Dual-mode shield waste slag separation system and separation method thereof

A technology of slag separation and shield tunneling, which is applied to the dual-mode shield slag separation system and its separation field, can solve the problems of equipment cost waste, environmental pollution of slag, and soil particles cannot be recycled, so as to save material costs and reduce The effect of excavation cost, saving on-site site and muck transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

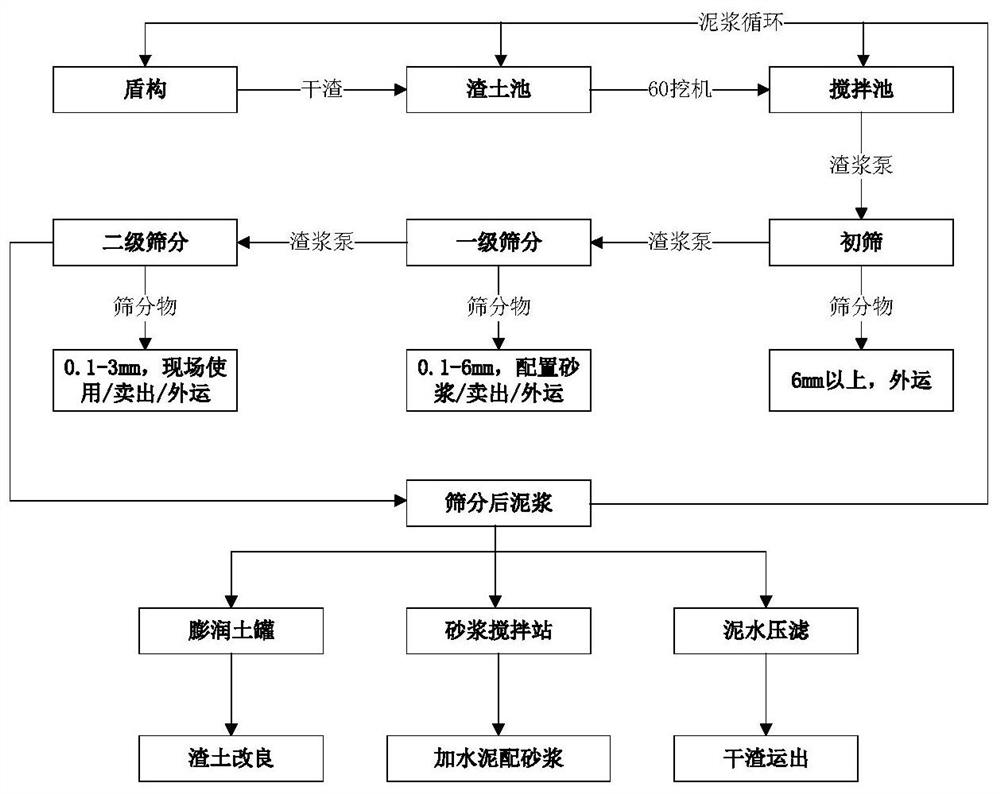

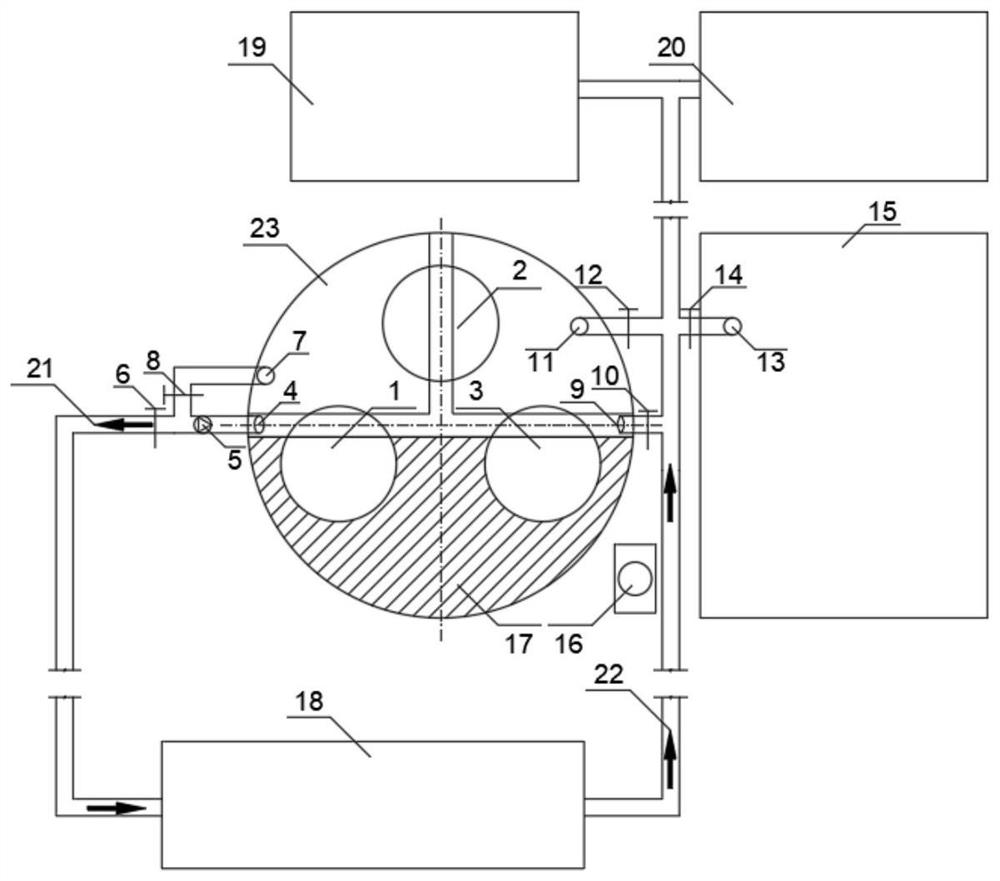

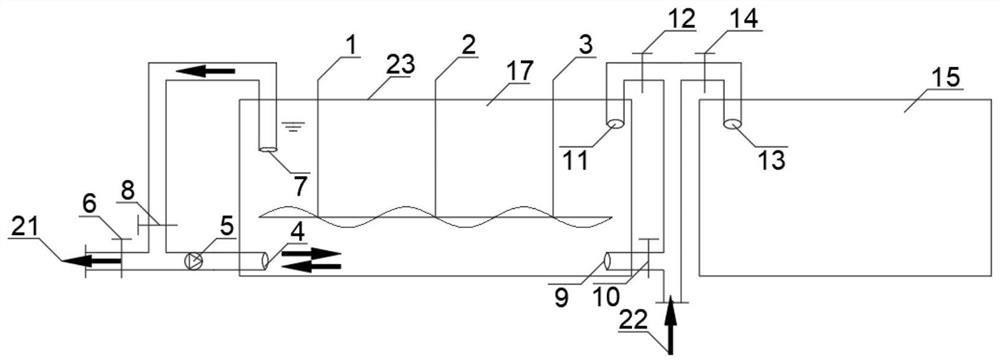

[0042] Considering that there is usually a certain distance between the slurry station and the excavation port of the shield machine, in order to facilitate the transfer of muck, the mixing tank is arranged next to the slag yard at the excavation port, and the mixing tank is connected with other functional systems such as the mud station by the mud discharge pipe and the mud inlet pipe. , a working system such as figure 2 shown.

[0043] The mud discharge pipe pumps the diluted slag to the mud water station for processing, and the mud inlet pipe pumps the adjusted mud to the mixing tank, shield machine, mortar mixing station and slag pond respectively according to the needs of the site. Pumped to the mixing tank for diluting the dregs, the mud index requirements are low, when the content of clay in the stratum is high, clean water can be directly input; pumped to the shield machine for dregs improvement; pumped to the mixing station mainly It is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com