Glass rotational-flow sand-removing device for potato starch production

A technology for removing sand and potato starch by swirling flow, which is applied in swirling devices, devices whose axial directions of swirling flow can be reversed, etc. problem, to achieve the effect of simple operation, simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

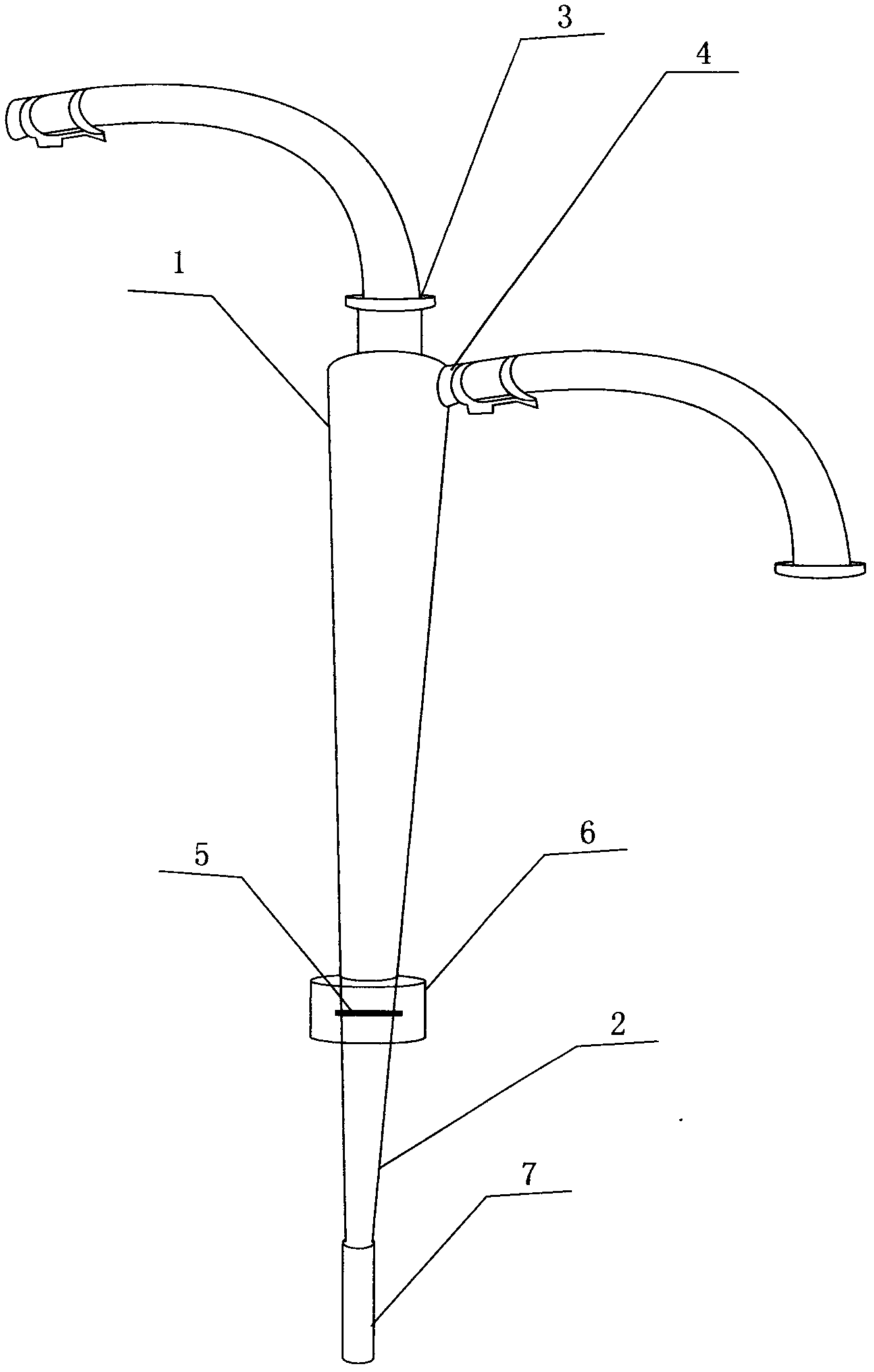

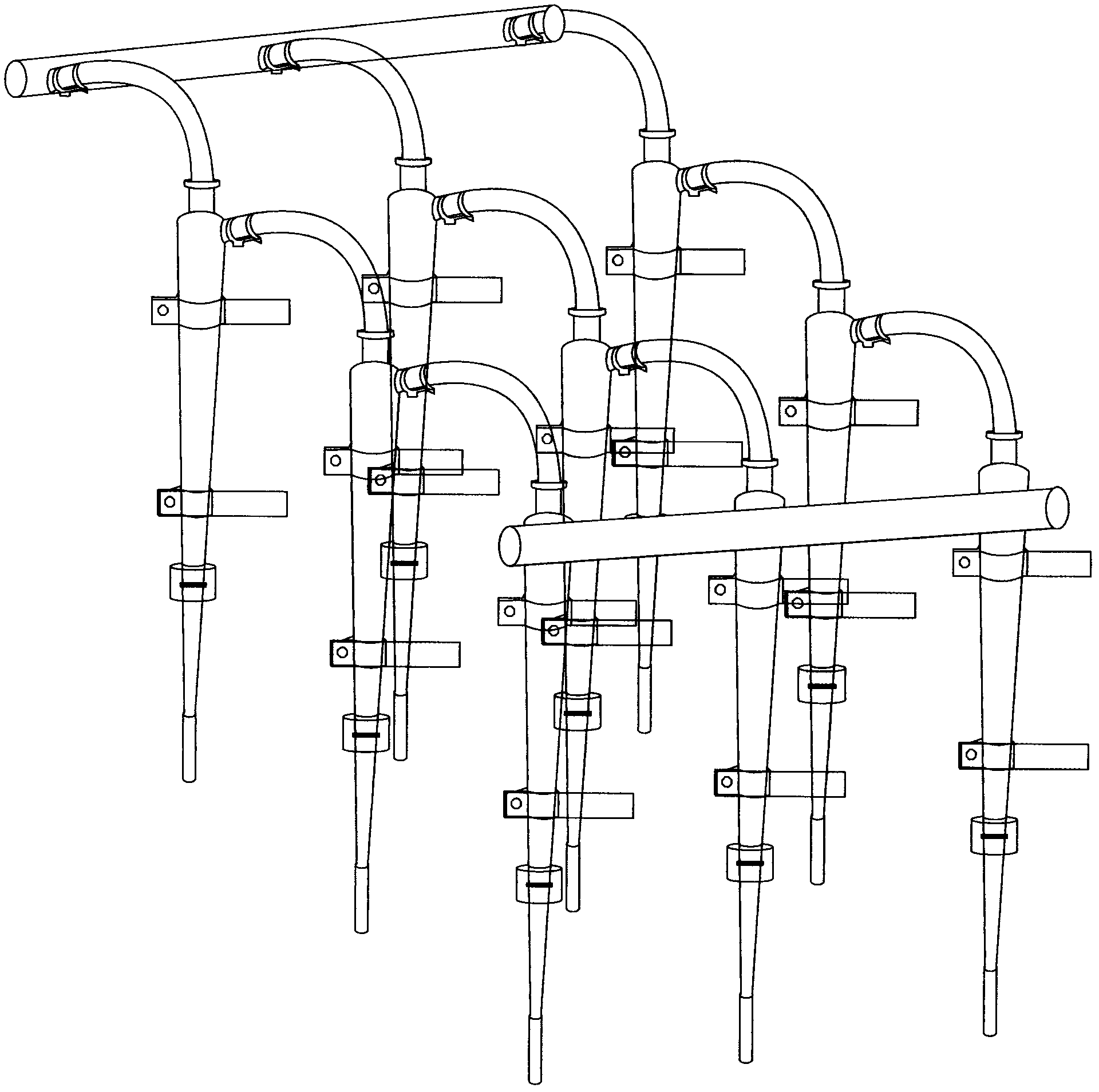

[0018] see figure 1 , 2 A glass cyclone sand remover for producing potato starch is shown, which is formed by connecting a cyclone cylinder (1) and a sedimentation body (2) through connecting fasteners (6), and is characterized in that: the cyclone cylinder A rubber pad (5) is set between the body (1) and the sand settling body (2), and the two are connected into a whole through connecting fasteners (6); mouth (3), a discharge port (4) is arranged on one side of the upper end, and the bottom of the sedimentation body (2) is connected with a sand discharge pipe (7).

[0019] The cyclone desander of the present invention is made of glass.

[0020] It works like this: see figure 1 , 2 , which is composed of multiple small-diameter glass cyclone cylinders (1), widely used in starch production industry and similar industries, generally adopts 3-6 grades, starch milk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com