Pilot-operated double-spool split-range adjusting valve

A technology of pilot valve core and double valve core is applied in the field of fluid control regulating valve, which can solve the problems of large dead zone and inability to realize precise adjustment of flow with small opening, and achieve the effect of saving the number of use, compact structure and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings.

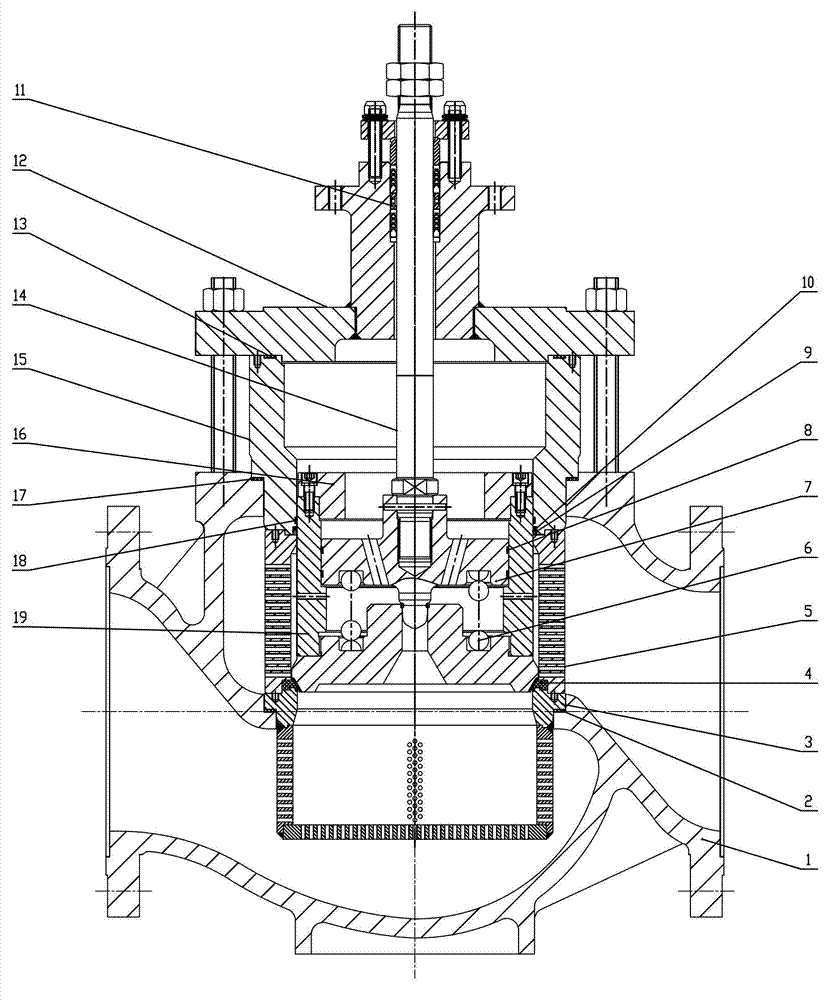

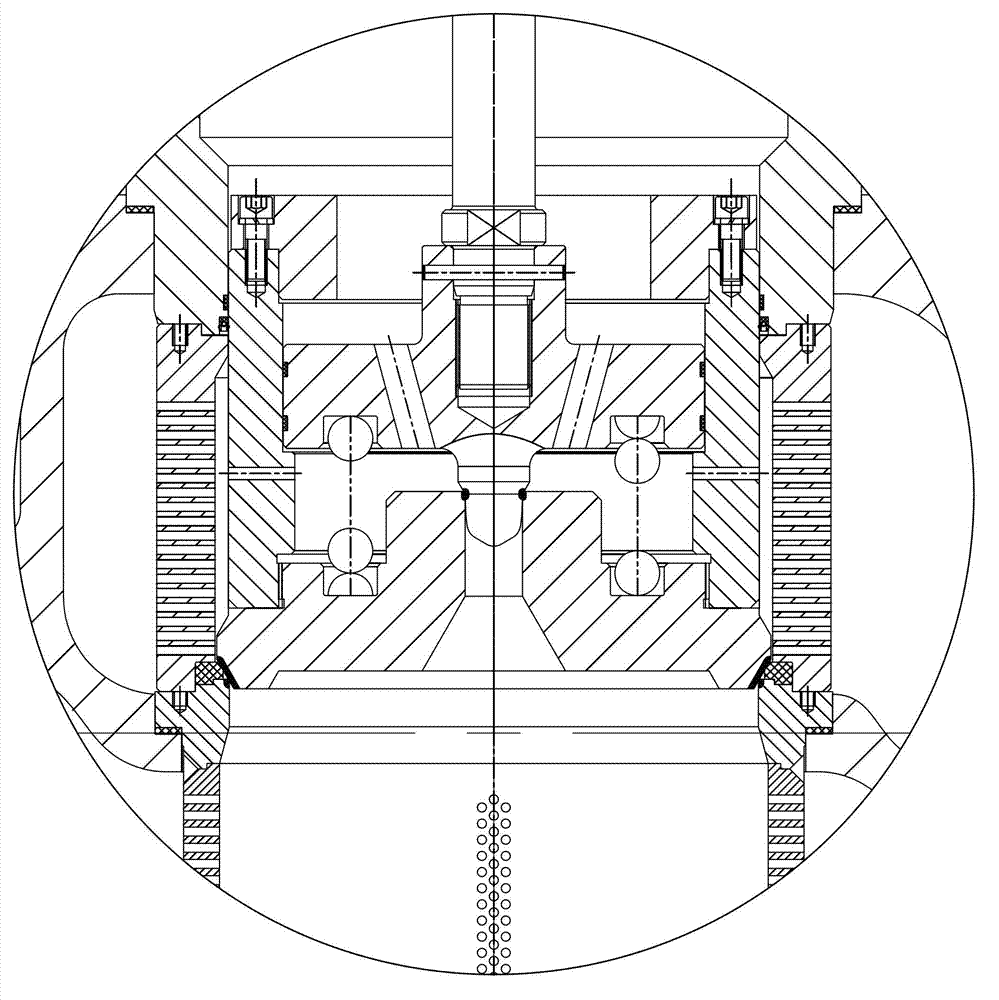

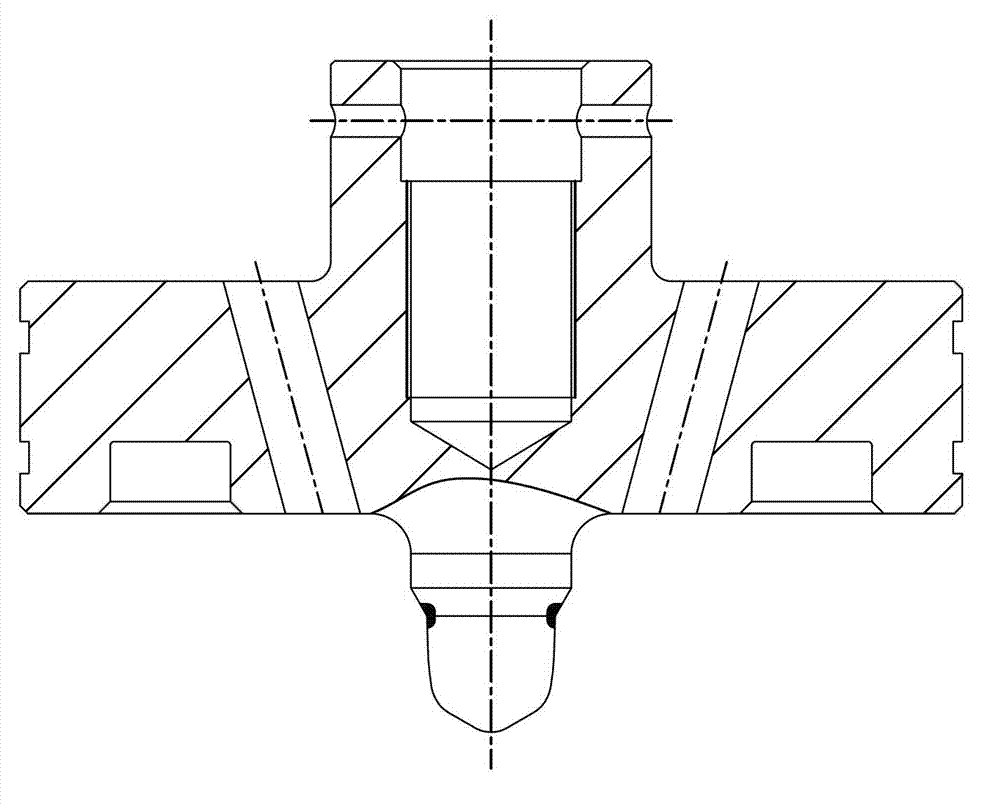

[0020] Such as figure 1 , 2 Shown: Pilot-operated double-spool split-range regulating valve consists of valve body 1, graphite composite gasket 2, valve seat 3, PTFE valve seat 4, noise reduction sleeve 5, compression spring 6, pilot spool 7, first four Fluorine guide belt 8, balance seal ring 9, energizer spring 10, packing assembly 11, upper cover 12, graphite composite gasket 13, valve stem 14, balance ring seat 15, thrust ring 16, graphite composite gasket 17, the first Parts such as PTFE guide band 18, main valve core 19 are formed.

[0021] The valve seat 3 is assembled on the inner bottom of the valve body 1, and a graphite composite gasket 2 is placed between the valve body 1, and a tetrafluoro valve seat 4 and a noise reduction sleeve 5 are assembled on the valve seat 3. After the valve stem 14 and the pilot spool 7 are connected together with pins, they are assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com