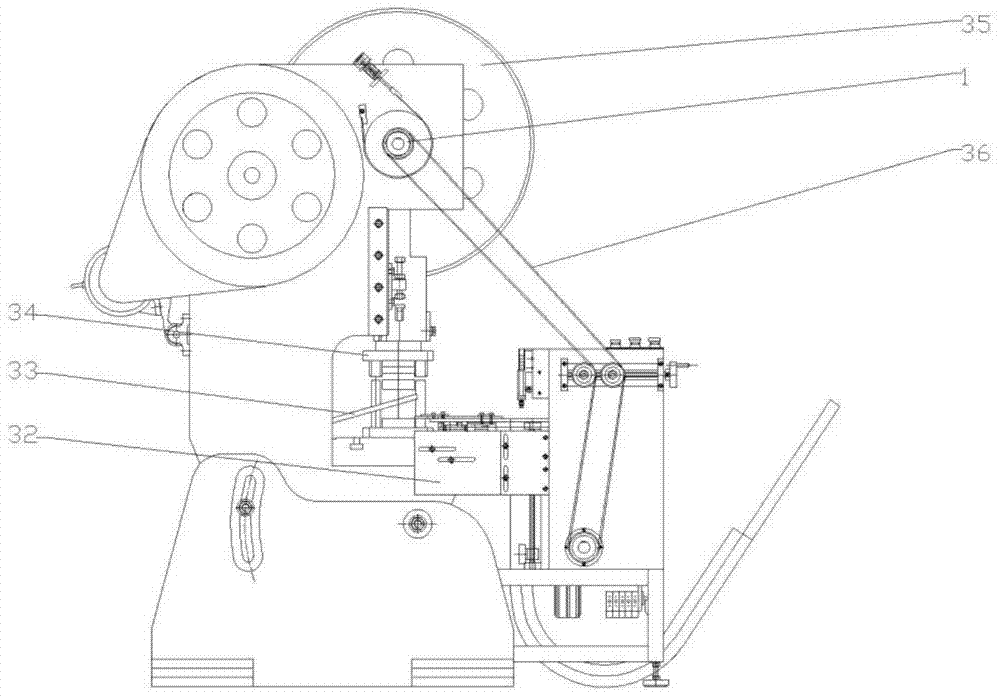

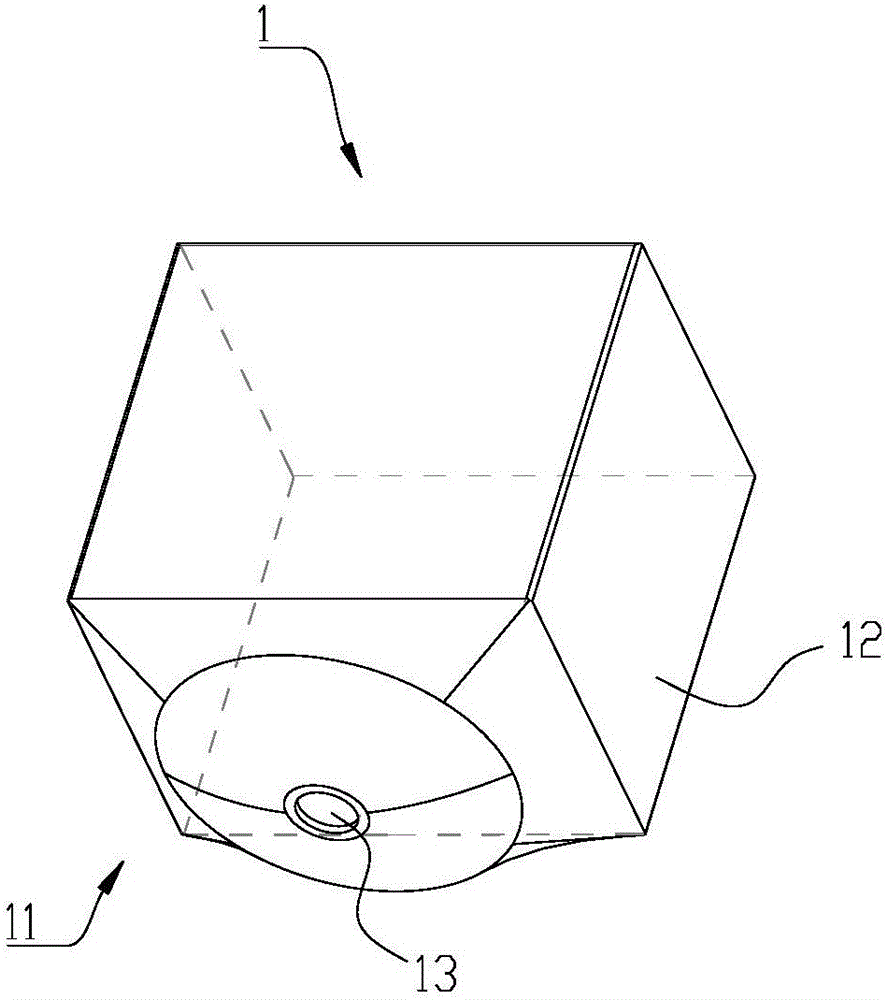

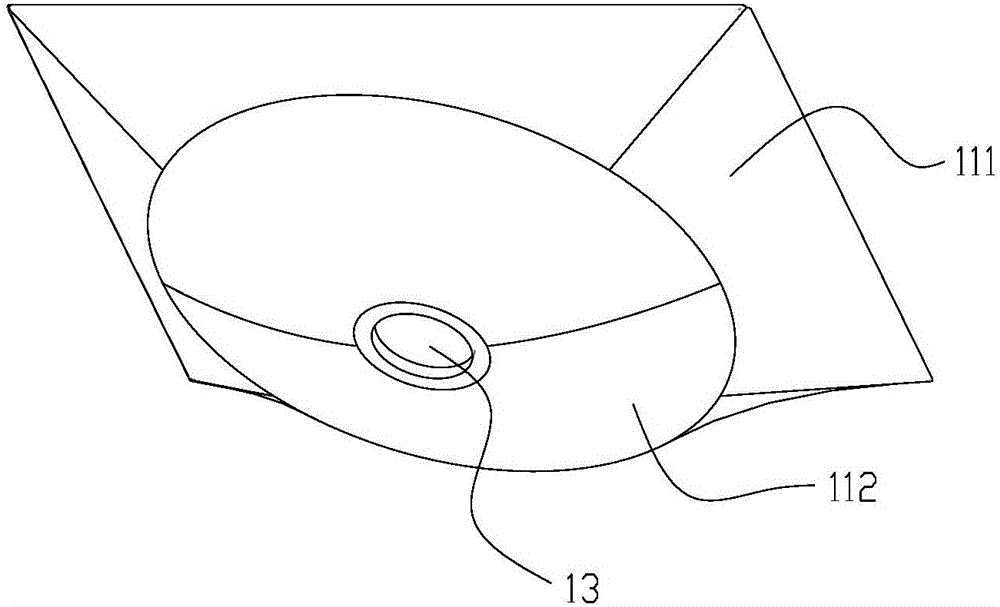

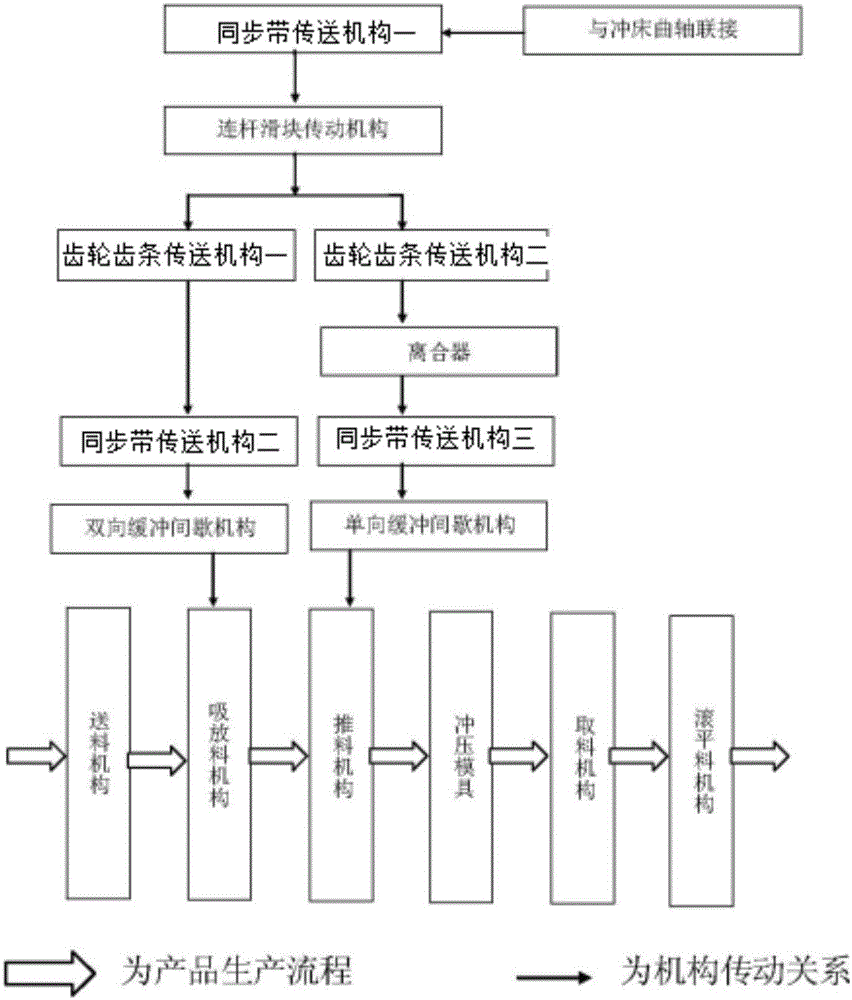

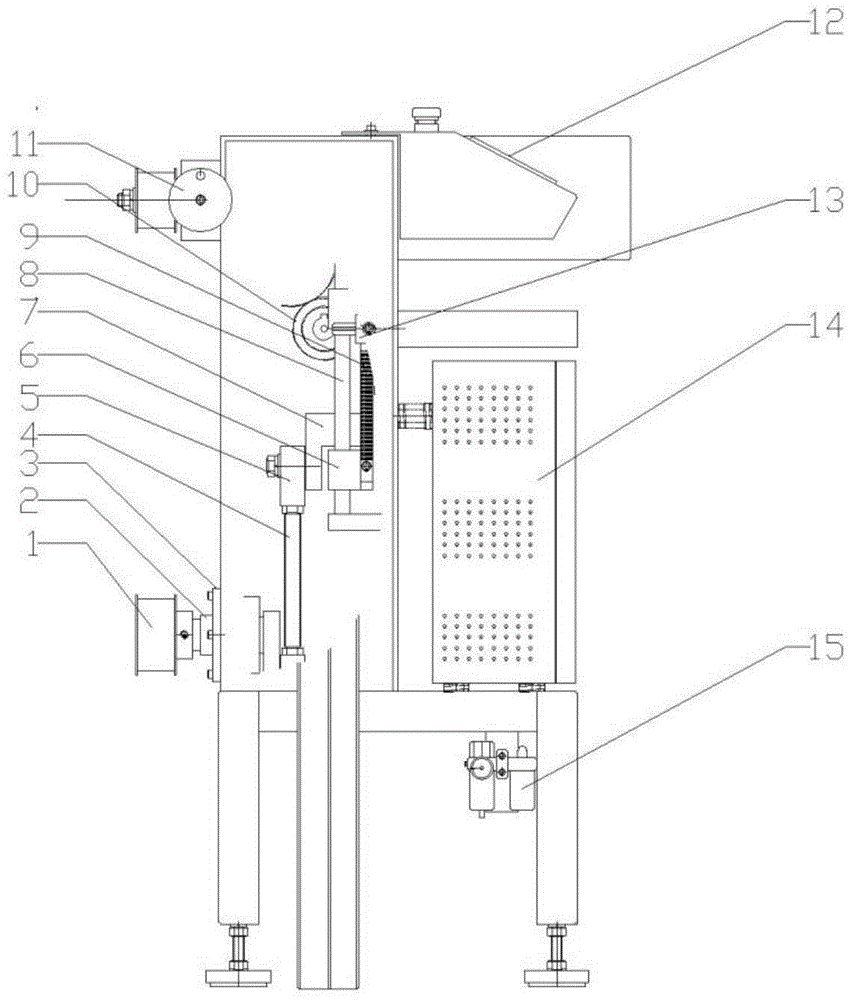

Full-automatic bulk sheet high-speed stamping manipulator

InactiveCN104511546AAdapt to market demandIncrease speedMetal-working feeding devicesPositioning devicesAutomatic controlGear wheel

The invention provides a full-automatic bulk sheet high-speed stamping manipulator which comprises a material suction and release mechanism, a material push mechanism and an electrical automatic control system, wherein the material suction and release mechanism consists of a synchronous belt conveying mechanism I, a connection rod sliding block transmission mechanism, a gear and rack transmission mechanism I, a synchronous belt conveying mechanism II and a bidirectional buffering intermittent mechanism which are connected in sequence; the material push mechanism consists of the synchronous belt conveying mechanism I, the connection rod sliding block transmission mechanism, a gear and rack transmission mechanism II, a clutch and a synchronous belt conveying mechanism III which are connected in sequence; the material suction and release mechanism is connected with the material push mechanism; the automatic control system is connected with the synchronous belt conveying mechanism I. One worker can supervise multiple machine tools; a stamping machine automatically finishes material releasing, stamping, material taking and rolling processes, no extra equipment needs to be added; furthermore, the stamping rate is high, continuous stamping is realized, and stopping to exchange materials is avoided; meanwhile, the production is safe, stable and efficient.

Owner:中山市东凤镇金荣峰精密模具厂

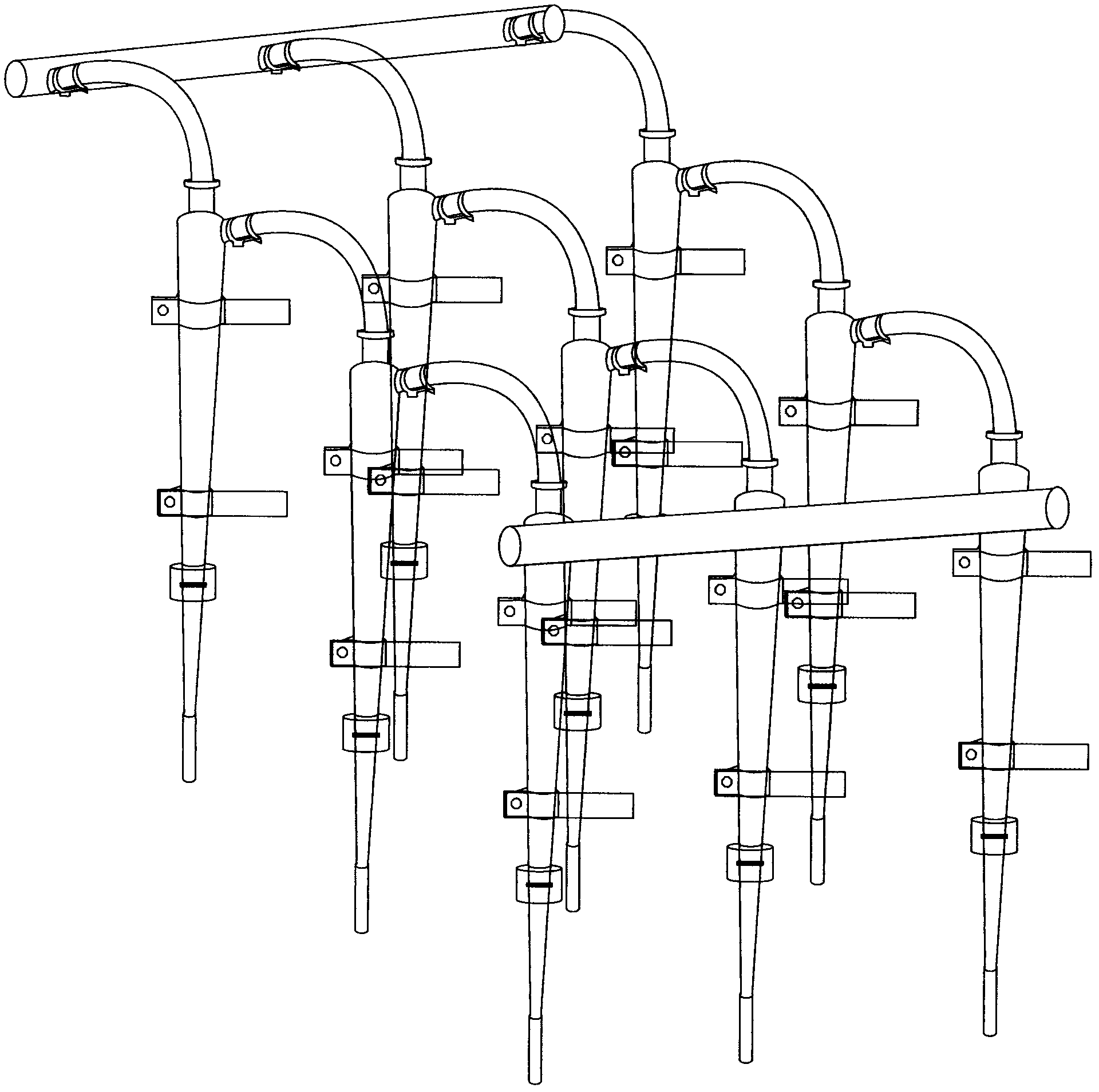

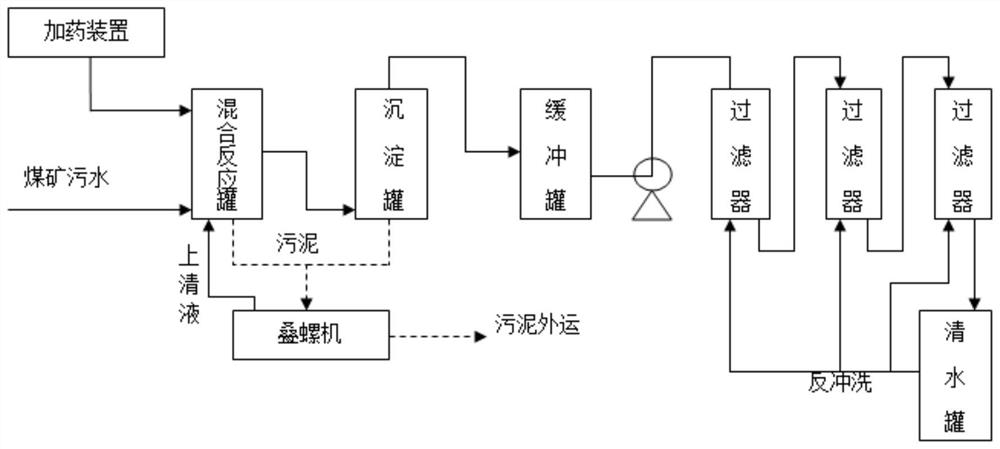

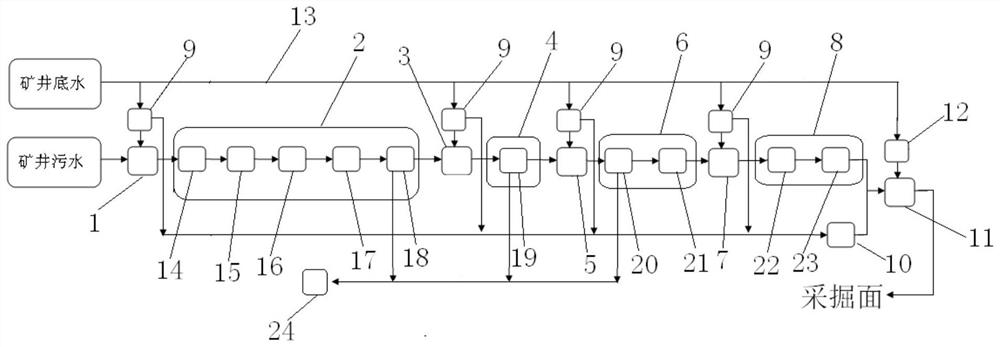

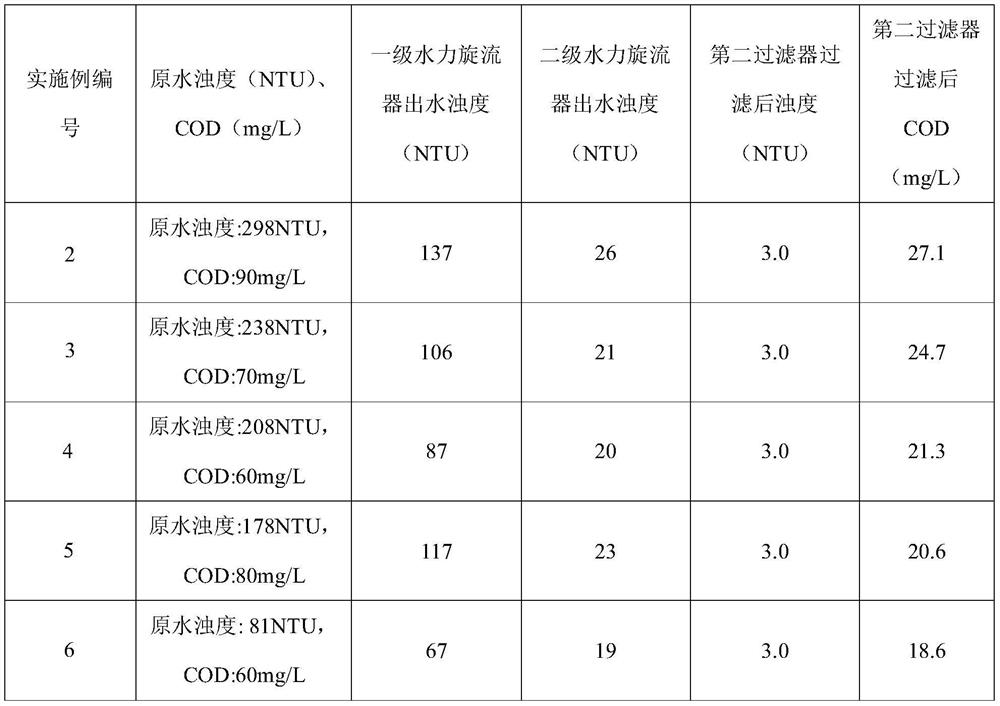

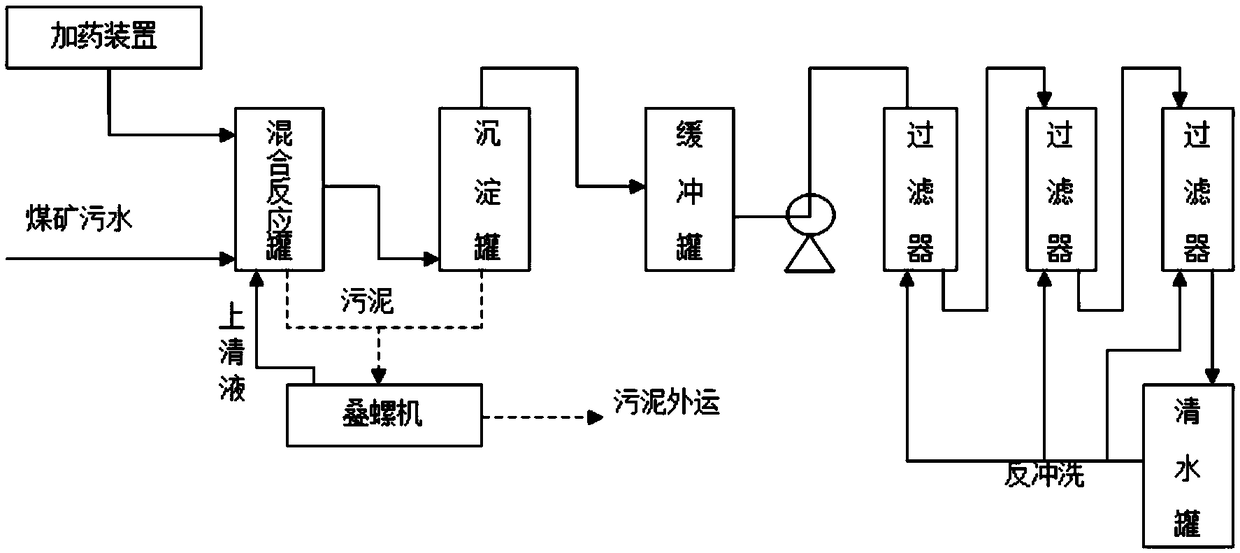

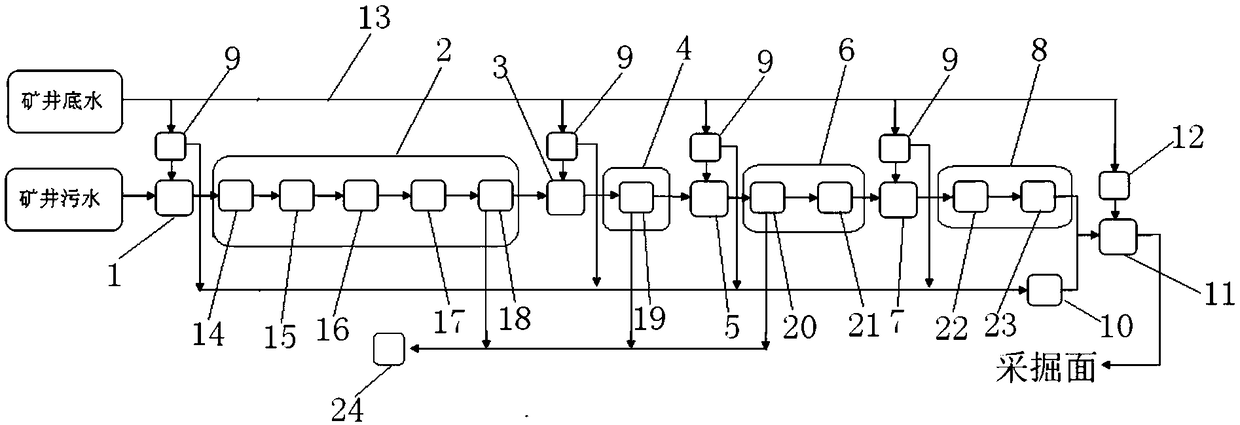

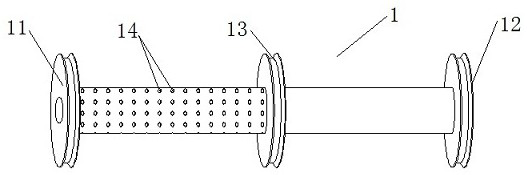

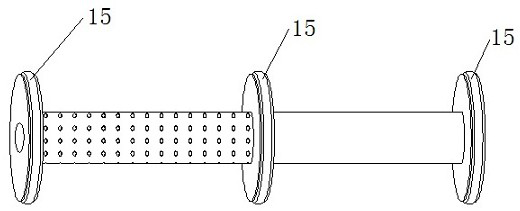

A skid-mounted equipment and treatment method for treating mine sewage

InactiveCN108862736BSave on-site spaceReduce construction costsWaste water treatment from quariesWater/sewage treatment by centrifugal separationWater turbineOutfall

The skid-mounted equipment for treating mine sewage disclosed by the present invention comprises a first lift pump, a first-level treatment unit, a second lift pump, a second-level treatment unit, a third lift pump, a third-level treatment unit, The fourth lifting pump, the fourth-stage processing unit, the first lifting pump to the fourth lifting pump are all connected to the first water turbine, and also include the first filter, and the water outlets of all the first water turbines are connected to the first filter, and the four-stage The water outlets of the processing unit and the first filter are connected with the fifth lift pump, and the fifth lift pump is connected with the second water turbine, and the water inlet of each first water turbine and the second water turbine is connected with a bottom water pipeline. The installed equipment has no power supply, and the treated water is directly used in the production process of the mining face; the mine sewage treatment method of the present invention realizes the power without power supply in the entire driving process, meets the safety requirements for sewage treatment in coal mines, and can be widely used.

Owner:屈撑囤 +3

A storage box for wiring

The invention provides a line arrangement storage box, and belongs to the technical field of electrical apparatus element auxiliary equipment. A plurality of electric wire inlets (2) are formed in theside face of one side of a box body (1) of the line arrangement storage box, and a plurality of electric wire outlets (3) are formed in the other side of the box body (1). Rotating shafts (6) locatedon the inner wall of the upper end surface (4) of the box body or the inner wall of the lower end surface (5) of the box body are arranged in the box body (1), and the rotating shafts (6) are provided with wire winding blades (7). Blade rod bodies (8) of the wire winding blades (7) are arranged of a structure arranged obliquely, blade bending parts I (9) are arranged of a structure bending upward, and blade bending parts II (10) are arranged of a structure bending downward. The line arrangement storage box has a simple structure, can conveniently and quickly realize the winding and discharging of a plurality of electric wires, completes the arrangement of electric wire lines, solves the problems of being in a mass and being excessive of occupied space due to the excessive electric wires on an electric wire arrangement site, avoids cross-winding of the electric wires, and improves the convenience of use.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

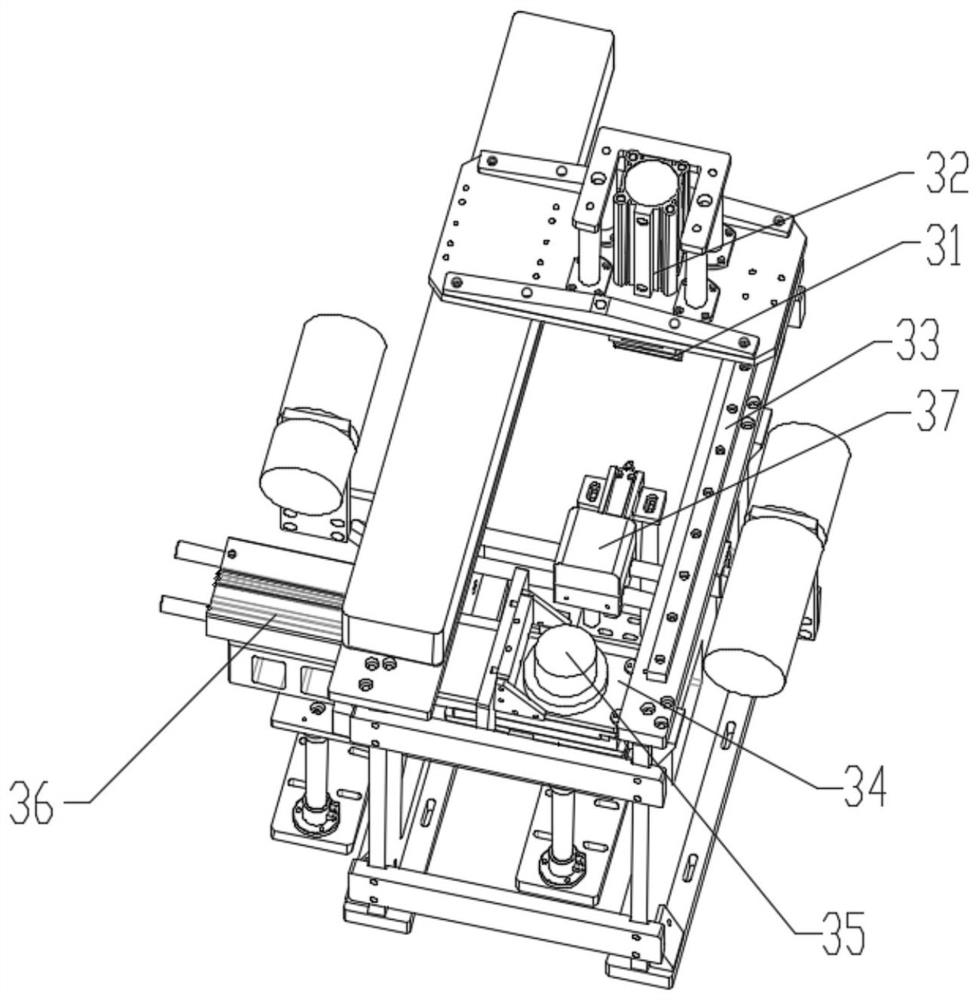

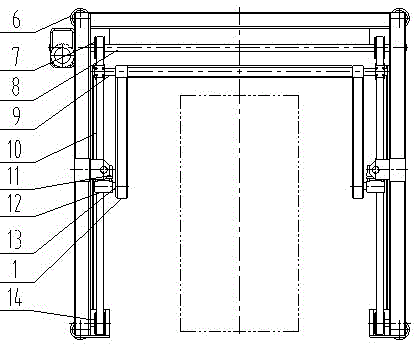

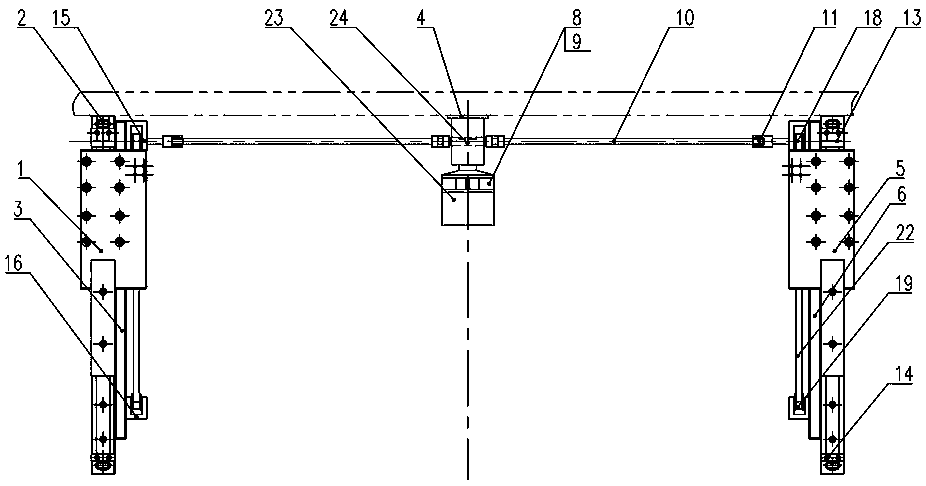

Electric overturning mechanism

ActiveCN104015026AImprove mechanical performanceImprove rigidityAssembly machinesMetal working apparatusDrive shaftElectric machine

The invention provides an electric overturning mechanism. The electric overturning mechanism comprises a U-shaped mounting rack, a speed reduction motor arranged on the outer side of the U-shaped mounting rack and positioned in any one of two top angle ends, and a motor driving shaft connected with the speed reduction motor, wherein other devices are symmetrically arranged along the center line of the bottom side of the U-shaped mounting rack, the devices on any side of the center line of the bottom side comprise a pair of synchronous pulleys, a synchronous belt arranged on the synchronous pulleys, a movable overturning fixing block connected with the synchronous belt, an overturning driving shaft and an overturning driven shaft, one of the synchronous pulleys is arranged at one end of the motor driving shaft and can synchronously move with the motor driving shaft, the other one of the synchronous pulleys is positioned at the top end of the U-shaped mounting rack, one end of the overturning driving shaft penetrates into the movable overturning fixing block and the other end of the overturning driving shaft is fixed with an overturning rack which is used for fixing and overturning a workpiece, and the overturning driven shaft is fixed with the overturning rack and can move up and down. The electric overturning mechanism can save the site area, does less work, and has low energy consumption, simple structure, convenience in maintenance and safety and reliability.

Owner:安徽唐古拉工业技术有限公司

Laser marking system based on EHRT punching and shearing machine

InactiveCN111571224AInteraction does not affectEasy identificationOther manufacturing equipments/toolsNibbling shearing machinesMachineConveyor belt

The invention discloses a laser marking system based on an EHRT punching and shearing machine. The laser marking system includes the EHRT punching and shearing machine for producing copper bars. A laser marking mechanism for plain code marking on the copper bars is arranged on the side edge of a discharging conveyor belt of the EHRT punching and shearing machine, and the laser marking mechanism isset in a tail area of the discharging conveyor belt of the EHRT punching and shearing machine. The laser marking system is based on the German EHRT punching and shearing machine and integrates a laser marking system, the system uses a machine interaction scheme combing hardware and software, and the interaction between an original punching and shearing machine and other equipment is not affected;that is, under the condition that the production efficiency and production layout are not affected, the identification of copper bar parts can be easily realized, and the intelligent promotion of a factory is facilitated; furthermore, due to sufficient use of hardware equipment such as the original conveyor belt of the punching and shearing machine, the marking quality requirements are met, the compactness of the equipment is maintained, and on-site space is saved; and furthermore, the marking production efficiency is balanced, and the marking time of a single part is controlled within 10 seconds, so that non major impact is exerted on the original production efficiency.

Owner:上海力族机械设备有限公司

Prying-mounting equipment for treating mine wastewater and treating method

InactiveCN108862736ASave on-site spaceReduce construction costsWaste water treatment from quariesWater/sewage treatment by centrifugal separationWater turbineEngineering

The invention discloses prying-mounting equipment for treating mine wastewater. The prying-mounting equipment comprises a first lifting pump, a first-level treating unit, a second lifting pump, a second-level treating unit, a third lifting pump, a third-level treating unit, a fourth lifting pump and a fourth-level treating unit which are communicated with one another sequentially through pipelines. The first lifting pump, the second lifting pump, the third lifting pump and the fourth lifting pump are all connected with first water turbines, the prying-mounting equipment further comprises a first filter, water outlets of all the first water turbines are communicated with the first filter, the first to the fourth-level treating units and the water outlet of the first filter are all connectedwith a fifth lifting pump, the fifth lifting pump is connected with a second water turbine, and water inlets of each first water turbine and the second water turbine are connected with bottom water pipelines. The prying-mounting equipment is not provided with power, and the wastewater after being treated is directly used for production process of face; and the treating method of the mine wastewater achieves non-power in the whole driving process, conforms to the safety requirements of mine undershaft wastewater treatment, and can be widely applied.

Owner:屈撑囤 +3

Plastic pipe sizing and cooling production device

ActiveCN108790105BControl deformationSave on-site spaceTubular articlesIntegrated designMechanical engineering

Owner:SICHUAN NIGALE BIOTECH

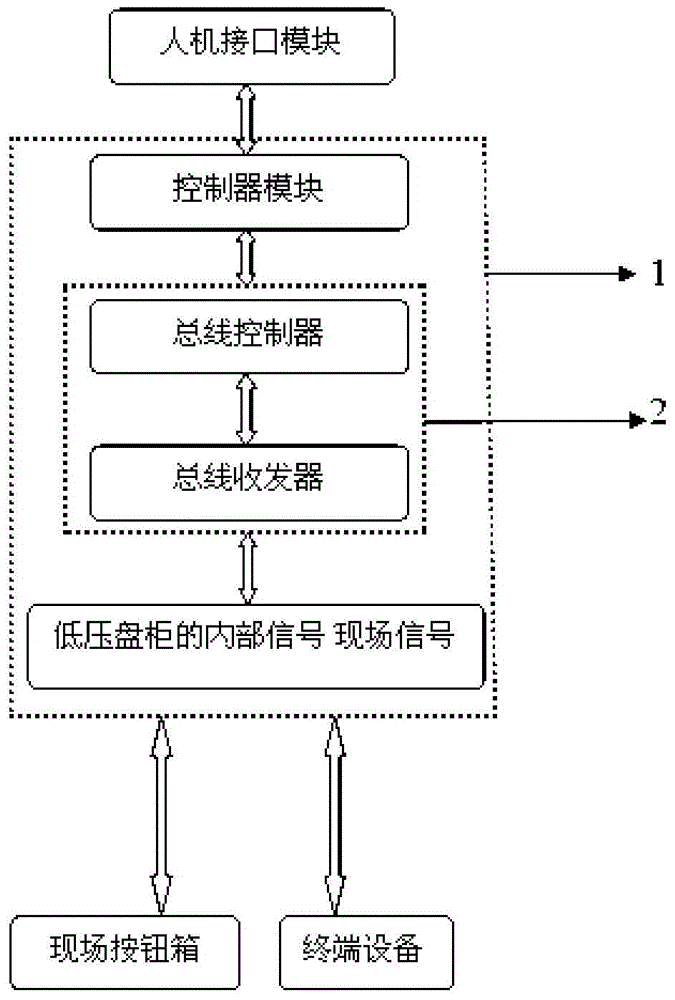

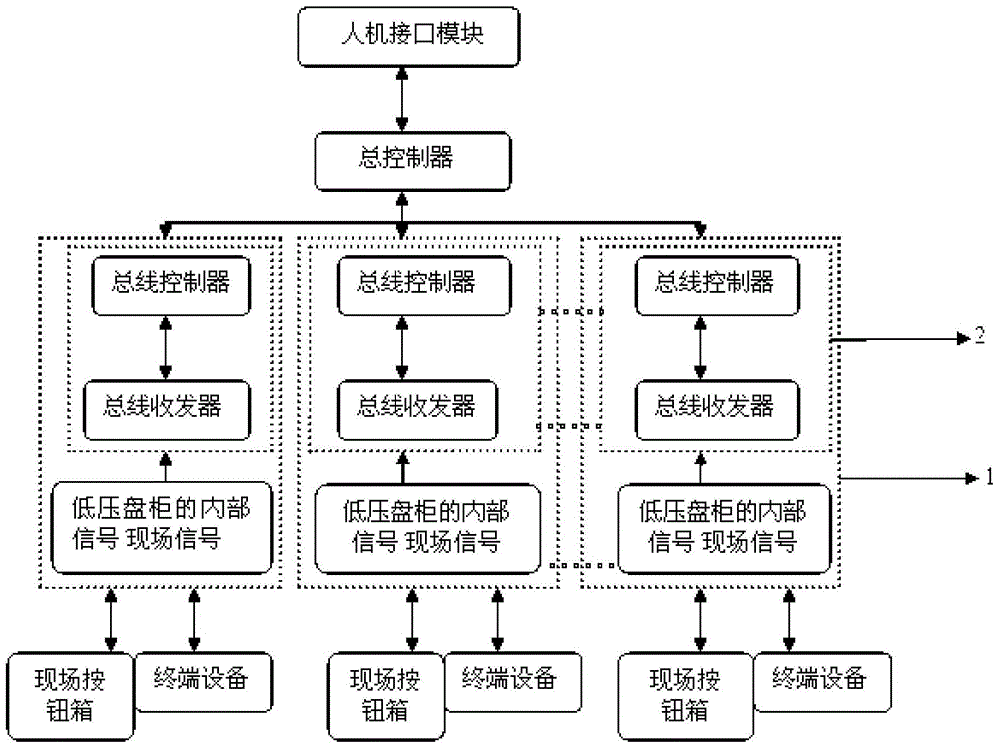

Low-voltage board cabinet informatization acquisition system based on onsite bus technology

InactiveCN104460537AReduce consumptionReduce distractionsTotal factory controlProgramme total factory controlInformatizationSignal quality

The invention provides a low-voltage board cabinet informatization acquisition system based on an onsite bus technology. The system comprises a low-voltage board cabinet, a controller module, a man-machine interface module, terminal equipment and an onsite button box. The controller module is embedded in the low-voltage board cabinet. An onsite signal or an internal signal received by the low-voltage board cabinet is transmitted to the controller module by an onsite bus module via an onsite bus. The controller module communicates with the man-machine interface module via an industrial ethernet. The onsite button box is connected with the low-voltage board cabinet via an onsite control loop. The terminal equipment is connected with the low-voltage board cabinet via a main loop. An original low-voltage board cabinet system and a computer control system are combined so that consumption of cables is reduced and nonferrous metals are saved; cabinet bodies are reduced, onsite space is saved and construction cost is lowered; signal transmission is performed via the bus, interference is reduced and signal quality is enhanced so as to be suitable for the requirement for sustainable development; and equipment cascading is supported and automatic control is realized.

Owner:TIANJIN SENYUAN ELECTRIC POWER ENG

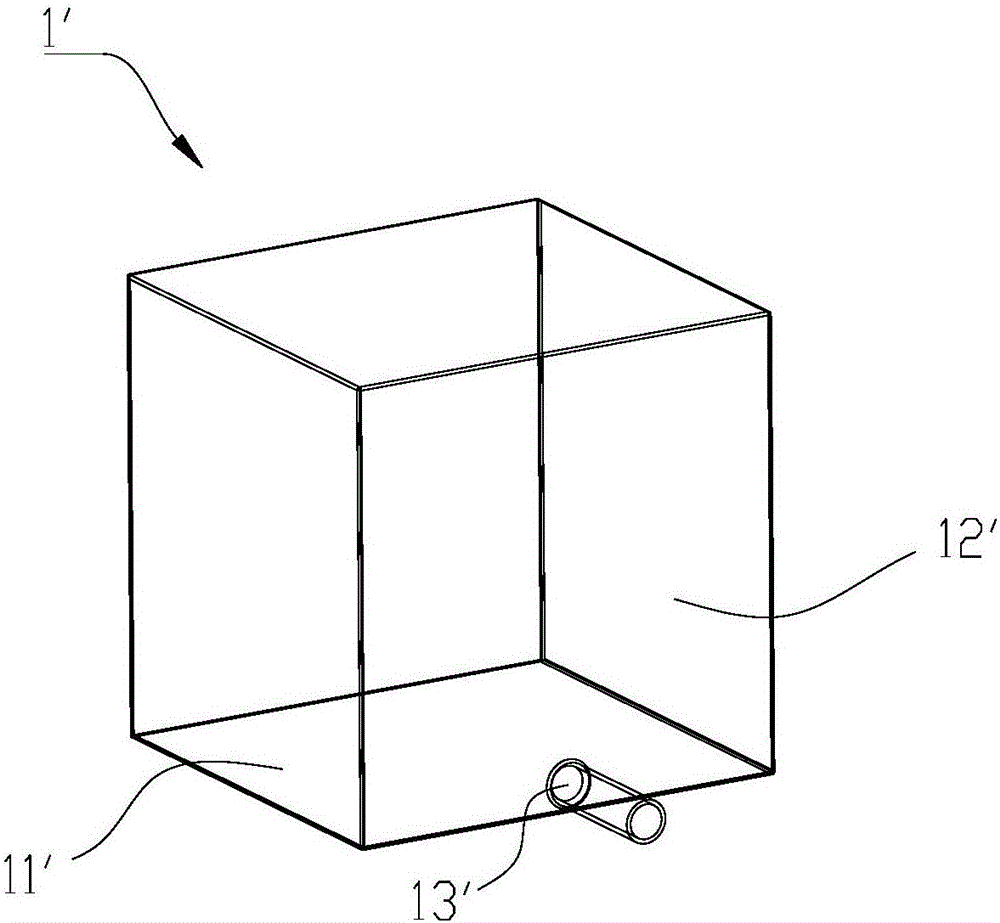

Off-line cyclic sedimentation tank of alkali wash water

InactiveCN106474780AQuality improvementEnsure normal dischargeSettling tanks feed/dischargeSedimentation settling tanksForeign matterWash water

The invention provides an off-line cyclic sedimentation tank of alkali wash water. The off-line cyclic sedimentation tank comprises a tank bottom and a tank wall, wherein the tank bottom forms a surface inclining towards the middle part and the lower part, and a sewage draining outlet is formed in the middle part of the tank bottom; specifically, the tank bottom comprises a first part and a second part; the second part is a paraboloid with an upward opening, and the sewage draining outlet is formed in the middle part of the second part; the upper edge part of the first part is connected with the lower edge part of the tank wall, and the lower edge part of the first part is connected with the upper edge part of the second part. The off-line cyclic sedimentation tank of the alkali wash water, provided by the invention, has a cuboid-shaped or cube-shaped tank body which is convenient for field installation, and meanwhile, foreign matters are enabled to be completely drained from the sewage draining outlet due to the paraboloid-shaped tank bottom.

Owner:BAOSHAN IRON & STEEL CO LTD

A fully automatic high-speed stamping manipulator

InactiveCN104511546BAvoid vibration effectsNo lossMetal-working feeding devicesPositioning devicesPunch pressAutomatic control

The invention provides a full-automatic bulk sheet high-speed stamping manipulator which comprises a material suction and release mechanism, a material push mechanism and an electrical automatic control system, wherein the material suction and release mechanism consists of a synchronous belt conveying mechanism I, a connection rod sliding block transmission mechanism, a gear and rack transmission mechanism I, a synchronous belt conveying mechanism II and a bidirectional buffering intermittent mechanism which are connected in sequence; the material push mechanism consists of the synchronous belt conveying mechanism I, the connection rod sliding block transmission mechanism, a gear and rack transmission mechanism II, a clutch and a synchronous belt conveying mechanism III which are connected in sequence; the material suction and release mechanism is connected with the material push mechanism; the automatic control system is connected with the synchronous belt conveying mechanism I. One worker can supervise multiple machine tools; a stamping machine automatically finishes material releasing, stamping, material taking and rolling processes, no extra equipment needs to be added; furthermore, the stamping rate is high, continuous stamping is realized, and stopping to exchange materials is avoided; meanwhile, the production is safe, stable and efficient.

Owner:中山市东凤镇金荣峰精密模具厂

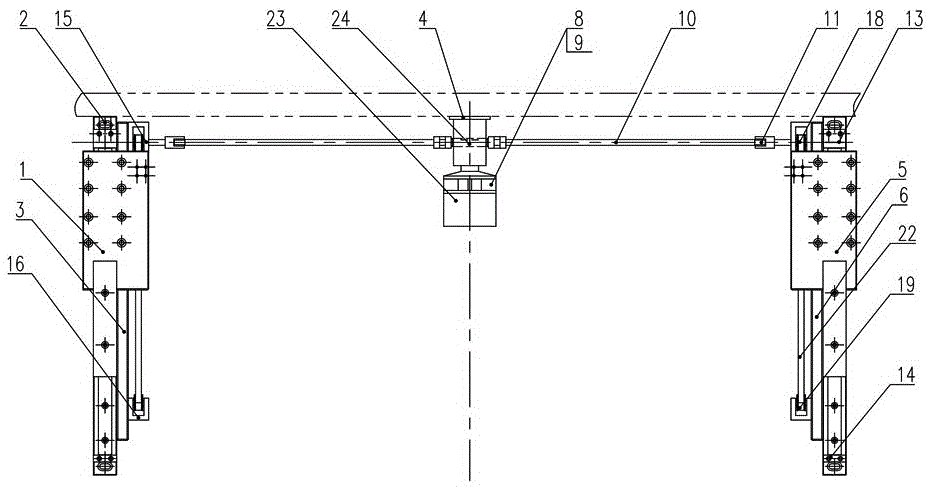

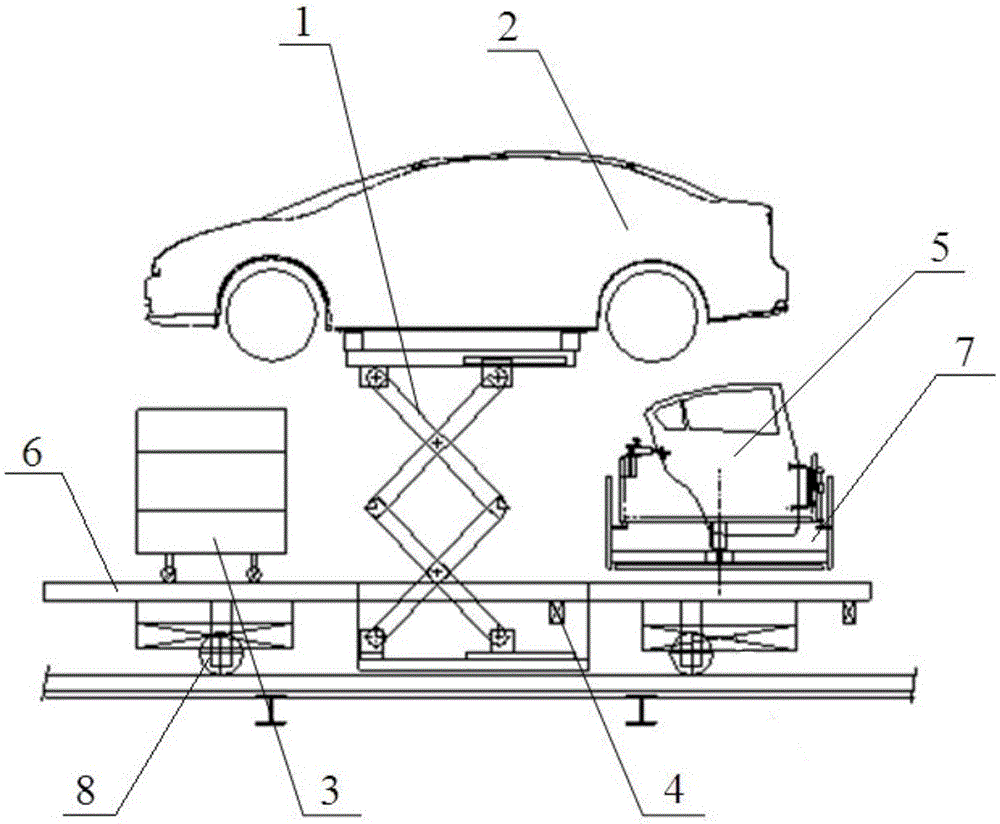

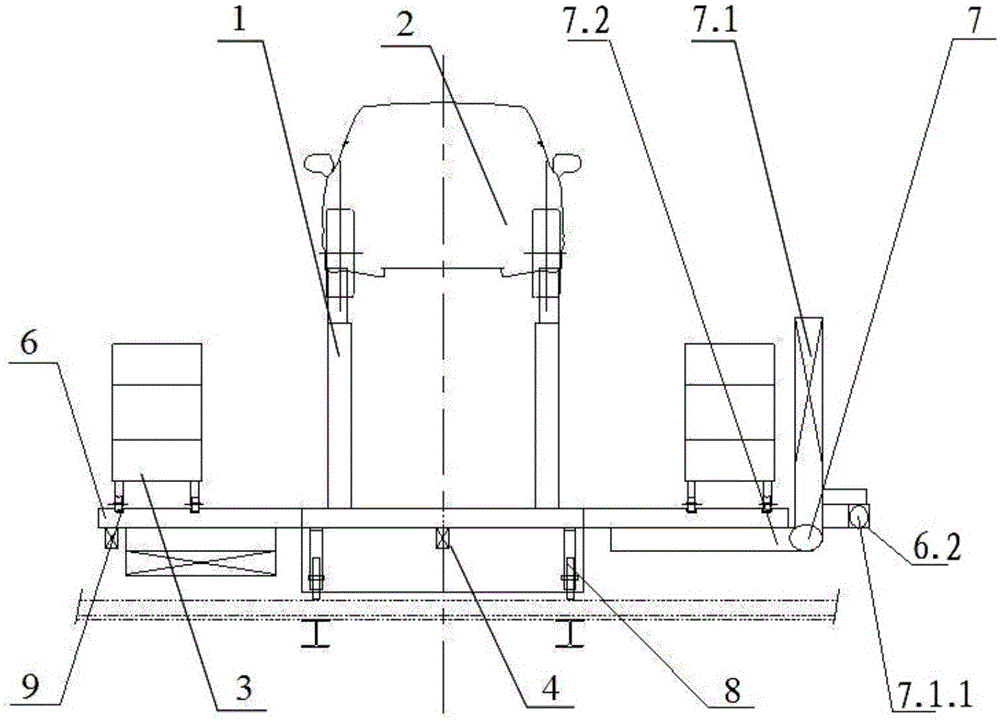

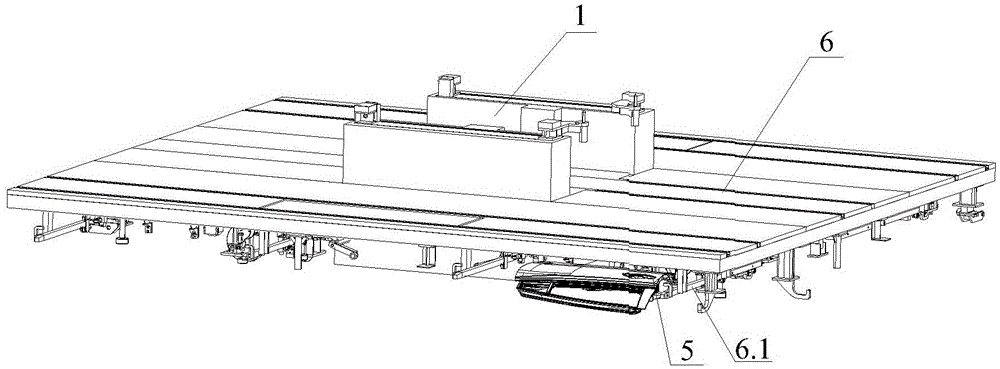

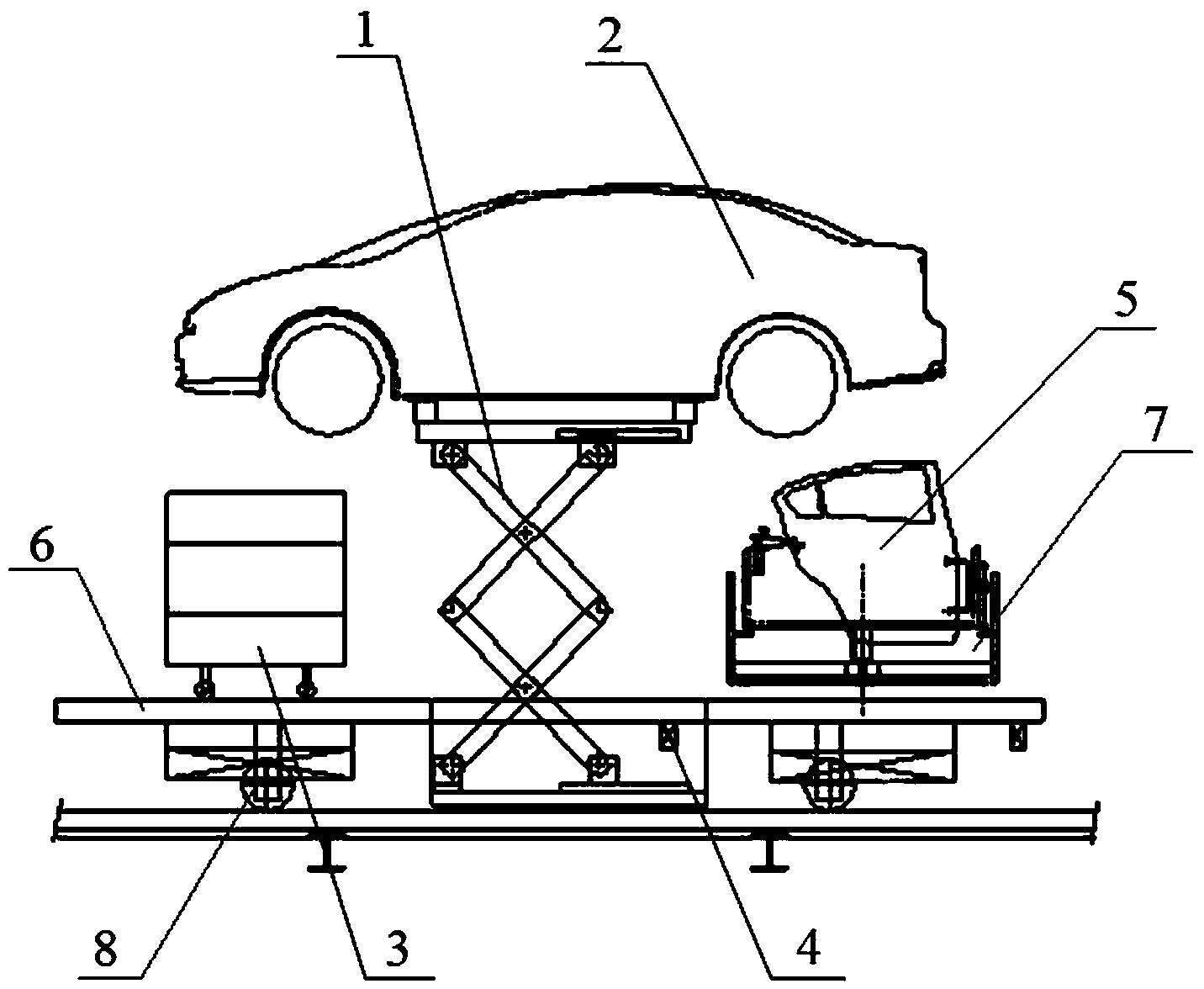

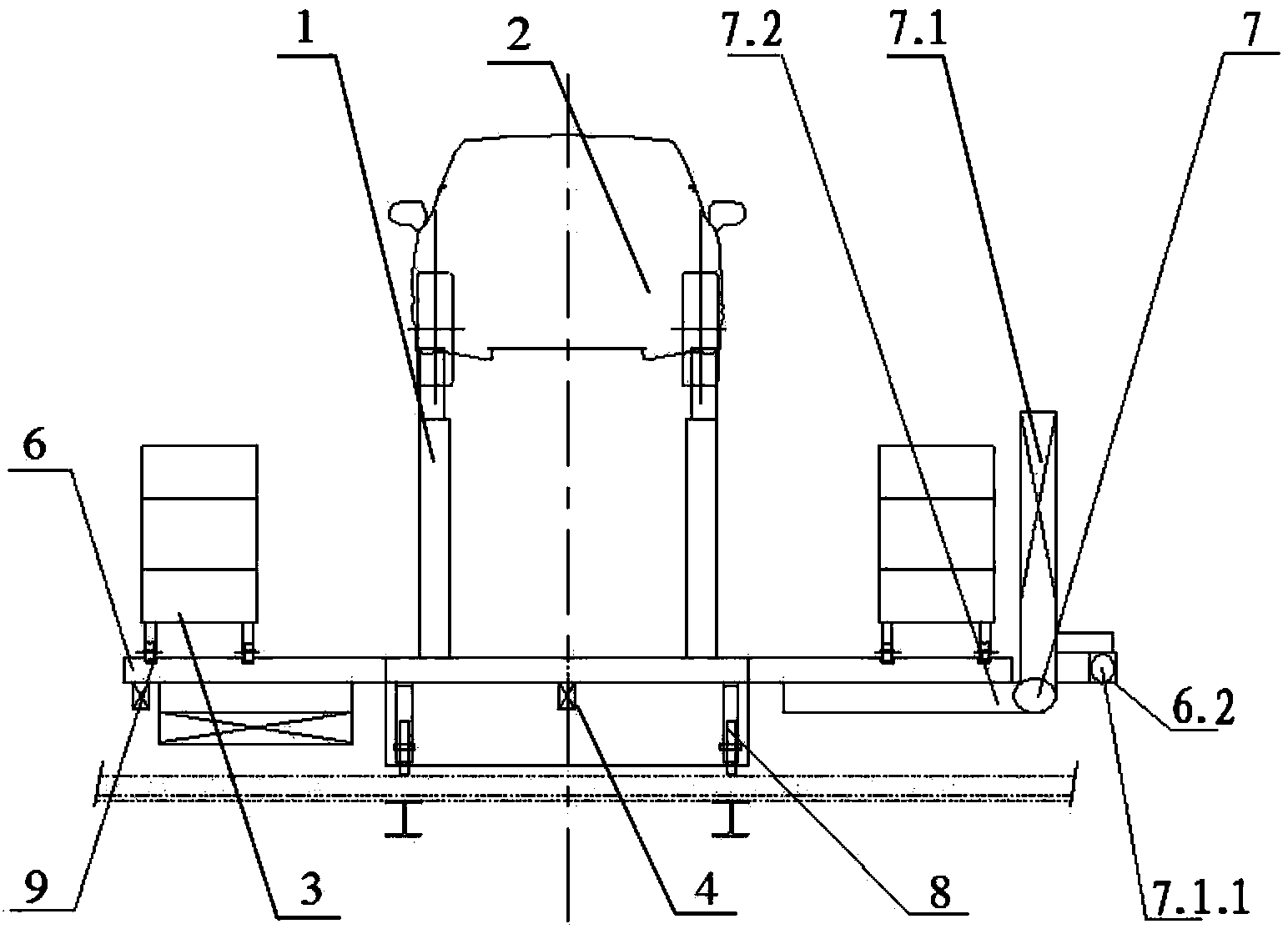

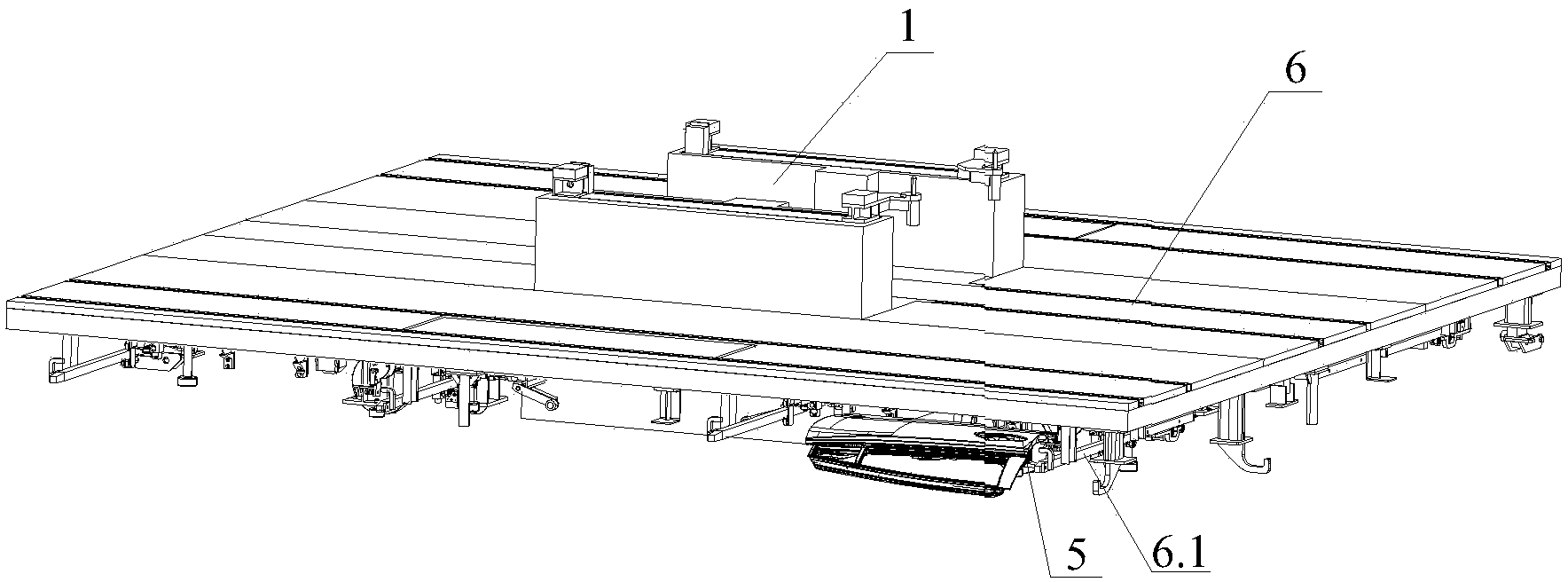

Multifunctional lifting main line table device

ActiveCN103587912BLarge lifting load rangeReliable carryingMechanical conveyorsPrincipal lineEngineering

The invention relates to a multifunctional lifting principal line bedplate device, and belongs to the technical field of conveying tray carrying devices of production conveyor lines. The multifunctional lifting principal line bedplate device comprises a bedplate and idler wheels arranged at the bottom of the bedplate. The bedplate is provided with a carrying device capable of ascending and descending, and the carrying device is connected with a power supplying device. The bottom of the bedplate is provided with a containing rail perpendicular to the heading direction of the bedplate, one side edge of the bedplate is provided with a walking rail, and one side edge of the bedplate is fixedly connected with a clamp device. The clamp device comprises a connecting component connected with the containing rail in a limiting mode and an overturning component hinged to the connecting component. The overturning component is provided with walking wheels which are arranged on the walking rail, a vehicle door pulling-out and containing device fixed on the floor is arranged between the walking rail and the containing rail, and the clamp device is provided with containing wheels. The automatic lifting bedplate has the advantages of being large in lifting load range, reliable in carrying, high in positioning precision, stable in lifting device and abundant in carrying form.

Owner:DONGFENG HONDA AUTOMOBILE CO LTD

Multifunctional lifting principal line bedplate device

ActiveCN103587912ALarge lifting load rangeReliable carryingMechanical conveyorsPrincipal lineEngineering

The invention relates to a multifunctional lifting principal line bedplate device, and belongs to the technical field of conveying tray carrying devices of production conveyor lines. The multifunctional lifting principal line bedplate device comprises a bedplate and idler wheels arranged at the bottom of the bedplate. The bedplate is provided with a carrying device capable of ascending and descending, and the carrying device is connected with a power supplying device. The bottom of the bedplate is provided with a containing rail perpendicular to the heading direction of the bedplate, one side edge of the bedplate is provided with a walking rail, and one side edge of the bedplate is fixedly connected with a clamp device. The clamp device comprises a connecting component connected with the containing rail in a limiting mode and an overturning component hinged to the connecting component. The overturning component is provided with walking wheels which are arranged on the walking rail, a vehicle door pulling-out and containing device fixed on the floor is arranged between the walking rail and the containing rail, and the clamp device is provided with containing wheels. The automatic lifting bedplate has the advantages of being large in lifting load range, reliable in carrying, high in positioning precision, stable in lifting device and abundant in carrying form.

Owner:DONGFENG HONDA AUTOMOBILE CO LTD

A retractable sliding table device controlled by plc closed loop

The invention discloses a flexible sliding table device controlled by a PLC closed loop. The flexible sliding table device comprises a sliding part, a drive part, a transmission part and a PLC control part, wherein the sliding part comprises two linear guide rails which are arranged in a direction of movement of a quartz boat seat, and the two linear guide rails are separately positioned on guide rail mounting plates at left and right sides; a slide block for driving the quartz boat seat to move is arranged on the linear guide rails in a sliding mode, and is driven by the drive part; the drive part comprises a step motor and a speed reducer; the transmission part comprises a left drive wheel assembly, a right drive wheel assembly and two connecting rods; the connecting rods are driven by the drive part to further drive the left drive wheel assembly and the right drive wheel assembly; the left drive wheel assembly and the right drive wheel assembly separately drive a left slide block mounting plate and a right slide block mounting plate as well as the slide bock on the two mounting plates to move along the linear guide rails through a synchronous belt; the quartz boat seat is mounted on the slide block; and the PLC control part is used for controlling the drive part. The flexible sliding table device has the advantages of being simple and compact in structure, simple and convenient to operate, high in control precision, good in reliability and the like.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com