Method for preventing flotation of light solid composite core formwork of composite floor system

A composite floor and composite core technology, applied in floors, building components, buildings, etc., can solve the problems of low construction quality and construction efficiency, difficulty in effectively controlling the displacement of mandrels, and affecting the thickness of concrete components, etc., to achieve convenient production and processing , low cost and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

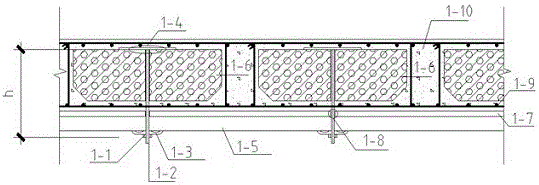

[0014] In the figure, a lightweight solid composite mandrel anti-floating method for a composite floor of the present invention includes the following construction steps:

[0015] Step 1. Before the construction of the internal formwork, according to the plane size of the floor slab in the design drawings, the location of the construction joints, the reserved pre-embedding situation, the arrangement direction and the design length of the internal formwork, the formwork layout design is carried out, and a picture of the internal formwork layout is drawn for each floor. Figure, formulate the amount of required accessories according to the internal model discharge map;

[0016] Step 2, mandrel anti-floating accessories 1-4 are made, and the length of screw rod 1-2 is determined according to the height of mandrel 1-6, the distance between mandrel 1-6 and the steel bar at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com