Prefabricated part stacking device

A technology of prefabricated components and braking mechanism, which is applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problems of unable to store the quantity and types of prefabricated components, unfavorable fast and convenient access of prefabricated components, and failure of prefabricated components to enter the site on time, etc., to achieve Save on-site space, improve the level of intelligence, and the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

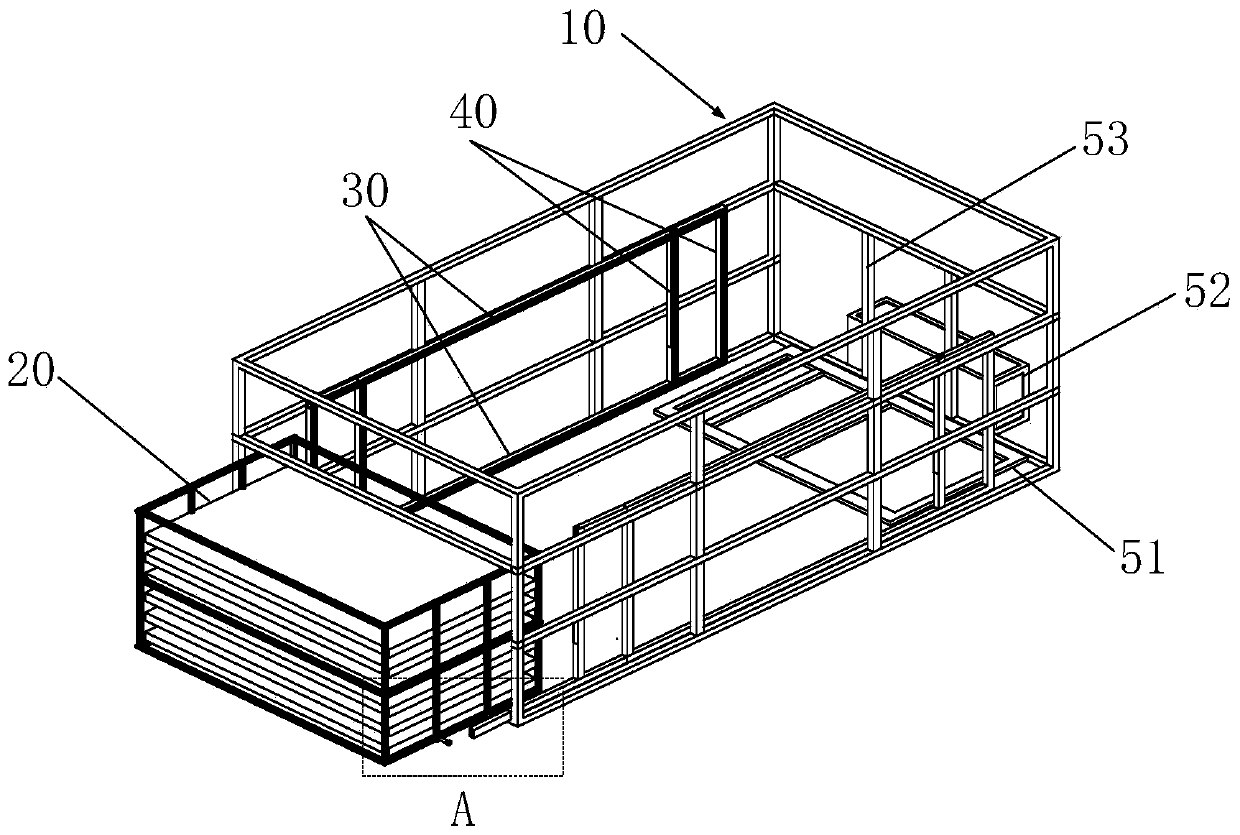

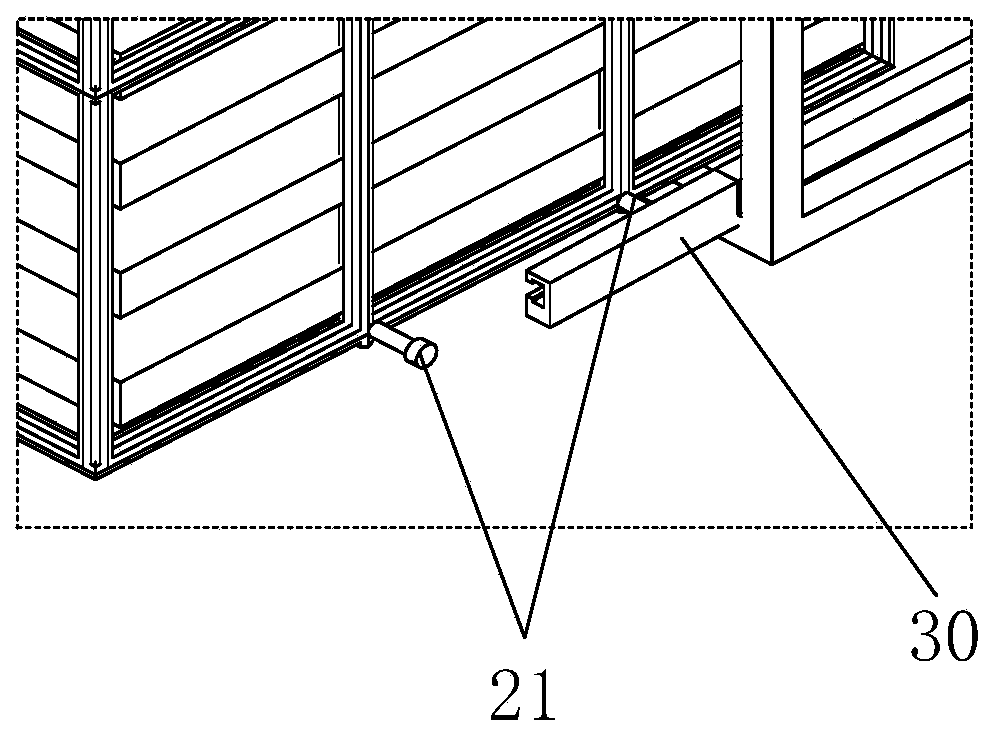

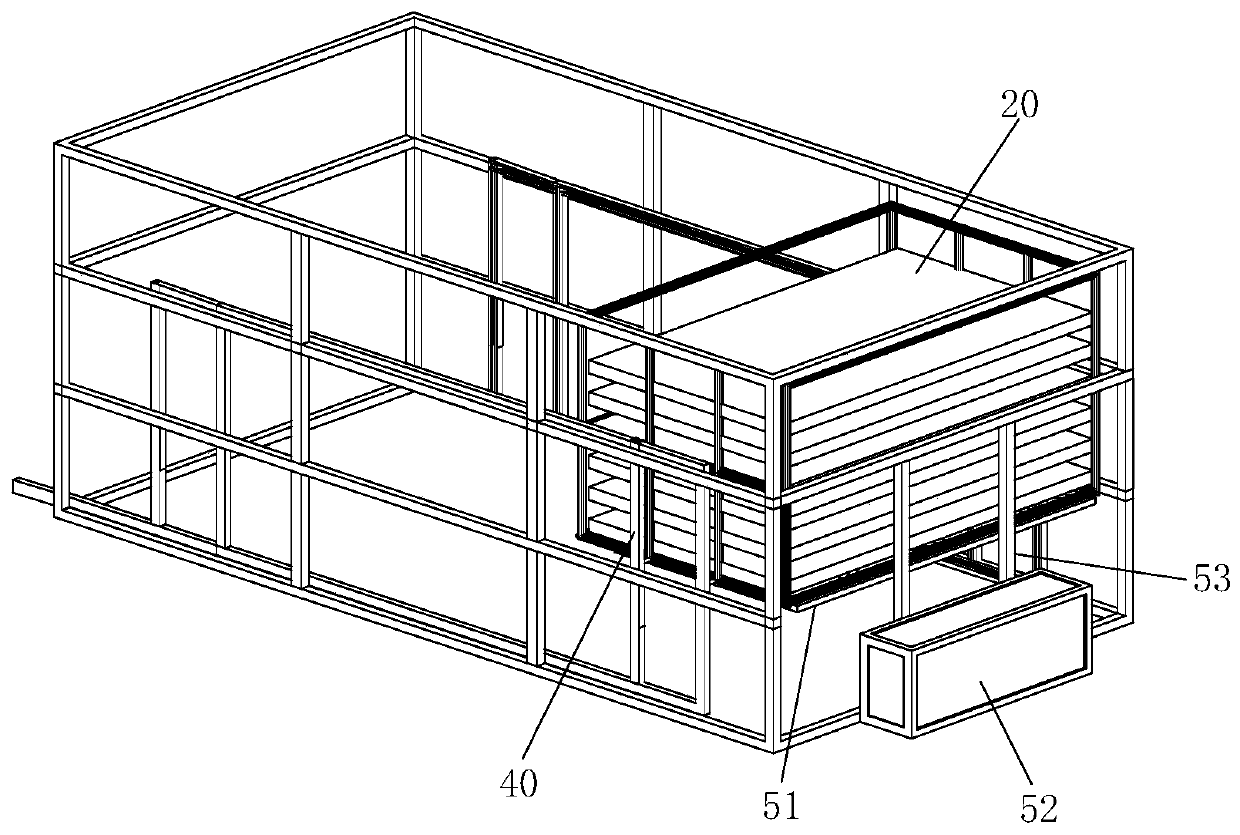

[0025] For the prefabricated component stacking device provided by the present invention, please refer to Figure 1 to Figure 4 , including: a steel frame 10 and several stacking baskets 20, the steel frame 10 is fixed with multi-layer horizontal chute 30, and multiple sets of vertical chute 40 are arranged between the two layers of horizontal chute 30, the vertical chute The end of the chute 40 communicates with the horizontal chute 30 ; the bottom of the stacking basket 20 is provided with a roller 21 , and the roller 21 can slide in the horizontal chute 30 and the vertical chute 40 . The present invention sets the horizontal chute 30 and the vertical chute 40, utilizes the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com