Harmonic teeth-driving stage-less speed variator

A continuously variable transmission, tooth transmission technology, applied in the direction of transmission, friction transmission, belt/chain/gear, etc., can solve the problem of low efficiency, achieve the effect of convenient speed change, improve efficiency, and save the trouble of shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

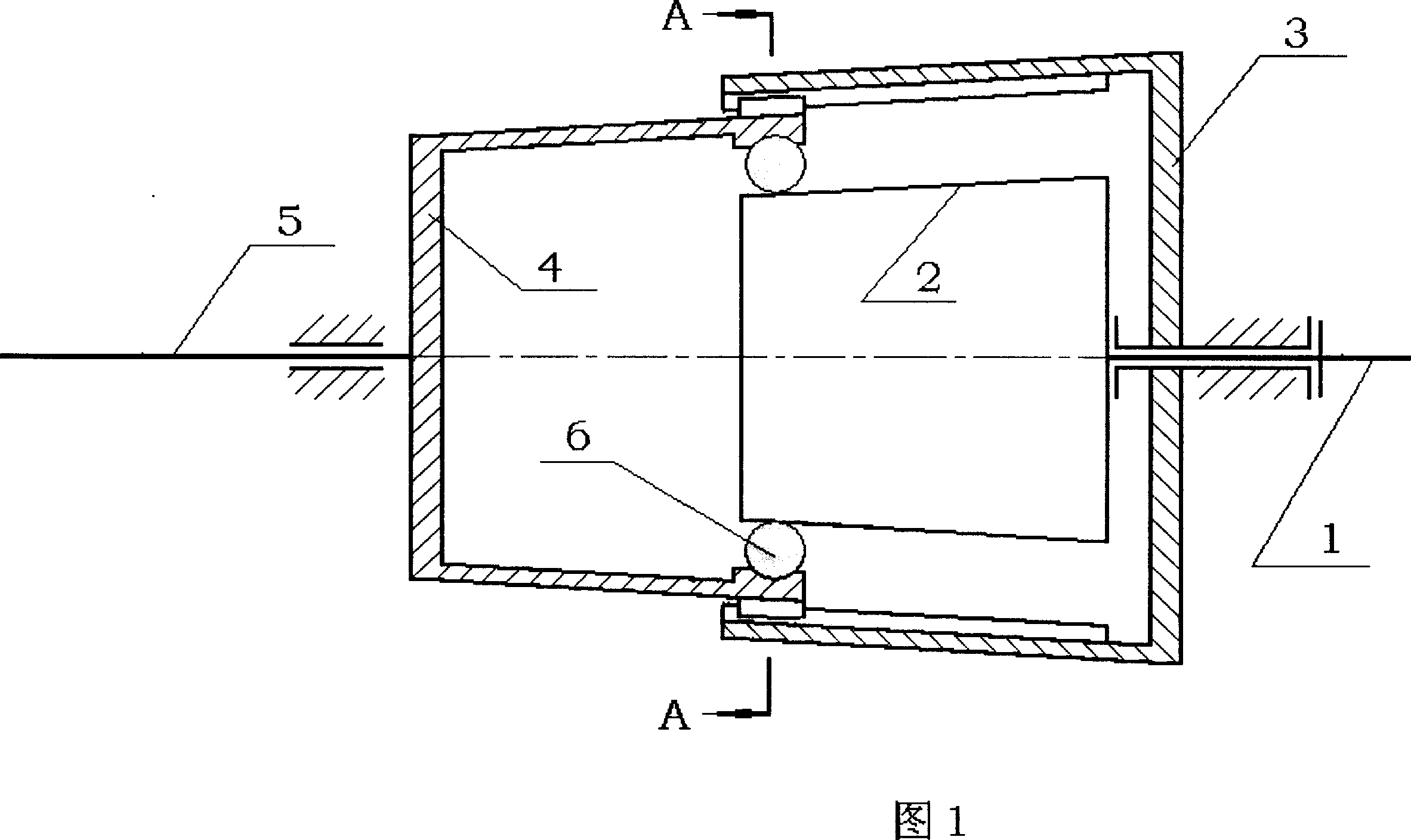

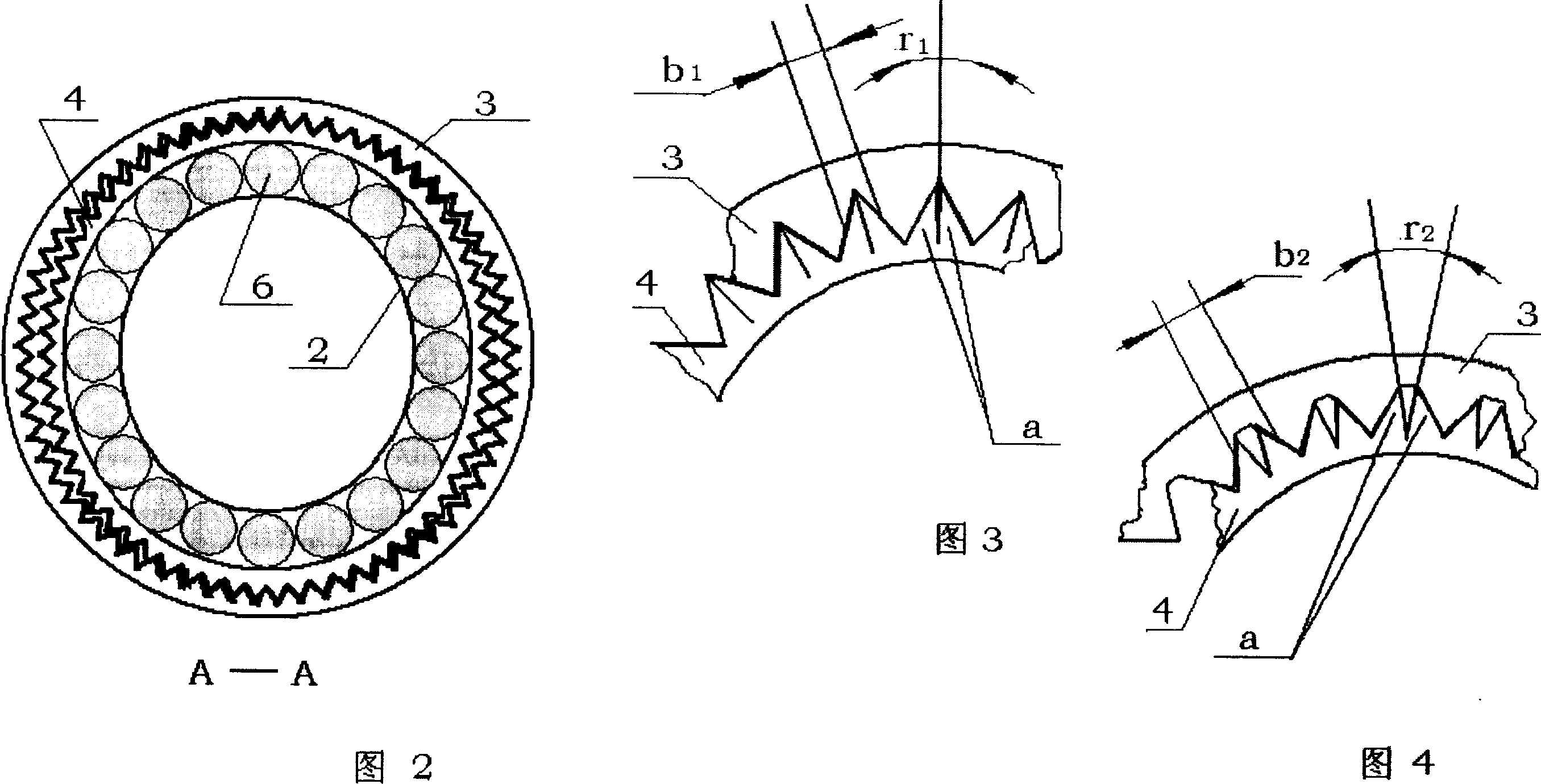

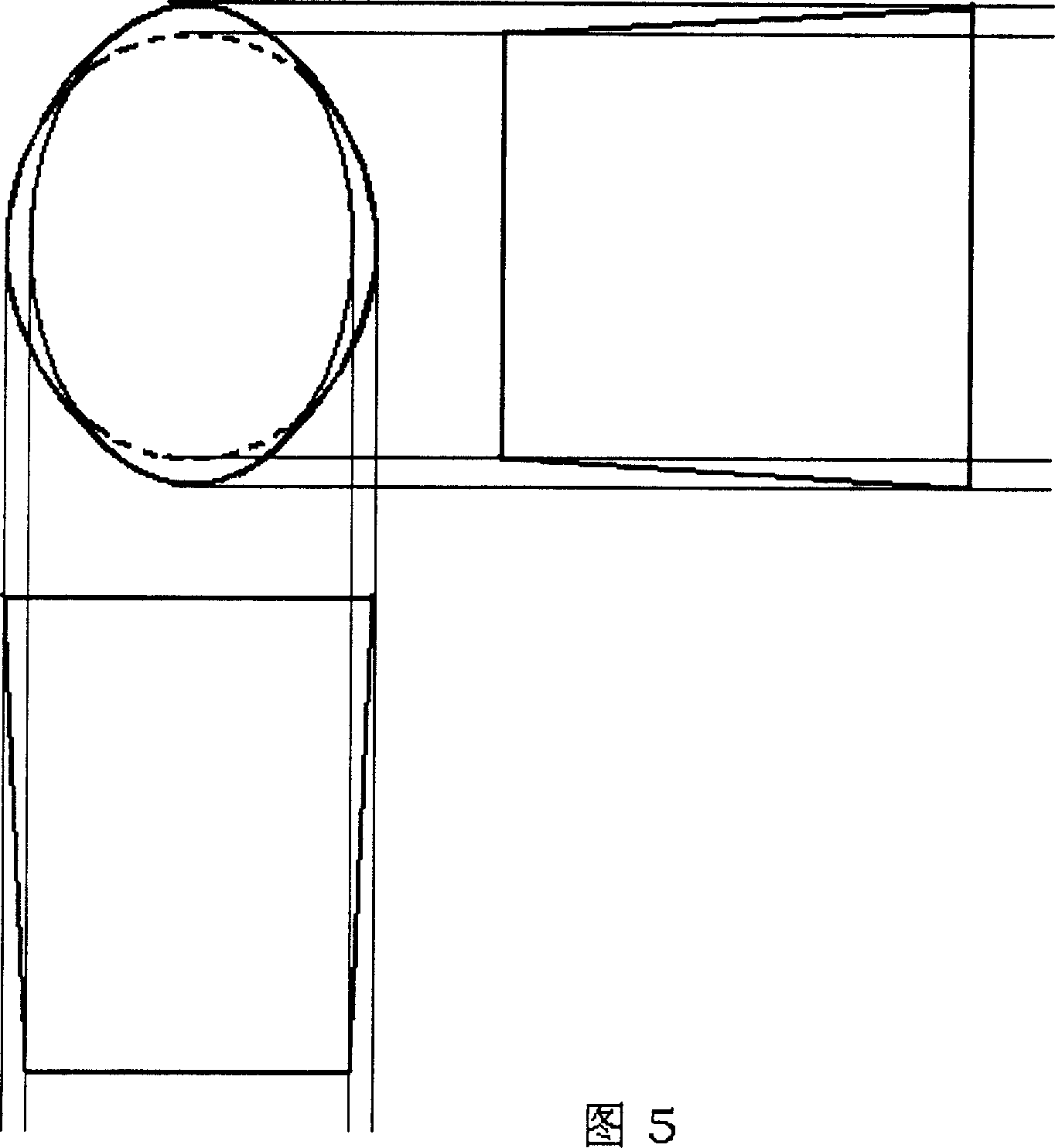

[0014] Embodiments of the present invention are shown in Figure 1 and Figure 2, in which 1 is an input shaft, 2 is a wave generator, 3 is a rigid spline, 4 is a flexible spline, 5 is an output shaft, and 6 is a roller. In the implementation, it can be designed and manufactured according to the schematic diagram of the mechanism and the specific application environment. The cone angle of the rigid wheel 3 should be within an appropriate range to ensure the proper clearance and lubrication of each part. You can refer to some relevant parameters of the existing harmonic reducer. When the rigid spline 3 does not move, the flexible spline 4 moves axially relative to the rigid spline, and the driving shaft 1 drives the wave generator 2 to rotate, the wave generator 2 forces the flexible spline 4 to produce continuous elastic deformation through the roller 6, although the rigid spline 3 When the number of teeth is fixed, the tooth thickness or tooth slot width is variable, but because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com