Plastic pipe sizing and cooling production device

A production device and technology for plastic pipes, applied in the field of plastic pipe manufacturing, can solve problems that affect production smoothness, product quality and yield, product standards that do not meet the requirements for use, and poor shaping ability, so as to improve quality and yield, Uniform cooling and small site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

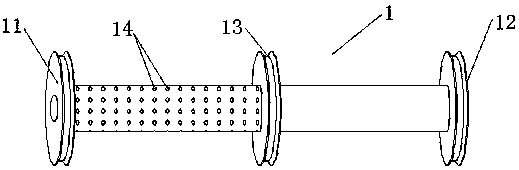

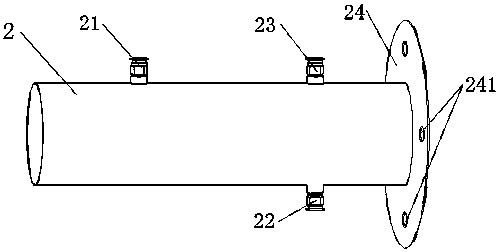

[0023] Plastic pipe sizing and cooling production device, including copper circular sizing core (1), stainless steel circular sizing shell (2), circular sizing core (1) including the inlet and outlet of the plastic pipe, in The two ends and the middle of the circular sizing inner core (1) are respectively fixed with an inlet sealing end plate (11), an outlet sealing end plate (12) and a boundary sealing plate (13); the inlet sealing end plate ( 11), the outer edges of the outlet sealing end plate (12) and the boundary sealing plate (13) are provided with ring-mounted sealing strips; the two ends of the circular sizing core (1) and the circular sizing shell (2) are flush, and The circular sizing core (1) is concentrically sealed and fixed in the inner chamber of the circular sizing shell (2) in a detachable manner.

[0024] The sizing zone is between the inlet sealing end plate (11) and the boundary sealing plate (13), and the preliminary cooling zone is between the outlet seal...

Embodiment 2

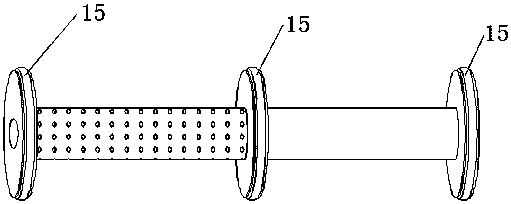

[0028] The difference between this embodiment and Embodiment 1 is that the circular sizing inner core (1) and the circular sizing shell (2) are made of copper, and the inlet sealing end plate (11) and the outlet sealing end plate (12) The circular sizing inner core (1) and the circular sizing shell (2) are connected and fixed by welding with the boundary sealing plate (13). In the primary cooling area between the outlet sealing end plate (12) and the boundary sealing plate (13), 2 split sealing plates (not shown in the drawings) are added to divide the primary cooling area into 3 secondary cooling areas. The shape and material of the sealing plate and the boundary sealing plate (13) are the same, and the connection and fixing method of the circular sizing inner core (1) and the circular sizing shell (2) is also the same. Water inlets (22) and water outlets (23) are provided on the circular sizing shells (2) to which the three secondary cooling zones belong. The difference fro...

Embodiment 3

[0030] The difference between this embodiment and embodiment 1 is that in embodiment 1, a split sealing plate is added, that is, the split sealing plate is welded on the circular sizing inner core (1) of the preliminary cooling zone, and the split sealing plate and the boundary sealing plate ( 13) The shape and material remain the same, and the same ring-mounted sealing strips are provided on the edges of the split sealing plate and the boundary sealing plate (13).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com