Cyclic treating system of working liquid for electrospark machining

A treatment system and working fluid technology, applied in the field of circulating treatment systems, can solve the problems of low filtration efficiency, inability to filter non-magnetic processing slag, shorten the service life of processing working fluid, etc., and achieve low cost, scientific design and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

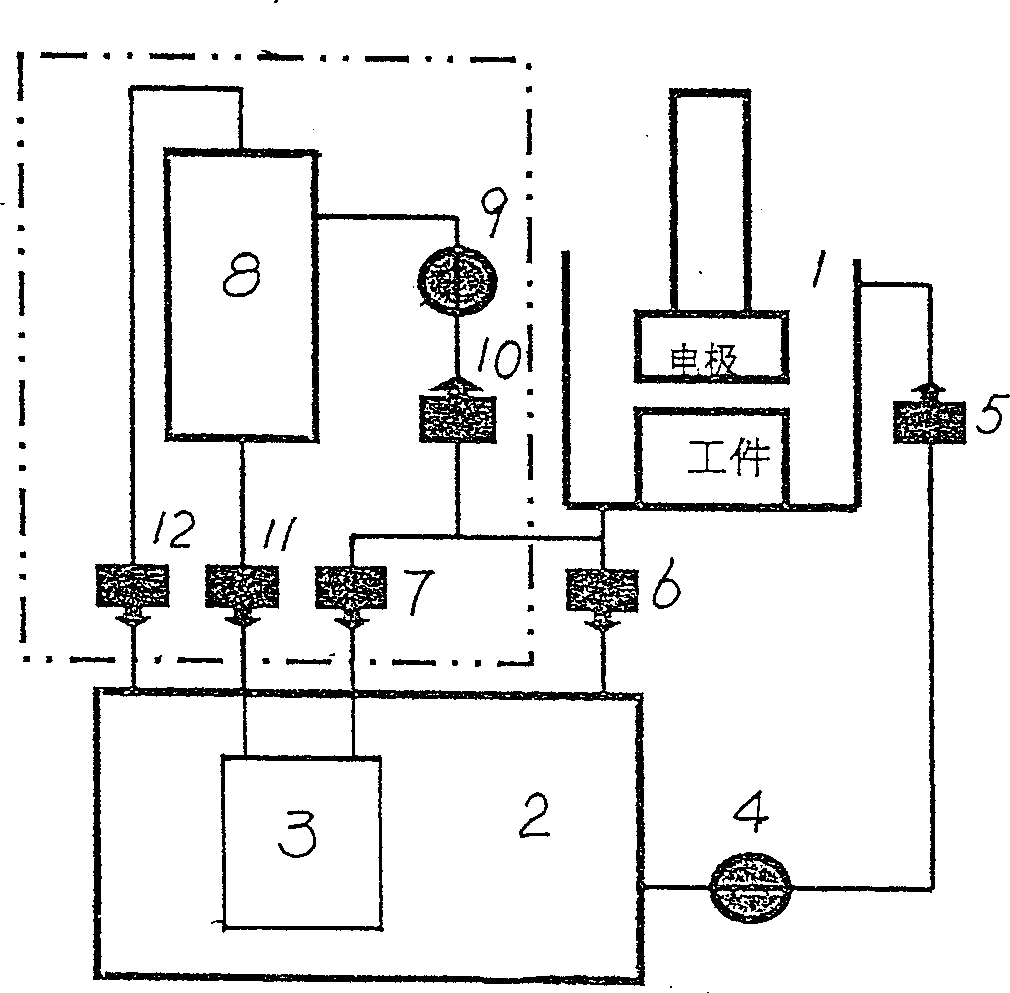

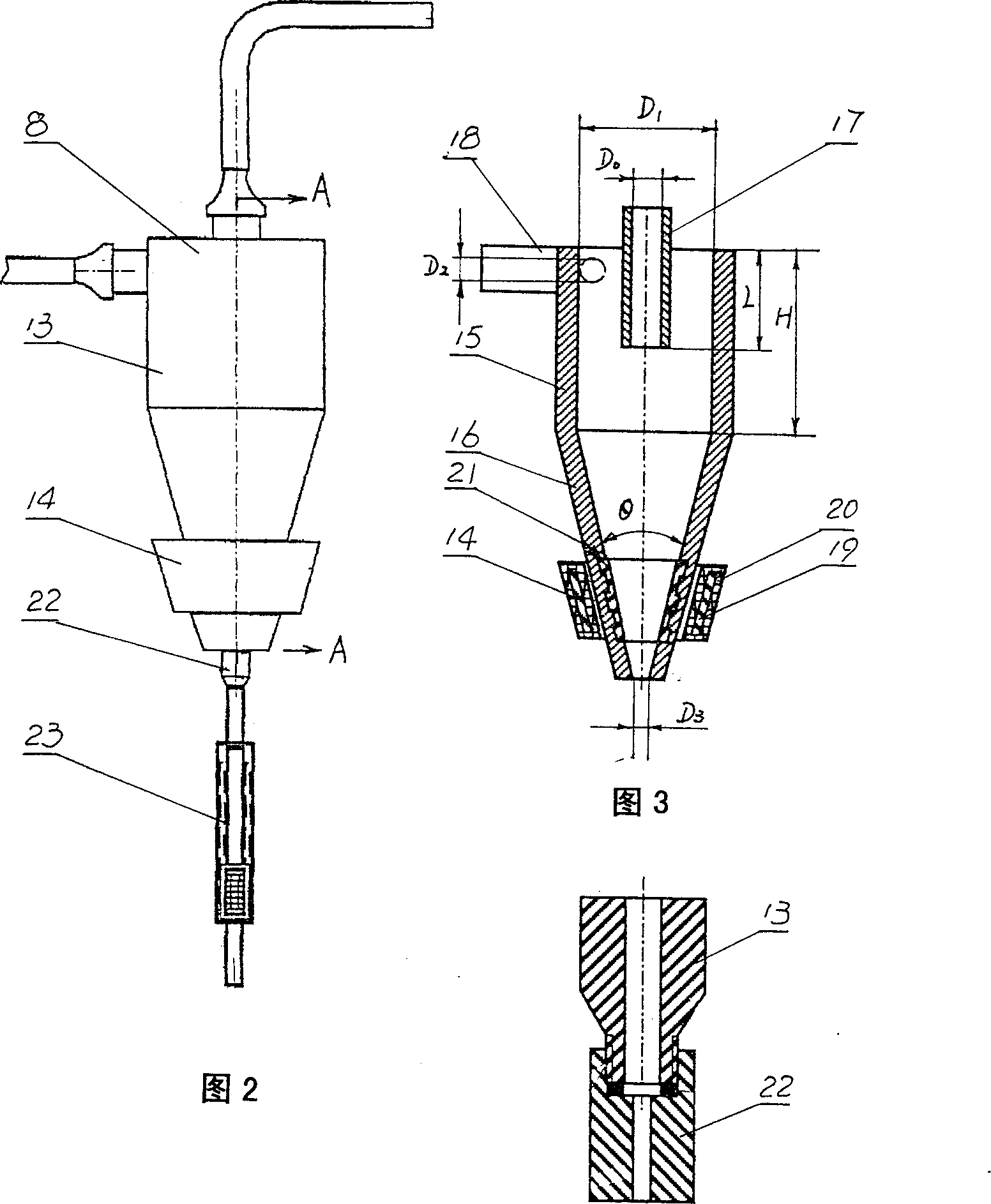

[0045] Example 1: from figure 1 It can be clearly seen that the processing system of the EDM working fluid includes: a liquid tank 1 for processing workpieces, a liquid storage tank 2 connected to the input port of the working fluid of the liquid tank 1 through a pipeline, and the input pipeline is A pump 4 and a control valve 5 are provided; the bottom of the liquid tank 1 is provided with a three-way pipe, and the parallel pipes through the three-way pipe are respectively connected to the oil tank 2 and the filter 3, and the parallel pipes are equipped with control valves 6 , 7; the filter 3 communicates with the liquid storage tank 2, and is characterized in that: on the pipeline connected between the liquid tank 1 and the filter 3, an underflow type magnetic hydrocyclone 8 is connected, and the underflow type magnetic force fluid A pump 9 and a control valve 10 are provided on the pipeline connecting the hydrocyclone 8 and the liquid tank 1, and the underflow magnetic hydr...

Embodiment 2

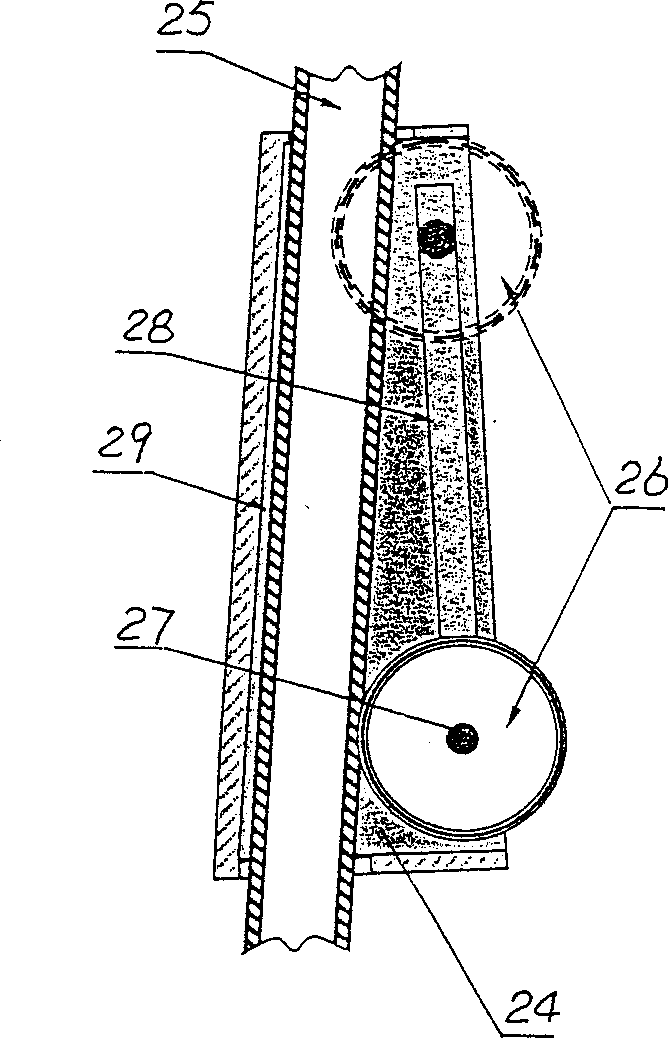

[0047] Embodiment 2: The composition of the treatment system of the EDM working fluid of this embodiment is the same as that of Embodiment 1, the difference being: in order to meet the variation of the size of the sediment port of the hydrocyclone 13, the sediment pipe of the hydrocyclone 13 The mouth is equipped with a stepless diameter changing device 23 that can quickly replace the diameter of the sediment mouth (see Figure 5 ), the infinitely variable caliber device 23 is made up of a pipe frame 24 and a roller 26 for extruding the flexible pipe 25. It can roll up and down along the rail groove 28, and a pipe groove 29 for inserting the sediment mouth hose 25 is offered at an angle with the rail groove 28. Use the roller 26 to roll up and down to adjust the squeezed degree of the hose 25. When the roller 26 is at the bottom, the hose 25 is not squeezed, and its original diameter remains unchanged; The pipe 26 is completely squeezed flat, and its caliber size becomes zero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com