Automatic packaging method, electronic equipment and storage medium

An automatic and photoelectric switch technology, applied in the direction of packaging automatic control, packaging, packaging machines, etc., can solve the problem of inability to complete the automatic assembly of the upper packaging cover and the lower packaging bottom support, so as to improve production efficiency and production quality, optimize Production environment, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

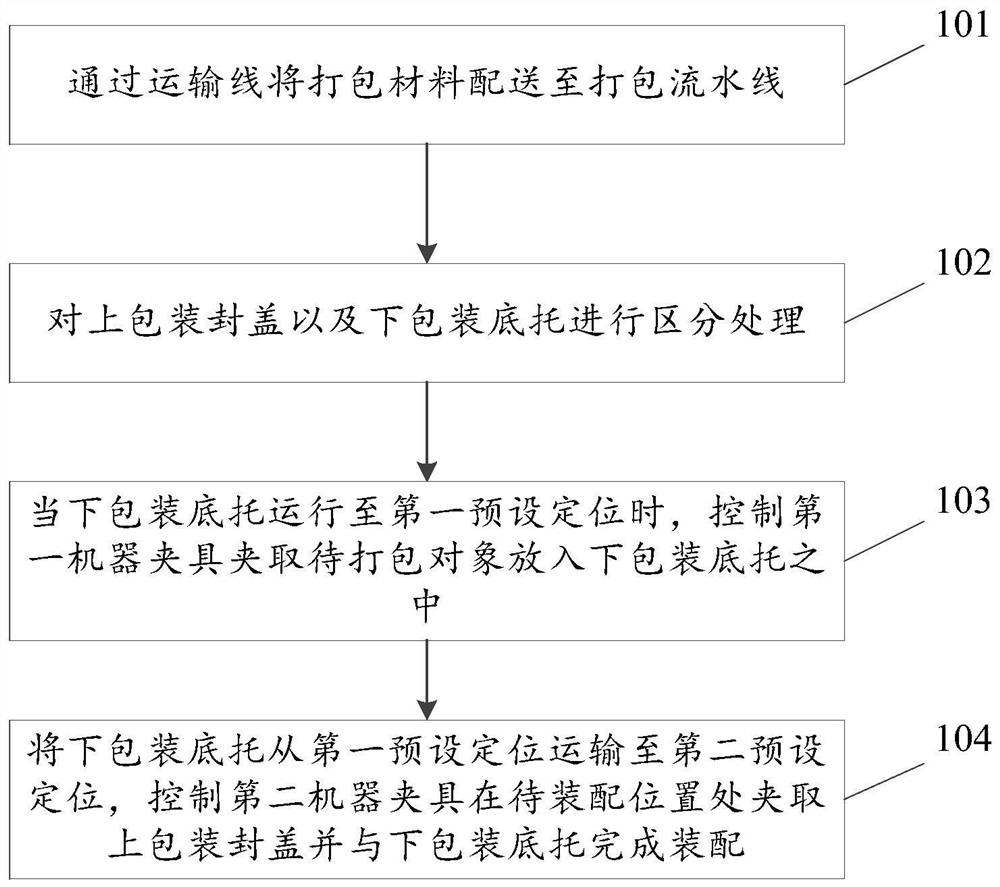

Embodiment 1

[0054]In the packaging workshop, the packaging materials need to be transported from the first floor to the side warehouse of the production line on the second floor, and then transferred from the side warehouse to the production line. In the production process, due to the large volume and quantity of packaging materials, the packaging process is complicated, and there are production breakpoints, not only the production personnel are prone to fatigue due to high labor intensity during the operation process, resulting in low production efficiency and poor production quality. Uncontrollable problems, and packaging materials take up a lot of on-site space, affecting the production environment. In the prior art, an automatic packing machine with a servo manipulator used in beverage bottle conveying and packaging uses a servo manipulator to automatically pack beverages, thereby improving the efficiency of beverage packing. However, the above-mentioned technical scheme can only real...

Embodiment 2

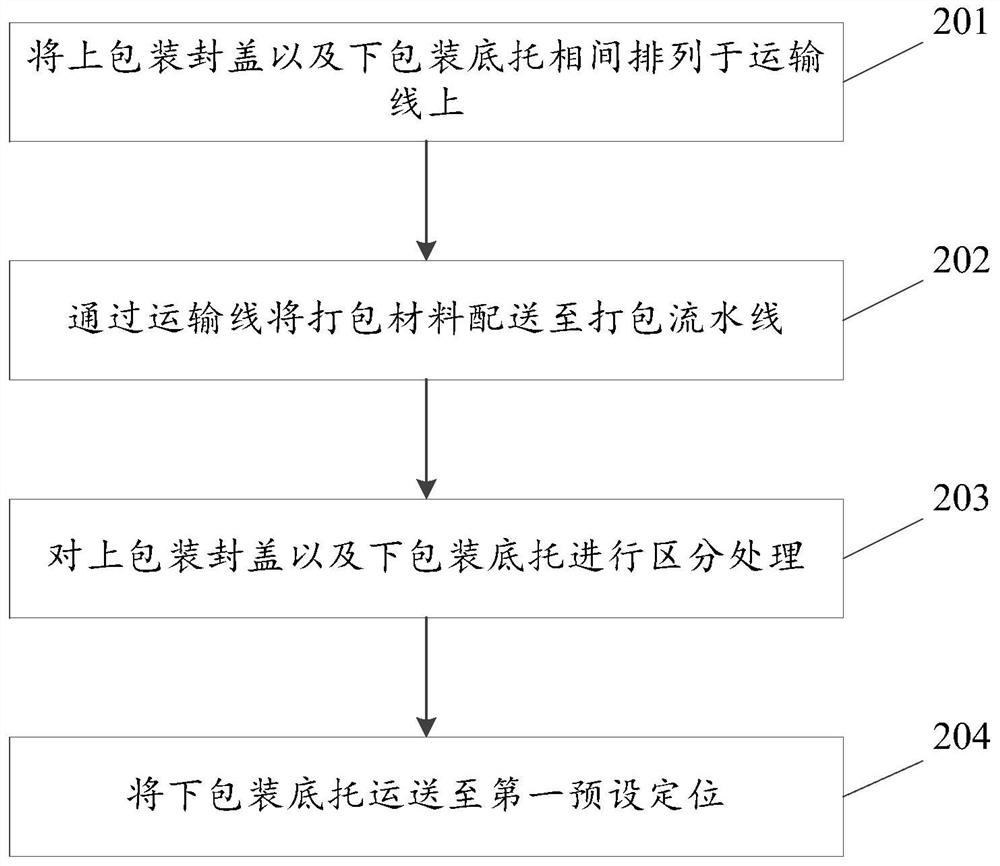

[0071] For ease of understanding, an example of an automatic packaging method is provided below for illustration. In practical applications, the upper packaging cover and the lower packaging bottom support will be arranged alternately on the transportation line, and the opening of the upper packaging cover will face downward. , the opening of the lower packaging base is facing upwards, so that the separation process can be performed more efficiently and the production efficiency can be improved.

[0072] figure 2 It is a schematic flowchart of Embodiment 2 of the automatic packaging method shown in the embodiment of the present application.

[0073] see figure 2 , the second embodiment of the automatic packaging method shown in the embodiment of the present application includes:

[0074] 201. Arrange the upper packaging cover and the lower packaging bottom support alternately on the transportation line;

[0075] According to the ECRS principle, the delivery process of the...

Embodiment 3

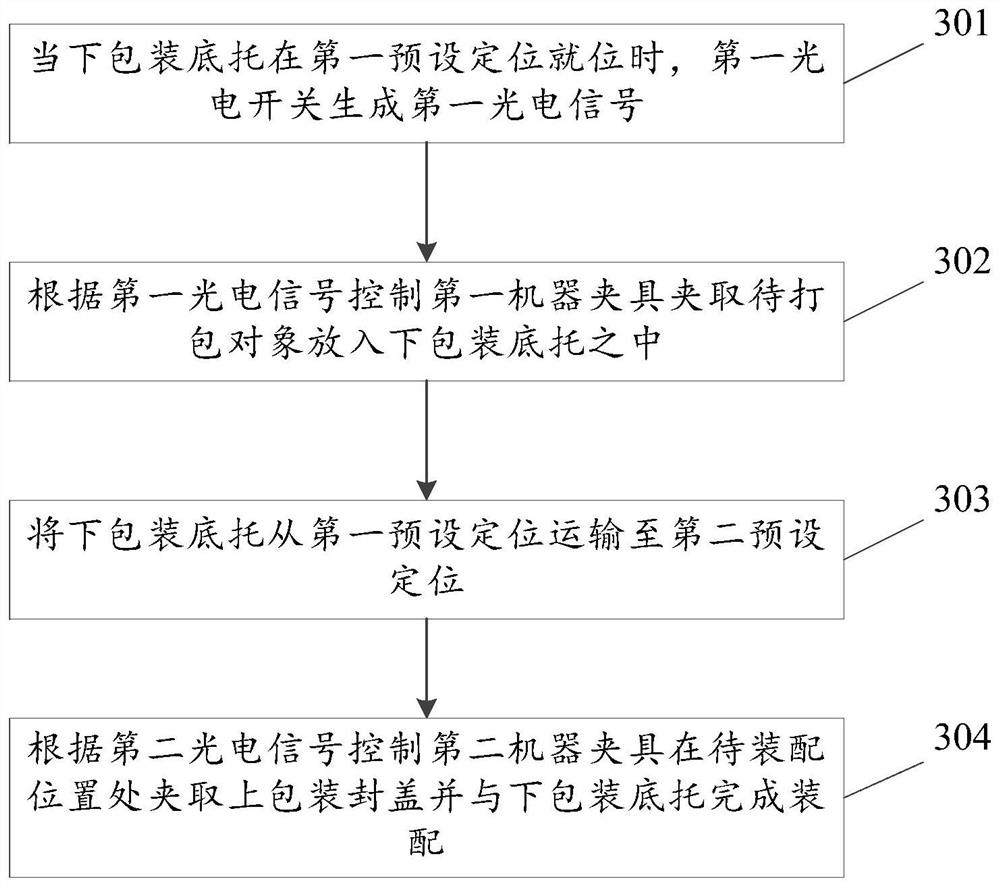

[0090] In order to facilitate understanding, an example of an automatic packaging method is provided below for illustration. In practical applications, the placement of the objects to be packaged and the automatic assembly of the upper packaging cover and the lower packaging bottom support will be completed through machine fixtures to achieve Automated and unmanned operation of packing process.

[0091] image 3 It is a schematic flowchart of Embodiment 3 of the automatic packaging method shown in the embodiment of the present application.

[0092] see image 3 The third embodiment of the automatic packaging method shown in the embodiment of the present application includes:

[0093] 301. When the lower packaging base is in place at the first preset position, the first photoelectric switch generates a first photoelectric signal;

[0094] The photoelectric switch refers to the photoelectric proximity switch, which uses the occlusion or reflection of the detected object to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com