Image acquisition device and fabric defect real-time detection system for circular knitting machine

A technology of image acquisition device and circular knitting machine, which can be applied to measurement devices, image communication, components of TV systems, etc., and can solve problems such as difficulty in providing stable and high-quality images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

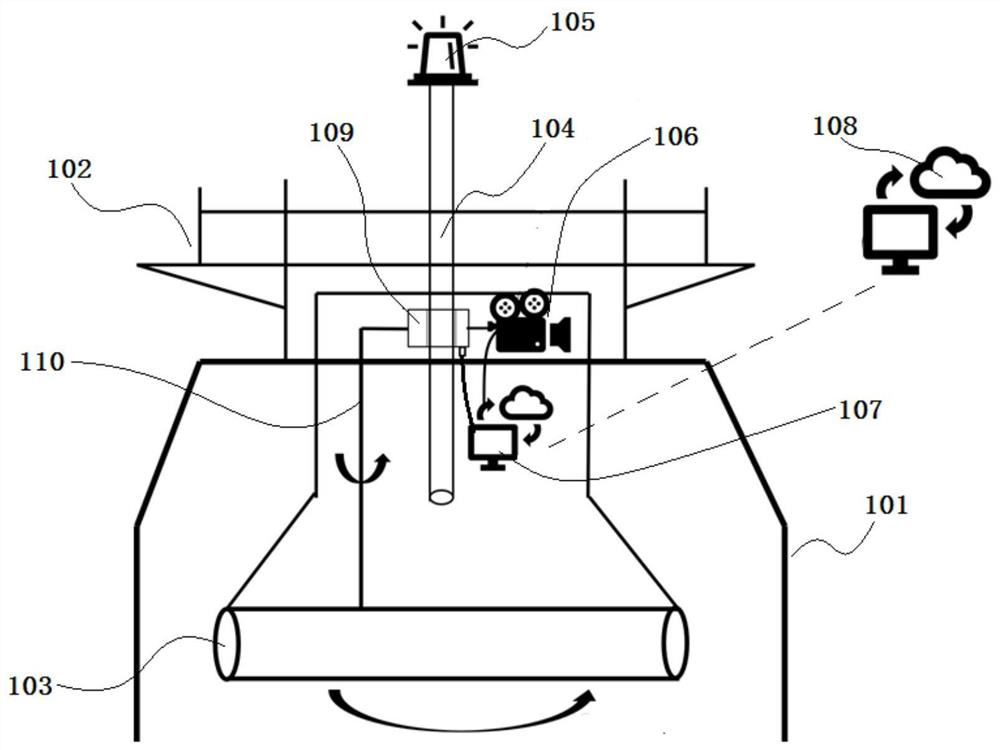

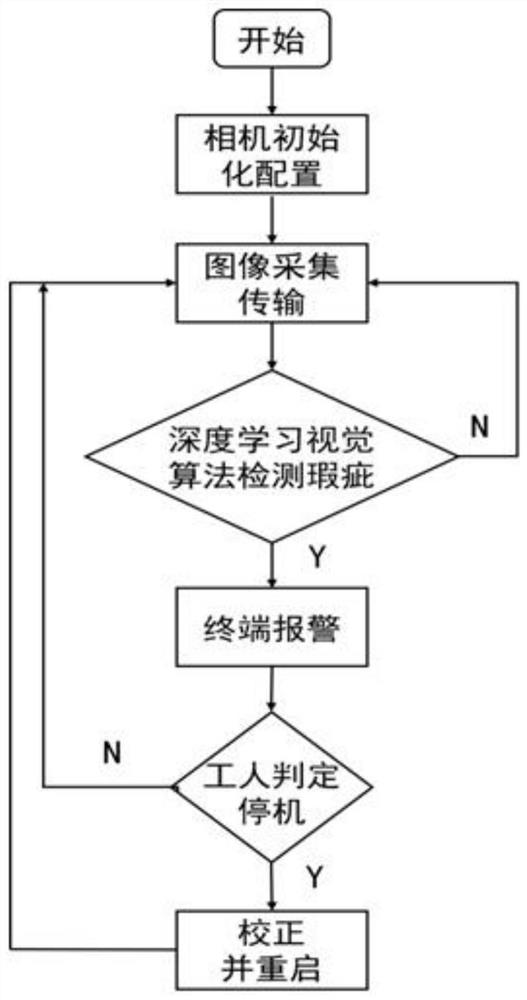

[0040] Such as figure 1 As shown, an illustrative embodiment of the present invention provides an image capture device for a circular knitting machine.

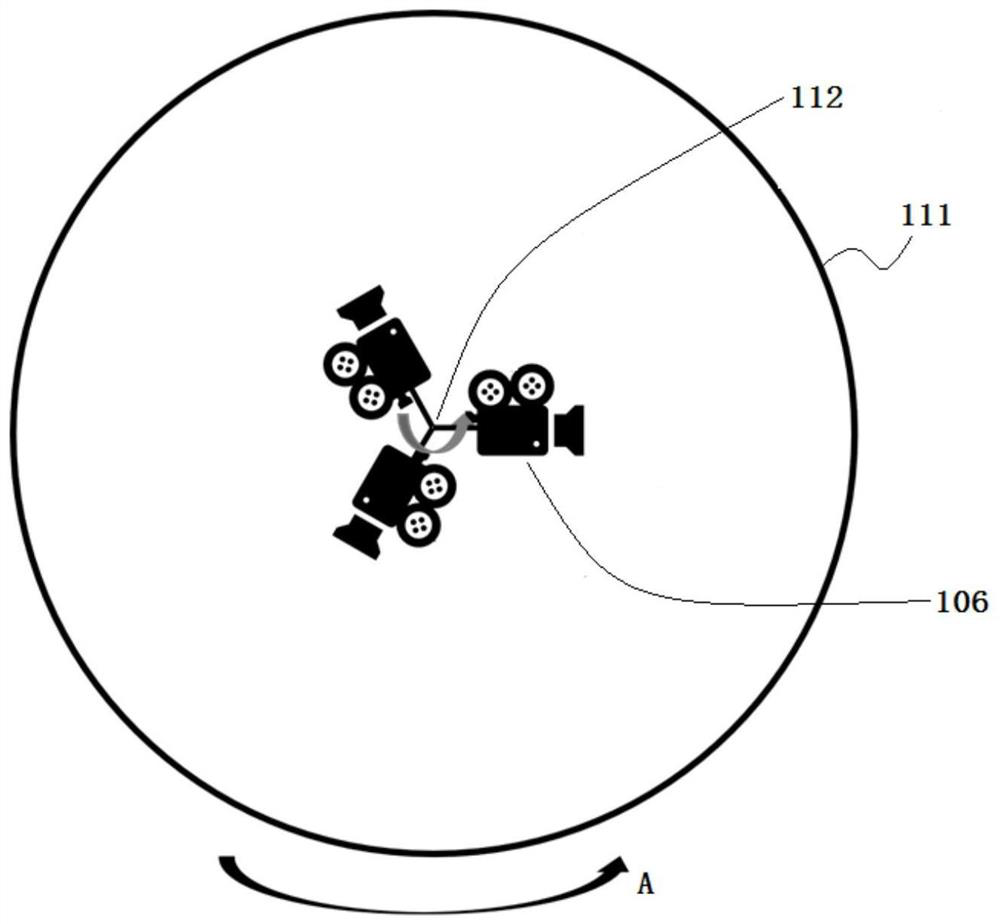

[0041] The circular knitting machine includes a housing 101, a head portion 102 located on the upper part of the housing, a winding device 103 installed on a rotating platform inside the housing, and a support shaft 104 located at the center of the housing. In addition, it also includes parts such as a creel for placing yarns, which are not shown in the figure for the sake of brevity. Since the structure of the circular knitting machine is well known to those skilled in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com