Y-shaped oblique opening sorting machine for high-speed sorting

A kind of technology of sorting machine and oblique port, which is applied in sorting and other directions, can solve problems such as the influence of lifting efficiency, and achieve the effect of flexible action, high sorting efficiency and precision, and small overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

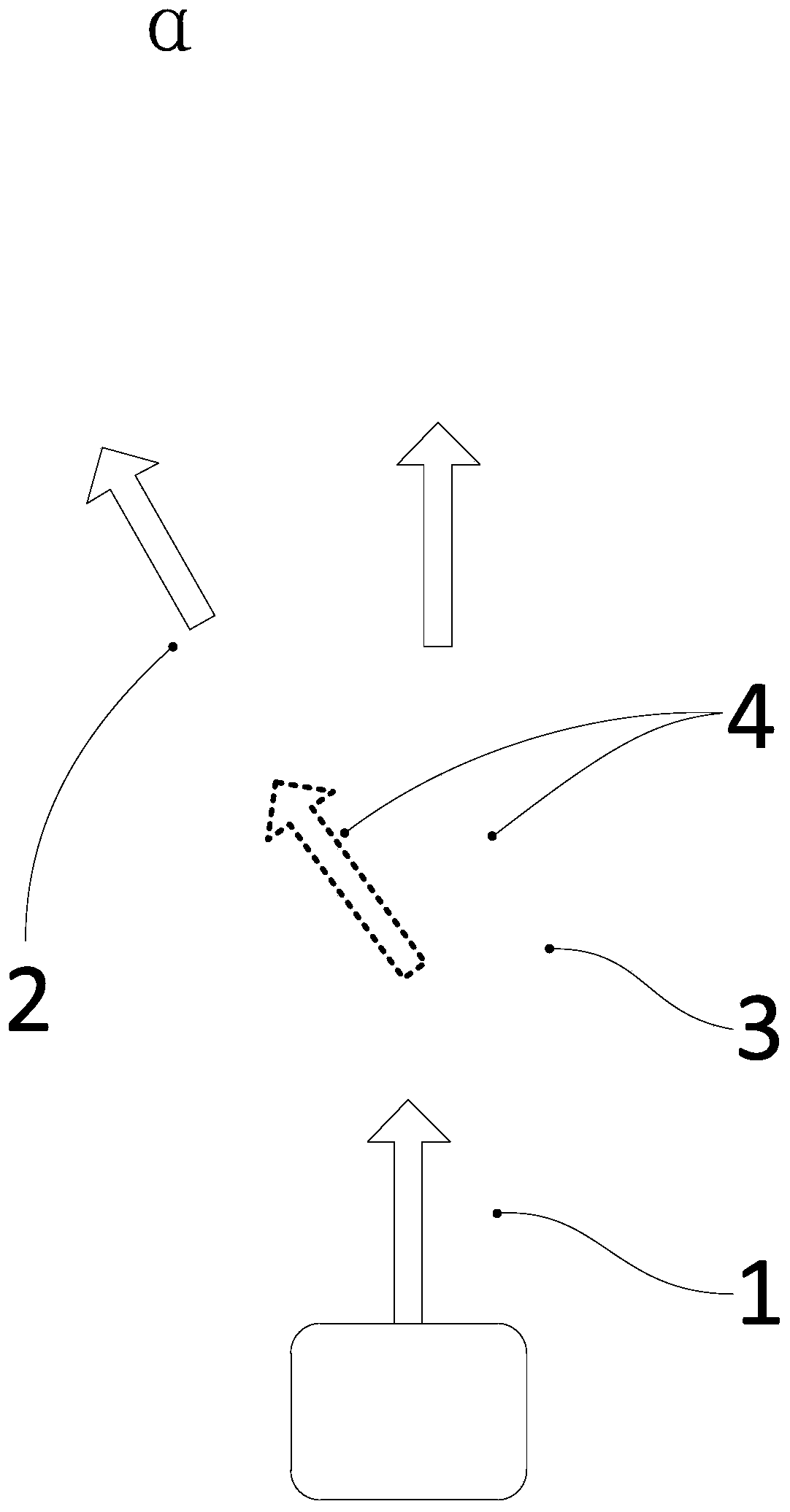

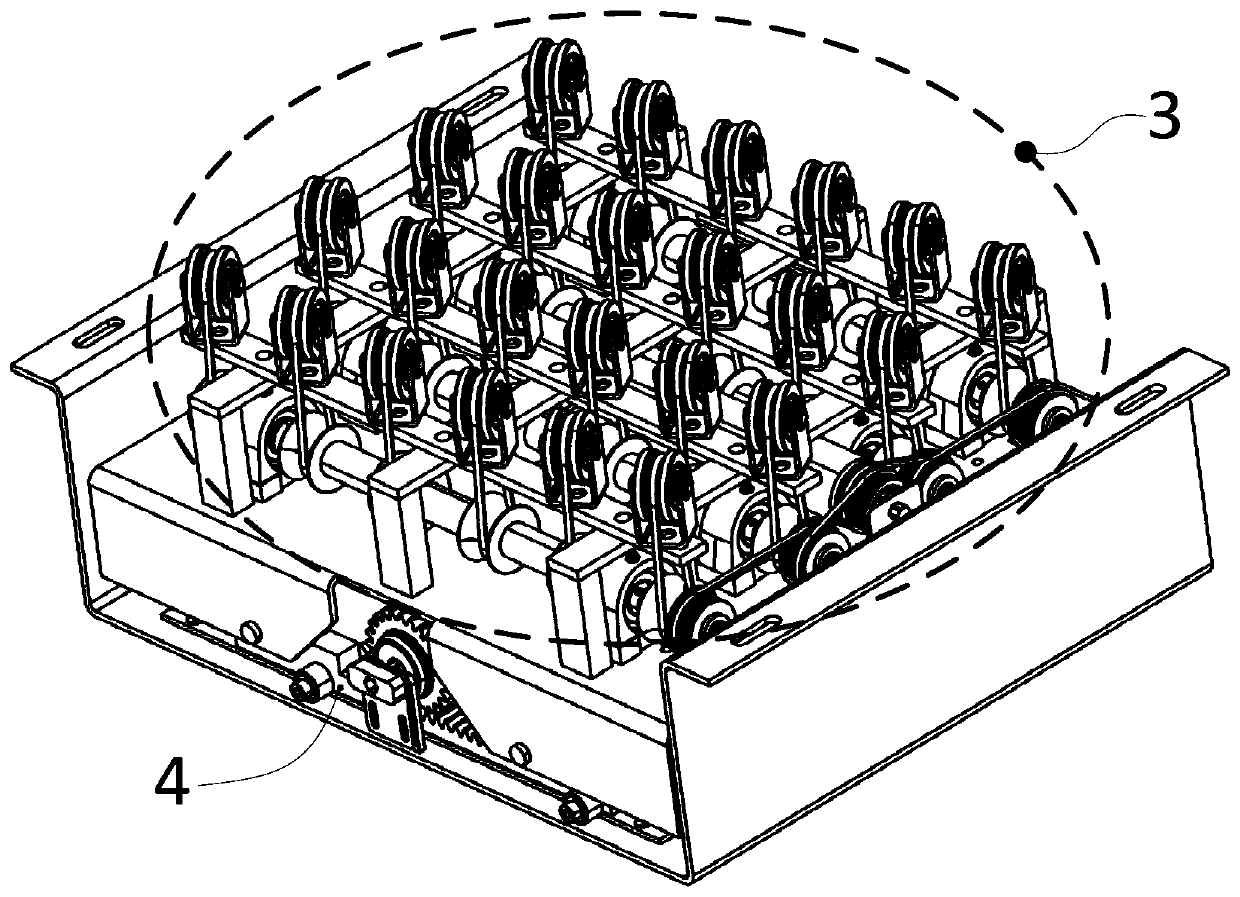

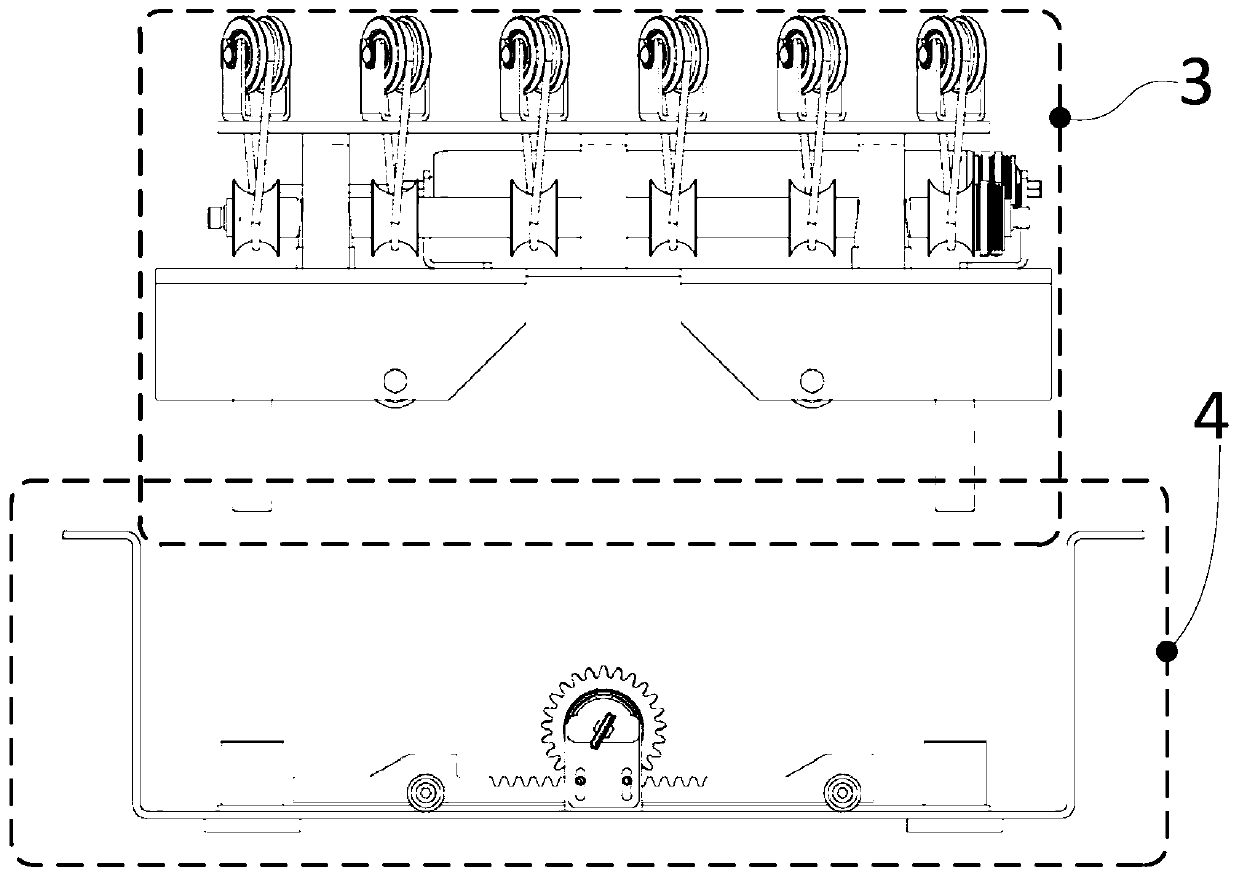

[0044] In order to improve work efficiency, ensure sorting accuracy, and reduce installation space, the present invention is mainly integrated in the automatic sorting system. When the items are transported to the Y-shaped crossing, the system judges the transport direction of the items. Conveying, the inclined wheel splitter moves, the lifting part lifts the inclined wheel group to contact the bottom of the article, and the driving part drives the inclined wheel group through the belt to transport the box to the direction of the inclined roller machine; if it is still along the straight roller Conveying in the direction of the machine, the inclined wheel splitter does not operate, and the items continue to be conveyed forward. During this action, the roller machine does not stop, realizing continuous conveying of articles, high conveying and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com