Traction type reciprocator for single point mooring liquid slip ring test

A technology of single-point mooring and reciprocating mechanism, which is applied in the testing of mechanical components, testing of fluid tightness, testing of machine/structural components, etc. It can solve the problems of high manufacturing and maintenance costs, low reliability, and high failure rate , to achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

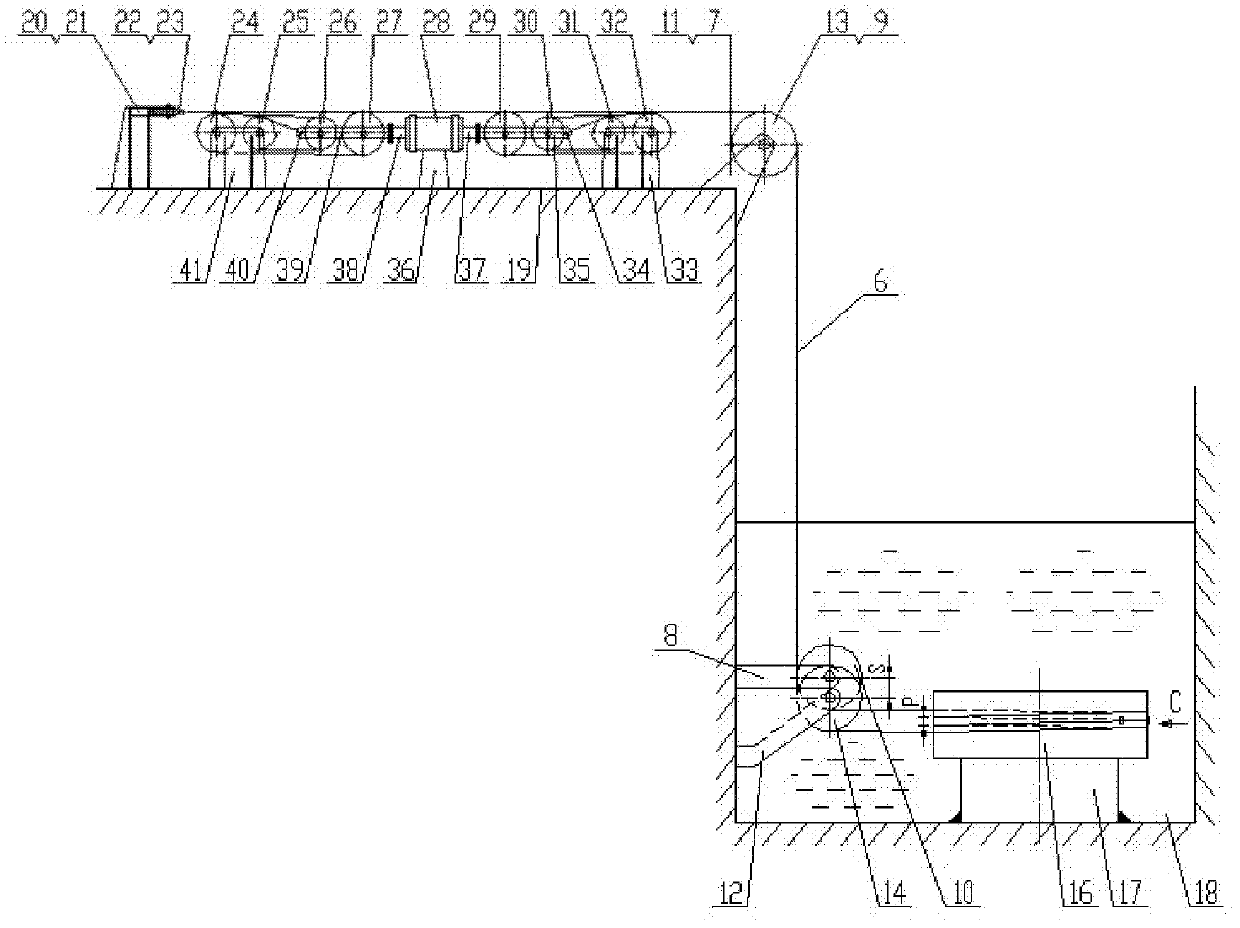

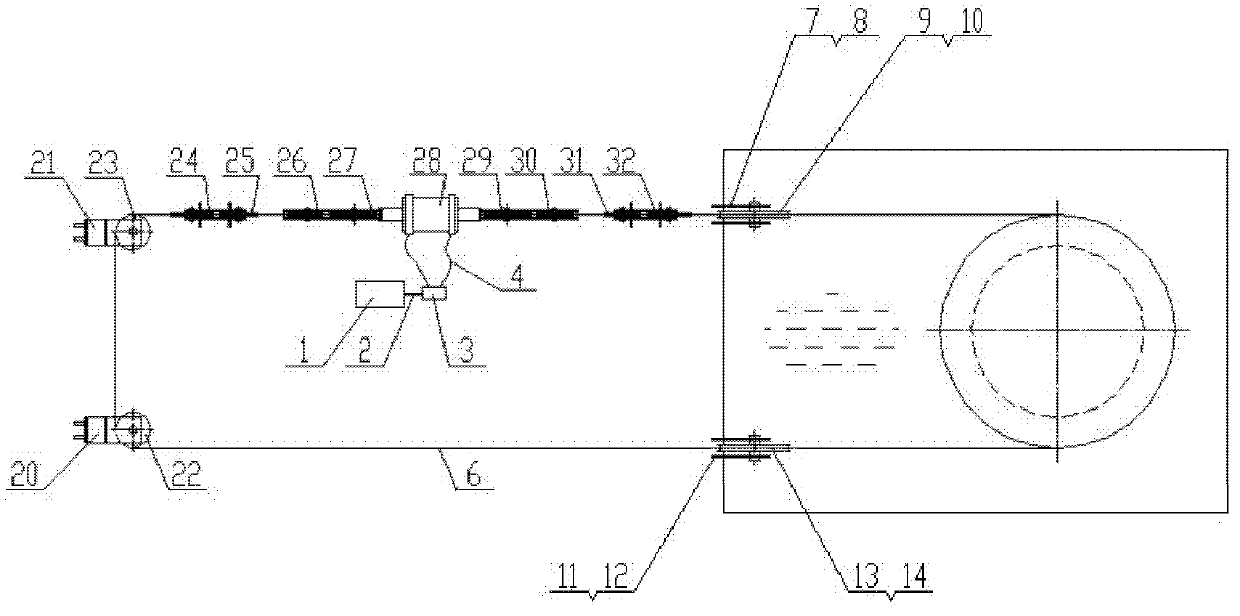

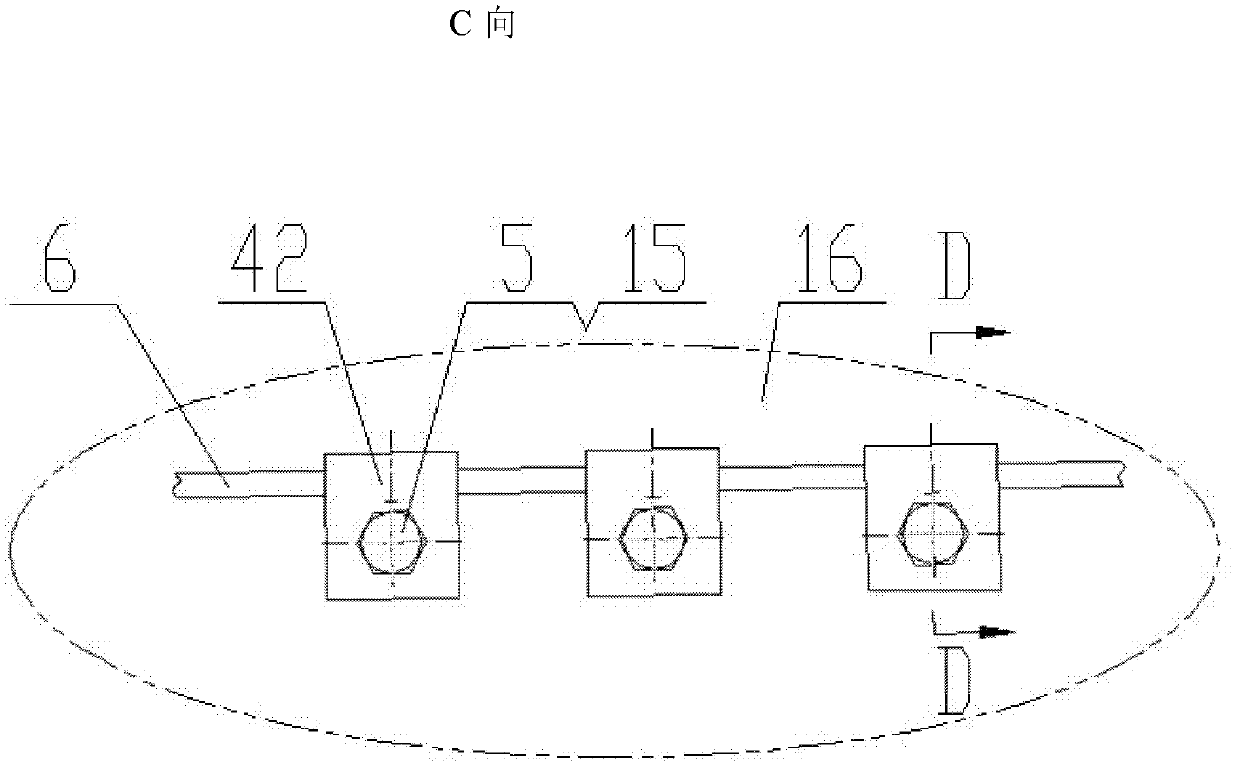

[0022] figure 1 , 2 Shown in , 3 is the specific embodiment of the present invention, and it is the traction type reciprocating mechanism that is used for single-point mooring fluid slip ring test that is installed in the wellhead of certain overseas oil well; Its structure comprises deep water tank 18, single-point system The upper body 16 of the mooring fluid slip ring, the lower body 17 of the single point mooring fluid slip ring and the wire rope 6 are characterized in that: a hydraulic cylinder 28 with an I support 36 is installed on the installation platform 19, and the hydraulic cylinder 28 The first oil cylinder piston 38 at one end drives the first traction pulley block through the steel wire rope 6; the second oil cylinder piston 37 at the other end of the hydraulic cylinder 28 drives the second traction pulley block through the steel wire rope, and the installation platform 19 that is consistent with the axial line of the hydraulic oil cylinder 28 is in order Insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com